Patents

Literature

119results about How to "Guaranteed wall thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

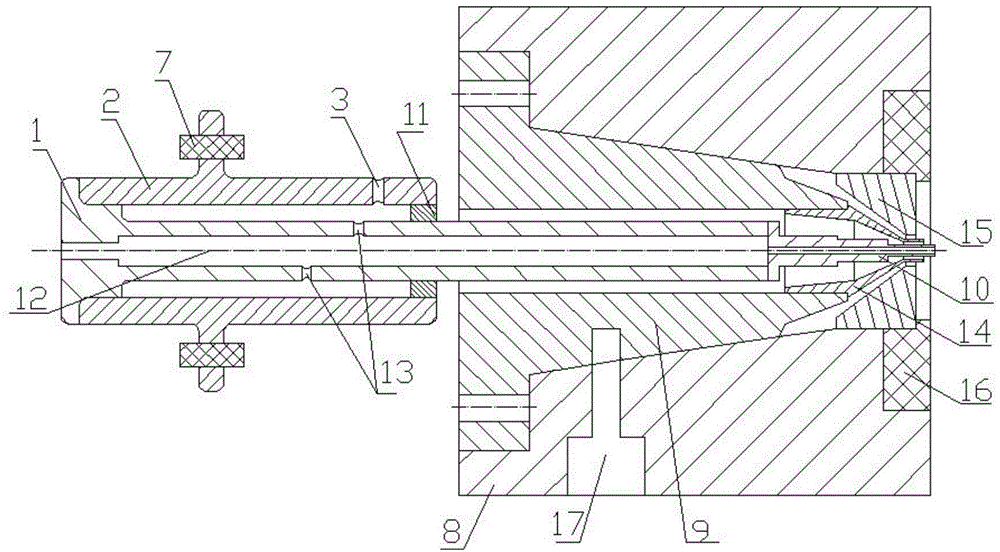

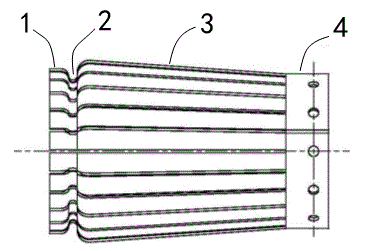

Wax injection mold for investment casting of hollow turbine blades and method for rapidly manufacturing wax injection mold

The invention discloses a wax injection mold for investment casting of hollow turbine blades and a method for rapidly and accurately manufacturing the wax injection mold. The mold consists of a cavity mold, a mold core and an accessory structure, wherein the cavity mold comprises an upper mold and a lower mold of a combined structure; each mold block forming the cavity mold consists of an external aluminum mold frame, an internal cast zinc alloy inlay and a conformal cooling copper pipe embedded into the inlay; a mold core positioning piece which can be decomposed at a high temperature is arranged on a longitudinal rib of the mold core; and water-soluble core blocks used for forming exhaust openings in the rear edges of the turbine blades are arranged on rear edge ribs of the mold core. The matching precision of the mold core positioning piece and the cavity mold is guaranteed by adopting a cavity mold interior running-in method, and the matching precision of the water-soluble core blocks and the cavity mold is guaranteed by adopting a cavity mold interior adhesion method. The wax injection mold disclosed by the invention is low in manufacturing cost and short in period, and the high wax pattern precision and core positioning precision can be obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

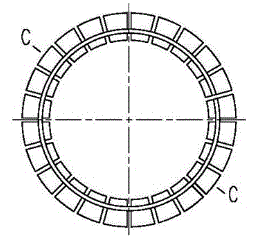

Casting method for exhaust branch pipe of thin-wall ball iron triplet

ActiveCN1907597AGuaranteed wall thicknessHigh dimensional accuracyFoundry mouldsFoundry coresExhaust pipeSerial code

The invention relates to a casting method for casting the three-way ventilate branch tube of thin-wall iron element, which comprises: (1), using the curvature formed by the central line of C exhaust open and the central line of A exhaust tube, to make the C and A exhaust opens above the parting surface, to be shaped via upper and lower outer moulds; the tube core and sand core are put via the serial number, and it uses pour system that combines side pour and bottom pour with contract cap and cold iron; (2), preparing outer mould, core box, section sheet, pour cap, and the wood mould that checking sample plate; (3), preparing the casting element and sand core; (4), drying the casting element and the sand core, and closing the tank after arranging the sand core; (5), smelting and pouring; (6), cooling and molding; (7), cleaning the casting element; (8), thermally treating; (9), testing the water pressure. The invention can improve the quality of casting element, and improve the producing efficiency.

Owner:HUDONG HEAVY MACHINERY +1

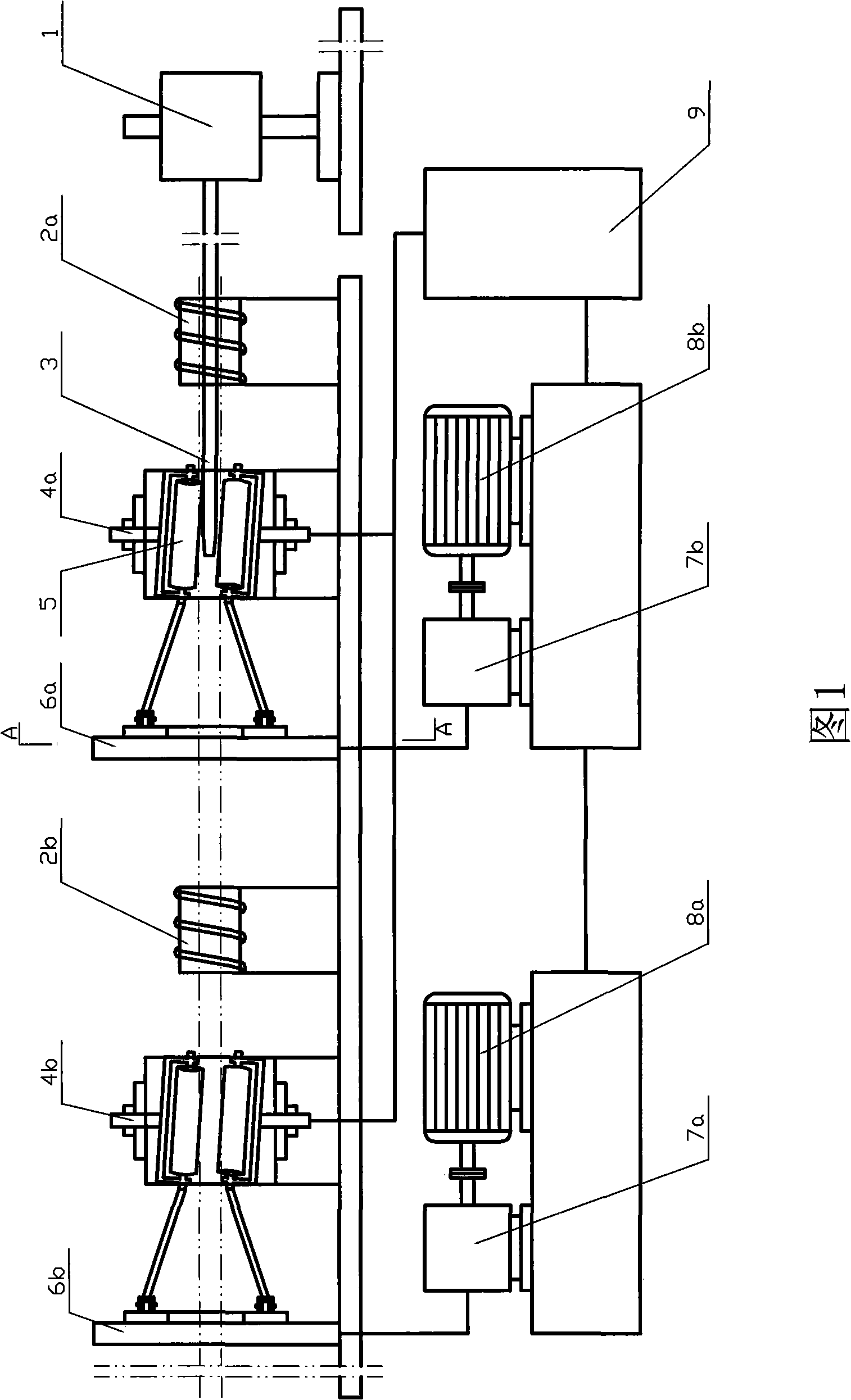

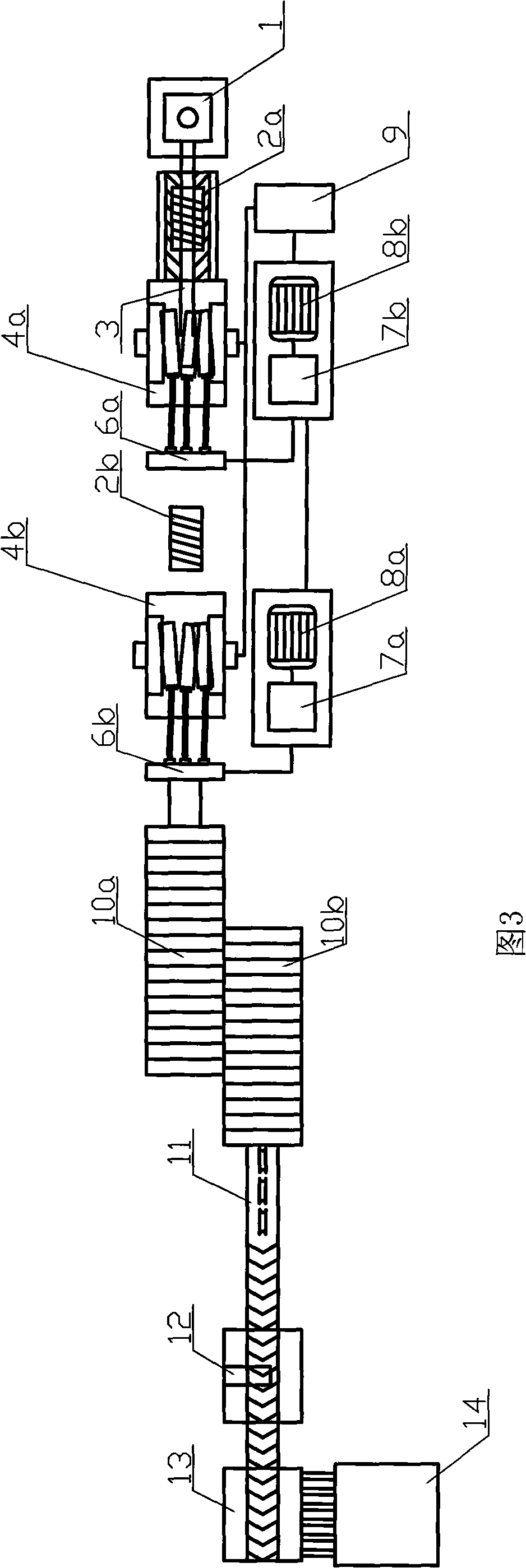

Two-stand angularly hot rolling minor diameter seamless steel tube rolling technique and equipment thereof

InactiveCN101259589AGuaranteed wall thicknessGuaranteed ovalityTemperature control deviceMandrelsIntermediate frequencyHeating furnace

The invention discloses the rolling technology of a double-stander oblique hot rolling small diameter seamless steel tube, and the rolling technology of the invention is that a mandrel trolley pushes a mandrel into a pierced billet and is pushed to move forward, the mandrel is heated to 950 DEG C to 1150 DEG C by an intermediate frequency induction heating electric furnace, the mandrel trolley continues to pushes the heating pierced billet into a rolling mill to carry out wall increasing and diameter reducing rolling, only the mandrel and a roller are cooled during rolling process; the pierced billet that breaks away from the mandrel is placed into a reheating electric furnace for heating to 950 DEG C to 1150 DEG C and is sent into a stretch reducing and wall increasing rolling mill to carries out the diameter reducing rolling, the heating while rolling can be realized, and only the roller is cooled during the rolling process; the invention is finished by cooling, straightening, cutting and online detecting after rolling. The invention realizes the technology of heating the mandrel and the roller while rolling and cooling by improving the heating method of a heating furnace, structure and the cooling method of the mandrel and the roller. The rolling technology of a double-stander oblique hot rolling small diameter seamless steel tub improves efficiency, simplifies the technology, reduces cost, saves energy and reduces pollution, thus the rolled steel tube is high in precision.

Owner:LUOYANG DINGRUI MATERIAL TECH

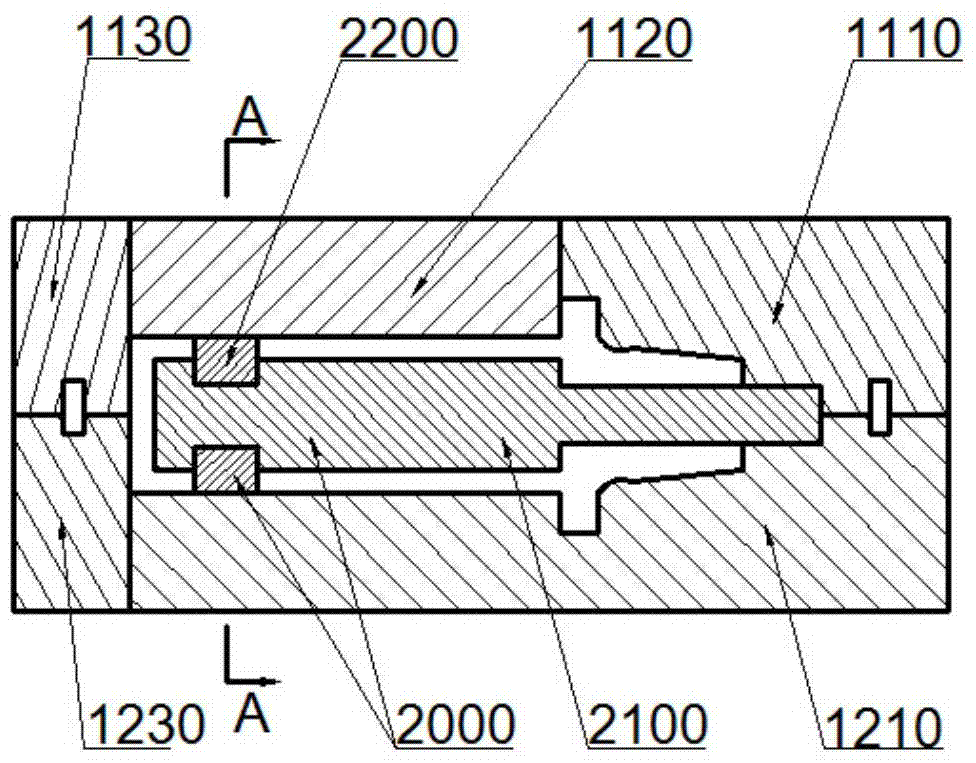

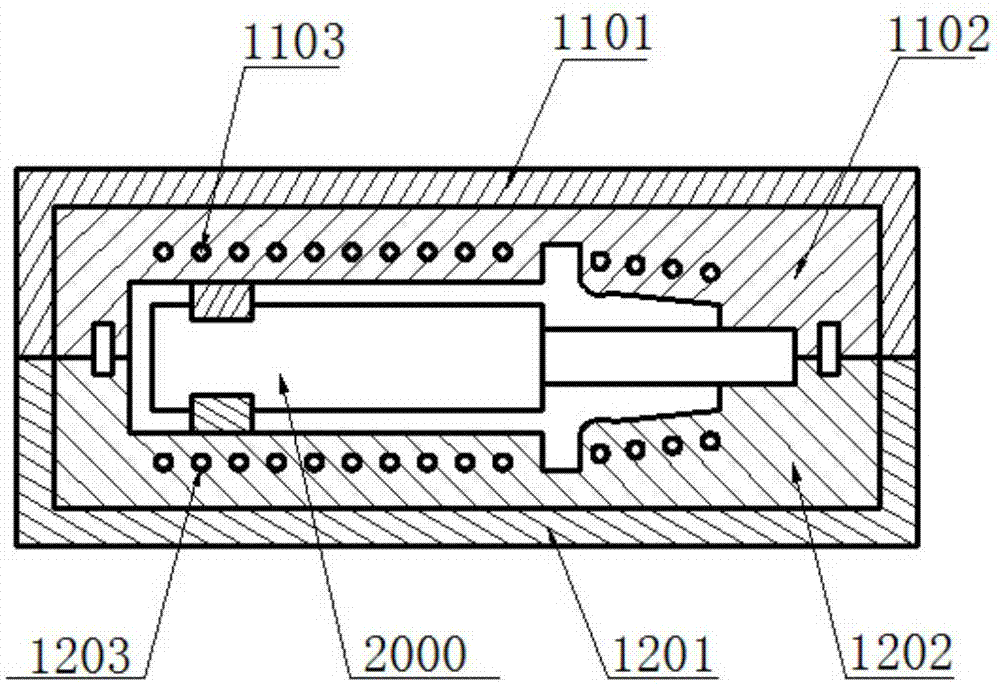

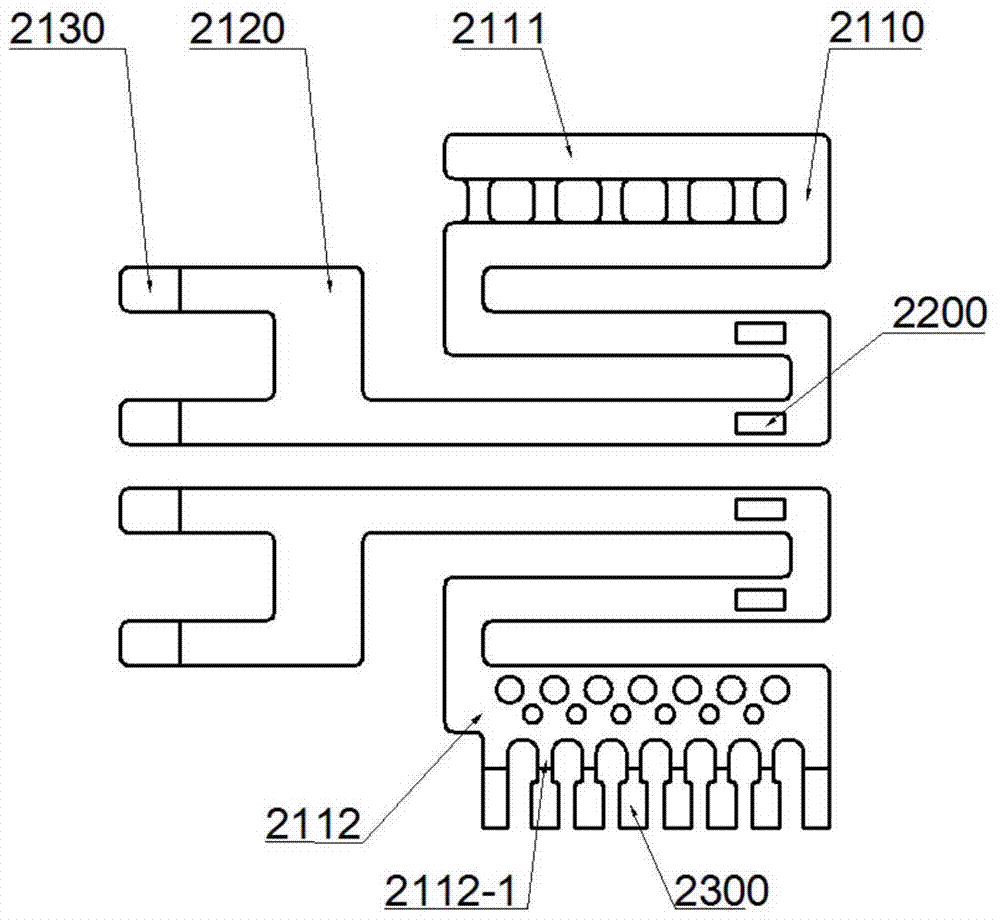

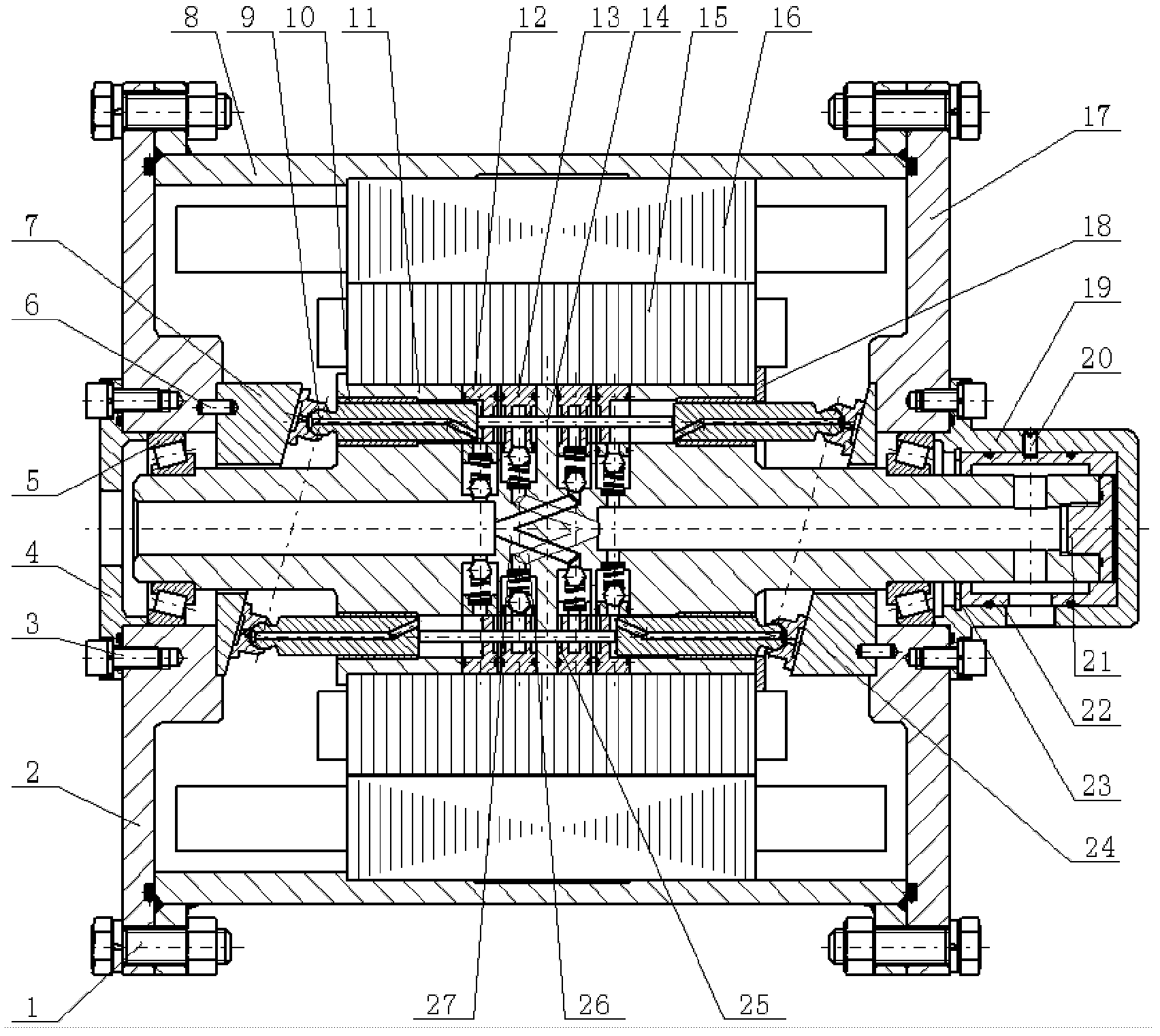

Plunger type motor pump

ActiveCN102619720AReduce intensityReduce stiffnessPositive-displacement liquid enginesMulti-cylinder pumpsEngineeringCylinder block

The invention discloses a plunger type motor pump, and belongs to a plunger pump. The problems of weak strength and low overall power density of a cylinder of the conventional plunger motor pump are solved. According to the plunger type motor pump, a motor stator is assembled in a housing. The two ends of the cylinder are supported in the centers of a left end cover and a right end cover respectively. A motor rotor is sleeved on and fixedly connected with a lug boss on the middle part of the cylinder. N plunger cavities are reserved in each of the left and right end faces of the lug boss of the cylinder. A plunger piston shoe component is arranged in each plunger cavity. Suction and forcing valve components are arranged in correspondence to each plunger piston shoe component on the lug boss of the cylinder. A left swash plate is fixed on the inner side of the left end cover, and a right swash plate is fixed on the inner side of the right end cover. The plate surfaces of the left and right swash plates are parallel. Every two coaxial plunger piston shoe components are pressed against each other through a support rod, and piston shoe heads at the two ends are pressed on the plate surfaces of the left and right swash plates respectively. Reverse thrust generated between the plunger piston shoe components at the two ends and the swash plates and hydraulic acting force in the cylinder are transmitted through the support rods, and internal reacting force is fully utilized, so that the number of the parts is decreased, the overall strength of the pump is strengthened, and the internal space utilization rate of the cylinder is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

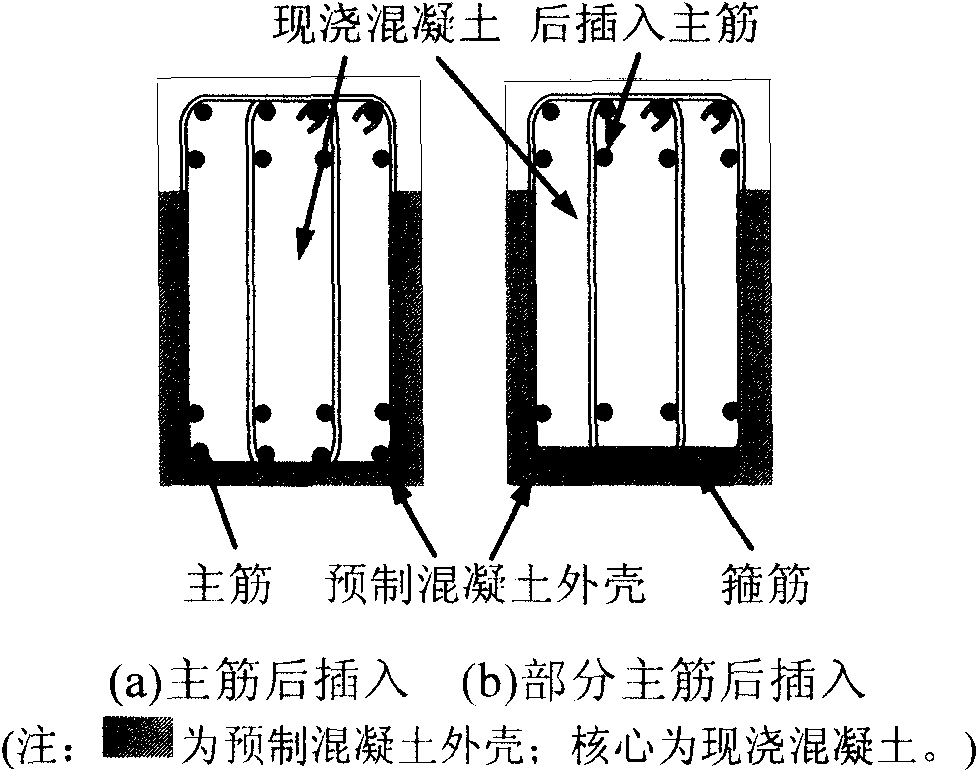

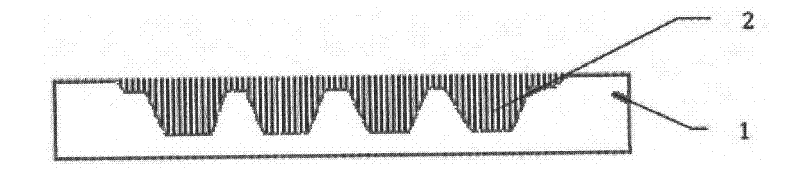

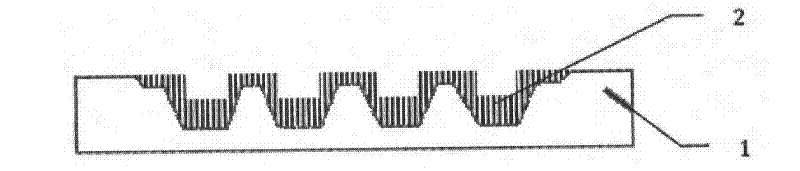

U-shaped precast concrete shell with inner ribs and manufacture method thereof

InactiveCN101565986AReduce usageSave resourcesCeramic shaping apparatusGirdersReinforced concreteRebar

The invention relates to a U-shaped precast concrete shell with inner ribs, which is mainly used for manufacturing a reinforced concrete beam. A hoping and a protective layer of the reinforced concrete beam are manufactured into a precast U-shaped shell which is not only used as a construction plank of the reinforced concrete beam, but also used as part of the structure to participate the joint work so as to be beneficial to saving a great amount of construction templates and workload thereof, improving the construction efficiency, lightening the labor force, realizing the cross operation, decreasing the construction cost, ensuring the building quality, saving resources and energy sources, protecting the environment and promoting the industrialized building development. The manufacture method of the U-shaped precast concrete shell adopts a rapid molding method, not only has simple manufacture and thin wall, but also can ensure the precast shell can be reliably bond and jointly work with post-cast core concrete by the inner ribs of the shell. In addition, the manufacture method of the U-shaped precast concrete shell can satisfy the thin-wall requirements and ensures that the protective layer thickness of the reinforced concrete beam main rib is the protective layer thickness of standard specifications.

