Complex component machining residual wall thickness self-adaptive compensation method based on coordinate origin translation

A technology of coordinate origin and components, which is applied in the field of adaptive compensation for the residual wall thickness of complex components, to reduce labor intensity, improve machining accuracy, and realize the effect of adaptive compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

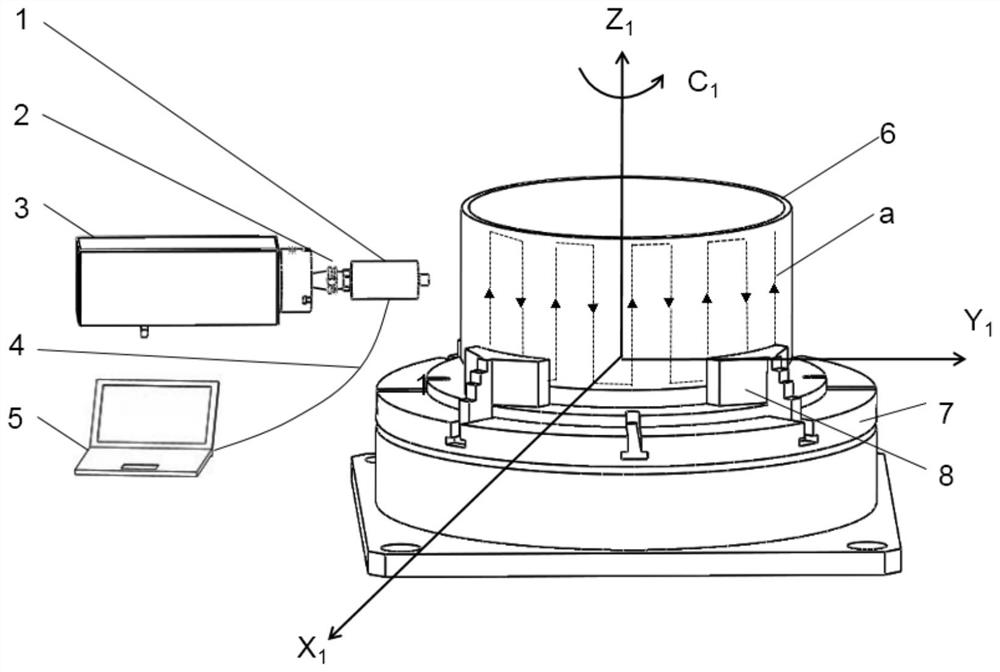

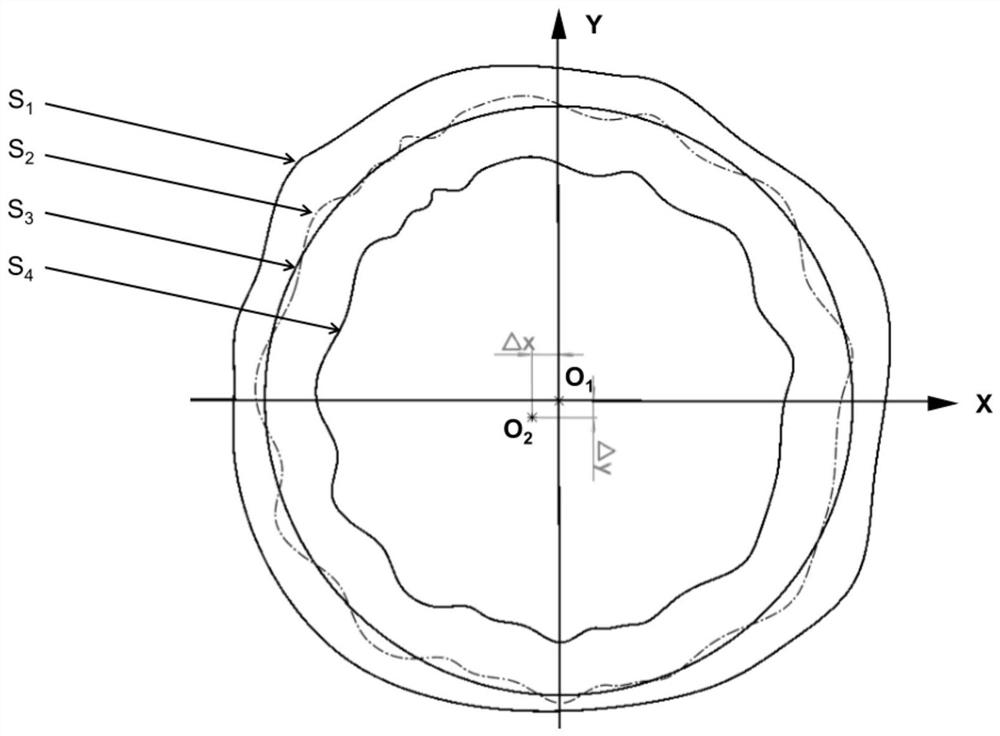

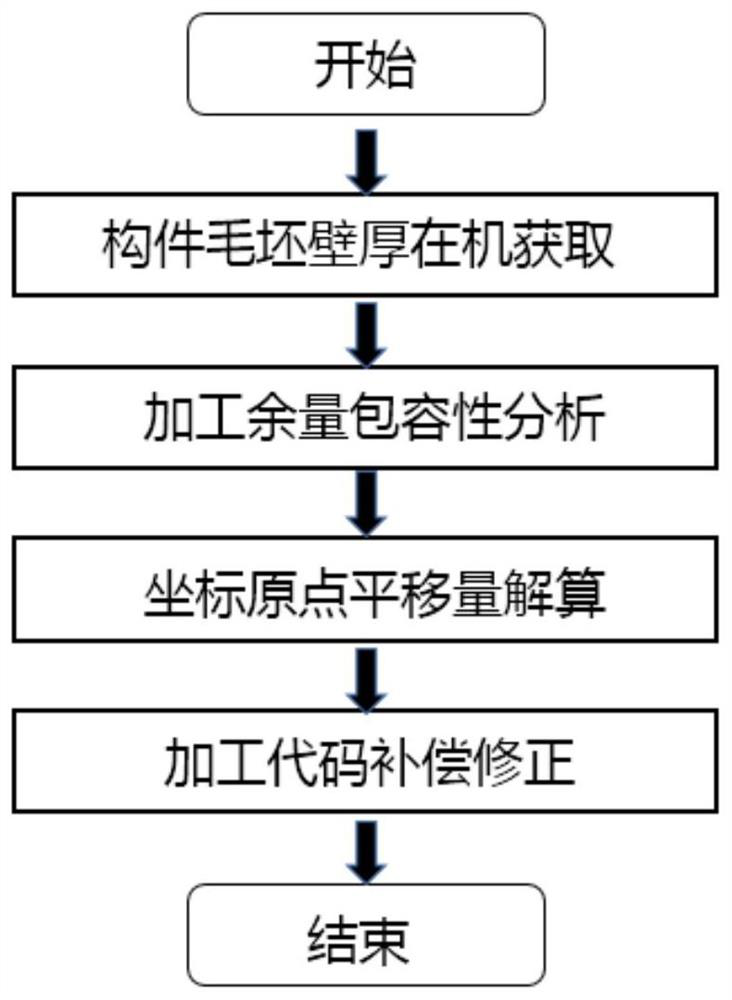

[0032] The member 6 to be processed has a diameter of 500-550 mm, a blank wall thickness of 7-8 mm, and a remaining wall thickness of 3-4 mm. The center frequency of the sensor of the ultrasonic thickness measuring device is 10MHz, and the point focusing method is adopted. The flow chart of the adaptive compensation method is as follows: image 3 As shown, the specific steps are as follows:

[0033] In the first step, the wall thickness of the component blank is obtained on the machine

[0034] The ultrasonic thickness measuring device 1 is clamped by the tool handle 2; the tool handle 2 is installed on the machine tool spindle 3; the ultrasonic thickness measuring device 1 is connected with the computer 5 through the ultrasonic cable 4, and scans and measures along the track a; the computer 5 completes the measurement in real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com