Method for producing seamless steel tube with heat preservation cover of pilger mill

A technology of seamless steel pipe and production method, applied in the direction of temperature control, metal rolling, etc., can solve the problems of deteriorating the inner surface quality of the finished steel pipe, and achieve the effects of improving the inner surface quality, improving the wall thickness accuracy and lowering the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

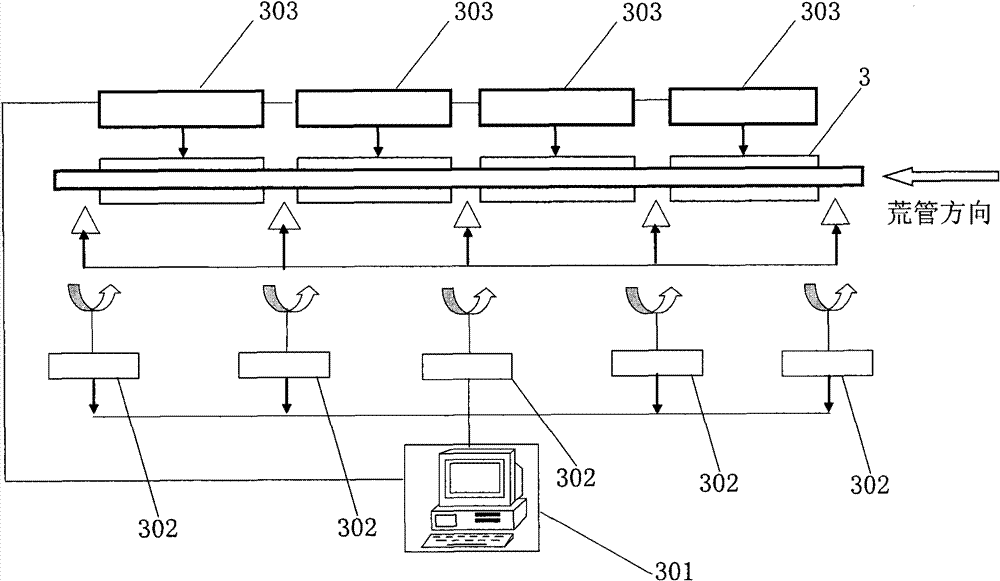

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

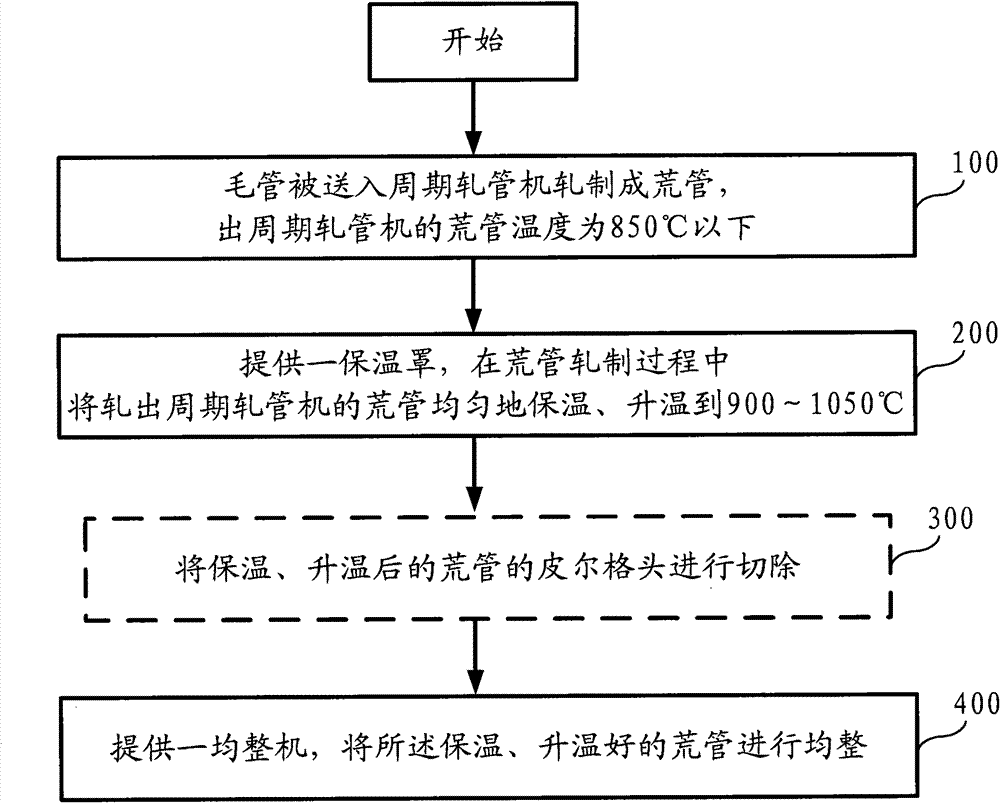

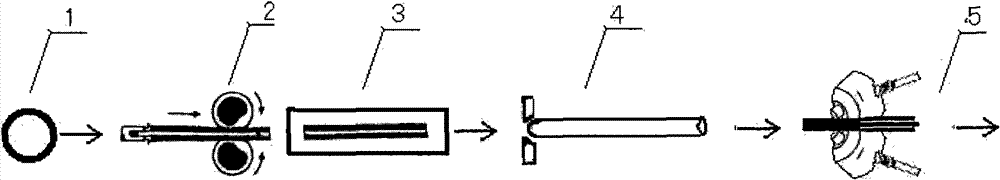

[0024] refer to figure 1 as shown, figure 1 It is a flow chart of the production method of the seamless steel pipe with the heat preservation cover in the periodic pipe rolling mill of the present invention. Depend on figure 1 As can be seen, the seamless steel pipe production method of periodic pipe rolling mill band insulation cover of the present invention mainly comprises the following steps:

[0025] The capillary is sent into the periodic pipe rolling mill to be rolled into a waste pipe, and the temperature of the waste pipe leaving the periodic pipe rolling mill is below 850° C. (step 100);

[0026] Provide a heat preservation cover, during the blank tube rolling process, uniformly keep the blank tubes of the rolled-out period tube rolling mill warm, and raise the temperature to 900-1050°C (step 200);

[0027] A leveling machine is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com