Owner:张大长 +1

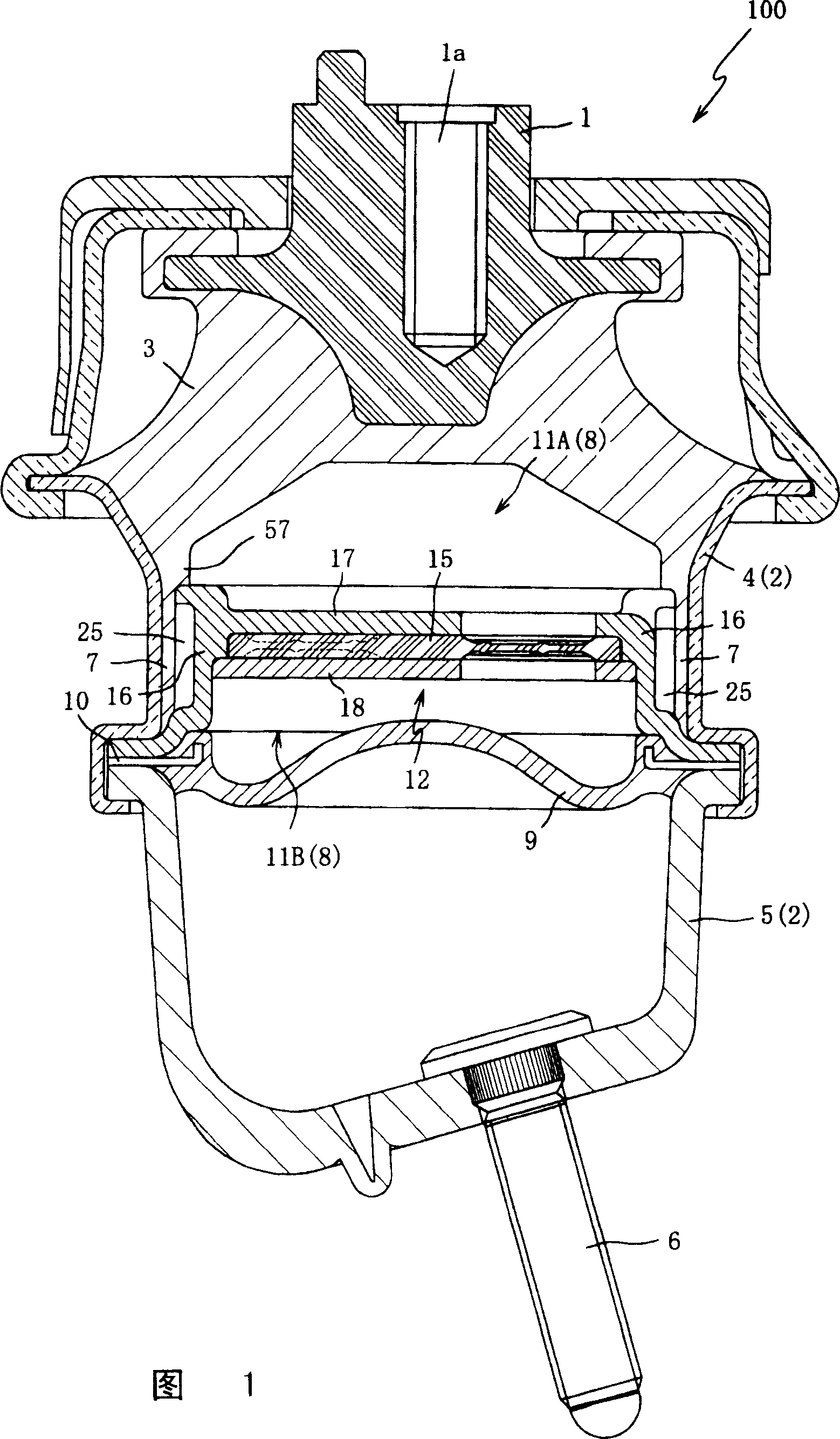

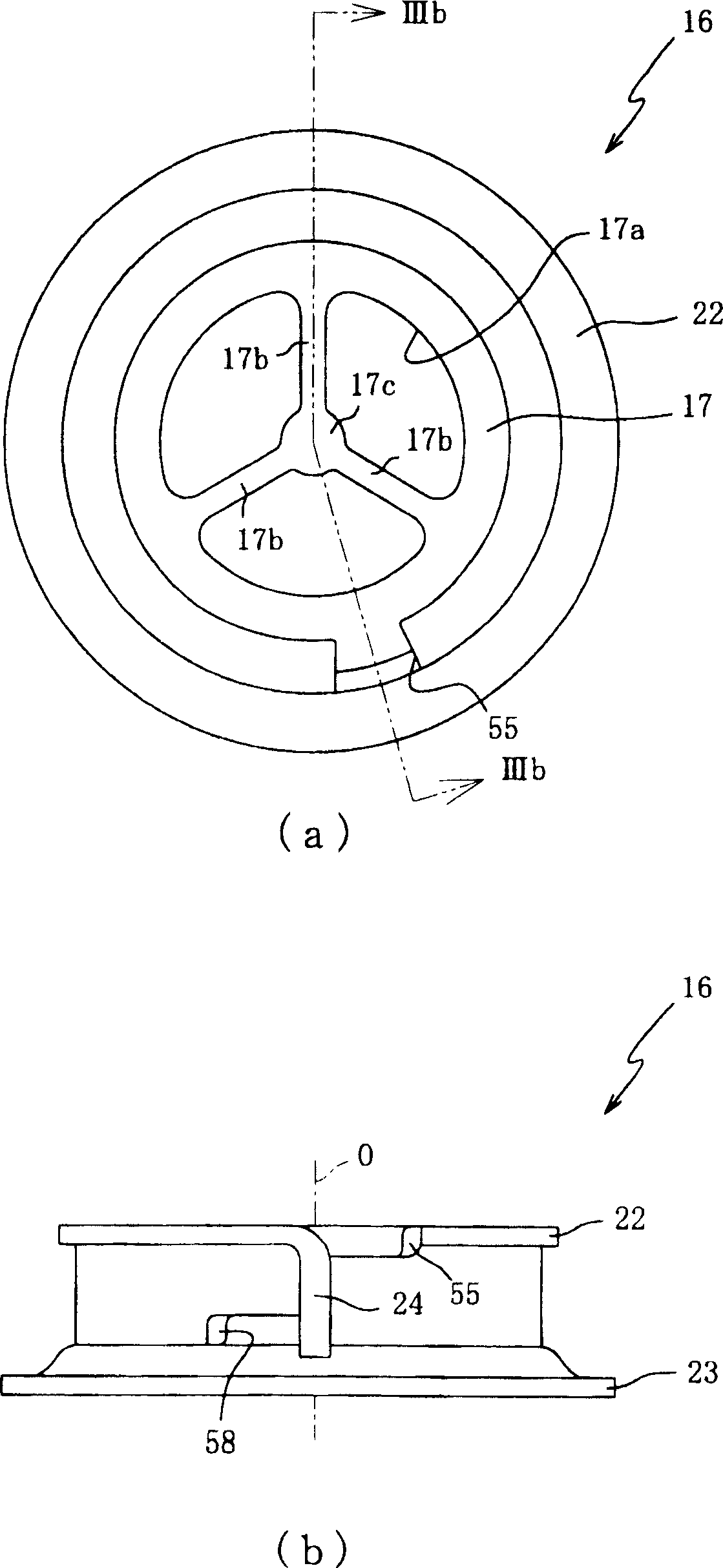

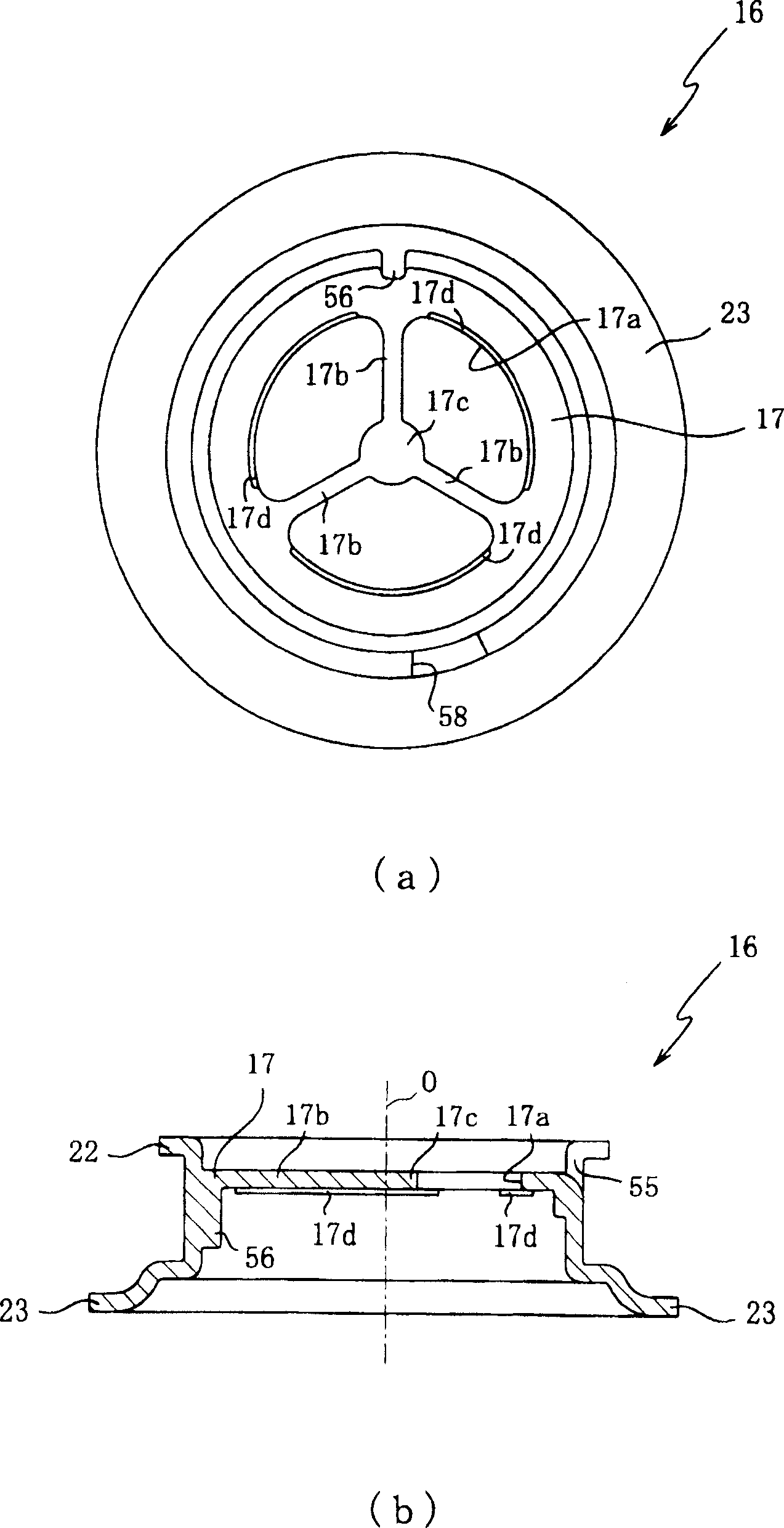

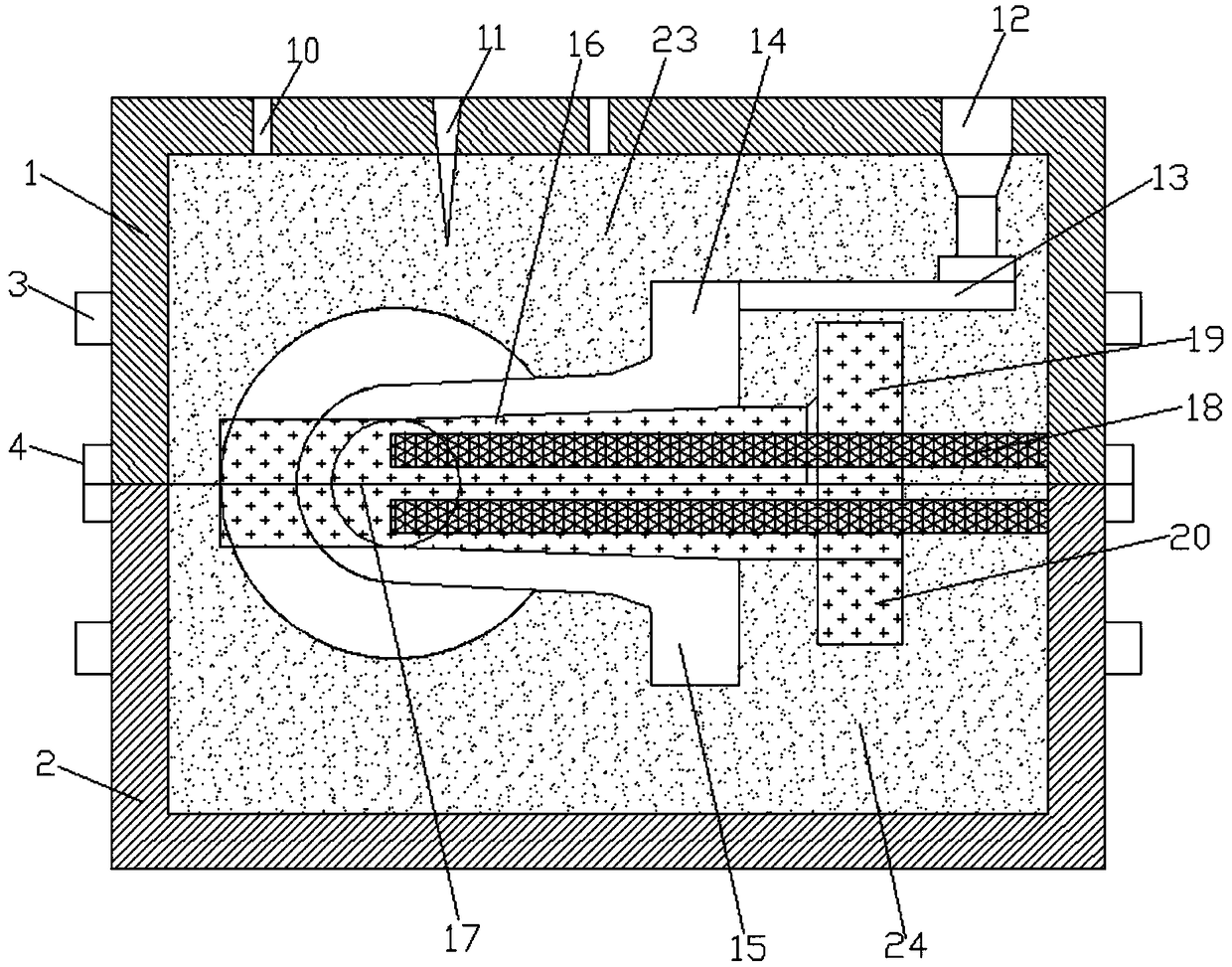

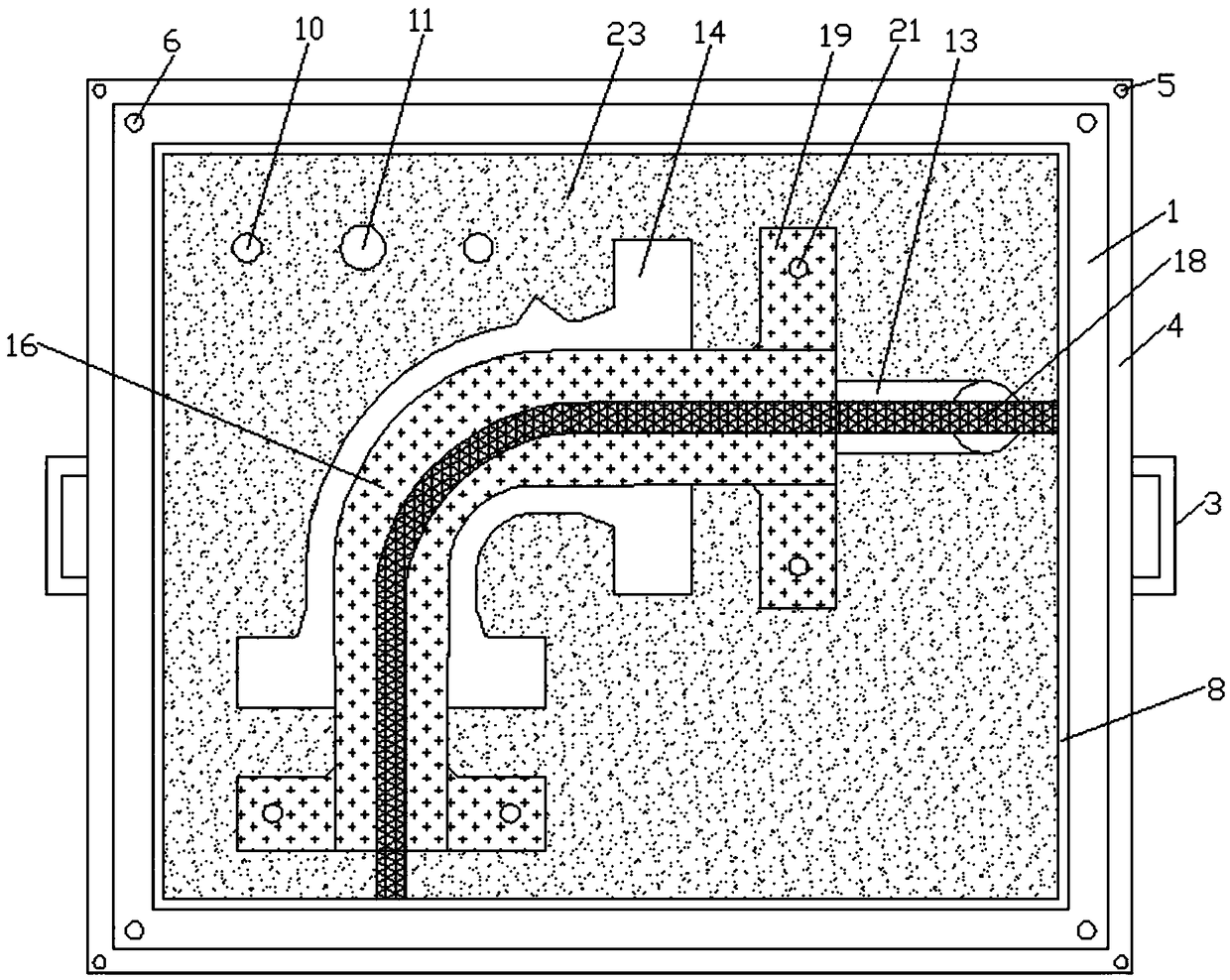

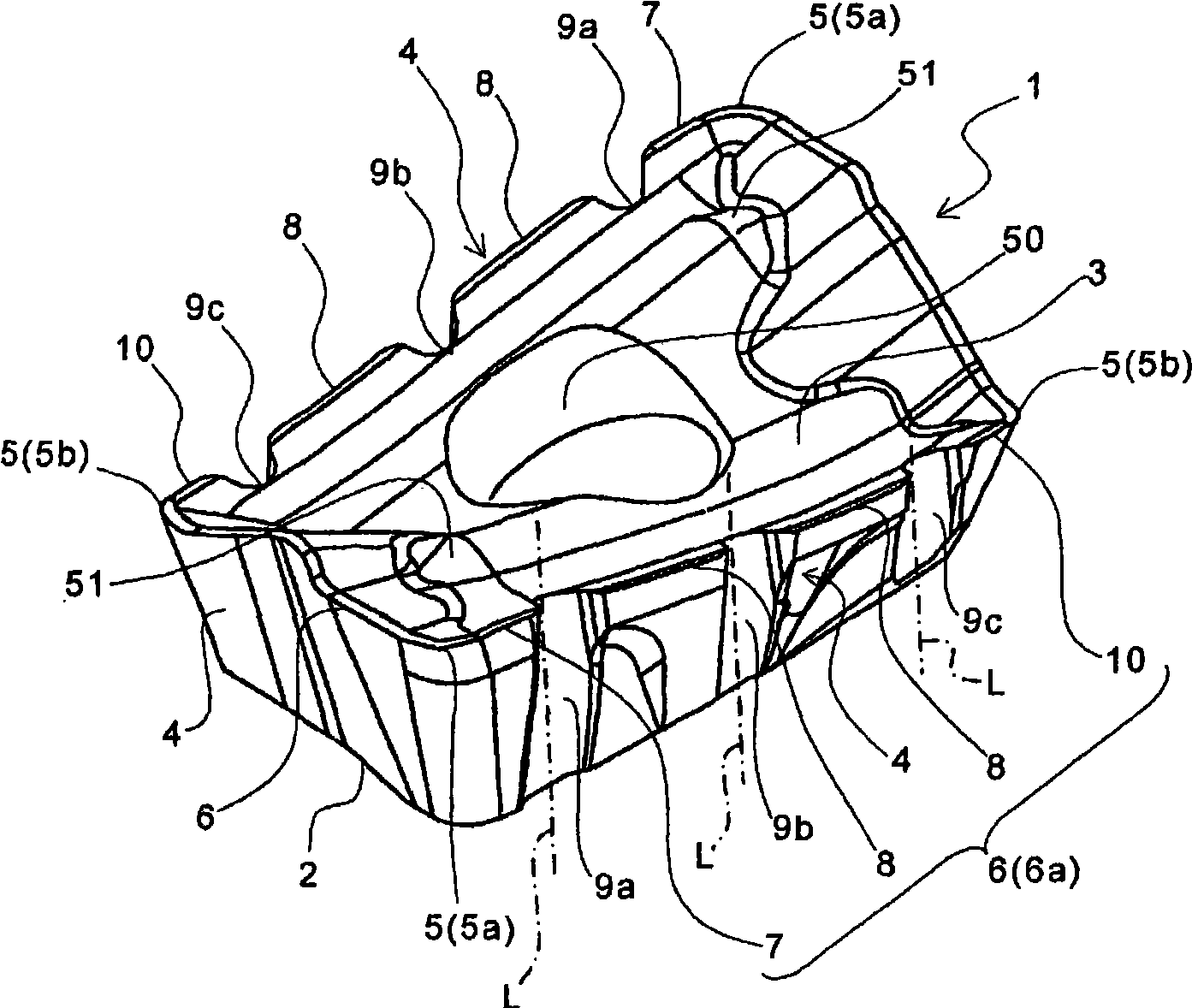

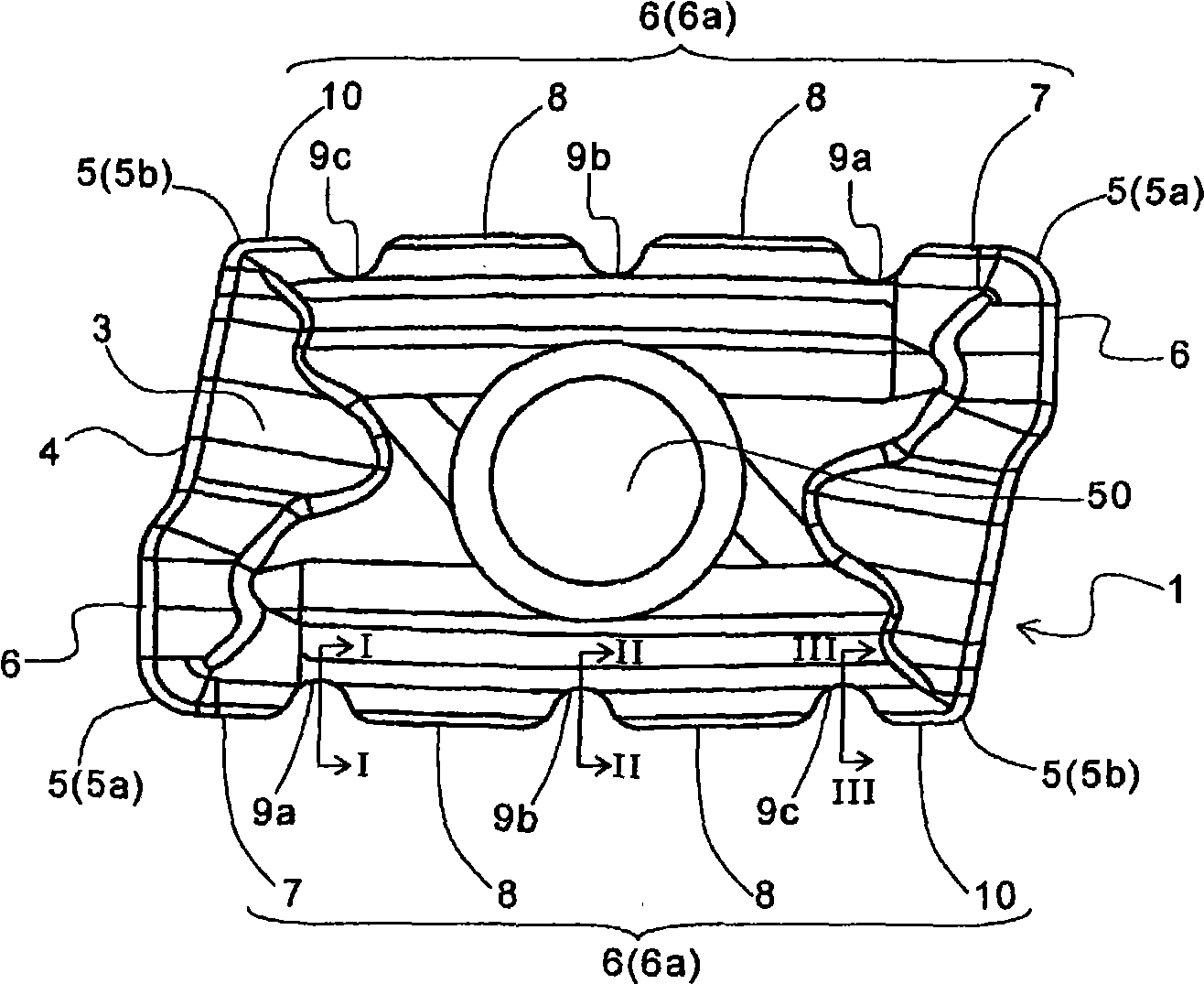

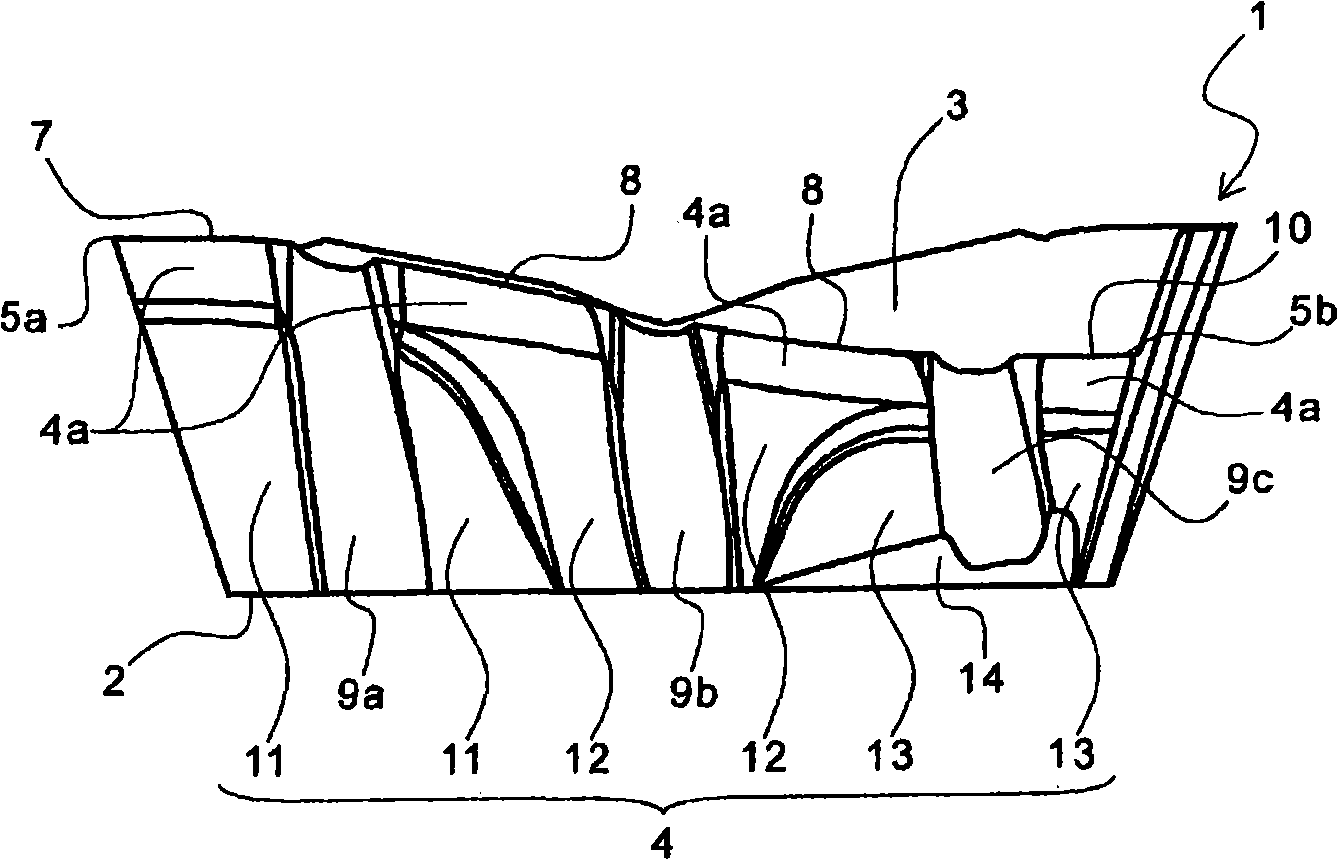

Liquid sealing type anti-vibration apparatus

InactiveCN1701189AAvoid collisionSuppress noiseSpringsJet propulsion mountingSmall amplitudeEngineering

A liquid-sealed vibration-isolating device capable of suppressing the occurrence of noise while securing low dynamic spring properties when vibration with a rather small amplitude is inputted and high-attenuation characteristics when vibration with a rather large amplitude is inputted. When the vibration with the rather large amplitude is inputted, the high-attenuation characteristics can be provided by restricting the displacement of an elastic partition membrane (15) by the displacement restriction ribs (17b) of a first holding member (17). Since the displacement restriction ribs (17b) are formed of three radially extended straight ribs, the low dynamic spring properties can be securely provided by sufficiently increasing the opening area of an opening part (17a). Also, since the displacement restricting projections (51) of the elastic partition membrane (15) are disposed at positions corresponding to the displacement restriction ribs (17b), the occurrence of noise can be securely suppressed.

