Cutting insert, cutting tool using the same, and cutting method

A technology for cutting inserts and cutting tools, used in milling cutting inserts, manufacturing tools, milling cutters, etc., can solve the problems of low cutting performance and large cutting resistance, and achieve the advantages of reducing cutting resistance, excellent cutting performance, and suppressing vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]

[0035] An embodiment of the cutting insert of the present invention will be described in detail below with reference to the drawings.

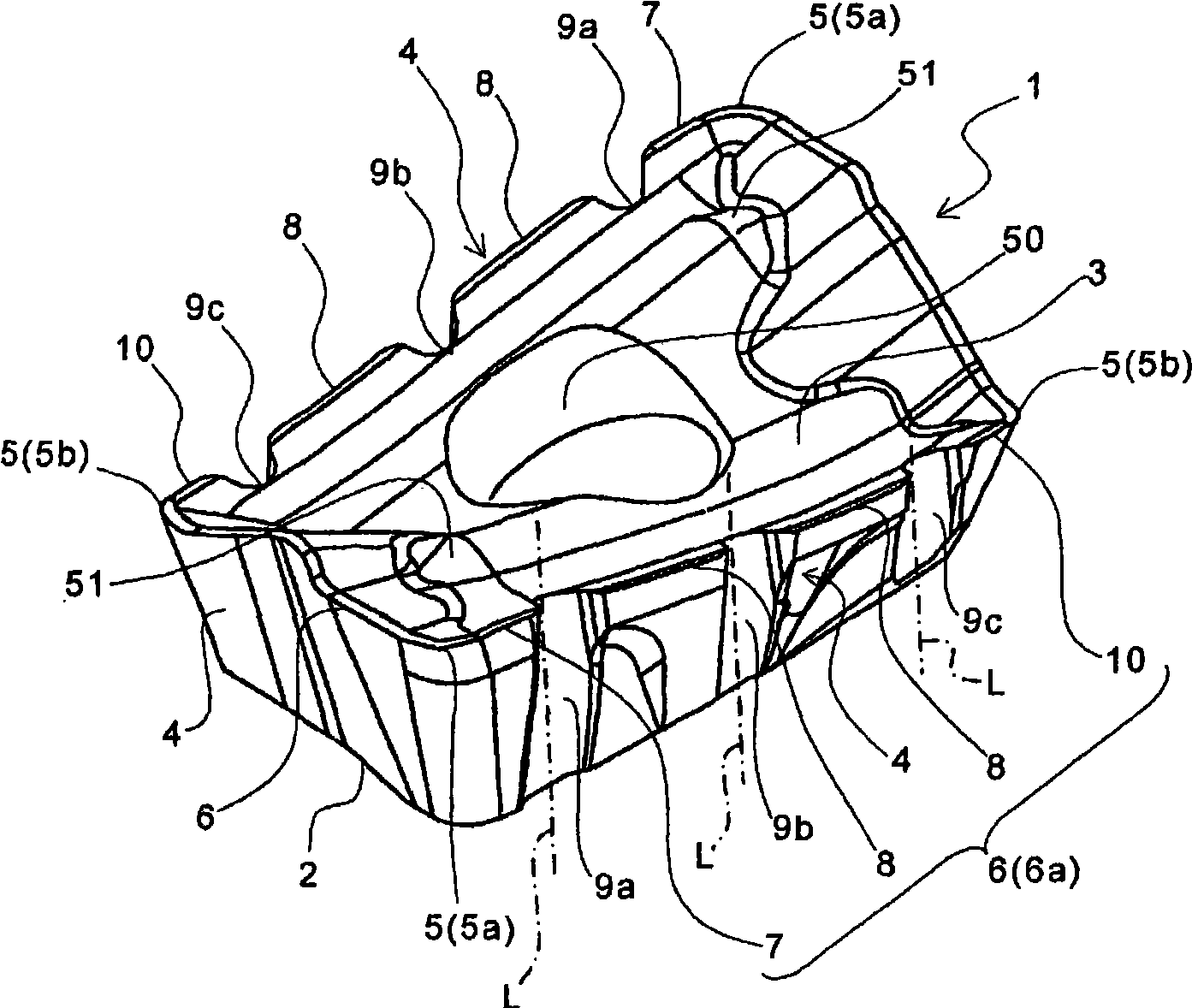

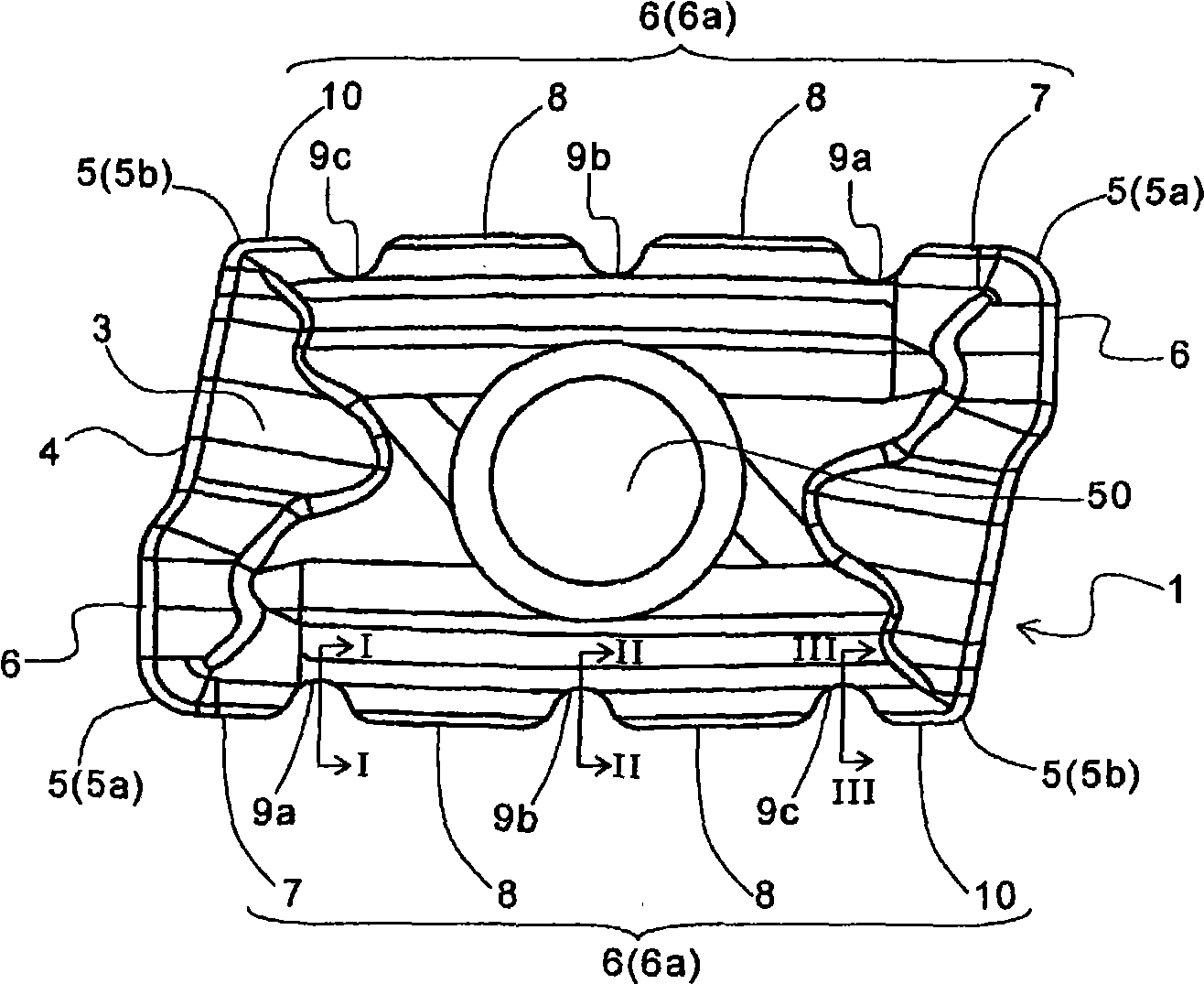

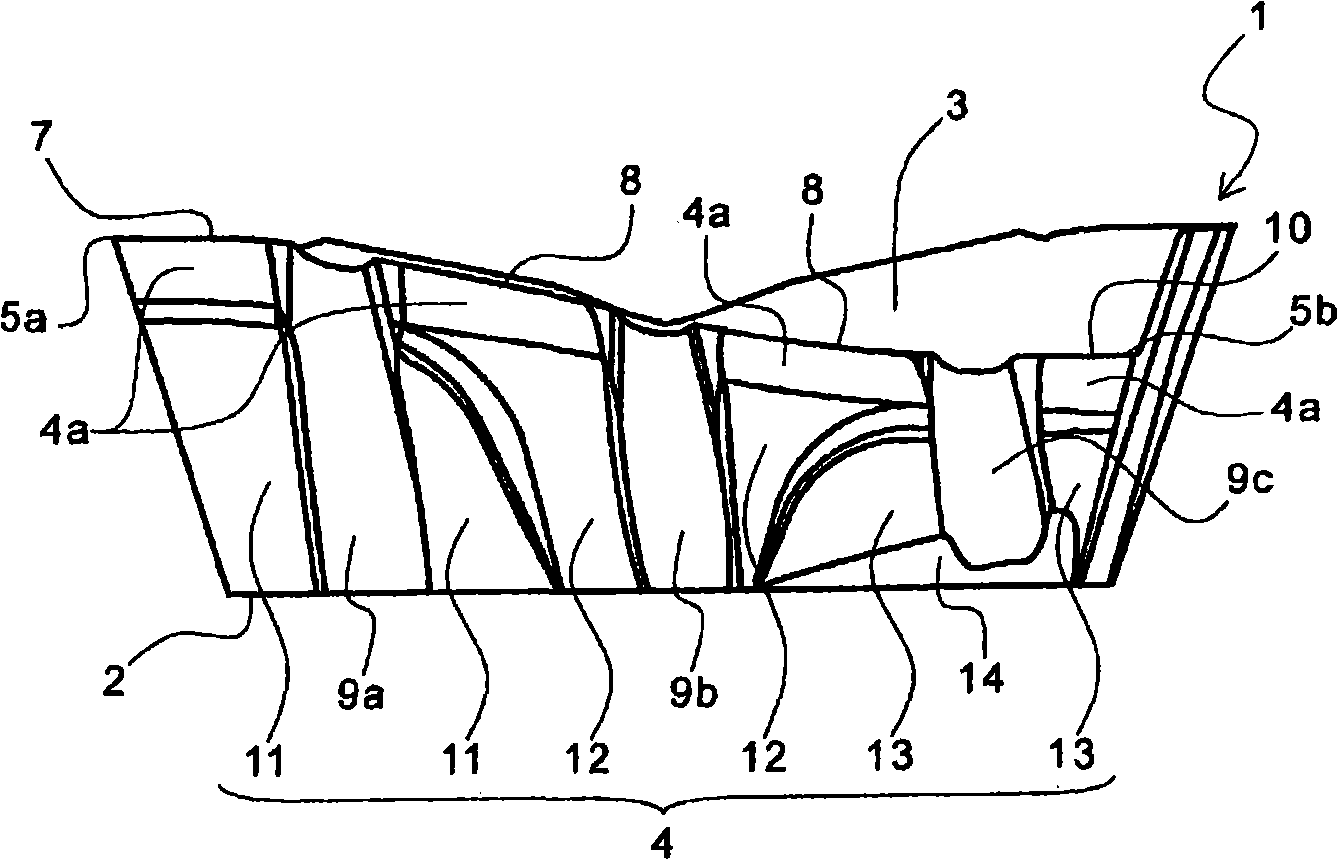

[0036] Such as Figure 1 ~ Figure 3As shown, the cutting insert (hereinafter simply referred to as insert) 1 of this embodiment has a substantially parallelogram-shaped insert body in plan view, including a bottom surface 2 forming a seat surface, an upper surface 3 with a rake surface, and a side of the face 4. Furthermore, the corners 5 (5a, 5b) located at the corners of the insert main body among the ridgelines having the upper surface 3 and the side surfaces 4, and the corners 5 (5a, 5b) located between the two corners 5, 5 of the ridgelines (that is, the Between the two ends of the ridgeline) and the cutting edge 6 connected to the two corners 5,5.

[0037] The rake surface of the upper surface 3 means a surface on which chips generated on the upper surface 3 are scraped. A through-hole 50 penetrating through the bottom surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com