A seamless steel pipe piercing machine ejector

A technology of seamless steel pipe and piercing machine, which is applied in the direction of manufacturing tools, mandrels, metal rolling, etc. It can solve the problems of continuous beating of ejector rods and unstable positioning of the center of the plug, so as to improve the accuracy of wall thickness and prolong the life of parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

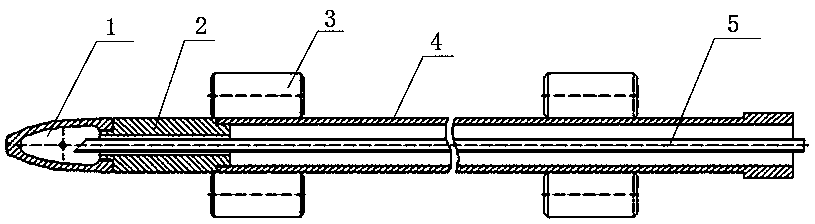

[0018] Such as figure 1 As shown, the traditional ejector rod used in the production of seamless steel pipes is composed of a plug, a connecting rod, a connecting section and a cooling water pipe. Internal water cooling; the connecting section rotates rapidly with the tube blank during the rolling process of the tube blank, and several sets of guide rollers of the three-roller guide device that can be opened and closed restrict the ejector rod from bending when it bears a large thrust. Due to the rapid rotation and the opening and closing of the guide rollers during the piercing and rolling process, the ejector rods continuously jump, resulting in unstable positioning of the center of the plug, which affects 1. The accuracy of the product wall thickness; 2. The three-roller guide device zero Component life is reduced.

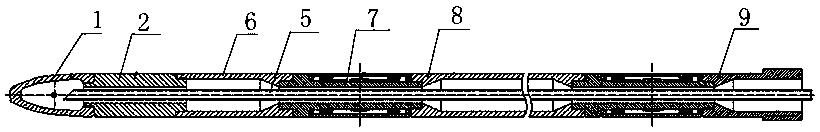

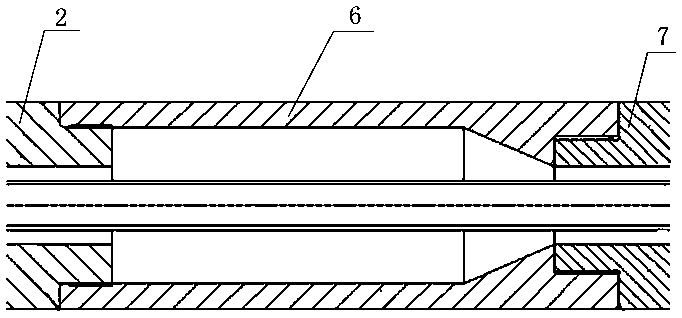

[0019] Such as figure 2 As shown, in order to solve the problems existing in the prior art, the invention improves the traditional mandrel, and divides the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com