Owner:TOYO TIRE & RUBBER CO LTD

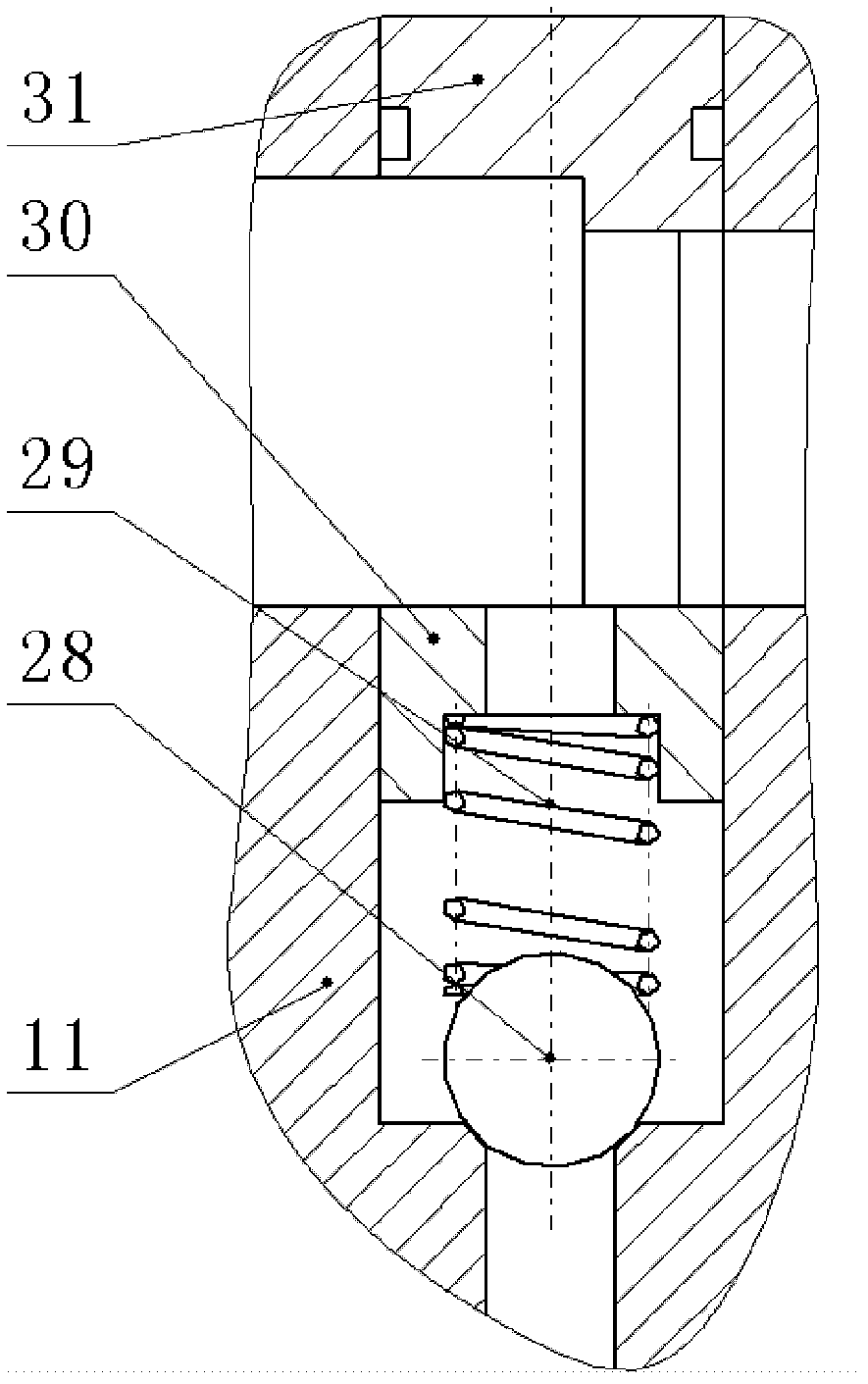

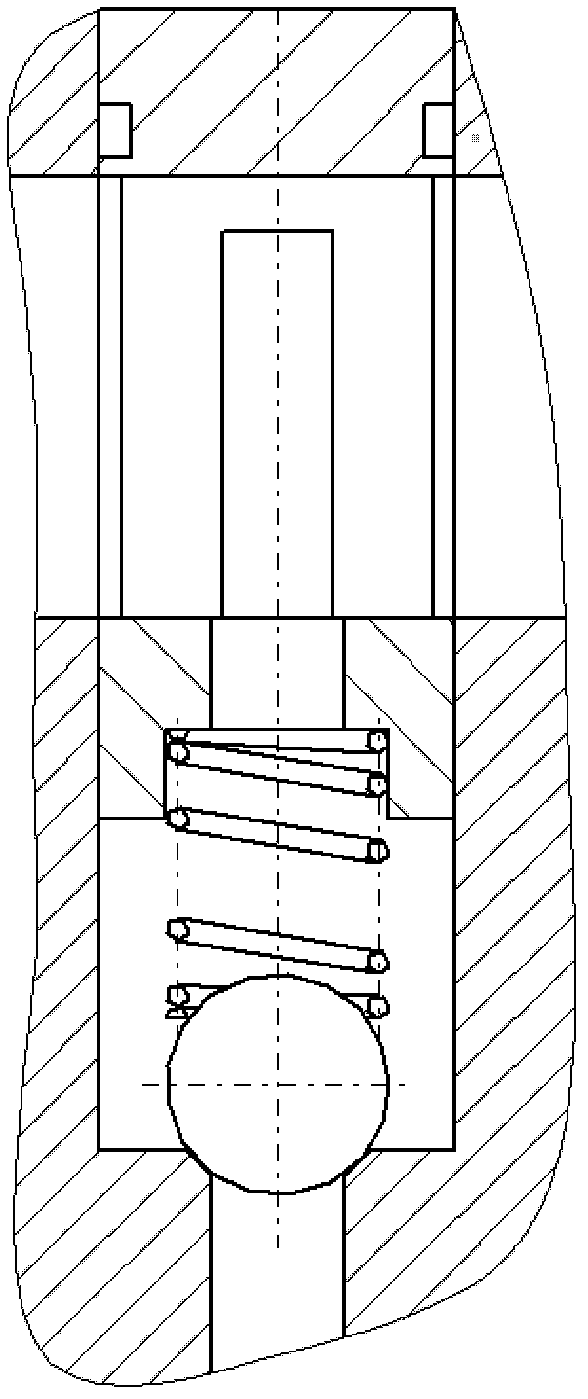

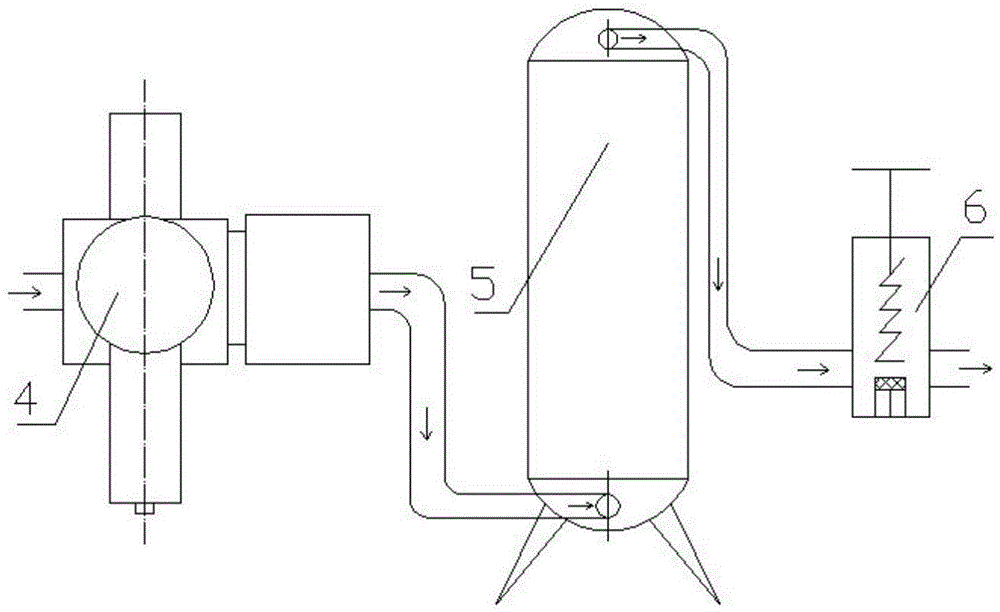

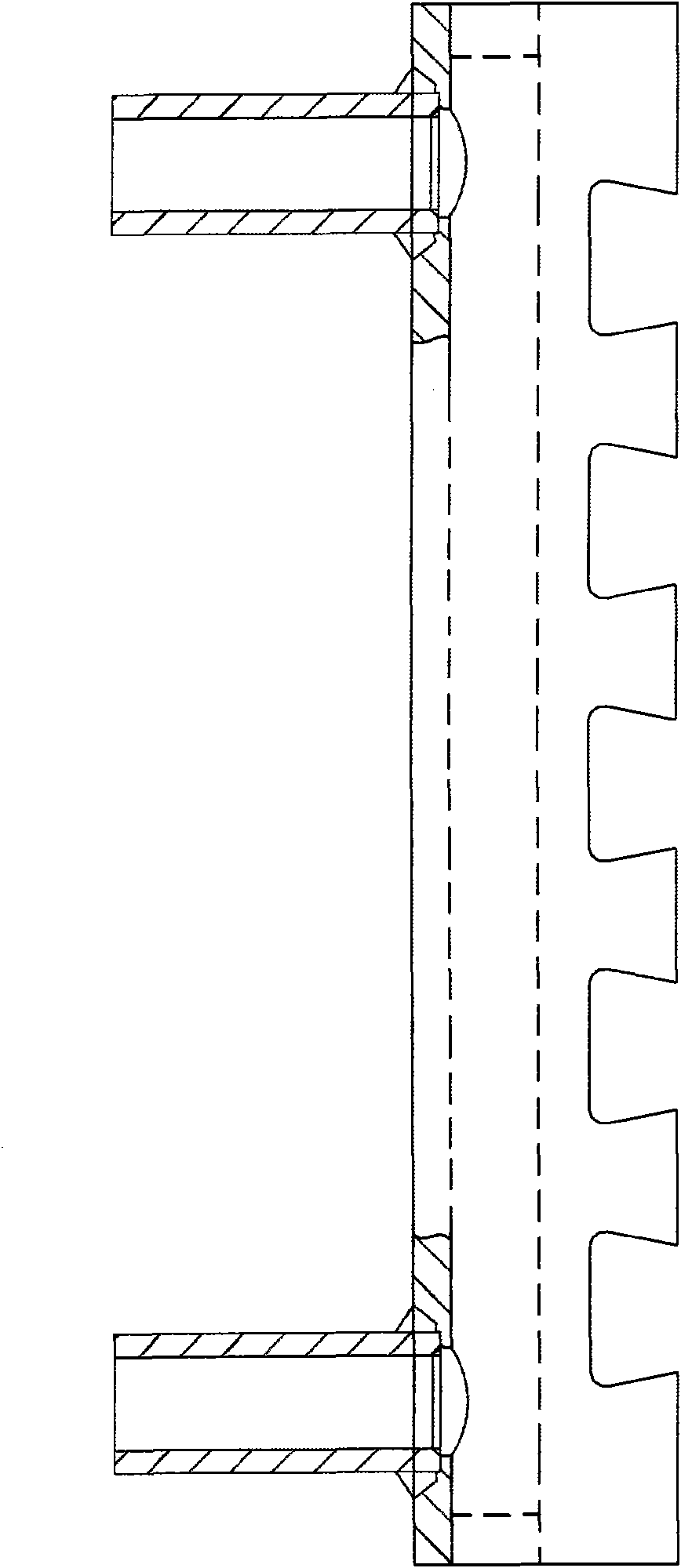

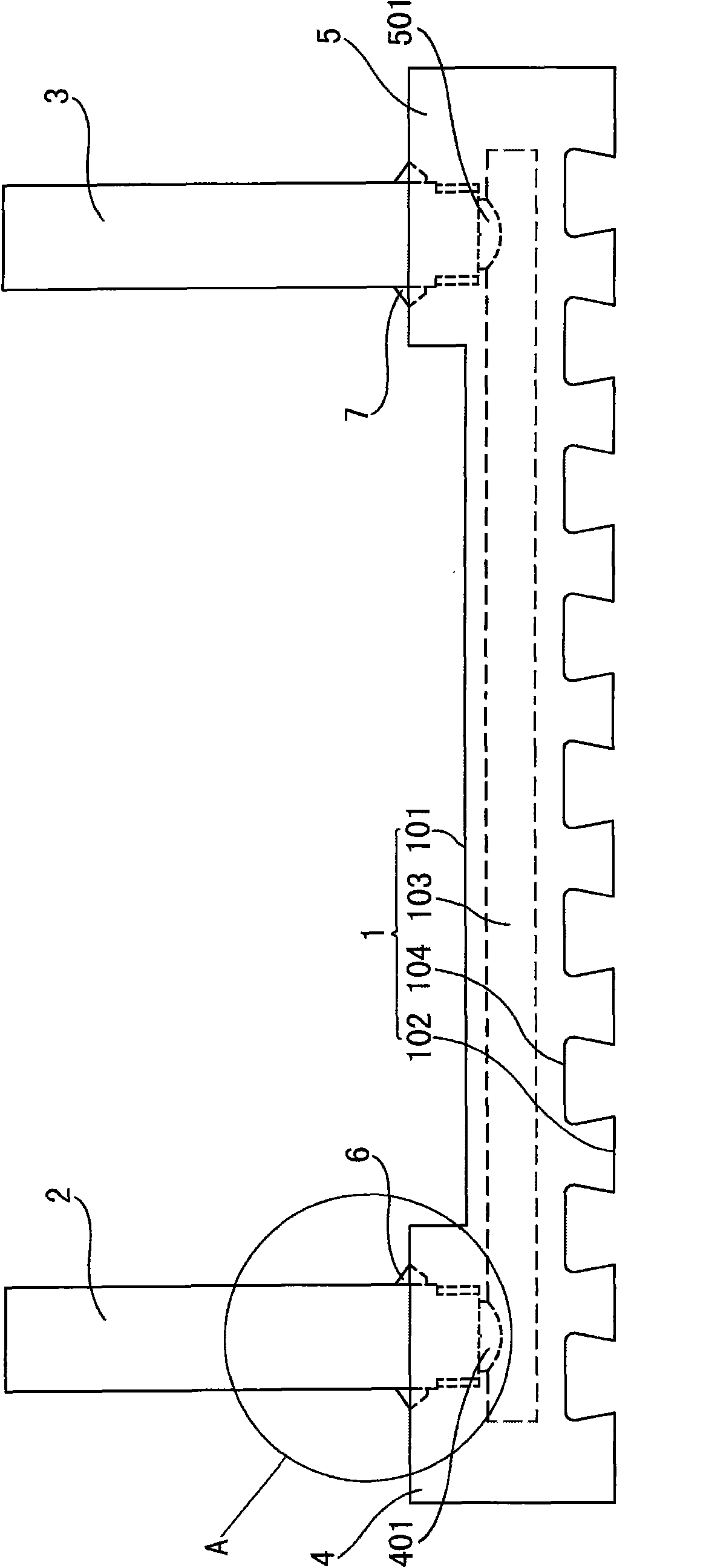

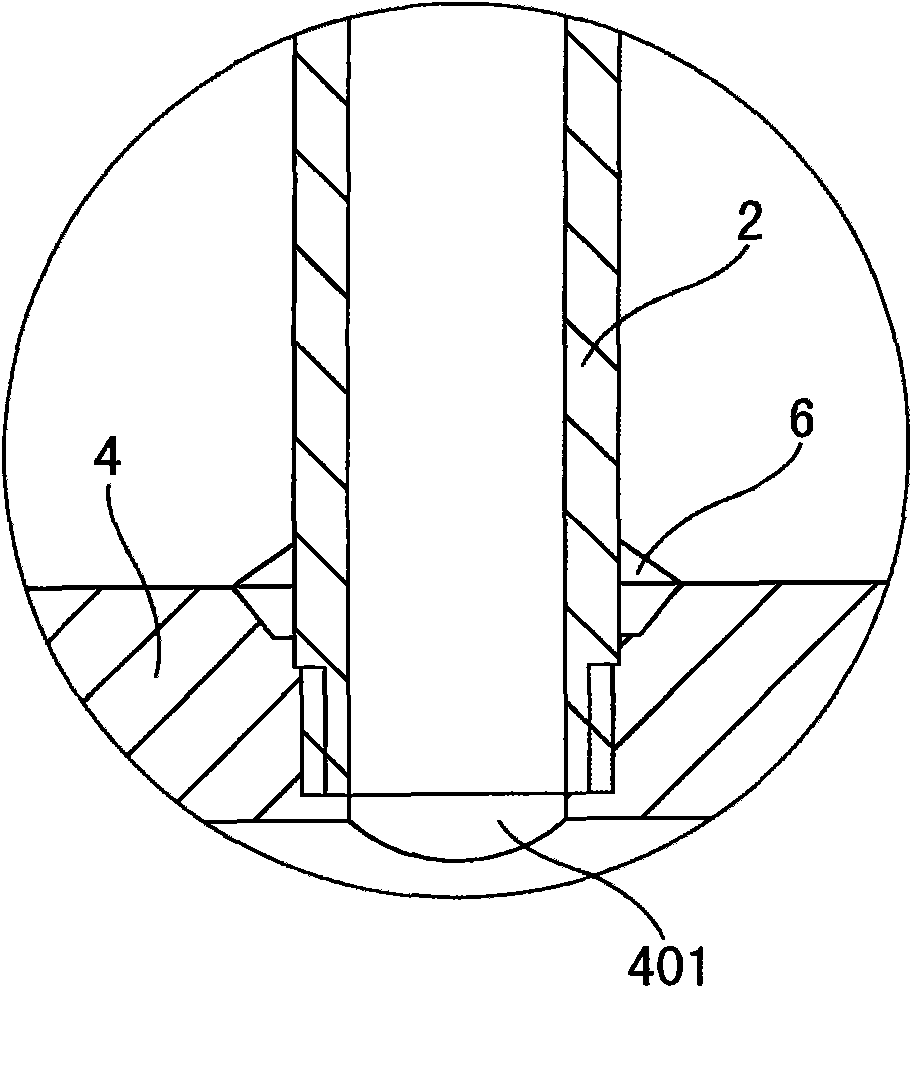

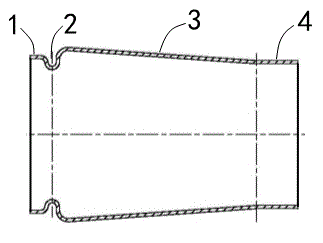

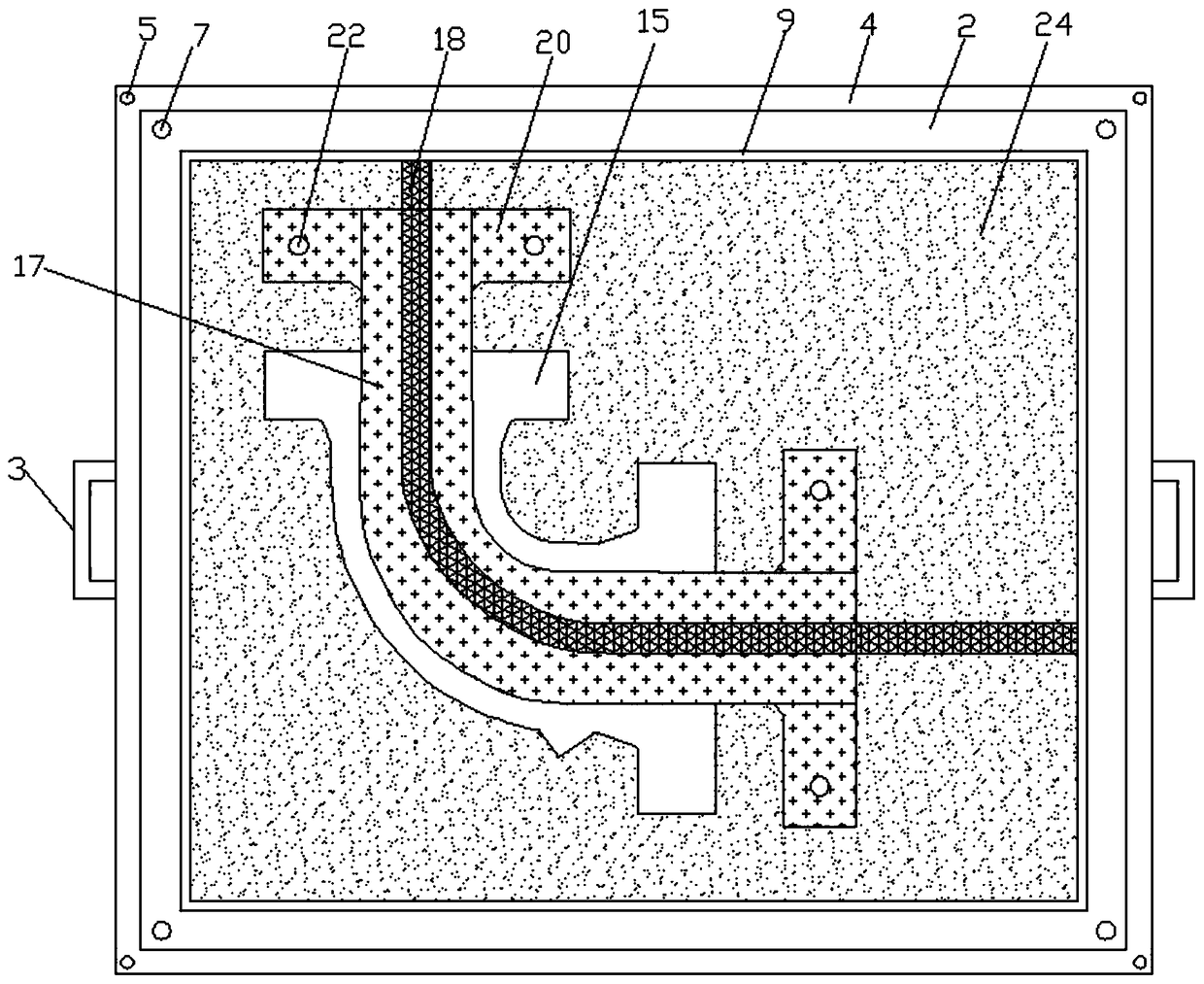

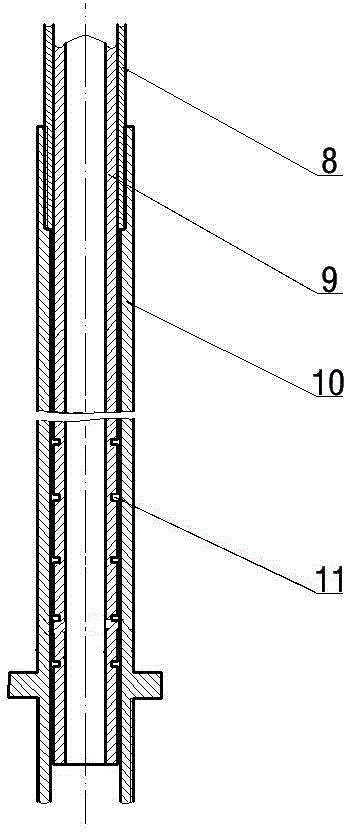

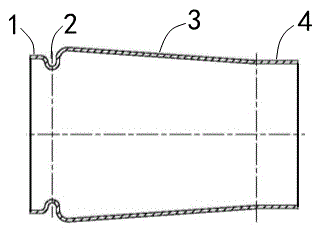

Mold for inflating, filling and forming of full-dry optical-cable loose tube

The invention discloses a mold for inflating, filling and forming of a full-dry optical-cable loose tube. The mold comprises a plastic extruding mold, a fiber guide tube, an inflating support and an air source mechanism, wherein the inflating support sleeves the fiber guide tube so as to form a sealed cavity, and air guide holes and an air inlet are dissymmetrically formed in the fiber guide tube and the inflating support; filtration and graded depressurization are performed twice on compressed air when the compressed air sequentially passes through a filter device and a pressure regulating device, the depressurized air enters the fiber guide tube through the air guide holes, the air, water blocking yarn and optical fibers are uniformly and stably injected in a formed loose tube through the fiber guide tube so as to form a full-dry optical-fiber loose tube through plastic extruding. The mold disclosed by the invention is simple in structure, the after shrinkage of the loose tube is small, and the fiber excess length is stable and controllable.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

