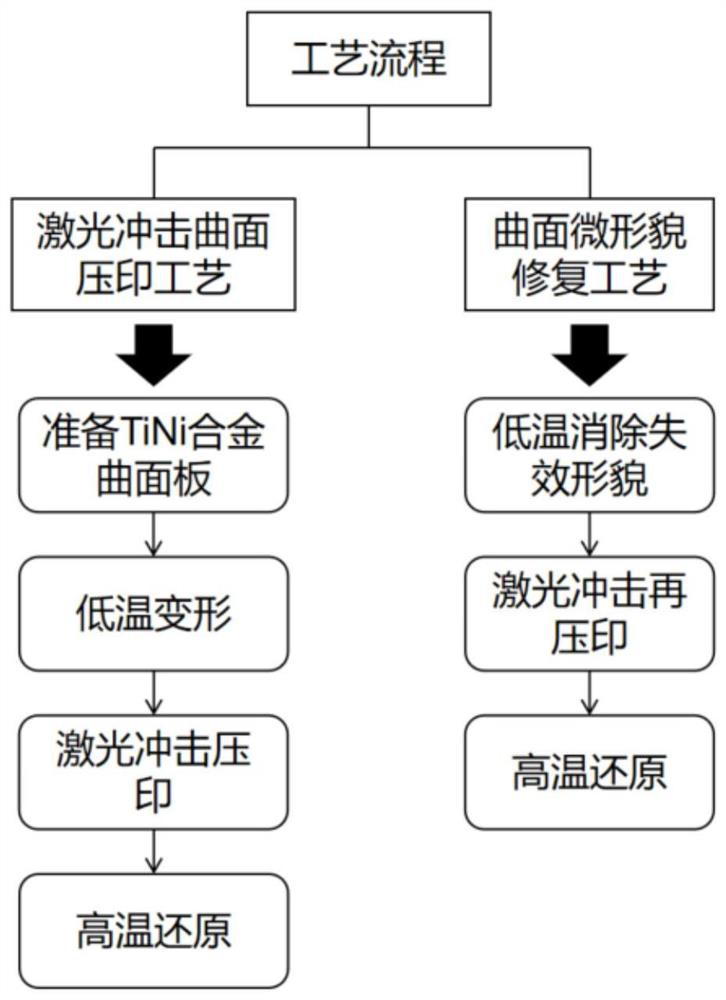

A Laser Shock Curved Surface Imprinting and Curved Surface Micro-topography Restoration Process

A technology of laser shock and micro-topography, which is applied in laser welding equipment, improvement of process efficiency, manufacturing tools, etc., can solve the problems of uneven laser shock effect and uneven embossing effect, and achieve fast and complete repair , the effect of uniform surface topography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

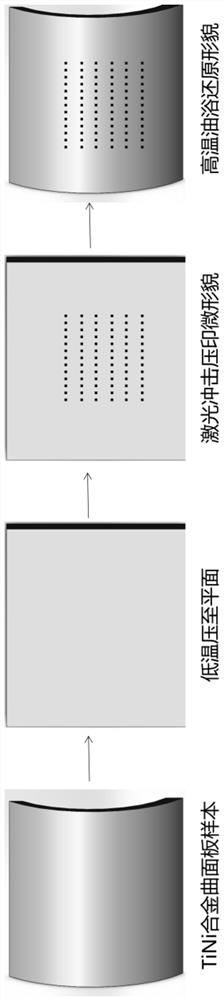

[0035] Treatment of Ti by laser shock imprinting process 50 Ni 50 Curved alloy plate

[0036] Grinding, polishing, and cleaning the purchased TiNi alloy curved plate with a phase transition temperature of 100°C, the surface was analyzed by an energy dispersive spectrometer (EDS) to obtain an elemental ratio of 50.1% Ni, 0.03% C, 0.005 %H, 0.01%O, the rest is Ti element. Place the sample in a refrigerated space with an ambient temperature of 0°C, and place the Ti on a metal roller 50 Ni 50 Curved panels are manually rolled and pressed into flat panels. Then use a picosecond laser to ablate 600 holes with a diameter of 50 μm on the surface of the Ti6Al4V alloy. The holes are distributed in a square array, the hole distance is 30 μm, and the ablation hole depth is 10-20 μm to clean the alloy surface. The deformed Ti 50 Ni 50 The alloy plate is put into the laser shock peening system, and the Ti 50 Ni 50The alloy plate and the Ti6Al4V alloy mold are wrapped together, wher...

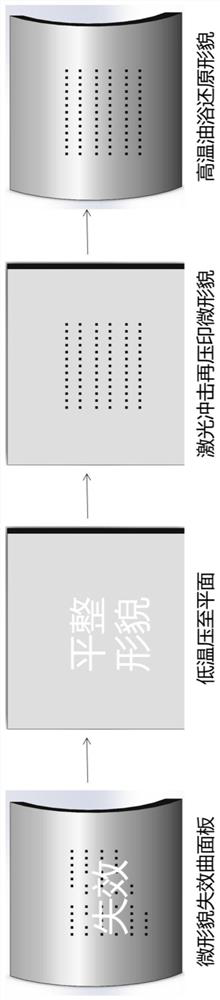

example 2

[0040] Conventional laser shock imprinting process for Ti 50 Ni 50 Alloy Curved Panel

[0041] The element ratio is 50.1% Ni, 0.03% C, 0.005% H, 0.01% O, the rest is Ti element, Ti with a phase transition temperature of 100°C 50 Ni 50 The alloy curved panel is put into the laser shock peening system, and the Ti 50 Ni 50 The alloy plate and the Ti6Al4V alloy mold are wrapped together, wherein the alloy plate is in contact with the patterned side of the mold, and the side corresponding to the impact is the non-patterned side of the Ti6Al4V alloy. The water layer is used as the constrained layer to perform laser shock imprinting at room temperature of 15°C. The parameters of laser shock imprinting are laser pulse energy 4J, spot diameter 3mm, laser wavelength 1024nm, frequency 10Hz, pulse width 20ns, and spot lengthwise and horizontally. The overlap rate is 30%, so that Ti 50 Ni 50 Micron-scale surface microtopography is produced on the surface of the alloy plate.

[0042...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com