Plug for large-hole series medium- and thick-wall capillaries

A series of capillary technology, applied in the field of plugs, can solve the problems of excessive wall thickness at the end of the steel pipe, unfavorable rod insertion, and high recutting rate, so as to improve the wall thickness accuracy, ensure the quality of the inner surface, and reduce metal consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

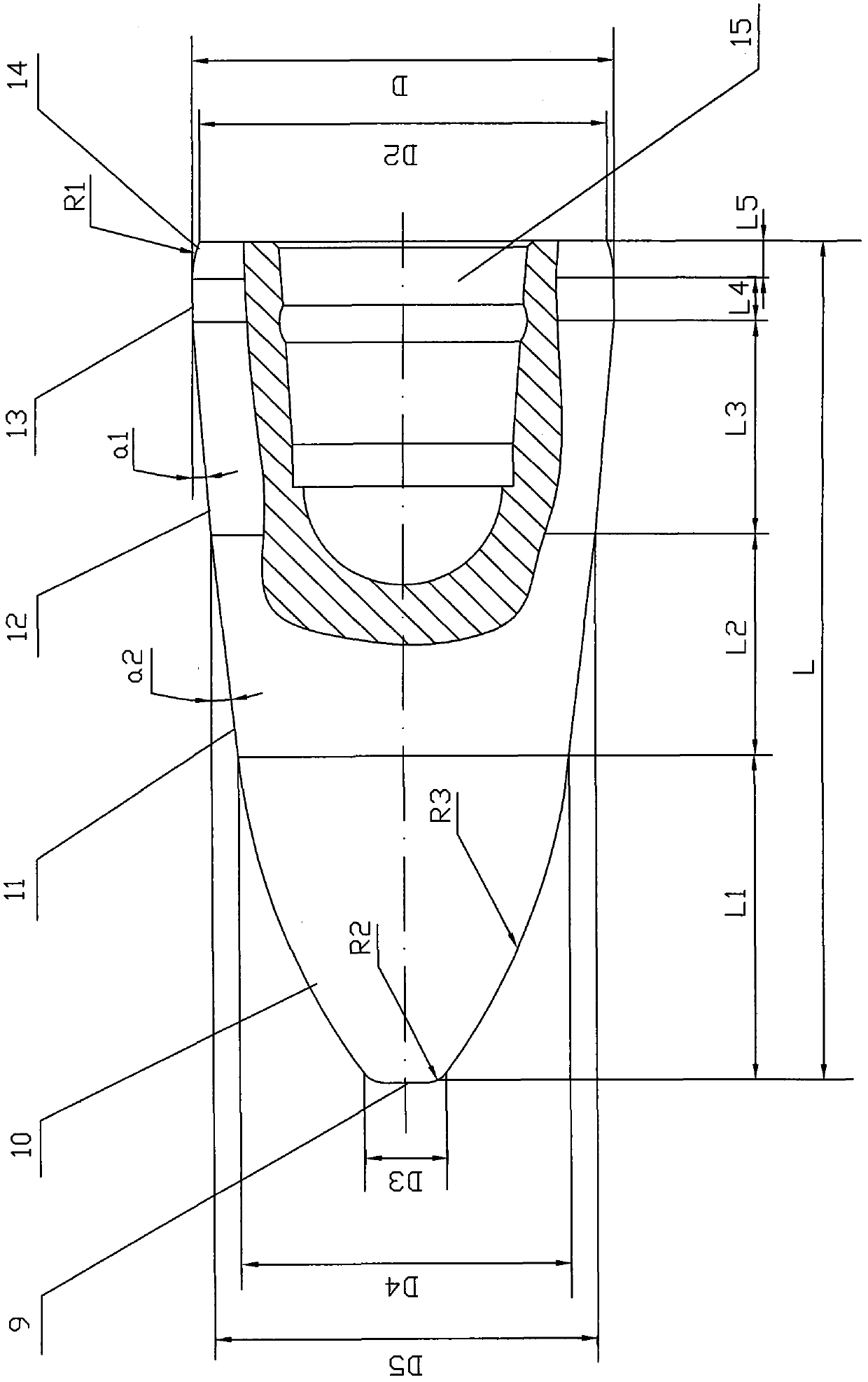

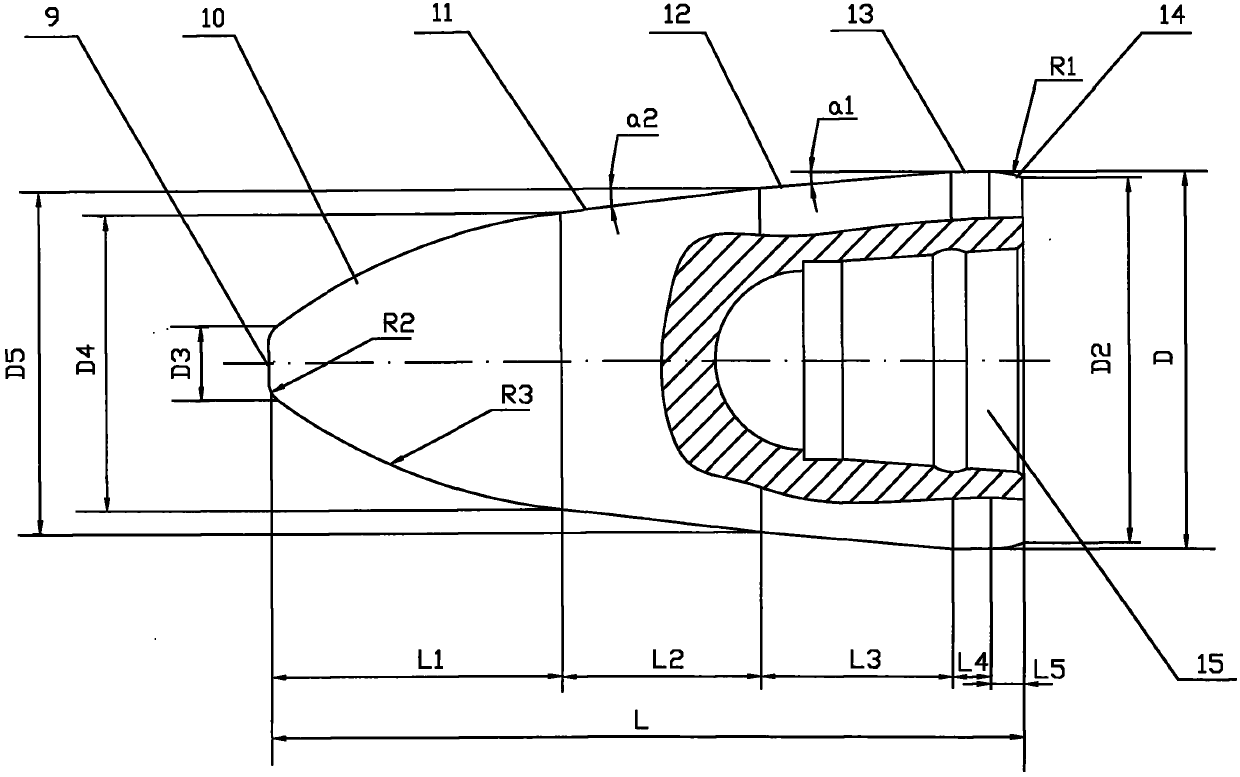

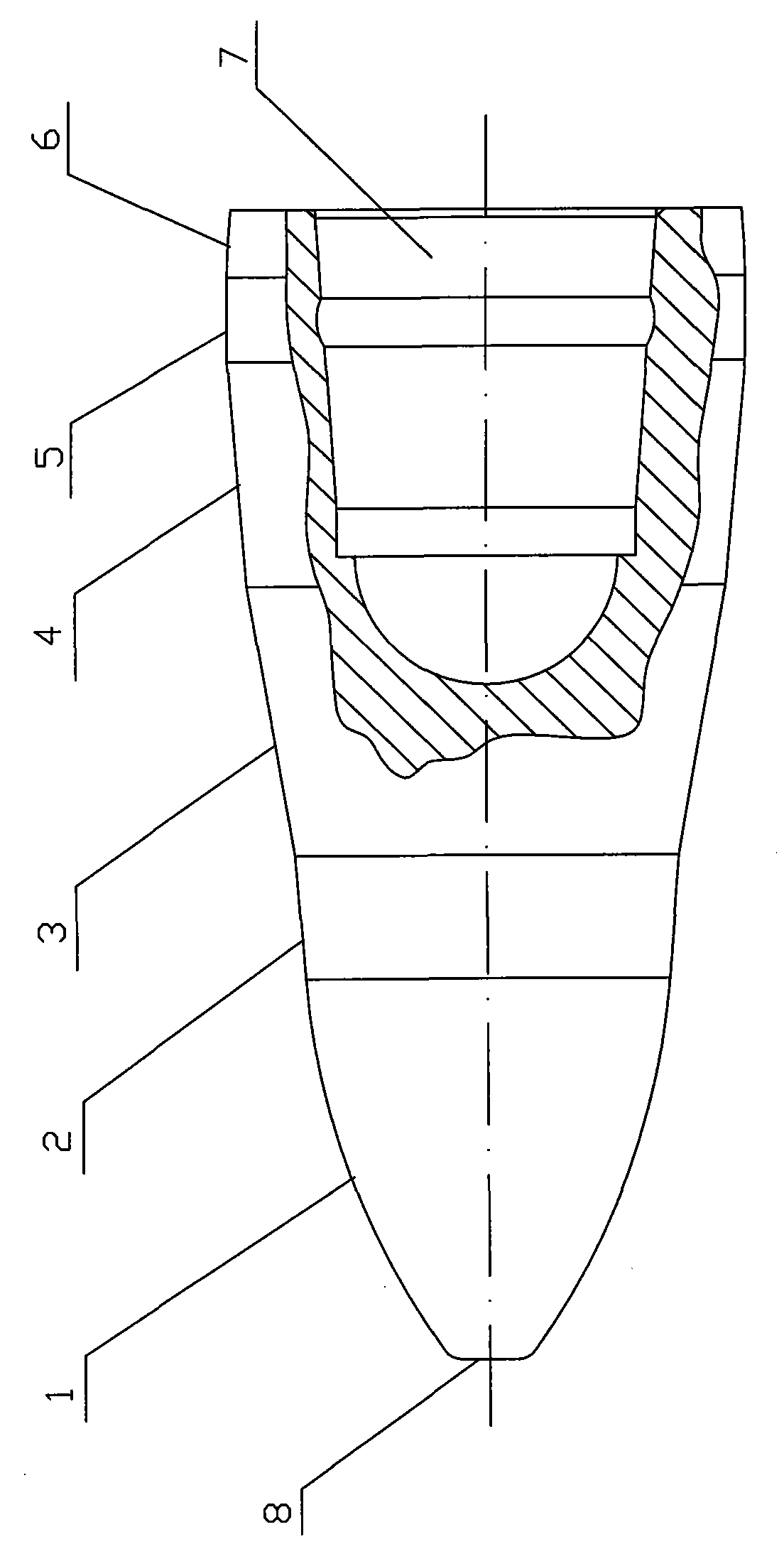

[0025] Embodiment 1: A type 303 large-hole medium-thick-wall capillary plug. The outer profile of the plug is composed of a perforated section 10 , a diameter-expanding section 11 , a rolling section 12 , a rounding section 13 and a reverse cone section 14 . The front end surface 9 of the plug adopts a flat head design, and the tail end of the plug is provided with a rod hole 15; the connection between the front end face 9 of the plug and the perforated section 10 adopts a circular arc transition, and the radius of the arc is R2, and the arc radius of the outer profile of the perforated section 10 is R3; diameter expanding section 11 and rolling