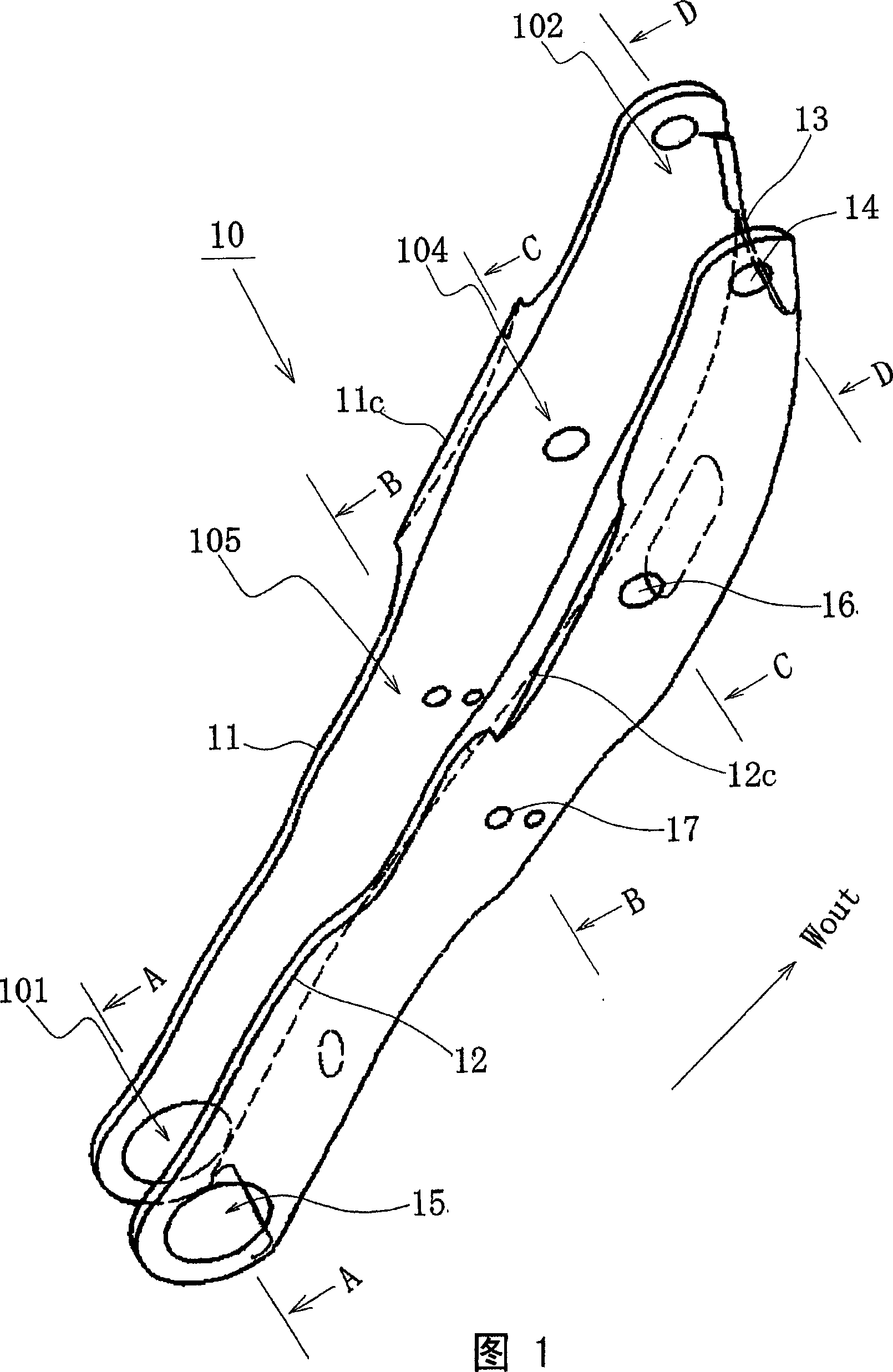

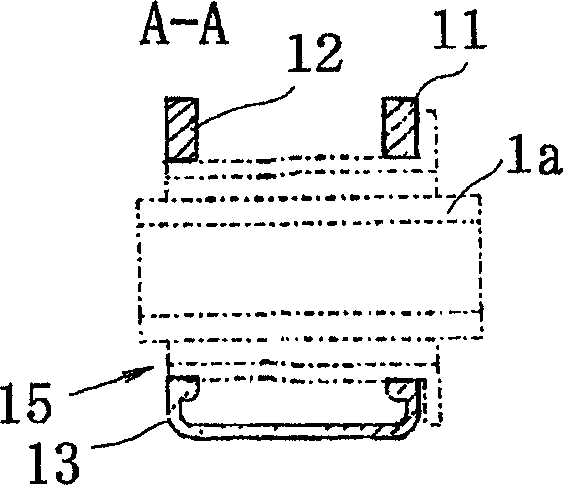

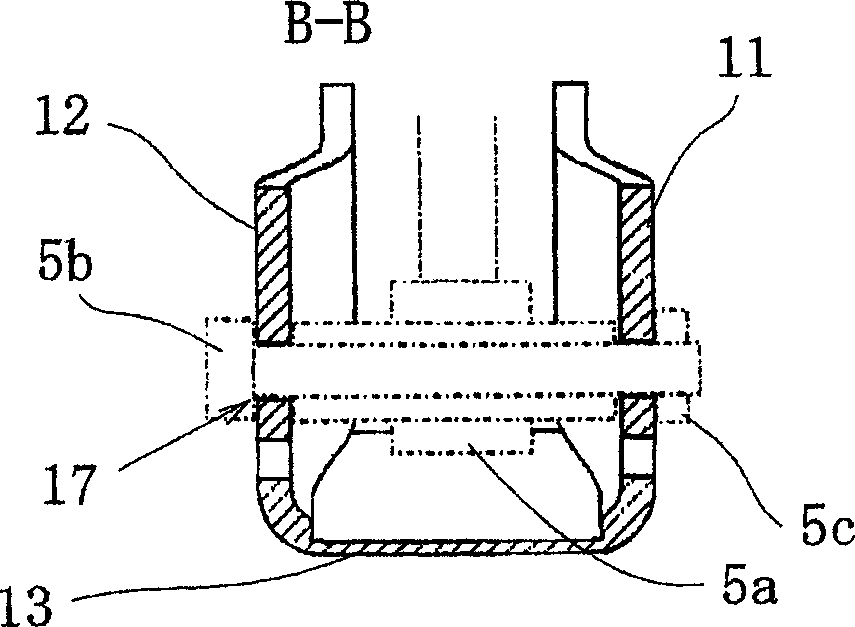

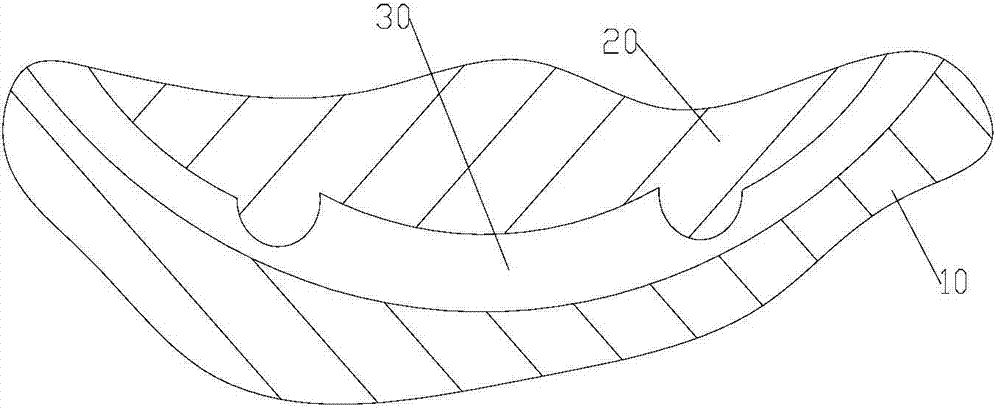

Suspension arm

The present invention provides a suspension arm made of an aluminum alloy extruded profile having a portion forming a bottom portion (43), portions forming at least two vertical walls (41, 42), and a horizontal rib (44) which connects the two vertical walls, wherein a suspension part lower end support portion is formed between the two vertical walls or at the bottom portion by removing a part of the horizontal rib. It is preferable to gradually change the interval between the two vertical walls in the portion in which the horizontal rib is removed.

Owner:AISIN KEIKINZOKU CO LTD +1

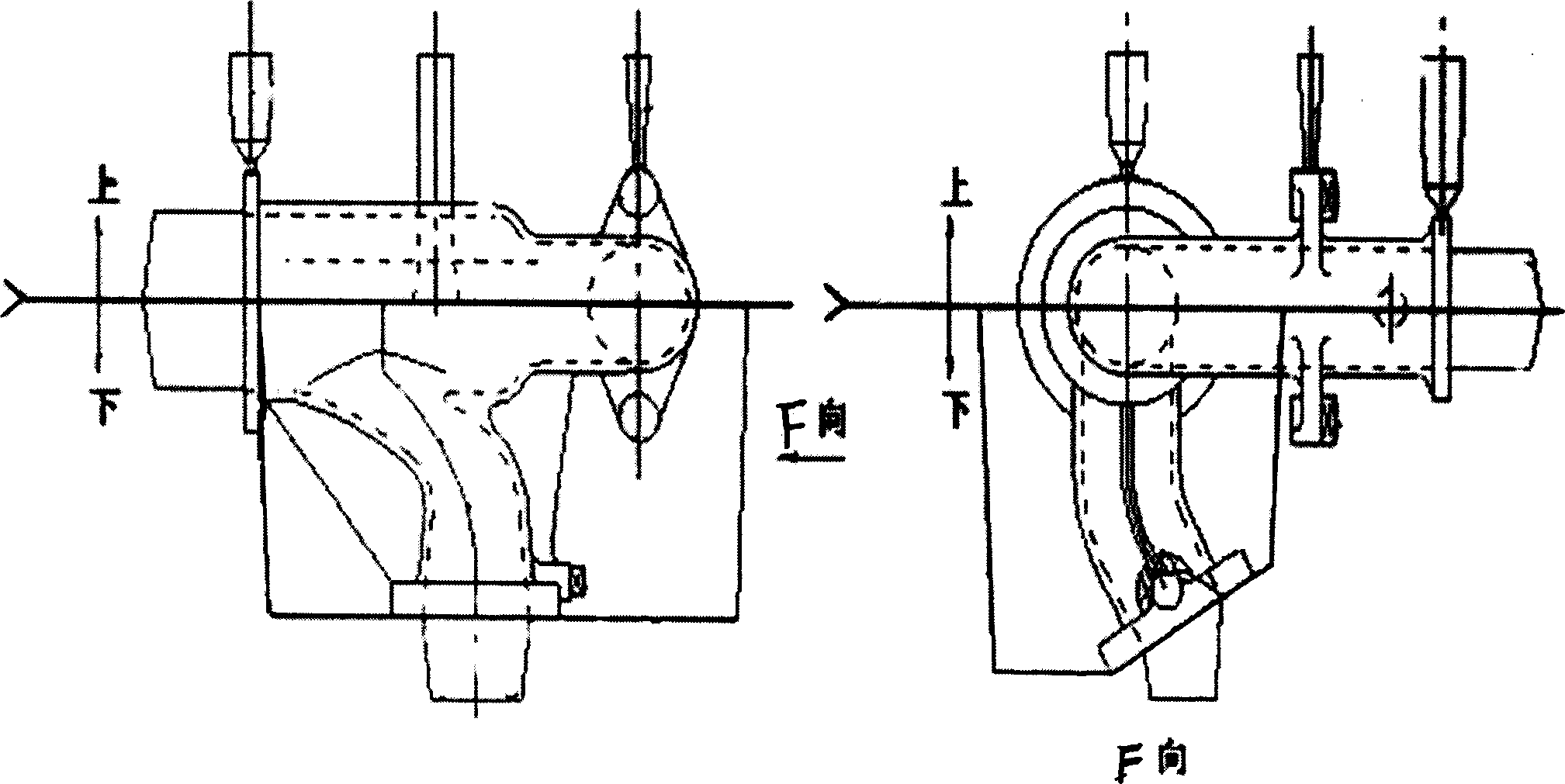

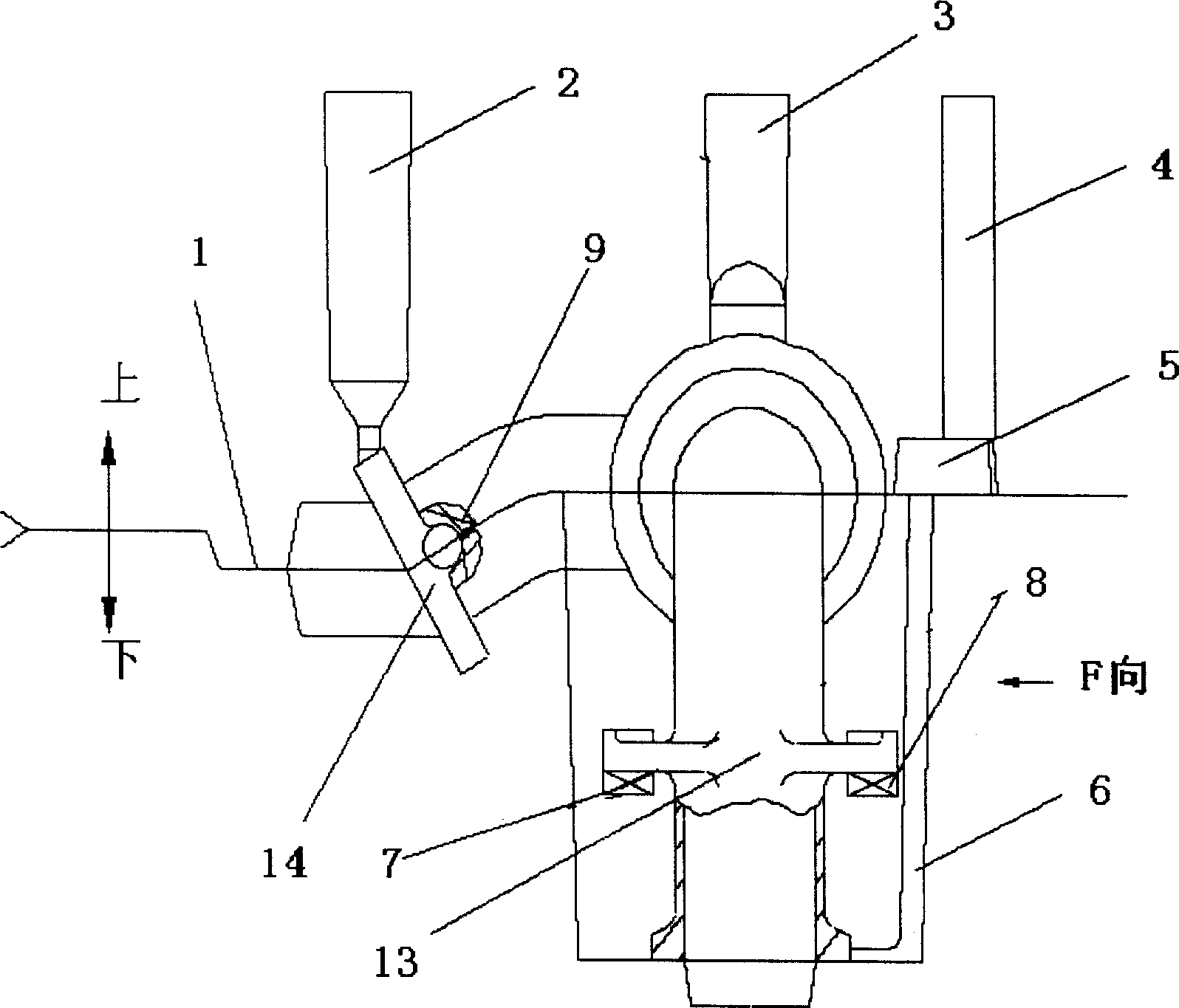

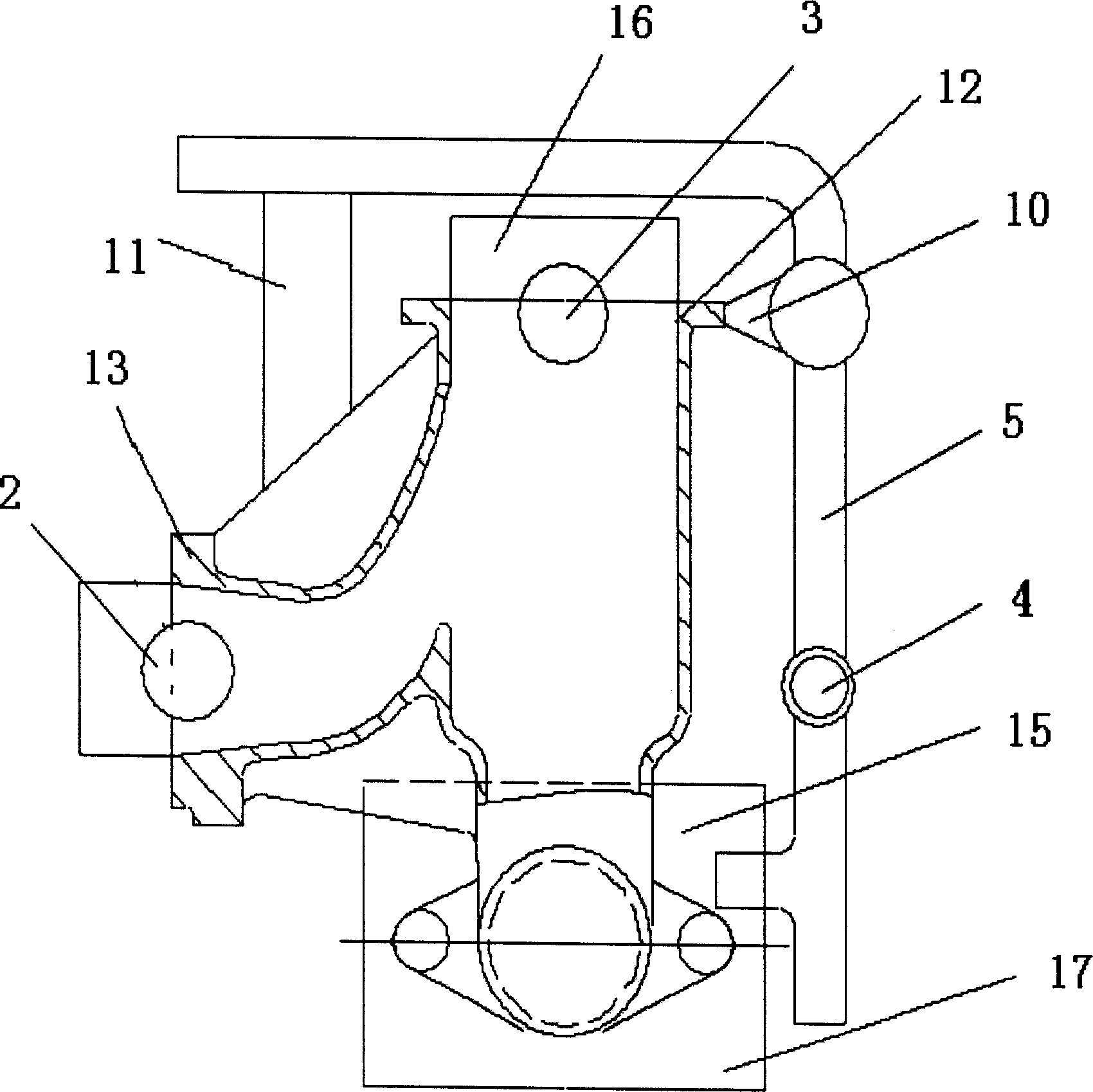

Casting technique for bracket casting of marine pod-type electric propulsion system

ActiveCN102513509AImprove cleanlinessUnique craftMolten metal pouring equipmentsFoundry mouldsElectric powerCasting

The invention relates to a casting technique, in particular to a casting technique for bracket casting of a marine pod-type electric propulsion system, characterized by comprising the following steps of: designing a three-dimensional technique, performing analog simulation conformation on the casting technique, manufacturing a mould and a sand box tool set, horizontally configuring, manufacturinga core, assembling the core and closing the box, pouring, cooling and opening the box. The casting technique provided by the invention has the advantages of improving the casting cleanness, reducing the shrinkage defects, meeting a wall thickness demand, satisfying UT and MT flaw detection demands, reducing the production cost, and realizing safe production and excellent batch production of bracket casting.

Owner:KOCEL EQUIP

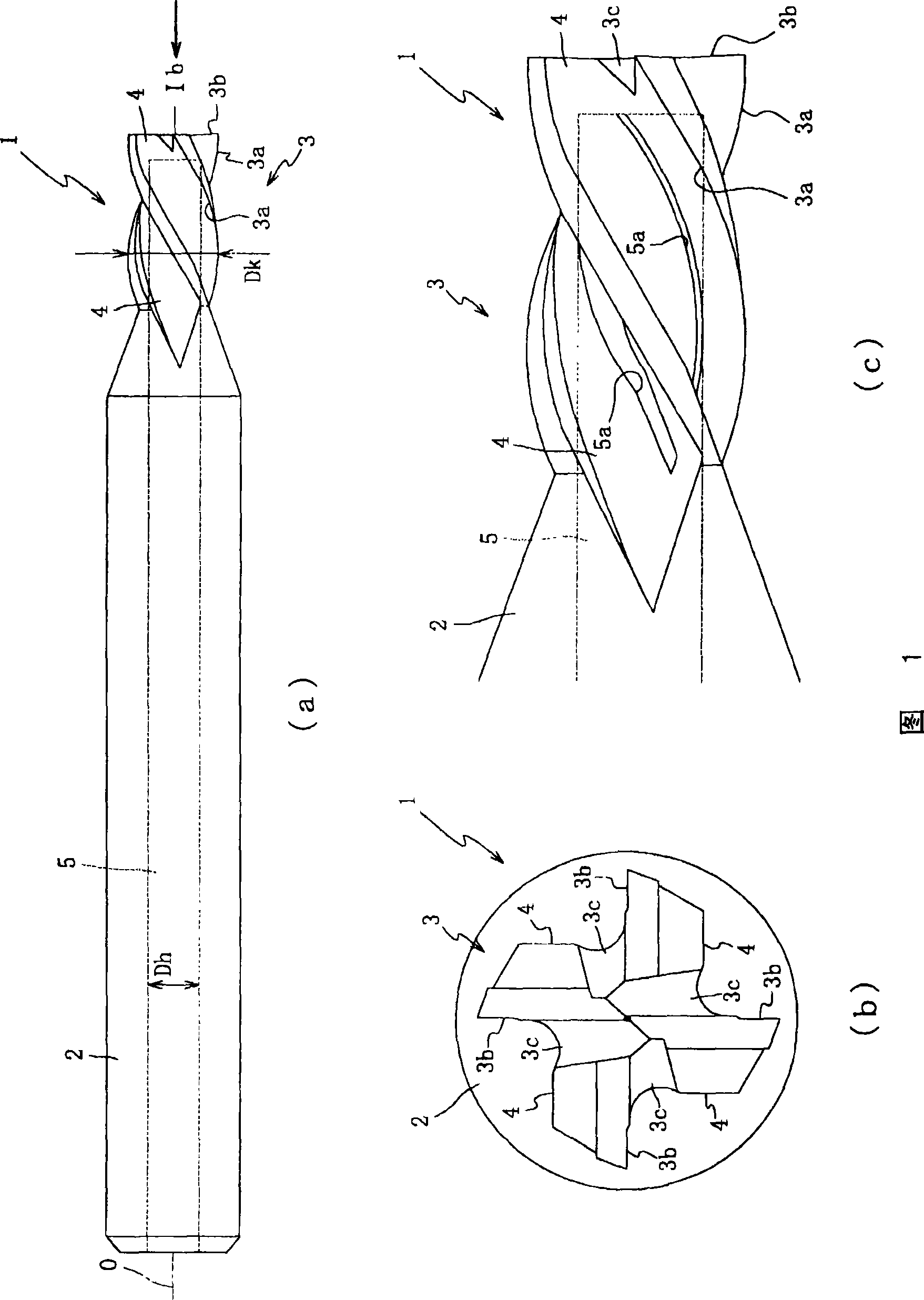

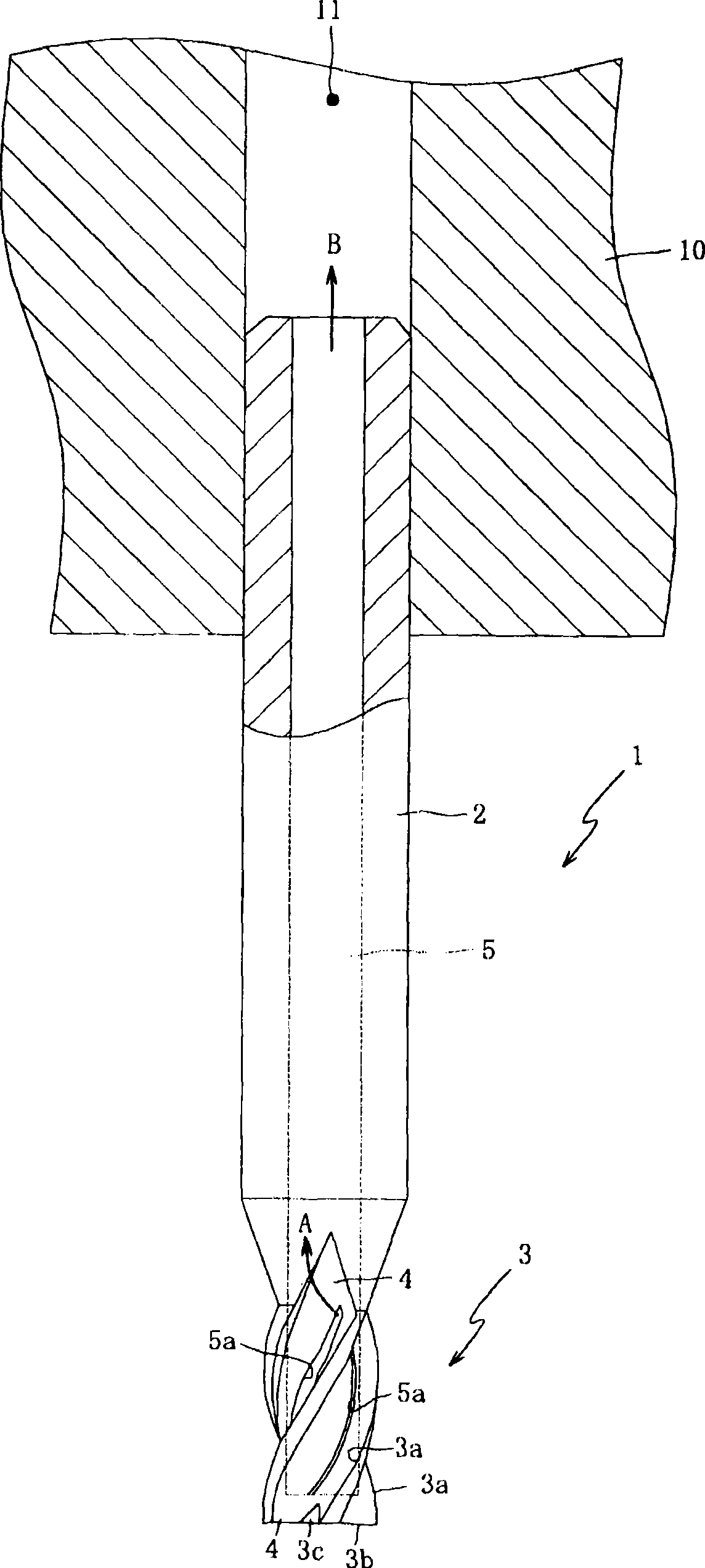

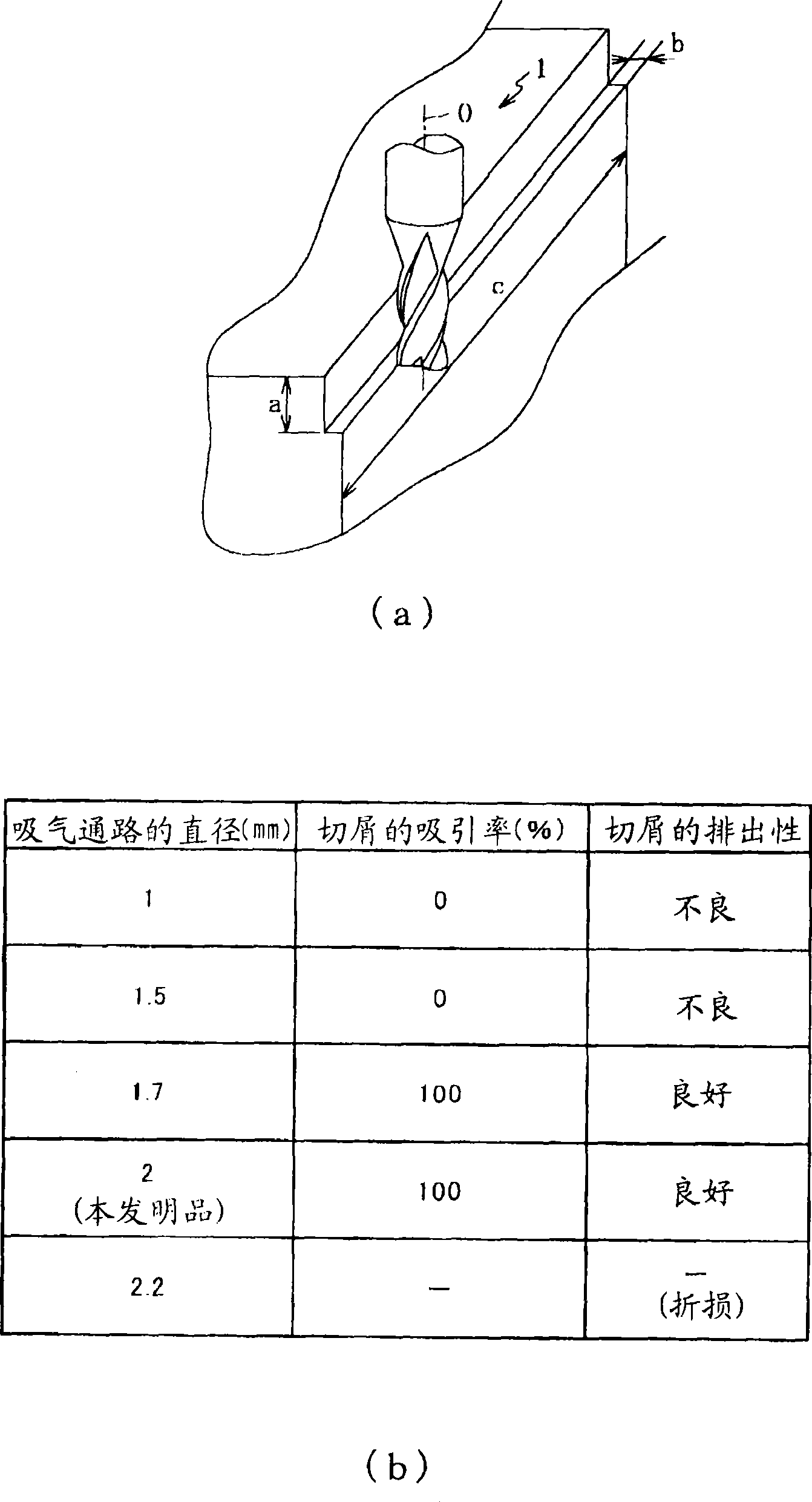

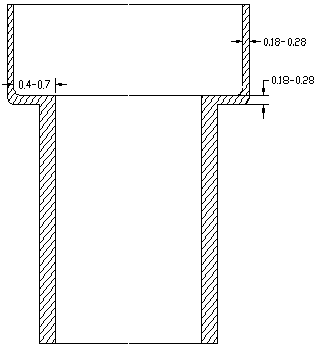

End milling tool

InactiveCN101394962AProhibition of useReduce recycling costsMilling cuttersShaping cuttersFluteMilling cutter

An end mill that realizes prevention of environmental pollution. End mill (1) has aperture (5a) resulting from opening forming along helical flute (4). The aperture (5a) is so structured as to communicate via air suction channel (5) with an opening of the rear end face of shank (2). Accordingly, by air suction through the air suction channel (5), chips generated at cutting processing can be forcibly suctioned from the aperture (5a), and the suctioned chips can be discharged outside from the opening of the rear end face of shank (2). As a result, as compared with conventional products, the use of cutting liquid for eliminating of chips can be suppressed (or rendered unnecessary) to thereby attain prevention of environmental pollution.

