A seamless thin-wall tube drawing die for integrated circuits

A technology for integrated circuits and thin-walled tubes, which is applied in the field of seamless steel pipe processing equipment and seamless thin-walled tube drawing dies for integrated circuits, can solve the problems of difficult to meet actual use and design roughness, and achieve improved smoothness. , The effect of improving wall thickness accuracy and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

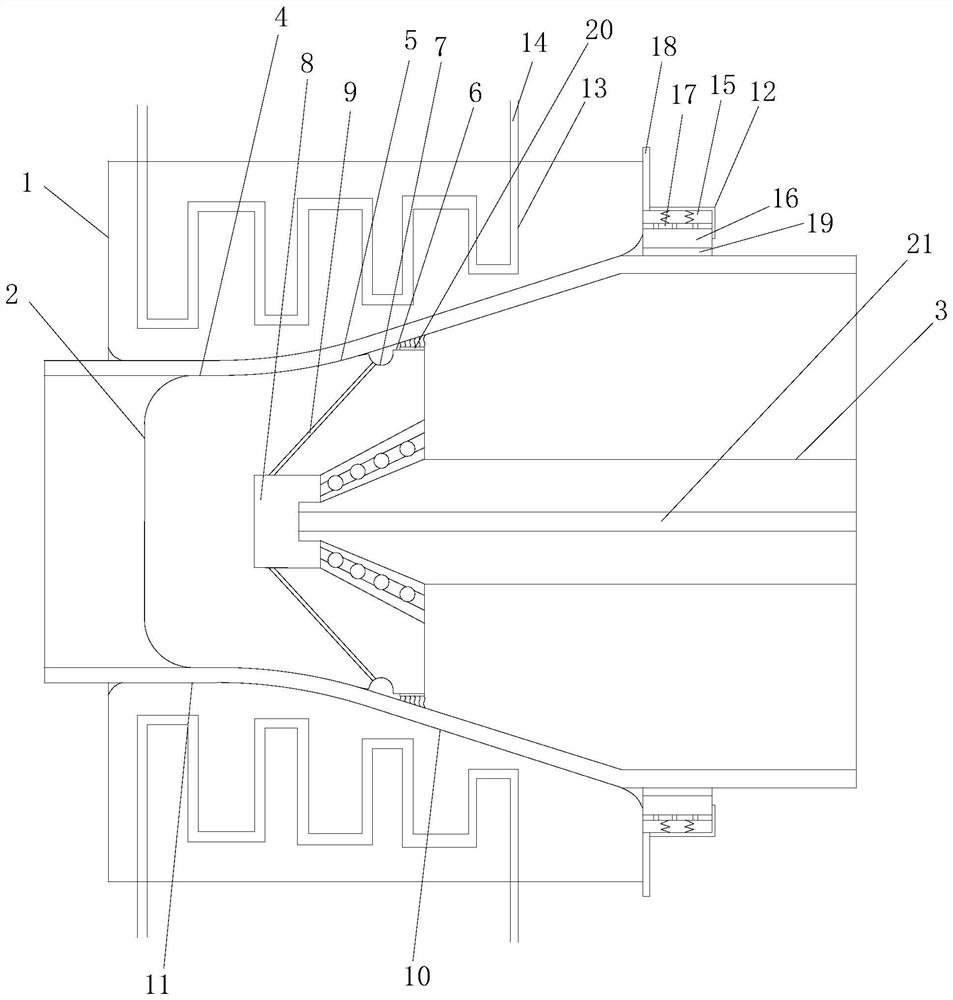

[0014] refer to figure 1 , a seamless thin-walled tube drawing die for integrated circuits of the present invention, comprising a drawing die set 1, an inner die set 2, a mandrel 3, a fixed-diameter inner die 4, a reduced-diameter inner die 5, and an oil-coated die post 6 , oiling ring groove 7, oil storage tank 8, oil guide channel 9, reducing die groove 10, fixed diameter die groove 11, annular oiling mechanism 12, heat conduction channel 13 and heat conduction copper pipe 14, and the inner mold cover 2 passes through The tapered bearing is installed on the mandrel 3, the front side of the inner membrane sleeve is provided with a fixed-diameter inner mold 4, and the rear side of the fixed-diameter mold core is provided with a reduced-diameter inner mold 5, and the reduced-diameter inner mold 5 The rear side of the oil-coated mold column 6 is provided with an oil-coated ring groove 7 on the upper ring of the oil-coated mold column 6, and an oil storage tank 8 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com