Rail traffic integrated grounding cable

A grounding cable and rail transit technology, which is applied in the field of railway cables, can solve the problems of short service life, poor wear and corrosion resistance, and poor cable quality of comprehensive grounding cables for railway rail transit, and achieve compact structure and improved durability. Corrosion performance, effect of lowering electrical resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

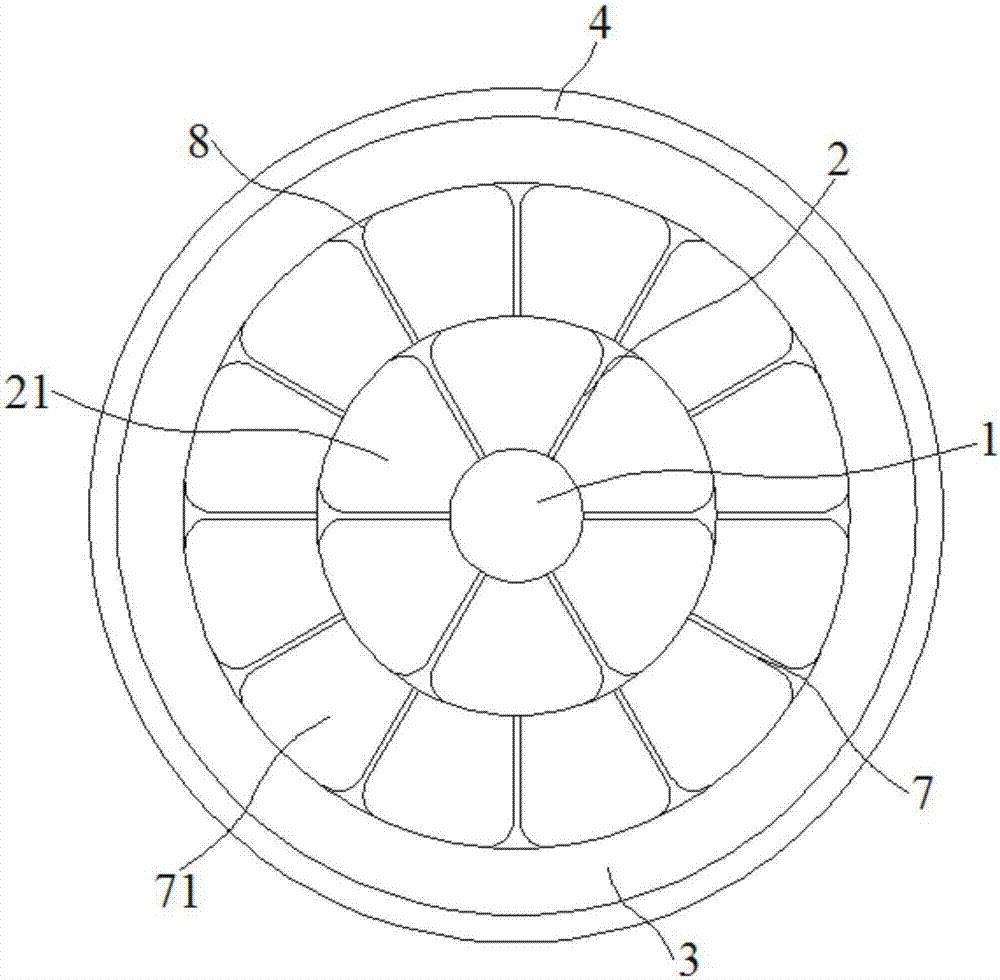

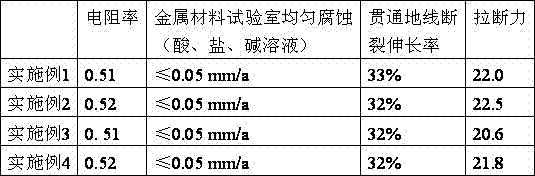

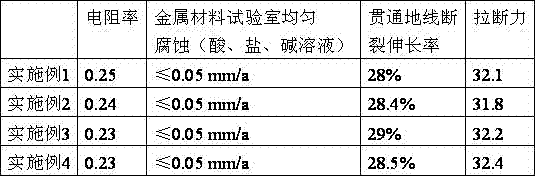

[0031] Embodiments 1 to 4: A comprehensive grounding cable for rail transit, comprising a centrally located round copper conductor 1, 5 to 7 first trapezoidal copper conductors 21 and 10 to 14 second trapezoidal copper conductors 7, the 5 to 7 A first trapezoidal copper conductor 21 is stranded on the outer surface of the round copper conductor 1 to form an intermediate conductive layer 2, and the 10-14 second trapezoidal copper conductors 71 are stranded on the intermediate conductive layer 2 to form an outer conductive layer 7. The stranding pitch of a trapezoidal copper conductor 21 and the second trapezoidal copper conductor 71 is 70-90mm, and a non-welded copper alloy sheath 3 is coated on the outer surface of the outer conductive layer 7, and the non-welded copper alloy sheath 3. The outer surface has a metal passivation layer 4.

[0032] The non-welded copper alloy sheath 3 is composed of the following components by weight:

[0033] Table 1

[0034]

Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com