Owner:OSG

Method for actively sealing sapphire sheet and metal

ActiveCN103949742AGuaranteed wall thicknessReduce the chance of burstingSoldering apparatusThermal dilatationTitanium zirconium

The invention provides a method for actively sealing a sapphire sheet and metal. The method is low in welding temperature, high in efficiency, good in reliability and low in cost. According to the method, high-temperature metallization is not required, expensive vacuum coating equipment and precious metal targets are also not required, the defects of long intermediate treatment process and time consumption are overcome, the total welding time is shortened, and the production efficiency is improved; the defect that flatness with high precise size and demanding requirement is required to be machined when welding sheets are adopted is avoided, and active titanium, zirconium, copper and nickel welding flux is directly adopted; the thickness of the wall of the sealing part of a metal piece is small, so that the thermal stress effect caused by the reaction of extrusion to the metal piece by the thermal expansion of the sapphire sheet during welding is reduced, and the probability of explosion of the sapphire sheet is reduced; meanwhile, welding can be accomplished at one step when the vacuum atmosphere temperature is lower than 1000 DEG C, the requirement on welding equipment is low, the product welding reliability and the yield are high, the air impermeability is good when baking is performed at the high temperature of 560 DEG C for 36 hours, and the requirement on the air impermeability of ultrahigh frequency electron tubes can be guaranteed.

Owner:XI AN JIAOTONG UNIV +1

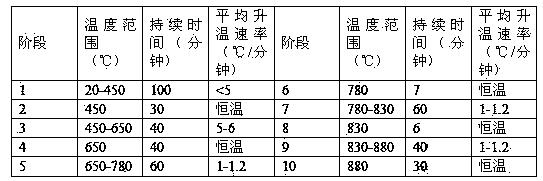

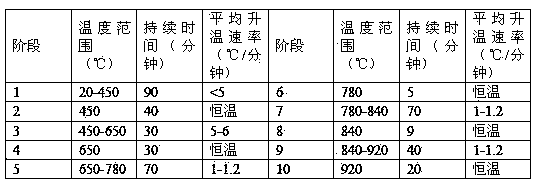

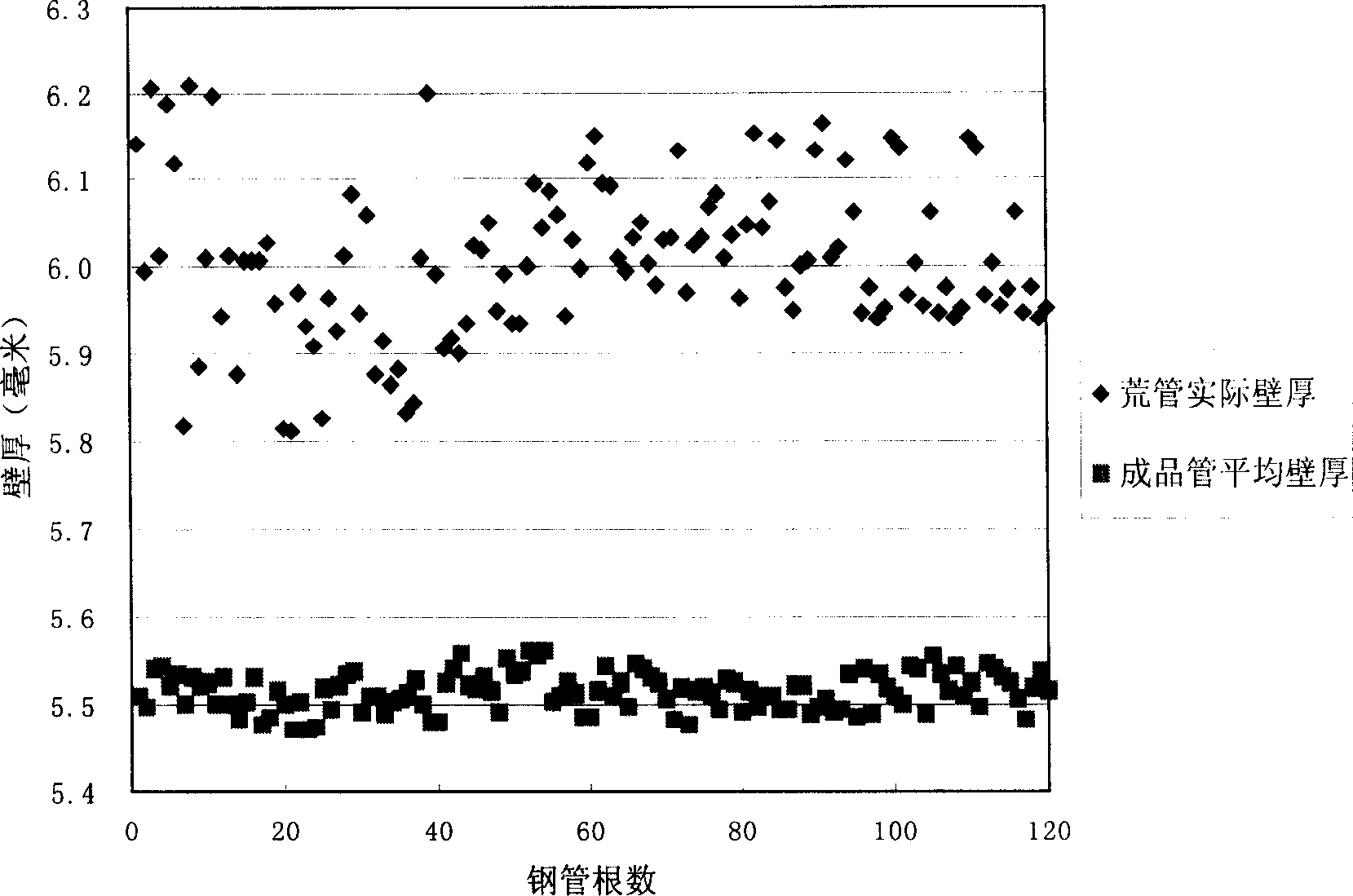

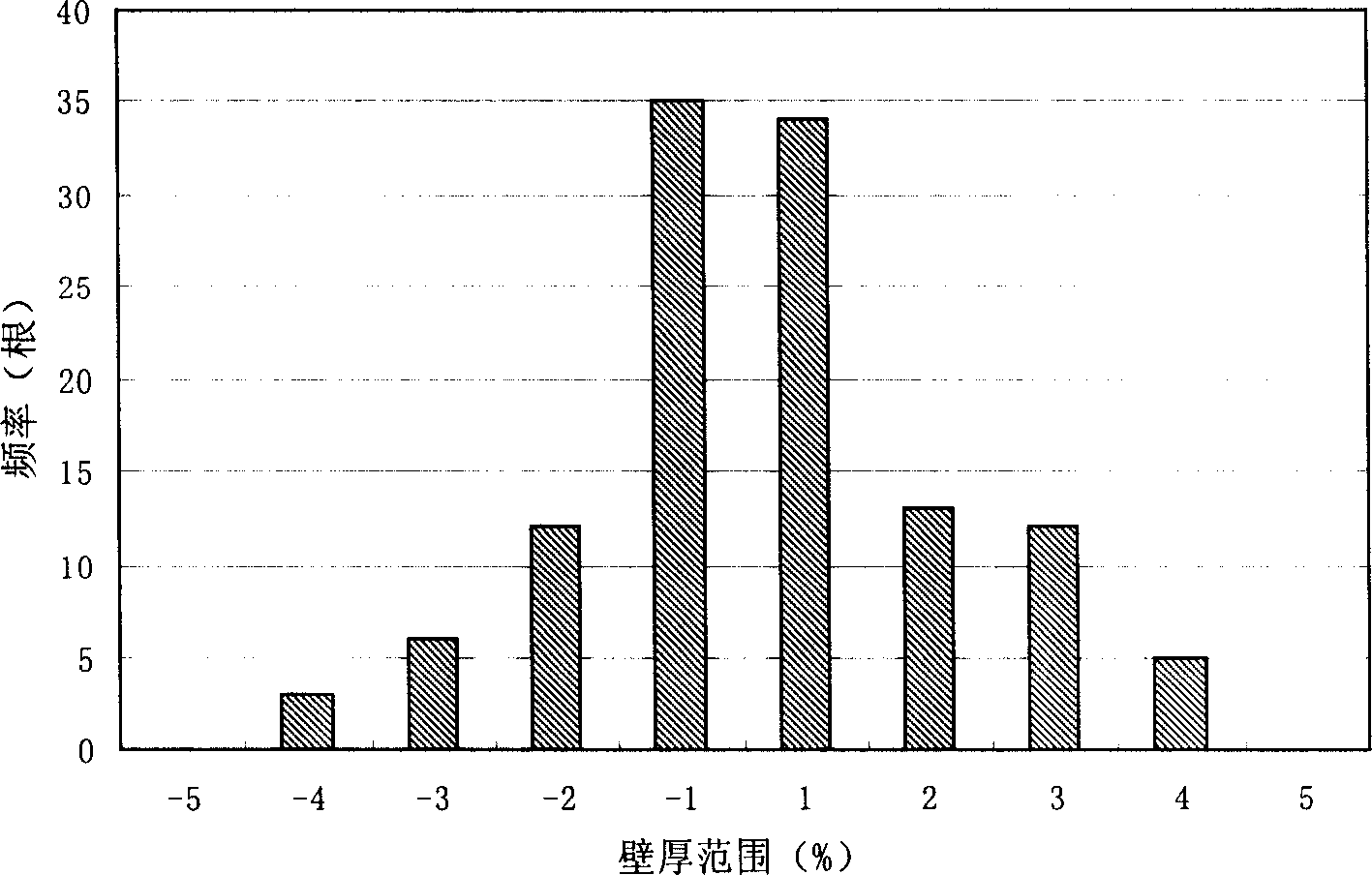

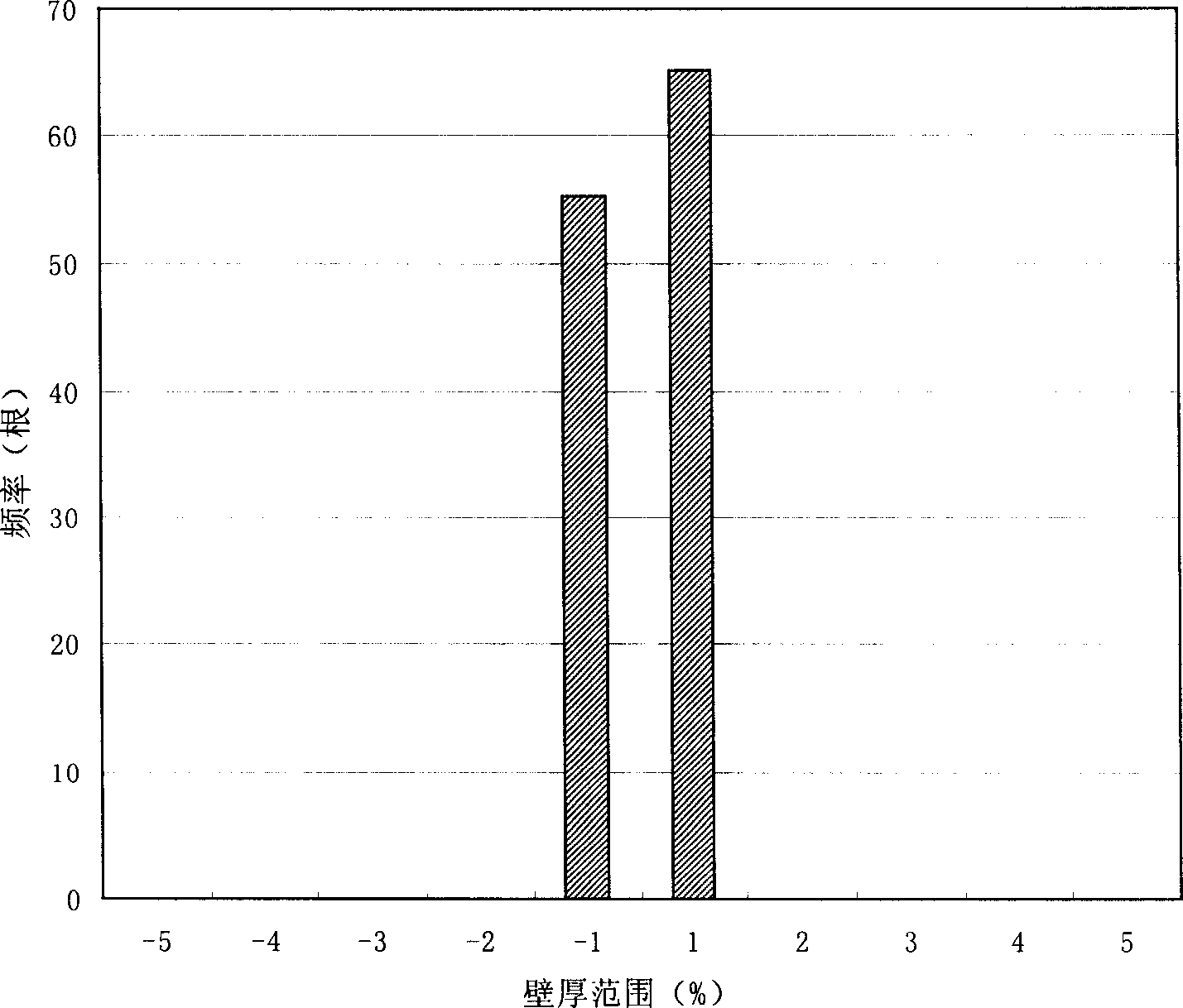

Feed forward control method for wall thickness of tension reducing machine

ActiveCN1887463ASmall wall thickness deviationGuaranteed wall thicknessRoll mill control devicesMetal rolling arrangementsEngineeringSteel tube

The feed forward control method for wall thickness of tension reducing machine includes the following steps: 1. reading out the ideal correlated technological parameter data of the steel pipe to be rolled and on-line measuring its practical correlated technological parameter data; 2. real-time on-line calculating the wall thickness of continuously rolled pipe and calculating the error; 3. regulating the roller rotation speed based on the expression I for reaching ideal thickness in the case of the error within the required range; and 4. calculating the roller rotation speed correcting amount based on expression II before returning to the step 3 in the case of the error beyond the required range. The present invention utilizes the on-line data of hot rolling process in regulating the rolling rotation speed distribution of rollers adaptively to raise the rolled pipe product wall thickness precision.

Owner:BAOSHAN IRON & STEEL CO LTD +1

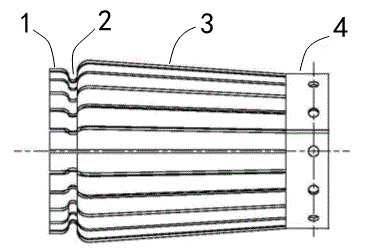

Copper cooling wall with reinforced piping structure

ActiveCN101935723AStressfulIncrease the stress pointCooling devicesManufacturing convertersStress conditionsWater channel

The invention provides a copper cooling wall with a reinforced piping structure. The copper cooling wall comprises a copper cooling wall body, at least one water inlet pipe and at least one water outlet pipe, wherein at least one cooling water channel is reserved in the copper cooling wall body; the water inlet pipe is welded on the cool surface of the copper cooling wall body, and is connected with the inlet of the cooling water channel; the water outlet pipe is welded on the cool surface of the copper cooling wall body, and is connected with the outlet of the cooling water channel; the water inlet pipe is inserted into the inlet of the cooling water channel, and is in threaded connection with the inner wall of the inlet of the cooling water channel; and the water outlet pipe is inserted into the outlet of the cooling water channel and is in threaded connection with the inner wall of the outlet of the cooling water channel. The copper cooling wall has the advantages of increasing stress points of the water pipe, and improving the stress condition of the water pipe to ensure that the stress of the water pipe is more uniform and a welding seam is hard to destroy; and because of lugs, the quality and the strength of the welding seam can be effectively improved, the consumption of copper can be greatly reduced, and the manufacturing cost of the copper cooling wall can be effectively controlled on the premise of ensuring the performance.

Owner:SHANTOU HUAXING METALLURGICAL EQUIP CO LTD

Measuring method for thickness of cavity

InactiveCN104501757AGuaranteed wall thicknessEasy to measureMechanical thickness measurementsMaterials science

The invention provides a measuring method for thickness of a cavity. The measuring method comprises the following steps: S1, putting a testing material in a drag flask; S2, buckling a cope flask onto the drag flask so as to enable the testing material to be extruded and extend in the cavity; S3, removing the cope flask; S4, taking out the testing material from the drag flask; S5, measuring the thickness of the testing material, wherein the thickness of the testing material is equal to that of the cavity. As the testing material is put in the cavity, and the testing material is adapted to the surface of the cavity and extends in the cavity through pressure, by measuring the thickness of the deformed testing material, the thickness of the cavity can be directly obtained; therefore, the thickness of the cavity has the characteristic of being easy to measure; further, the inner wall of the cavity can be repaired according to the thickness of the cavity, so the wall thickness of a casting product is ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

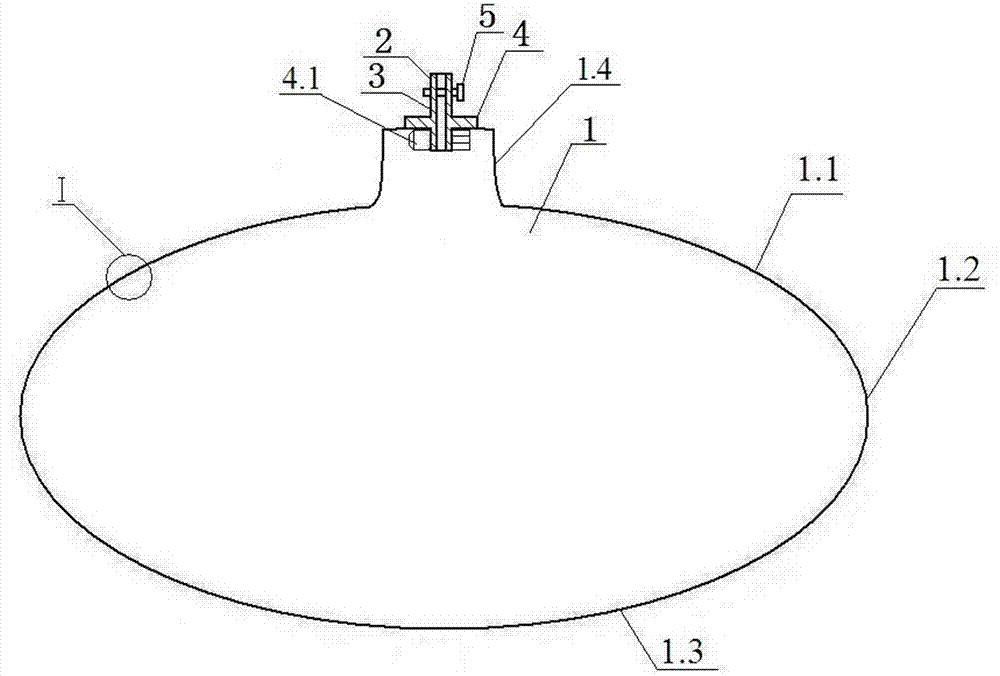

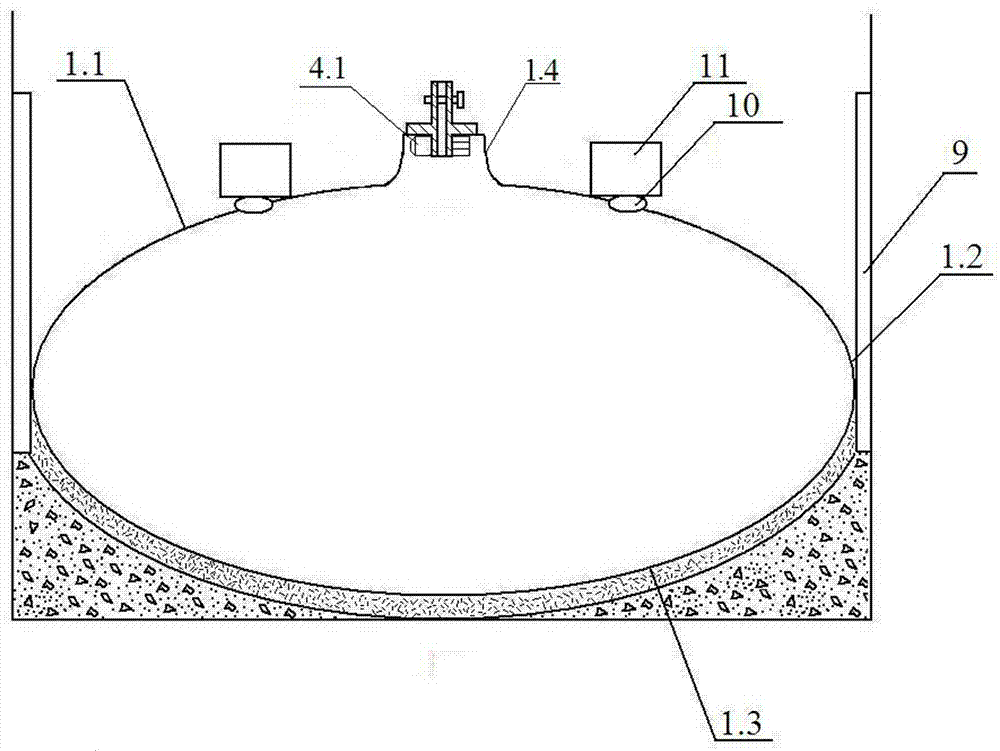

Mould for building spherical or cylindrical cellar and method for building cellar by adoption of mould

InactiveCN103669951AReduce weightSimple structureForms/shuttering/falseworksBulk storage containerArchitectural engineeringStructural engineering

The invention discloses a mould for building a spherical or cylindrical cellar and a method for building the cellar by the adoption of the mould. The mould comprises an air bag and an inflation and deflation device fixed on the air bag, wherein the air bag (1) is designed to be spherical or cylindrical and is made of one layer of soft material, a bag cap (1.4) is connected with the top end of the air bag (1), and the inflation and deflation device (2) is arranged on the bag cap (1.4) and is composed of an inflation and deflation pipe (3), an intercalated disc (4) fixed to the lower section of the inflation and deflation pipe (3) and a valve (5) arranged on the inflation and deflation pipe (3). The mould is simple in structure, low in production cost and stable and reliable in construction, and the construction method is simple, easy to operate, and high in construction efficiency.

Owner:YUNNAN TAIYUAN CONSTR ENG PROJECT MANAGEMENT CO LTD

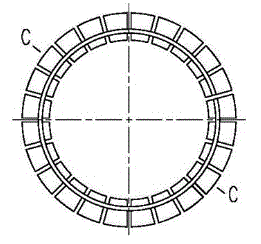

Spinning method of electrically conductive contact finger and matched spinning device

The invention discloses a spinning method of an electrically conductive contact finger and a matched spinning device. The spinning method is characterized in that a spinning technology of the electrically conductive contact finger is divided into two working procedure, namely spinning forming of a bottle body part and a bottle bottom part of the electrically conductive contact finger and spinning forming of a bottle neck part and a bottle opening part of the electrically conductive contact finger; and in the forming procedure of the bottle neck part, while radial force is applied by a spinning wheel, axial pressure is further applied to a cylinder-shaped blank of the electrically conductive contact finger in the axial direction of a core mold by utilizing a pressure loading mechanism, so that material can be pushed to flow towards a stretched and thinned part of the bottle neck part in real time to timely supplement the stretched part. The spinning technology is simple to operate, is very convenient to implement and effectively guarantees the wall thickness of the bottle neck part of the electrically conductive contact finger in the spinning process, thereby guaranteeing that the electrically conductive contact finger manufactured by adopting the spinning technology has high flow capacity and satisfies the requirement of a megavolt power transmission and transformation line for an effective area of a through-flow cross section of the electrically conductive contact finger of a bypass isolating switch, and laying a solid foundation for smooth passing of 6300A of current.

Owner:HENAN PINGGAO ELECTRIC +3

Method for packing alkali metal simple substance

ActiveCN102241389AAvoid perishableReduce the content of atomic impuritiesDecorative surface effectsChemical vapor deposition coatingParaffin oilsAlkali metal

The invention discloses a method for packing an alkali metal simple substance, which is applied to the technical field of alkali metal atom steam reaction chambers. The method is characterized by comprising the following steps of: making a paraffin seal molding die; coating a paraffin layer on a bottom die; processing a micro blind hole array on the paraffin layer by using a male die or laser light; injecting a liquid-state alkali metal simple substance into the micro blind hole array on the paraffin layer by using a micro sample injection device; coating a layer of paraffin on a step layer of a top die; aligning the top die to the bottom die along a step groove and laminating; uniformly heating the laminated top die and bottom die till the paraffin layer at the joint of the top die and the bottom die is in molten or critical molten state; removing silicon from the buckled top die and bottom die by corroding with a potassium hydroxide solution to obtain a paraffin bag array; and separating to obtain a paraffin bag coated with micro alkali metal simple substances. Alkali metal is rubidium (Rb) or caesium (Cs). The invention has the advantages of capabilities of preventing the alkali metal simple substance from being deteriorated and reducing impurities in an atom steam chamber, convenience for batch manufacturing, simple process, easiness for integration with a next stage system, and the like.

