Modified polyethylene film and its production technology

A technology of polyethylene film and chlorinated polyethylene, applied in the field of modified polyethylene film, can solve the problems of high production cost and raw material cost, complicated production process of plastic film, etc., so as to improve production efficiency, improve internal quality and appearance quality , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] 1. Production formula (weight ratio, the same below):

[0014] Chlorinated polyethylene (CPE): 55%, low-density polyethylene (LDPE): 40%, carbon black: 2.9%, antioxidant (1010): 0.1%, epoxidized soybean oil: 2%.

[0015] 2. Production process:

[0016] After weighing the raw materials, mix them evenly, send them to the extruder to extrude, then blow the film, and finally carry out the winding inspection.

[0017] The length-to-diameter ratio of the screw of the extruder used in this process is 32, the rotating speed of the roller is 40r / min, the barrel temperature: the feeding section is 170-175°C, the metering section is 160-165°C, and the head temperature is: 170-175°C; the inflation ratio is 2.0 when blowing the film.

specific Embodiment approach 2

[0018] The production process of the specific embodiment 2 is the same as the specific embodiment 1, and the difference is the production formula, which is as follows:

[0019] Chlorinated polyethylene (CPE): 64%, low-density polyethylene (LDPE): 30%, carbon black: 3.9%, antioxidant (1010): 0.1%, epoxidized soybean oil 2%.

[0020] The product produced according to the above process has a thickness of 0.3±0.02 millimeters and a width of 0.2-0.6 meters.

[0021] name

model, specification

place of origin

CM0136

Kyrgyzstan

polyethylene

2F2A

Kyrgyzstan

level one

Nanhua

extruder

LD3200-I

Shandong

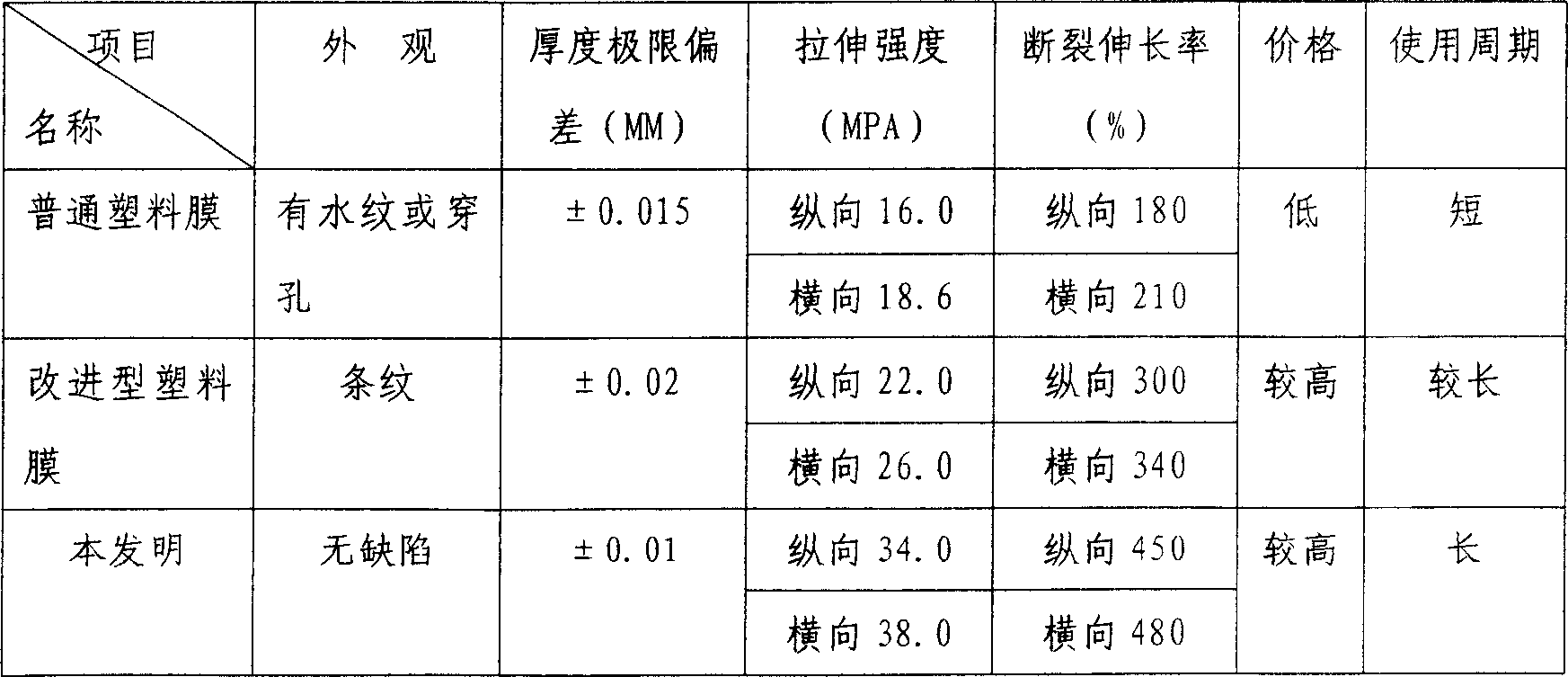

[0022] The following table is a technical performance comparison table between the present invention and the prior art:

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com