section 12 are cones, the taper of expanding diameter section 11 is a2, and the taper of rolling section 12 is a1; is R1; the return-to-circle segment 13 is a cylinder. Its specific dimensions are as follows:

[0026] The total length L=685mm of the plug; the length L1=227mm of the perforated section 10, the diameter D3=53.11mm of the...

Embodiment 2

[0027] Embodiment 2: A type 309 large-hole type medium-thick-walled capillary plug. The outer profile of the plug is composed of a perforated section 10, a diameter-expanding section 11, a rolling section 12, a rounding section 13 and a reverse cone section 14. The front end surface 9 of the plug adopts a flat head design, and the tail end of the plug is provided with a rod hole 15; the connection between the front end face 9 of the plug and the perforated section 10 adopts a circular arc transition, and the radius of the arc is R2, and the arc radius of the outer profile of the perforated section 10 is R3; diameter expanding section 11 and rolling section 12 are cones, the taper of expanding diameter section 11 is a2, and the taper of rolling section 12 is a1; is R1; the return-to-circle segment 13 is a cylinder. Its specific dimensions are as follows:

[0028] The total length L=685mm of the plug; the length L1=238mm of the perforated section 10, the diameter D3=56.36mm of ...

Embodiment 3

[0029] Embodiment 3: A type 323 large-hole type medium-thick-walled capillary plug. The outer profile of the plug is composed of a perforated section 10, a diameter-expanding section 11, a rolling section 12, a rounding section 13 and a reverse cone section 14. The front end surface 9 of the plug adopts a flat head design, and the tail end of the plug is provided with a rod hole 15; the connection between the front end face 9 of the plug and the perforated section 10 adopts a circular arc transition, and the radius of the arc is R2, and the arc radius of the outer profile of the perforated section 10 is R3; diameter expanding section 11 and rolling section 12 are cones, the taper of expanding diameter section 11 is a2, and the taper of rolling section 12 is a1; is R1; the return-to-circle segment 13 is a cylinder. Its specific dimensions are as follows:

[0030] The total length L=685mm of the plug; the length L1=280.04mm of the perforated section 10, the diameter D3=61.14mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com