Owner:江苏智能微系统工业技术股份有限公司

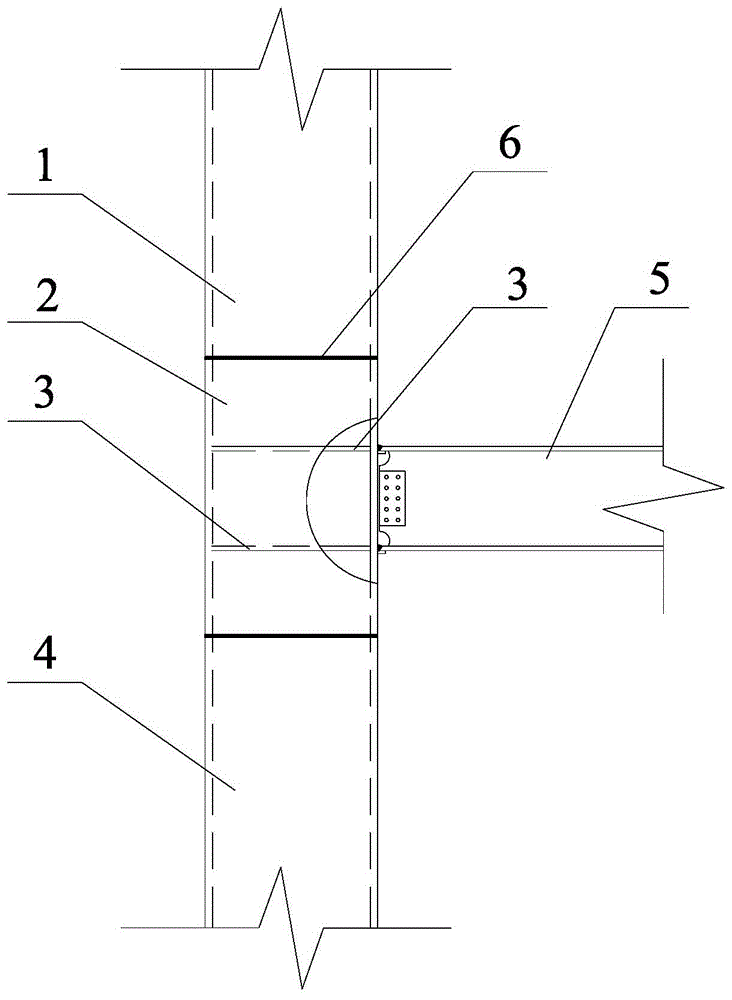

Rectangular steel pipe column

ActiveCN104088398AGuaranteed wall thicknessImprove seismic performanceStrutsPillarsUltimate tensile strengthCarbon dioxide

The invention discloses a rectangular steel pipe column. The rectangular steel pipe column comprises a box-type short column, a first steel pipe column and a second steel pipe column, wherein the cross sections of the box-type short column, the first steel pipe column and the second steel pipe column are rectangular and are same in size, the box-type short column comprises an inner partition plate and a plurality of outer steel plates; the inner partition plate is fixed on the inner wall of the box-type short column through carbon dioxide gas shielded welding; two ends of the box-type short column are respectively fixed on the first steel pipe column and the second steel pipe column in a welding manner. According to the technical scheme, a small section of box-type short column with the cross section size as same as that of the rectangular steel pipe column can be manufactured in a factory; the inner partition plate is welded in the box-type short column by using a carbon dioxide gas shielded welding manner; after the box-type short column is manufactured, the box-type short column is directly integrally welded together with the steel pipe columns at two ends so as to form a section of integral rectangular steel pipe column. By virtue of the technical scheme, the electric slag welding process is omitted, the wall thickness of a node domain column can meet the design requirement, the anti-seismic property of the node is improved, the labor intensity of workers is alleviated, and the processing efficiency and the welding quality are improved.

Owner:山东高速莱钢绿建发展有限公司

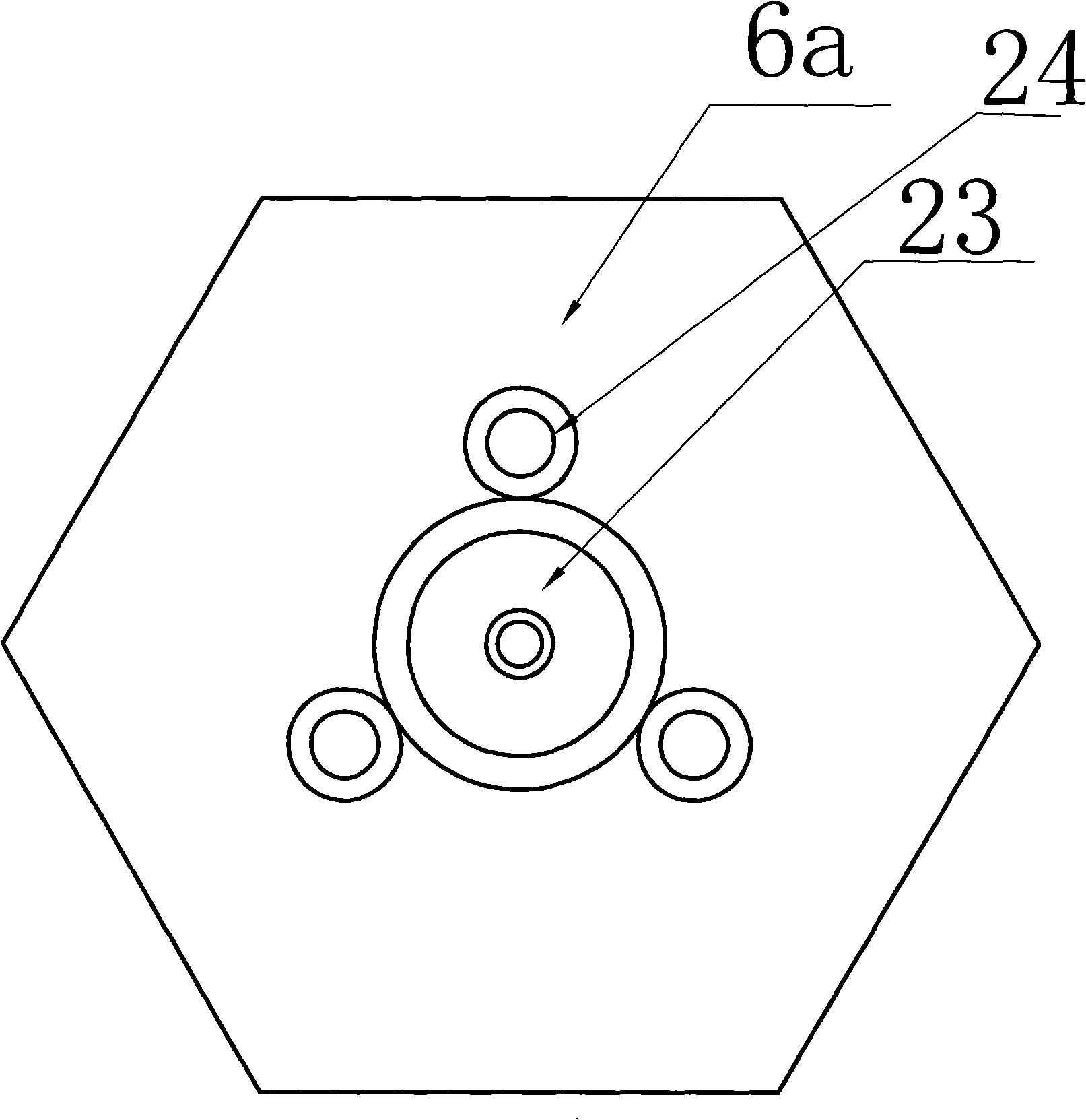

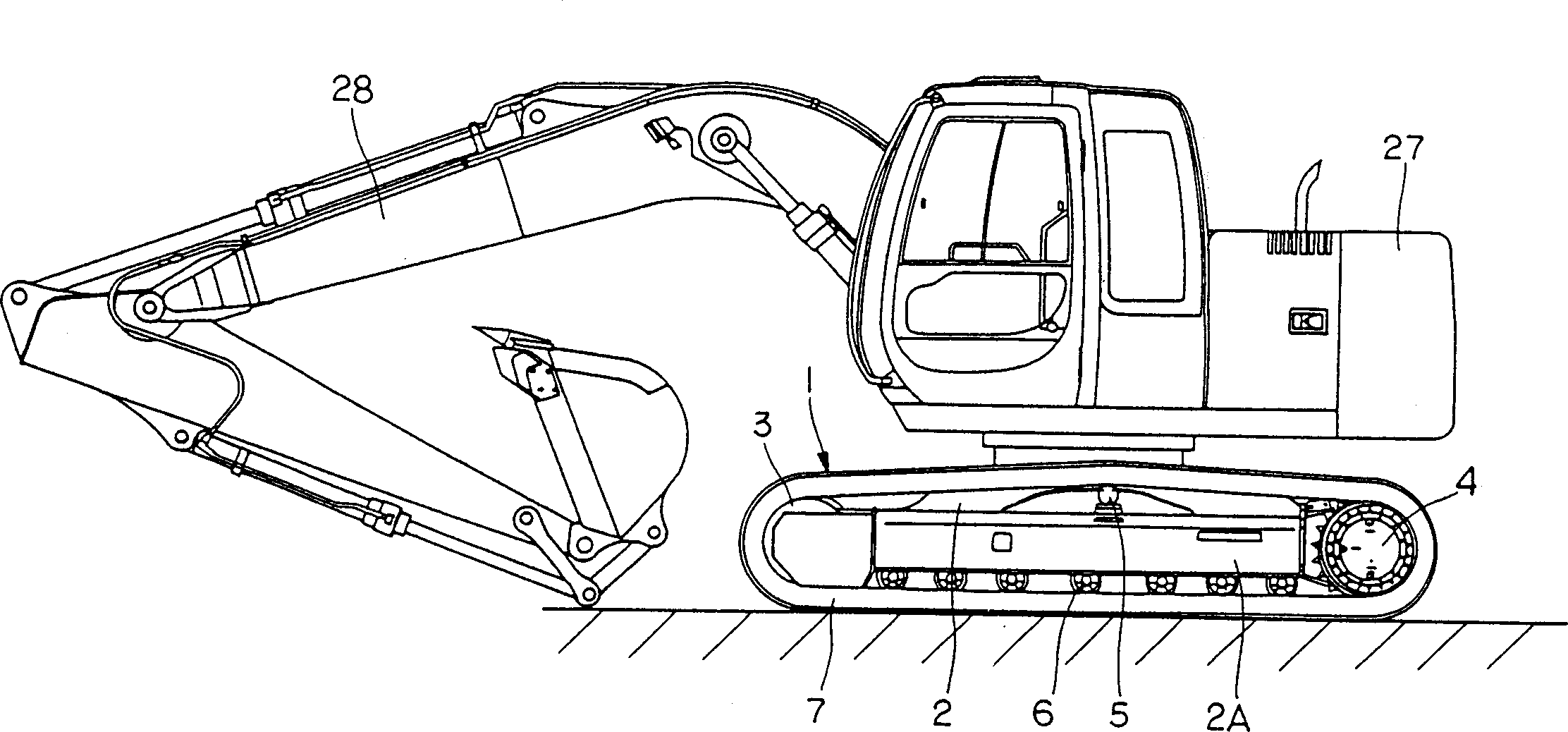

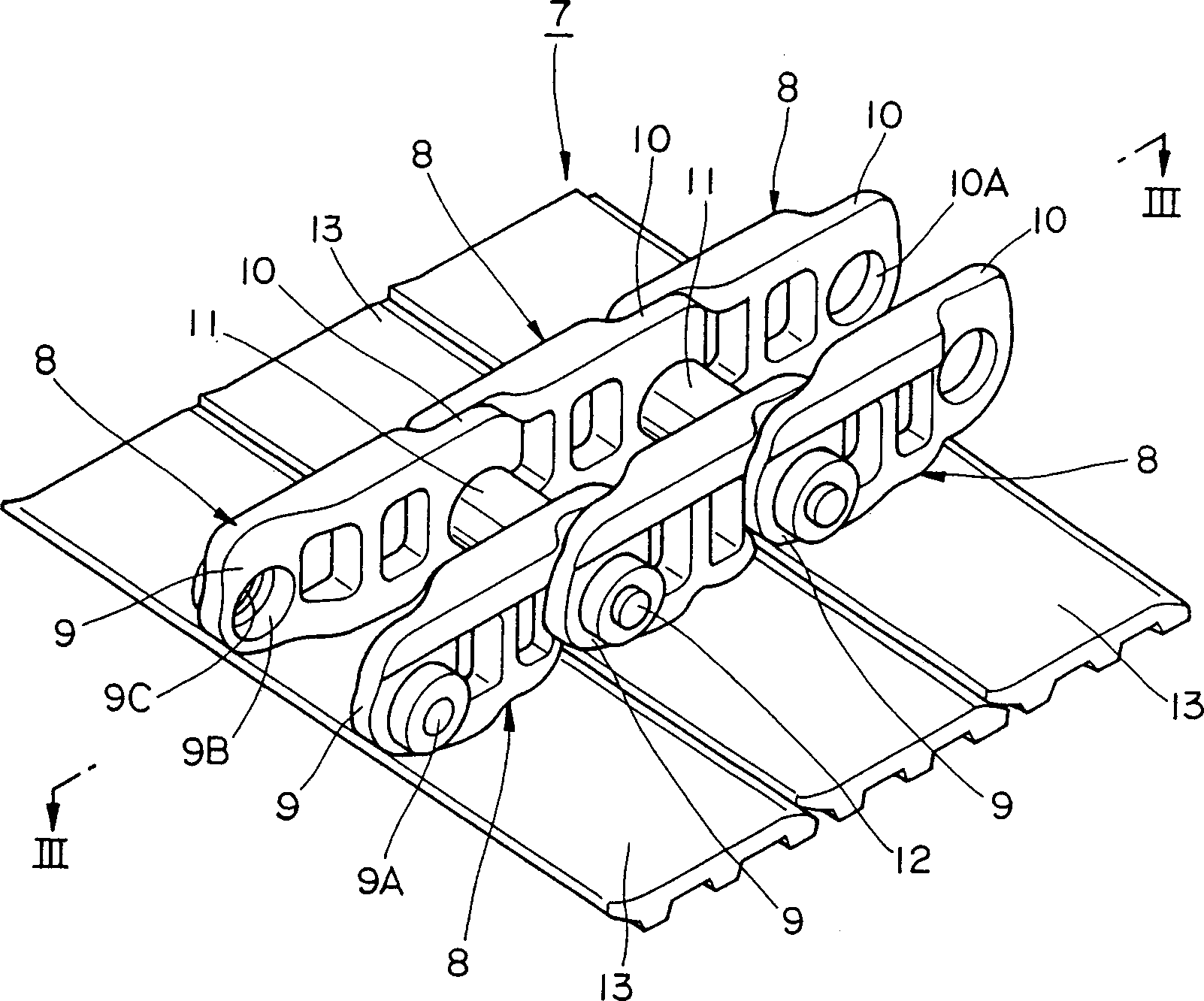

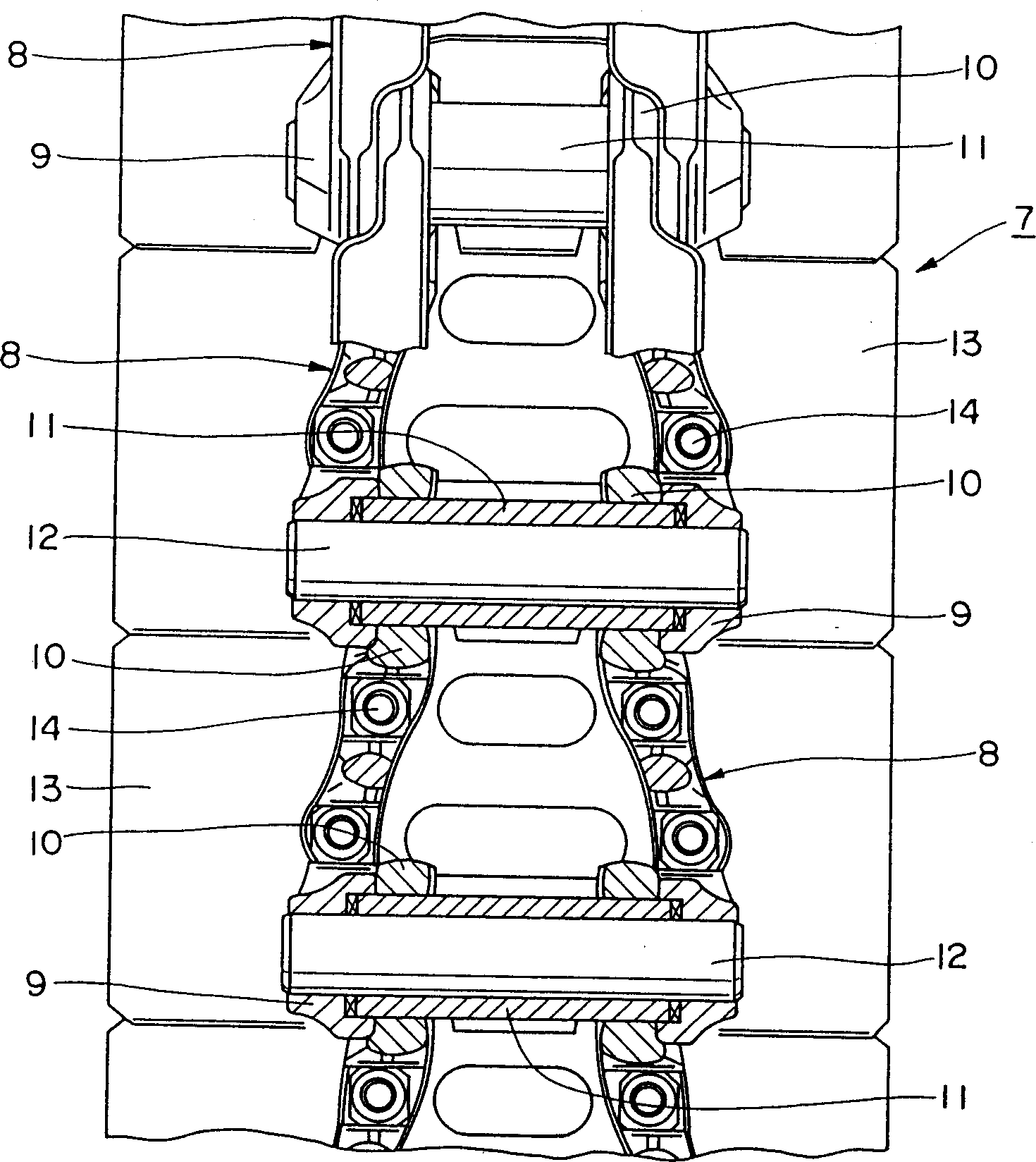

Crawler belt and sealt for use therein

InactiveCN1392852AUniform pressureUniform surface pressureMechanical power transmissionEndless track vehiclesEngineering

A seal ( 21 ) is constituted by an outer lip portion ( 22 ) to be held in abutting engagement with an outer link portion ( 9 ) of a crawler belt ( 7 ), an inner lip portion ( 23 ) to be held in abutting engagement with a bush ( 11 ), and an interconnecting bridge portion ( 24 ) bridged and connected between the outer and inner lip portions ( 22, 23 ). The outer lip portion ( 22 ) on the side of track link, the inner lip portion ( 23 ) on the side of bush, and outer bridge portion ( 24 A) and inner bridge portion ( 24 B) of the interconnecting bridge portion ( 24 ) are formed in thicknesses (T 1 , T 2 , T 1 ' and T 2 '), respectively, which are in the relations of (T 2≈ T 2 '>T 1 ≈T 1 '). A maximum outside diameter portion ( 24 C) of the interconnecting bridge portion ( 24 ) is located radially outward of a median point between inner and outer peripheral ends of the lip portion ( 23 ) on the side of bush. The inner lip portion ( 23 ) as a whole is uniformly pressed against an end face ( 11 A) of the bush ( 11 ) by the interconnecting bridge portion ( 24 ).

Owner:NIHON KENKI CO LTD

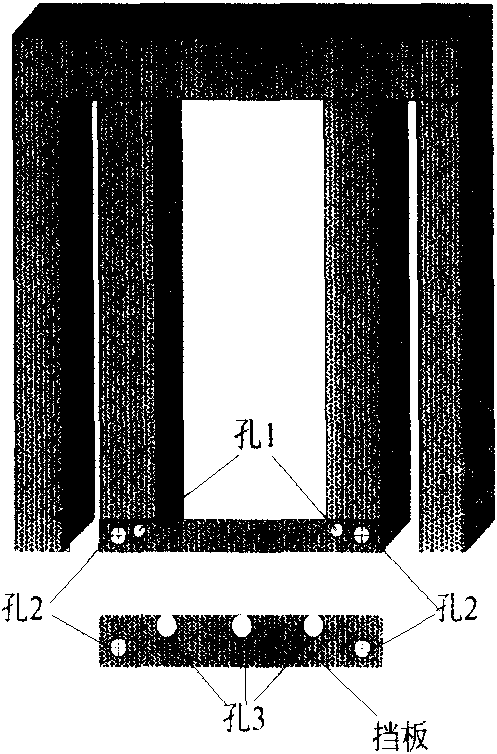

Sand box for sand casting of bent pipe and sand core of sand box

PendingCN109175272AImprove the fixing strengthAvoid leaningFoundry mouldsFoundry coresSand castingMaterials science

The invention discloses a sand box for sand casting of a bent pipe and a sand core of the sand box. The sand box comprises an upper sand box and a lower sand box, wherein two or more sand shooting holes are formed in the upper sand box; an exhaust hole and a sprue are formed in the upper sand box; the sprue communicates with a runner; an upper mold cavity is arranged in the upper sand box; a lowermold cavity is arranged in the lower sand box; the sand core comprises an upper half sand core and a lower half sand core; formed core bars are correspondingly arranged in the upper half sand core and the lower half sand core; both ends of the formed core bars correspondingly penetrate out of both ends of the upper half sand core and the lower half sand core, and are welded with the inner wall ofthe sand box; cuboid core heads I are correspondingly arranged at both ends of the upper half sand core; cuboid core heads II are correspondingly arranged at both ends of the lower half sand core; anupper sand mold is arranged between the upper sand box and the upper mold cavity; and a lower sand mold is arranged between the lower sand box and the lower mold cavity. The sand box for the sand casting of the bent pipe and the sand core of the sand box have the beneficial effects that the use of a core support for supporting is not needed; the sand core can be effectively prevented from tiltingand floating; and the phenomenon of misalignment during the box assembling process can be prevented.

Owner:HUSN CASTING ANHUI YINGLIU GROUP

Tool holder for grooving cutting blade

ActiveCN102601403AAvoid deformationReduced positioning contact areaTurning toolsTool holdersEngineeringSupport surface

The invention discloses a tool holder for grooving a cutting blade. The tool holder comprises a tool holder body and a fastener, a clamping portion of the tool holder body consists of an upper clamping portion and a lower supporting portion, an upper positioning surface of the upper clamping portion and a lower positioning surface of the lower supporting portion enclose a blade clamping groove, a rear supporting surface and an elastic extending section are arranged at the rear end of the blade clamping groove, the elastic extending section extends backwards to the neck of the tool holder body, the fastener penetrates through the upper portion and the lower portion of the elastic extending section, M discontinuous upper positioning tables are arranged on the upper positioning surface, and N discontinuous lower positioning tables are arranged on the lower positioning surface, wherein 2<=M<=6, and 2<=N<=6. The tool holder for grooving the cutting blade has the advantages that positioning positions and angles can be automatically adjusted, plastic deformation of the tool body can be effectively suppressed, and the tool holder is stable in structure and long in service life.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

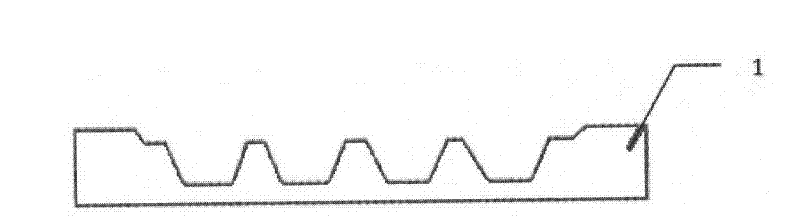

Cutting insert, cutting tool using the same, and cutting method

InactiveCN101522350AReduce cutting resistanceReduced inhibitory strengthTransportation and packagingMilling cuttersMechanical engineeringRidge

A cutting insert has a cutting edge formed at a ridge between an upper face and a side face. The side face has grooves running from the side face to the upper face to divide the cutting edge. A clearance angle in each groove is formed so that the angle is greater from one end of the cutting edge toward the other end, and as a result, the cutting insert has small cutting resistance and excellent cutting performance. Of the grooves, the groove nearest the one end of the cutting edge is preferably formed so that its width is greater from the upper face toward the lower face of the cutting insert.

Owner:KYOCERA CORP

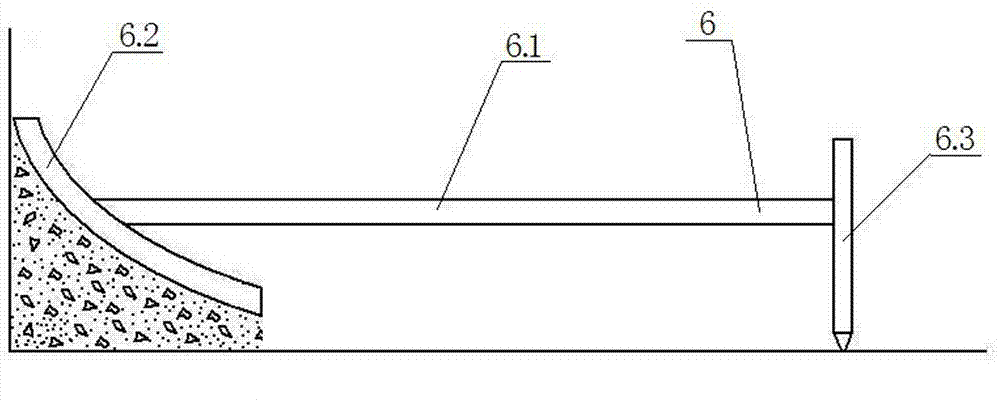

Special drill bit for underground pipeline exploration

The invention discloses a special drill bit for underground pipeline exploration. The special drill bit for underground pipeline exploration comprises a drill bit body, wherein the drill bit body is cylindrical, a connecting part matched with a drill stem of a drilling rig is arranged on the upper portion of the drill bit body, and the lower end of the drill bit body is planar. A water jetting hole is formed in the center of the drill bit body, a water drainage groove is vertically formed in the outer wall of the drill bit body, a water guide groove corresponding to the water drainage groove is formed in the bottom face of the drill bit body, the inner side of the water guide groove is communicated with the water jetting hole, and the outer side of the water guide groove is communicated with the water drainage groove. The special drill bit for underground pipeline exploration has the advantages that because the drill bit body is cylindrical, and the lower end of the drill bit body is of a planar structure, the requirement for cutting soft soil and medium-hardness soil and the backfill requirement can be met, but hard components such as a metal pipeline will not be cut; when the drill bit encounters a hard component, the drill bit can only feed back hole bottom information to the ground surface but cannot cut the hard object, and thus damage to underground pipelines can be effectively avoided. The drill bit body is formed by machining ABS hard plastics, and the special drill bit for underground pipeline exploration is simple in structure, convenient to manufacture, safe in use and low in cost.

