Horizontal type automatic profiling pineapple peeling machine

A technology of peeling machine and pineapple, which is applied in the field of horizontal automatic profiling pineapple peeling machine, can solve the problems of losing rest time, etc., and achieve the effects of high cutting efficiency, reducing cutting resistance and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

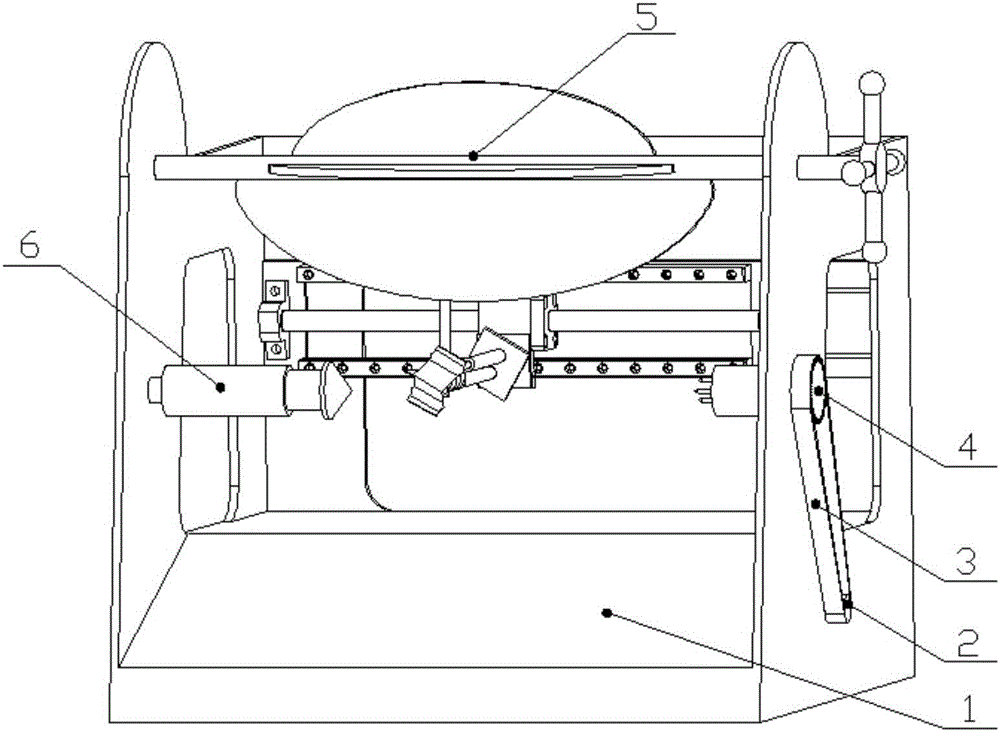

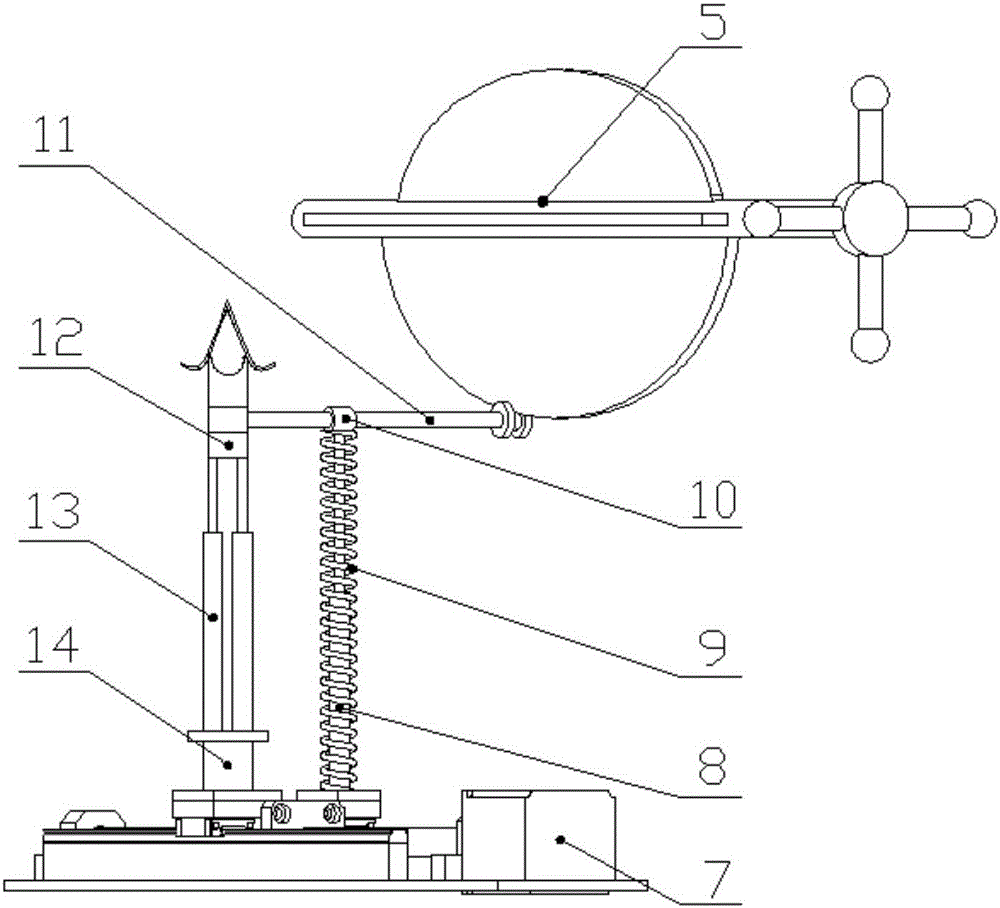

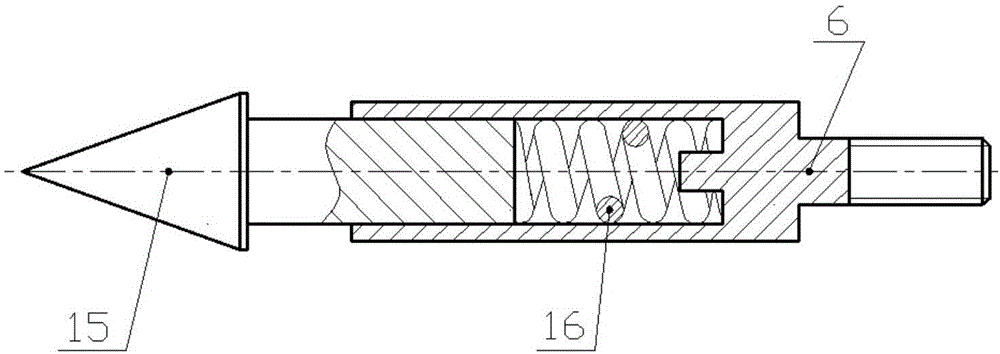

[0040] Such as Figure 1 to Figure 8 As shown, the horizontal automatic profiling pineapple peeling machine of the present invention comprises a screw drive mechanism, a tool system, a cam mechanism, a synchronous belt drive mechanism, a clamp system and a frame, and the specific structure and connection mode are:

[0041] The screw drive mechanism includes a screw motor 7, a screw 27, a shaft coupling 22, an A-type key, a slide rail 23, a slide block 26, a nut 25, a fixed block 24, a bearing seat 19, a rolling bearing 20 and a circlip twenty one. Among them, the lead screw motor 7 and the lead screw 27 are connected by an A-type key through the coupling 22; the slide block 26 and the slide rail 23 form a moving pair; the slide rail 23 is fixed on the machine base by hexagonal screws; form a spiral pair; the fixed block 24 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com