Owner:浙江省工程勘察设计院集团有限公司

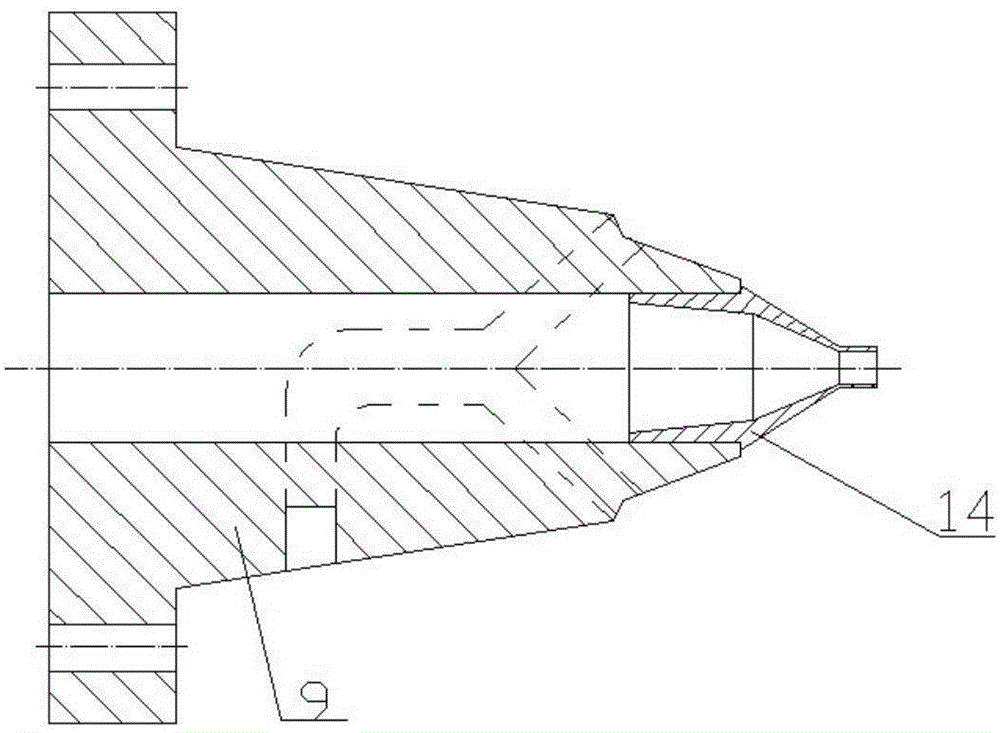

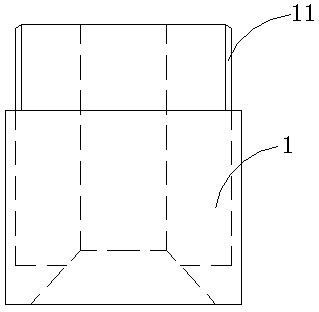

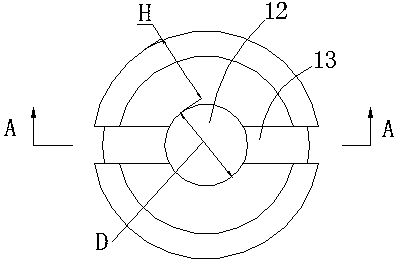

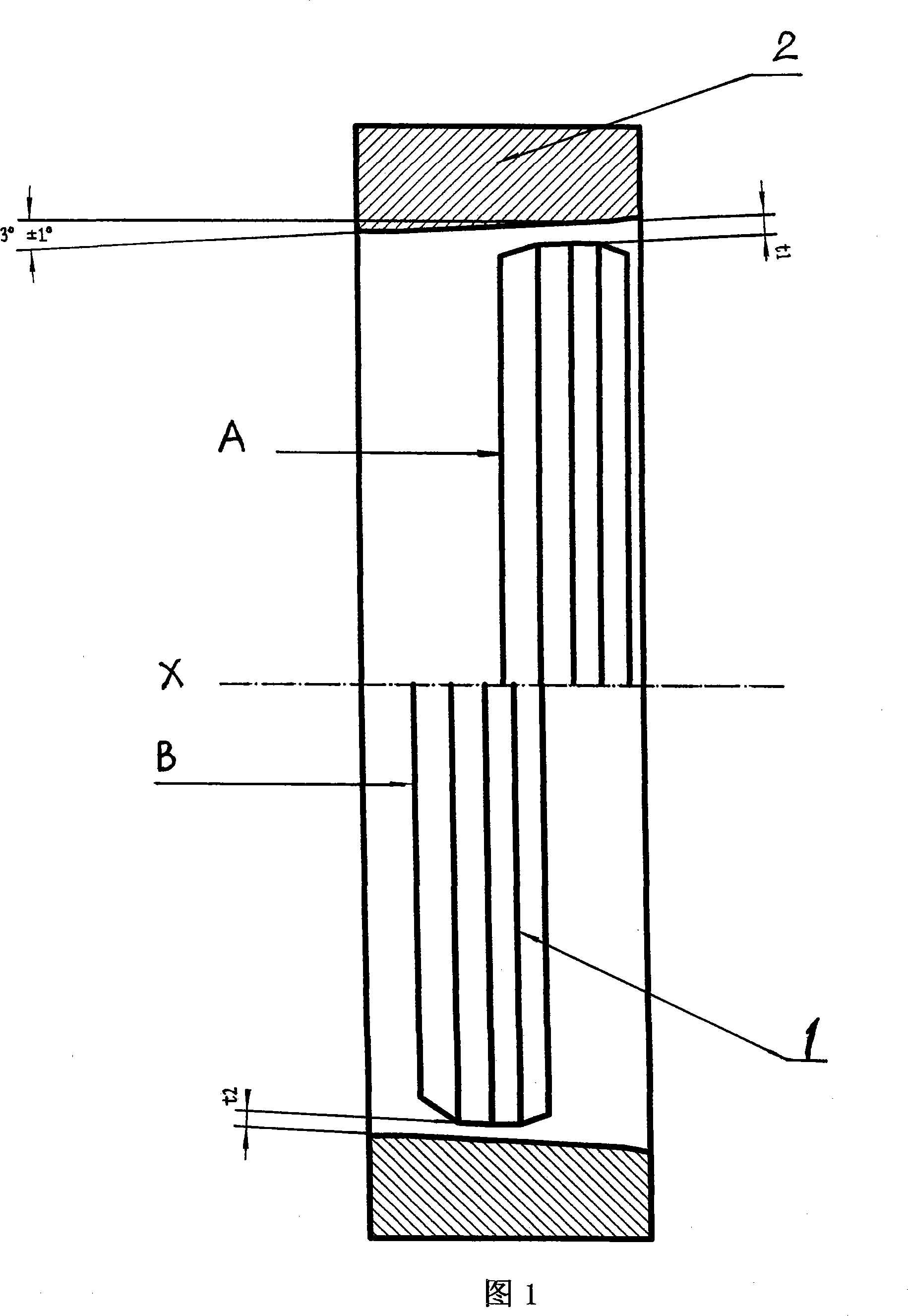

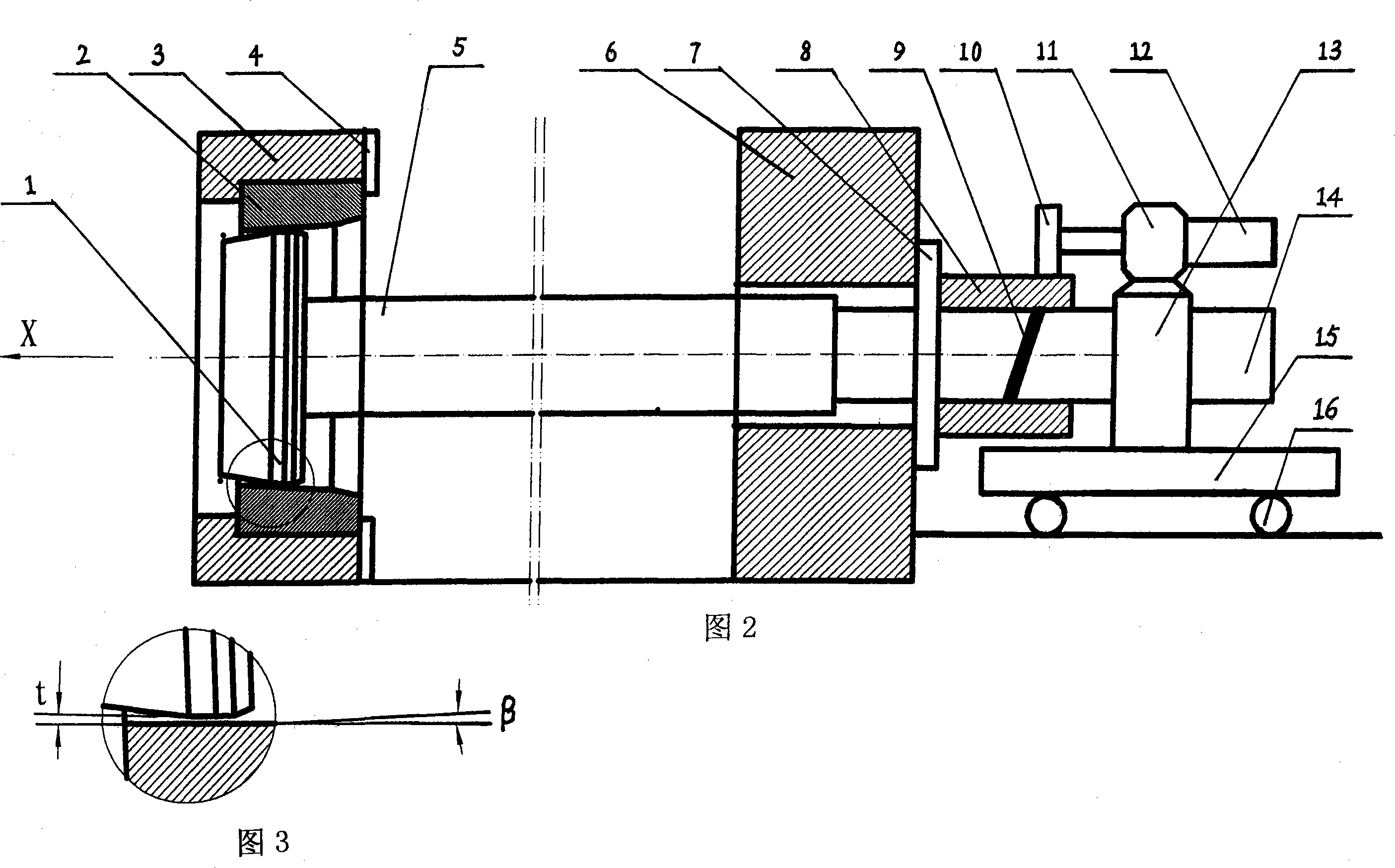

Cold drawing accurate steel tube wall thickness adjusting mechanism

The invention relates to an adjusting device for the wall thickness of cold drawn precision steel pipes, comprising an external mold and a core mold, wherein, the external mold provided with the core mold is arranged on an intermediate stand post of a drawbench. The invention is characterized in that: a working tape of the external mold is provided with a small cone angle of 2-4 DEG C; the core mold is connected with one end of a tie, the other end of which is connected with a screw; a leptospira is sleeved on the outside of the screw; the external surface of the leptospira is provided with a tooth and connected with an AC servo motor through a gear and a speed reducer. The invention can drive the tie which is connected with the core mold and a spiral breadth on the tail of the tie through the AC servo motor according to DEG C of wear of moulds; the influence of the wear of a compensation mould on the deviation of the wall thickness of the steel pipes is achieved by adjusting the relative positions of the external mold and the core mold on the axle wire, thereby the problem that the wall thickness of the steel pipes is made to be changed due to the wear of the moulds when the cold drawn precision steel pipes are used.

Owner:沈阳兆通精密异型管有限公司

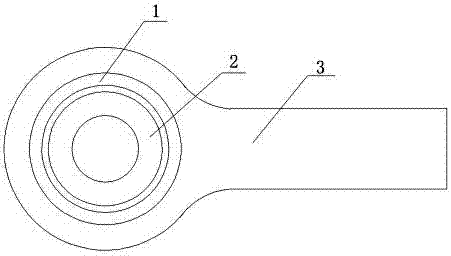

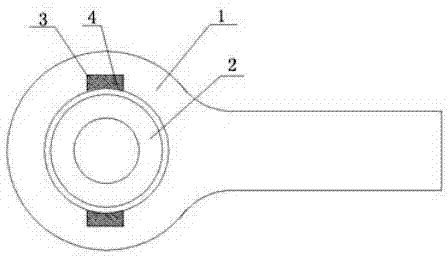

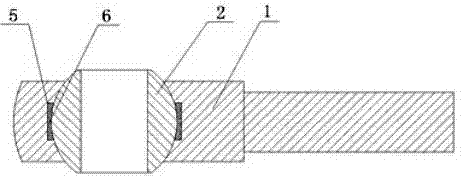

Knuckle bearing structure

InactiveCN104763741AGuaranteed wall thicknessAchieve separationBearing componentsSliding contact bearingsEngineeringKnuckle

The invention relates to a knuckle bearing structure. The knuckle bearing structure comprises an outer ring with a pulling rod, wherein the outer ring is internally provided with an inner ring. The knuckle bearing structure is characterized in that the inner sides of the two ends of the outer ring are respectively provided with a gap; the length of the gap corresponds to the outer diameter of the inner ring; the width of the gap corresponds to the thickness of the inner ring; the inner ring is placed in the outer ring by the gaps; and the outer ring and the inner ring form matched spherical-surface contact. The knuckle bearing structure has the advantages that the inner sides of the two ends of the outer ring are respectively provided with the gap, the length of the gap corresponds to the outer diameter of the inner ring, the width of the gap corresponds to the thickness of the inner ring, the inner ring is horizontally placed in the gaps and is placed into the outer ring by rotation, and the outer ring and the inner ring form matched spherical-surface contact, and since the inner ring is placed into the outer ring by rotation, the separation of the inner ring and the outer ring is conveniently realized, the convenient replacement of the inner ring or the outer ring is realized and the production cost is effectively reduced.

Owner:新昌县明瑞关节轴承有限公司

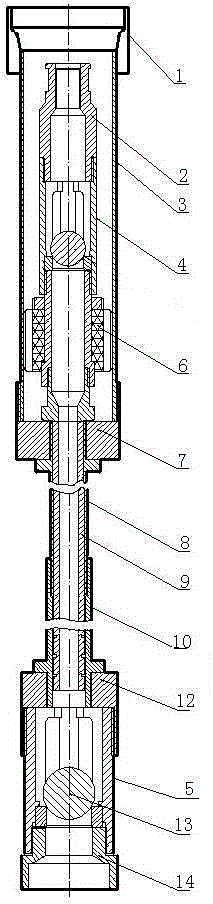

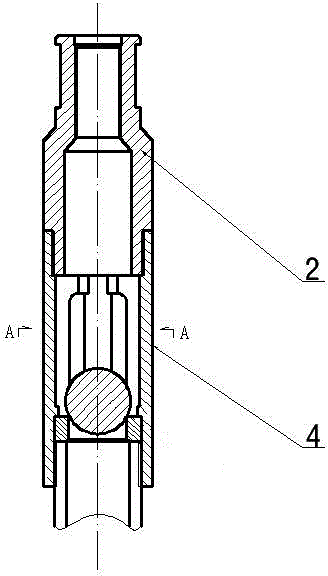

Combined pump barrel small-diameter oil well pump

ActiveCN104912782AGap leakage reductionReduce wearPositive displacement pump componentsFlexible member pumpsOil wellEngineering

The invention relates to a combined pump barrel small-diameter oil well pump. The combined pump barrel small-diameter oil well pump comprises a pump barrel assembly, a plunger assembly and an oil inlet valve assembly, an upper cover, a closed oil outlet valve cover, a traveling valve ball, a traveling valve seat and a plunger centering device are arranged in an oil pipe nipple, the upper cover is in threaded connection with the closed oil outlet valve cover, the traveling valve ball and the traveling valve seat are arranged in the closed oil outlet valve cover, the closed oil outlet valve cover is a quincuncial oil outlet hole structure with guide ribs, the upper end portion of the oil pipe nipple is connected with an oil pipe coupling, the lower end of the oil pipe nipple is connected with an upper pump barrel coupling, a hollow plunger is connected to the lower end of a traveling valve assembly, and a rectangular balance groove is formed in the lower portion of the hollow plunger; the upper end of the upper pump barrel is connected with the upper pump barrel coupling, the lower end is in threaded connection with a lower pump barrel, and the inner diameter of the lower pump barrel is 1mm larger than the diameter of the upper pump barrel; the lower pump barrel is connected with a lower pump barrel coupling. The combined pump barrel small-diameter oil well pump has the advantages that the interstitial leakage of the oil well pump can be reduced and the degree of wear between the pump barrel and the plunger is reduced.

Owner:NORTHEAST GASOLINEEUM UNIV

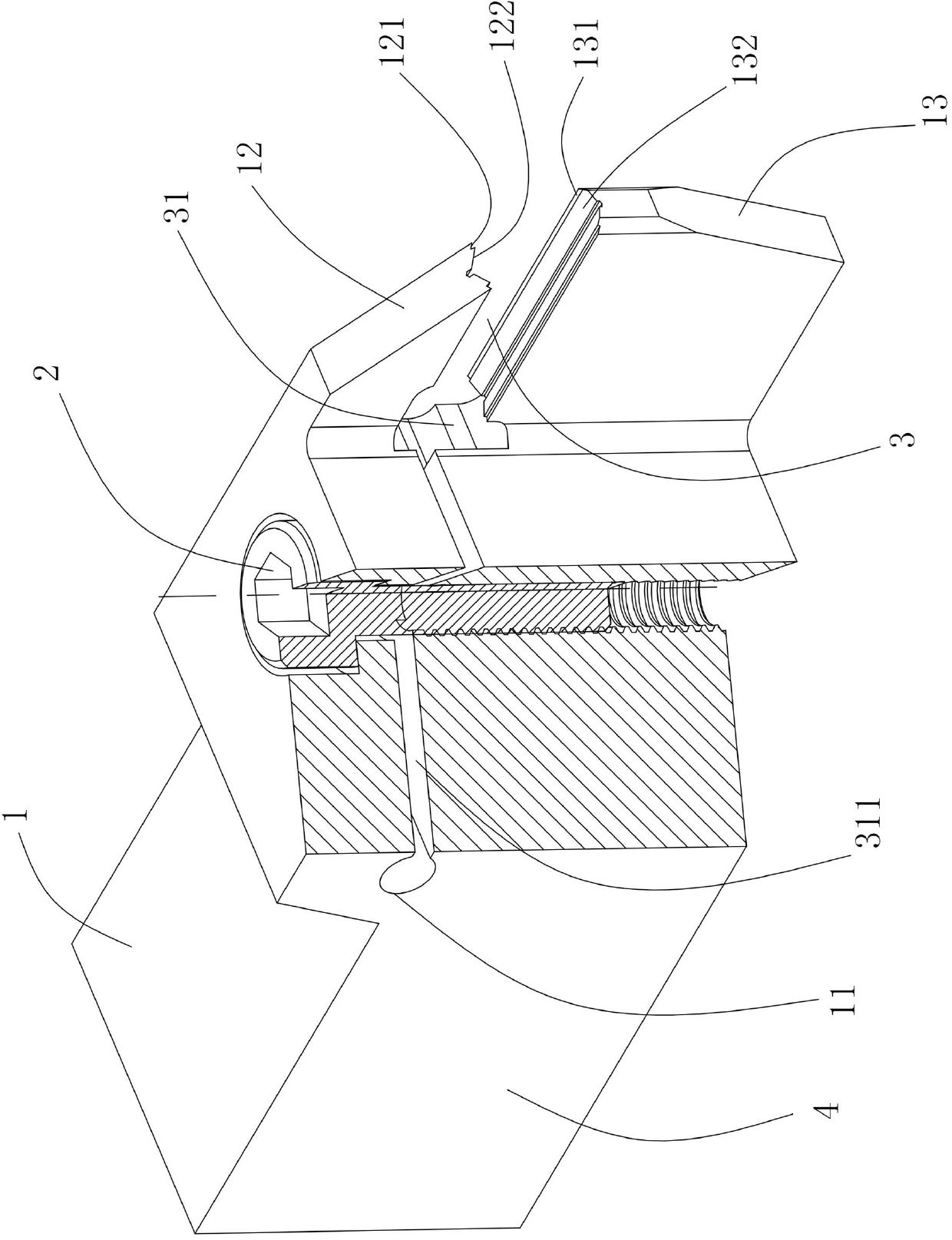

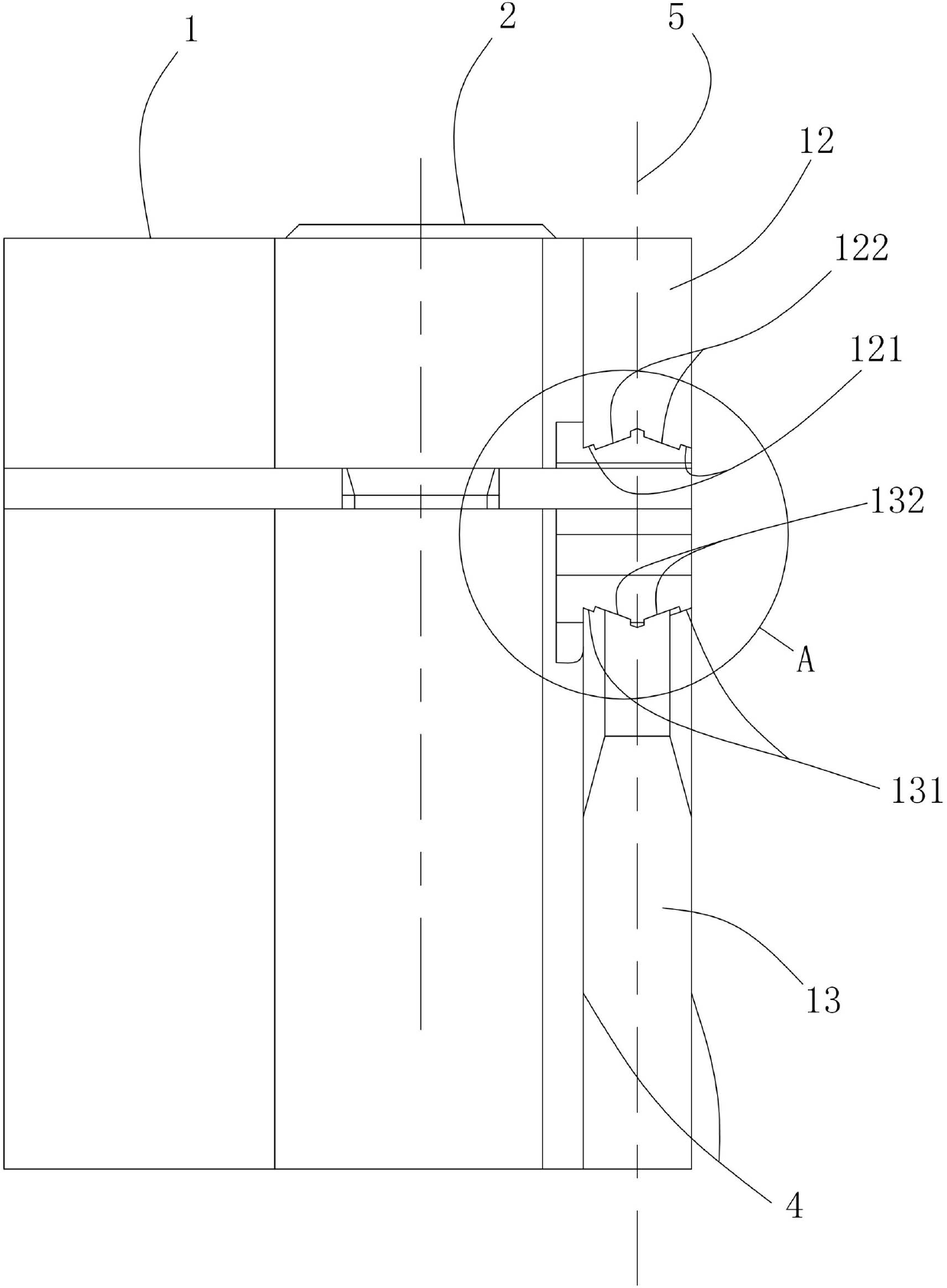

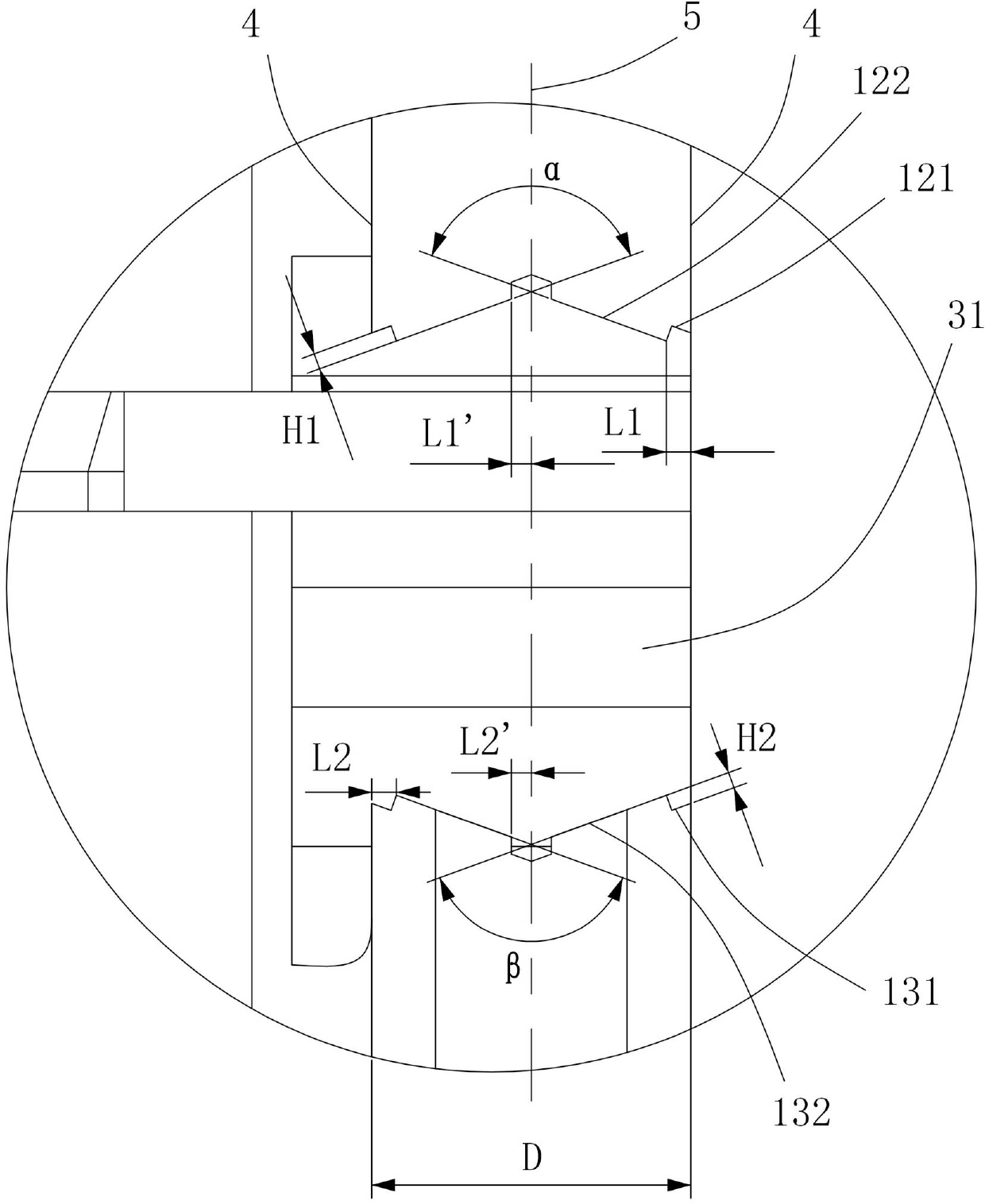

Spinning method for bottle neck part of electrically conductive contact finger and matched spinning device

The invention provides a spinning method for a bottle neck part of an electrically conductive contact finger. The spinning method is characterized in that while radial force is applied to a cylinder-shaped blank of the electrically conductive contact finger in the spinning process, axial pressure is applied to the cylinder-shaped blank of the electrically conductive contact finger in the axial direction of a core mold by utilizing a pressure loading mechanism, so that once the bottle neck part of the electrically conductive contact finger is stretched to be thinned under the action of the radial pressure of a spinning wheel, the axial pressure applied to the cylinder-shaped blank of the electrically conductive contact finger can push material to flow towards the thinned part of the bottle neck part in real time to timely supplement the stretched part, thereby preventing the bottle neck part of the electrically conductive contact finger from being stretched to be thinned. The spinning technology is simple to operate, is very convenient to implement and effectively guarantees the wall thickness of the bottle neck part of the electrically conductive contact finger in the spinning process, thereby guaranteeing that the electrically conductive contact finger manufactured by adopting the spinning technology has high flow capacity and satisfies the requirement of a megavolt power transmission and transformation line for an effective area of a through-flow cross section of the electrically conductive contact finger of a bypass isolating switch, and laying a solid foundation for smooth passing of 6300A of current.

Owner:HENAN PINGGAO ELECTRIC +2

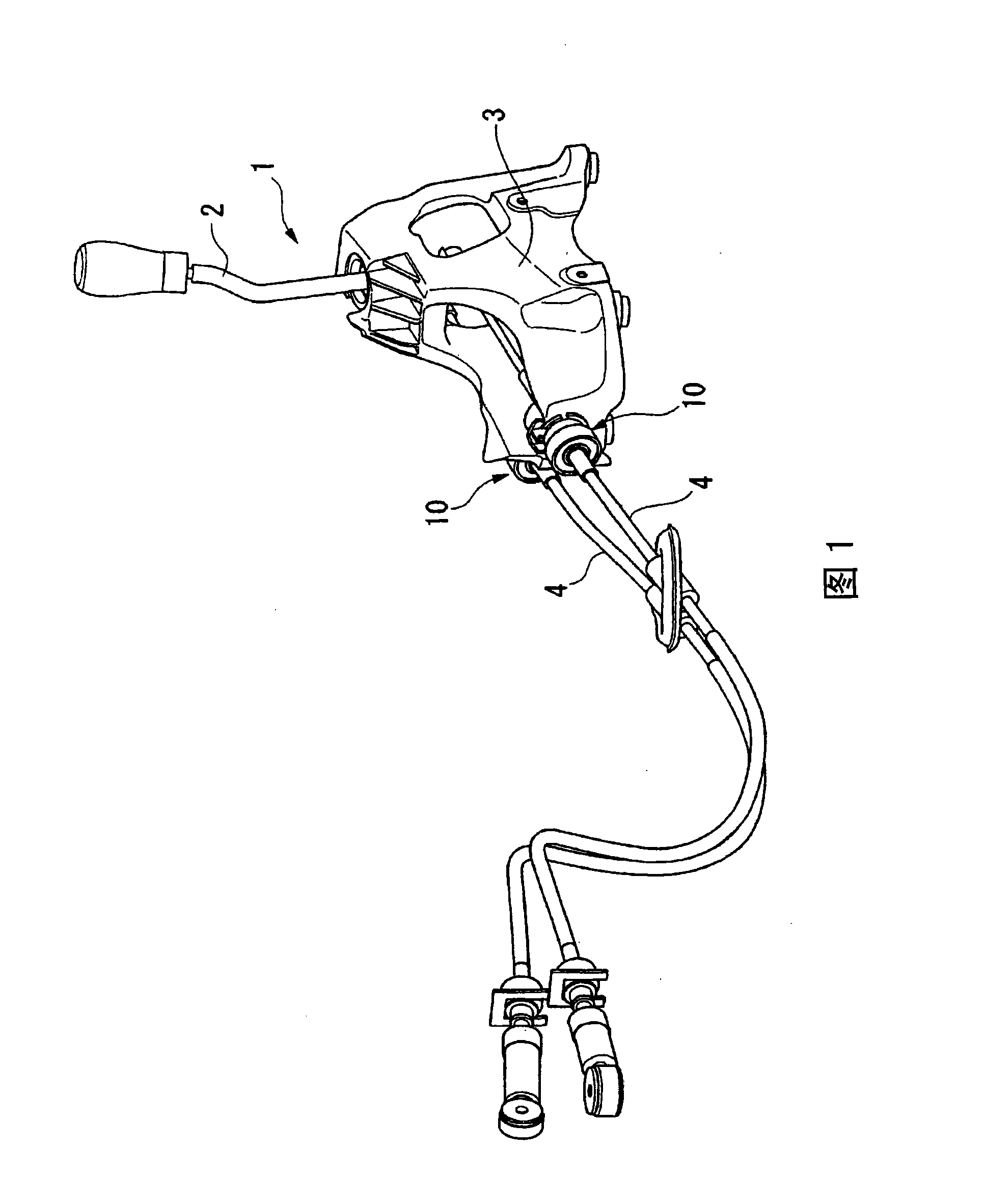

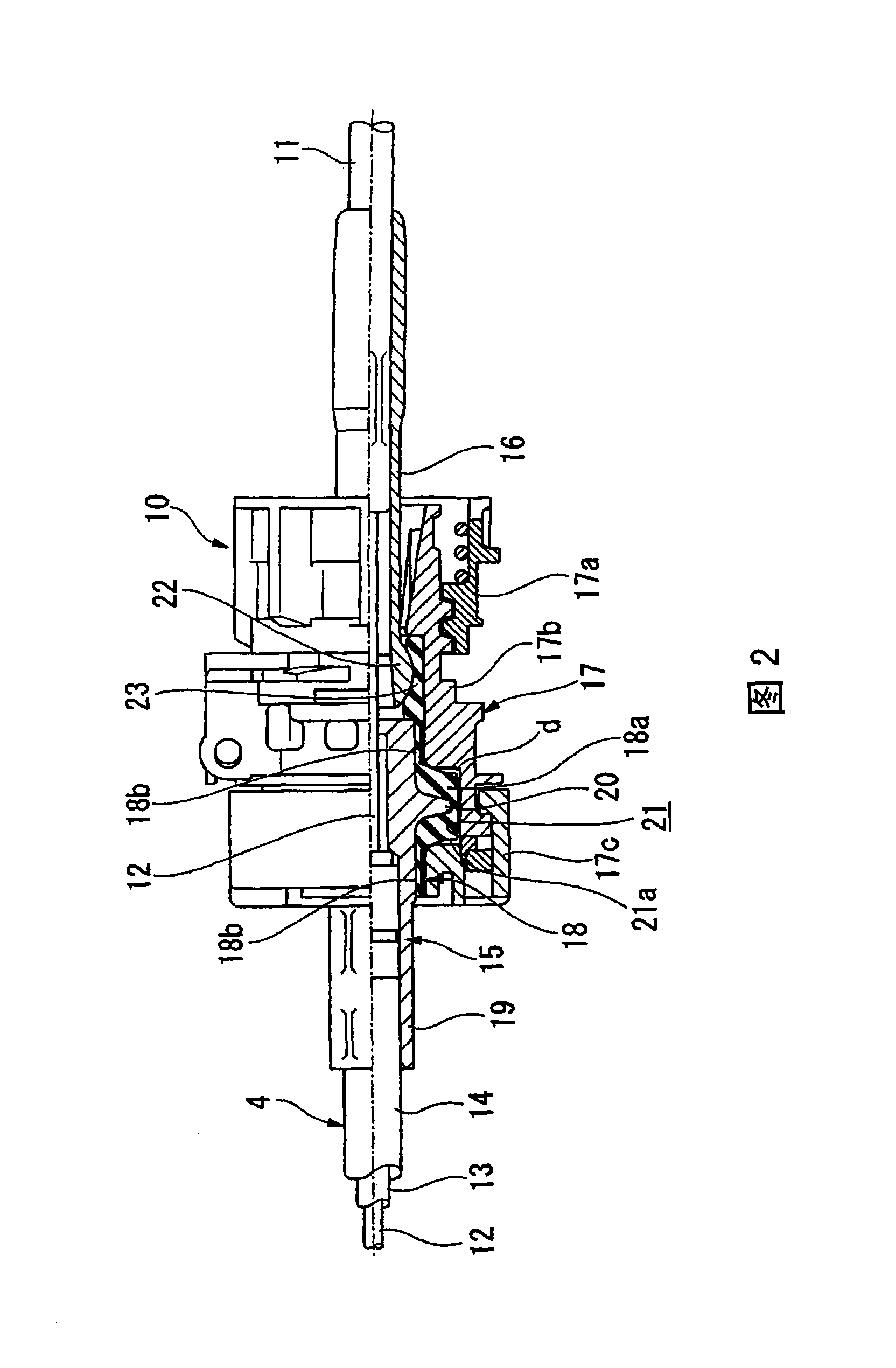

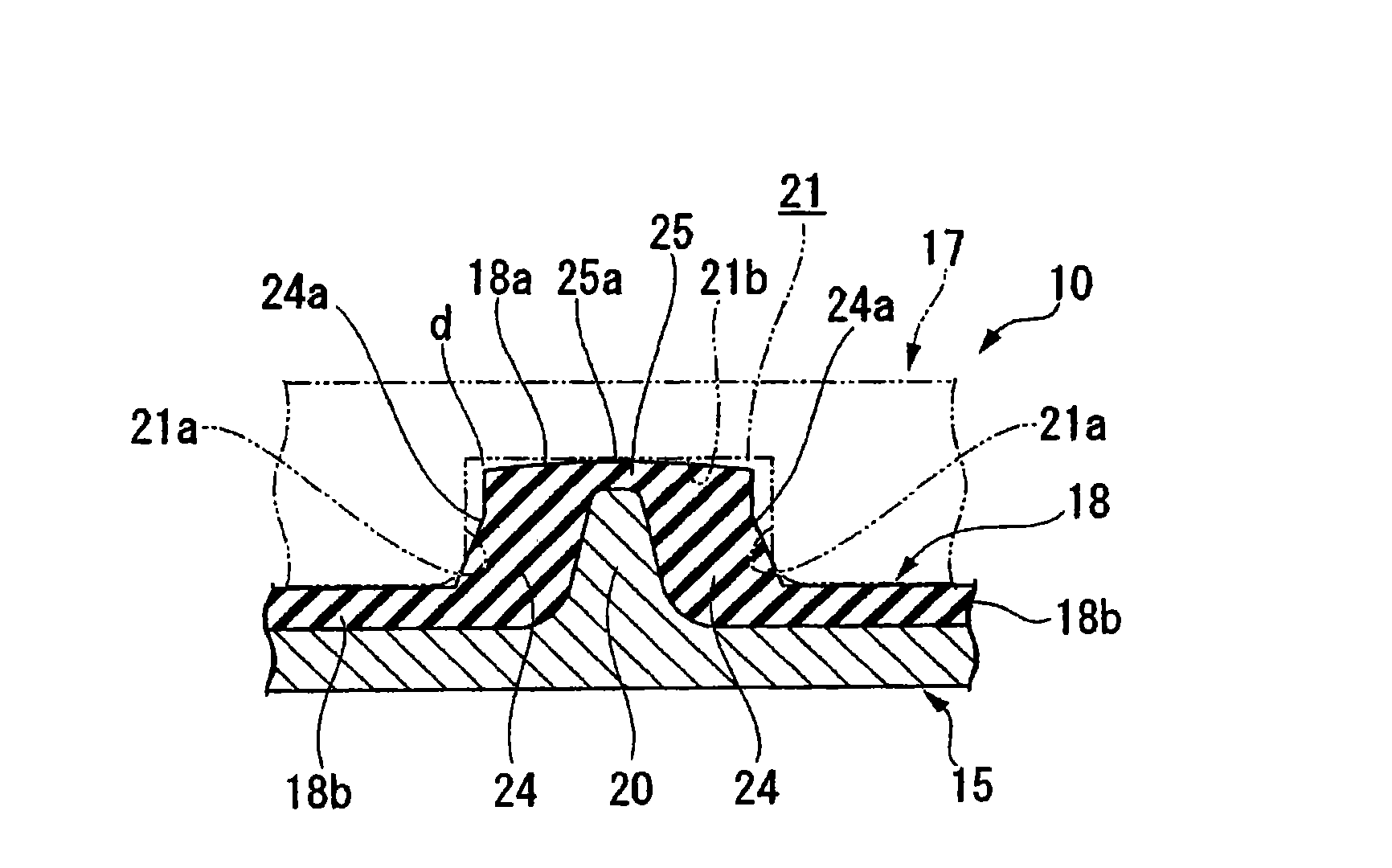

End supporting apparatus for controlling backstay cable

InactiveCN101514722AEnsure vibration absorptionEnsure AbsorbencyShaft for linear movementEngineeringVibration absorption

The present invention provides end supporting apparatus for controlling backstay cable which can improve vibration absorption, shock absorption and operation response without reducing operation sensation. External circumstance of the package cover (15) that coupled with terminal part of guiding tube (14) is provided with block-stop flange (20), and an annular storage chamber (21) is provided inside the socket (17) for collecting the block-stop flange (20). Covering rubber cover (18) onto the block-stop flange (20) in closing state and simultaneity making flange coverage of the rubber cover (18) into core with narrowing width facing external circumstance countershaft of the block-stop flange (20). The space width between cone face of flange coverage and the interior surface (21a) of storage chamber (21) corresponding to cone face of the rubber cover (18) flange coverage facing external side in radial direction and enlarge.

Owner:HONDA MOTOR CO LTD +1

Special-shaped wall integral anchor rod

The invention discloses an abnormal wall integral anchor-pouring anchor rod, which comprises a steel pipe body drilled with eyelets, wherein an exposed section of the steel pipe body is processed with screw threads, and the wall thickness of the end of the exposed section of the steel pipe body is enlarged so that the steel pipe body becomes an abnormal wall steel pipe; the front end of the steel pipe is processed into a braided shape and is used as the anchoring end; and a reducing part of the steel pipe body is in a convex ring shape. The anchor rod has the advantages that the front end of the steel pipe is provided with the anchoring end to play a role of the anchor rod and prevent the abnormal wall steel pipe from rushing out of a bore hole in the process of slip casting; the exposed section of the steel pipe is processed with the screw threads after the wall thickness thereof is enlarged so as to ensure the effective wall thickness of the exposed section of a slip-casting anchor rod and enhance the tensile strength thereof so that the abnormal wall steel pipe plays the role of the anchor rod and plays the role of the slip casting; the wall thickness of the externally exposed end, and the tensile strength is enhanced, thus the anchoring force is improved; and because a convex ring at the reducing part plays a role of a check ring, a stop-grouting plug has good leak tightness, and slurry is not thrown up in the slip casting.

Owner:王光平 +3

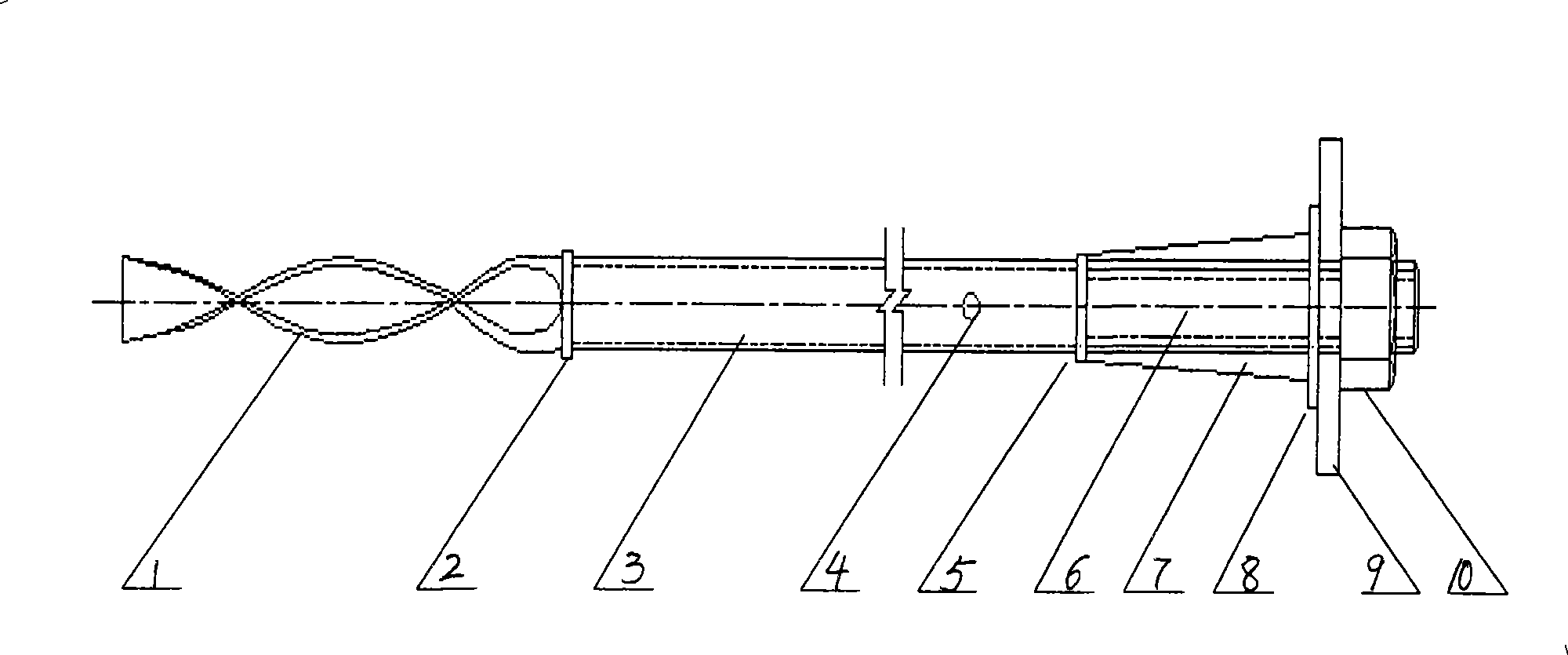

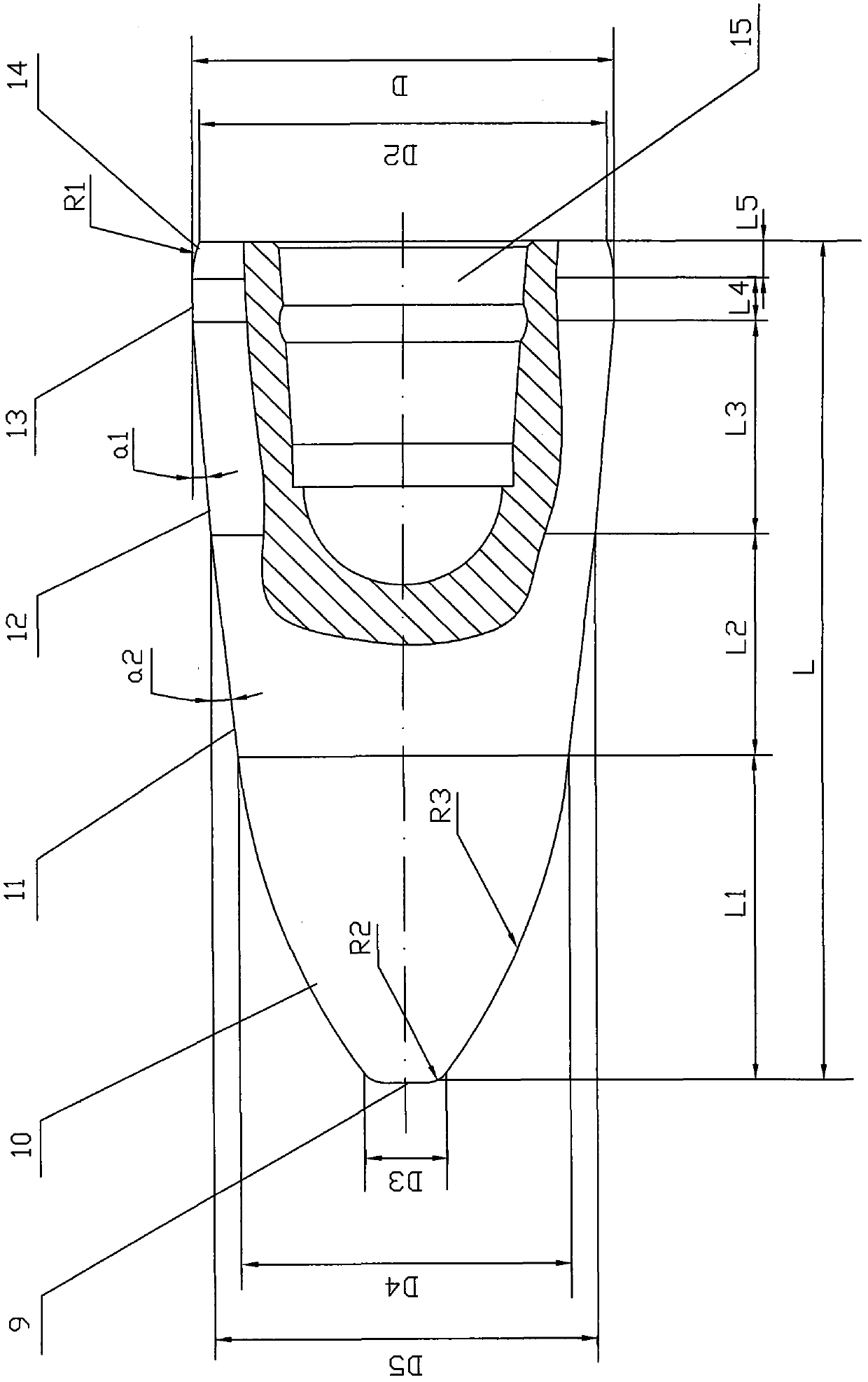

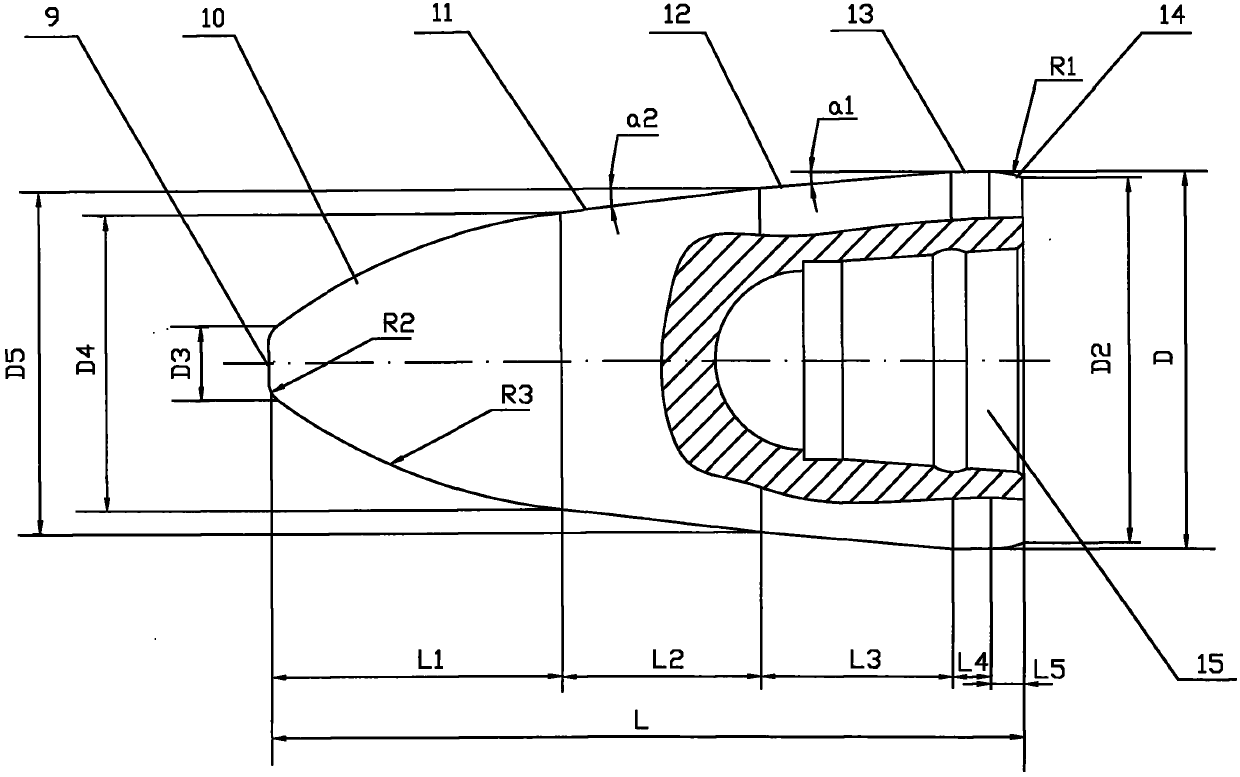

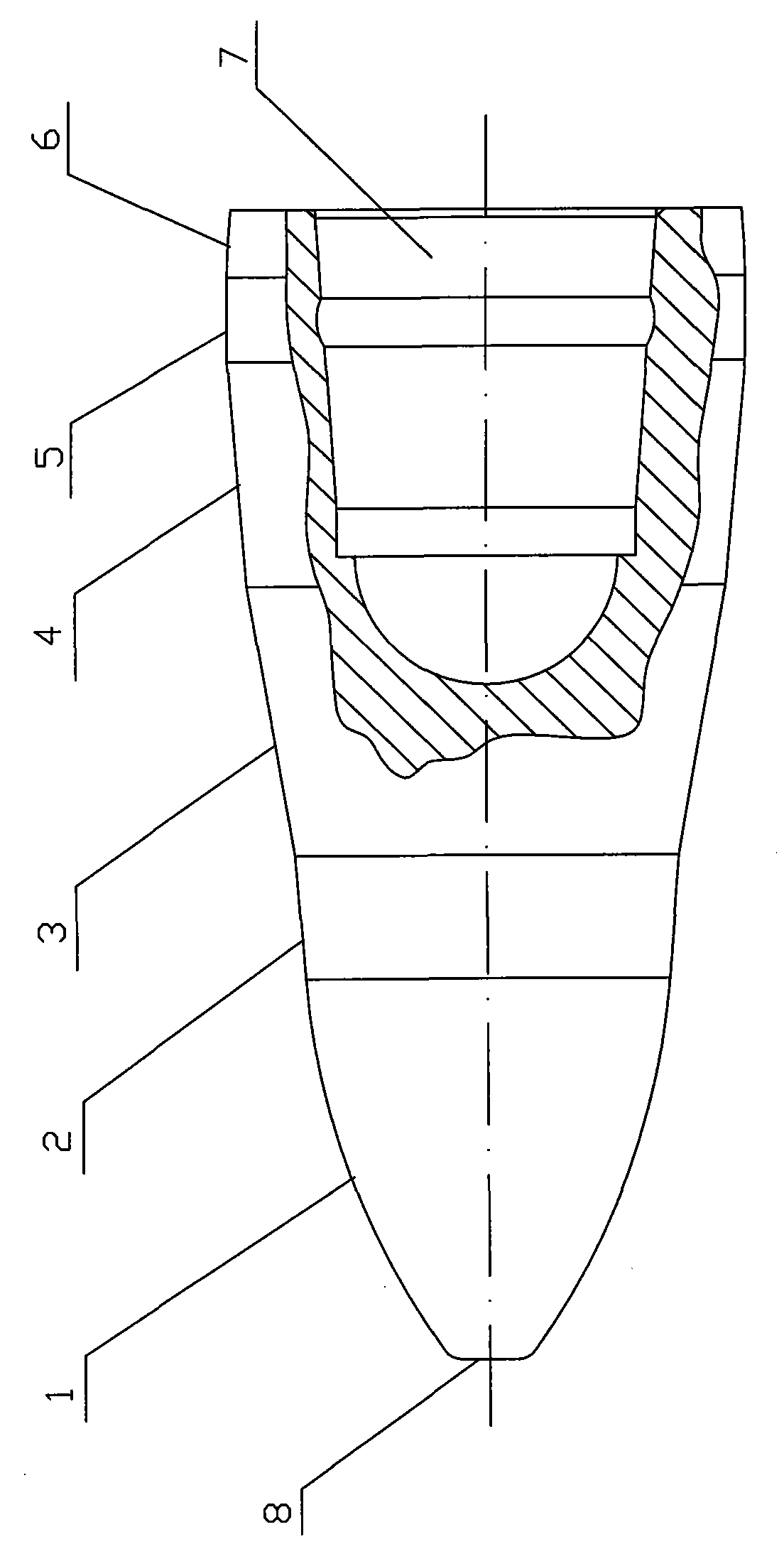

Plug for large-hole series medium- and thick-wall capillaries

InactiveCN101947551AImproved Wall Thickness AccuracyImprove straightnessMandrelsMetal rolling arrangementsPunchingThick wall

The invention relates to the field of steel pipe production, in particular to a plug for punching of large-hole series medium- and thick-wall capillaries. The outline of the plug consists of a punching section, an expanding section, a rolling section, a circling section and a reverse cone section. The front end surface of the plug adopts a flat head design, and a bar inserting hole is formed on the tail end of the plug; connection between the front end surface of the plug and the punching section is realized through arc transition, wherein the arc radius is R2, and the arc radius of the outline of the punching section is R3; the expanding section and the rolling section are cones, wherein the taper of the expanding section is a2, and the taper of the rolling section is a1; the outline of the reverse cone section is an arc of which the arc radius is R1; and the circling section is a cylinder.

Owner:HENGYANG VALIN STEEL TUBE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com