Stream turbine rotor blade root arc groove roughing milling cutter

A steam turbine rotor and arc groove technology, which is applied to milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of difficult chip removal, slow cutting amount, and many chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

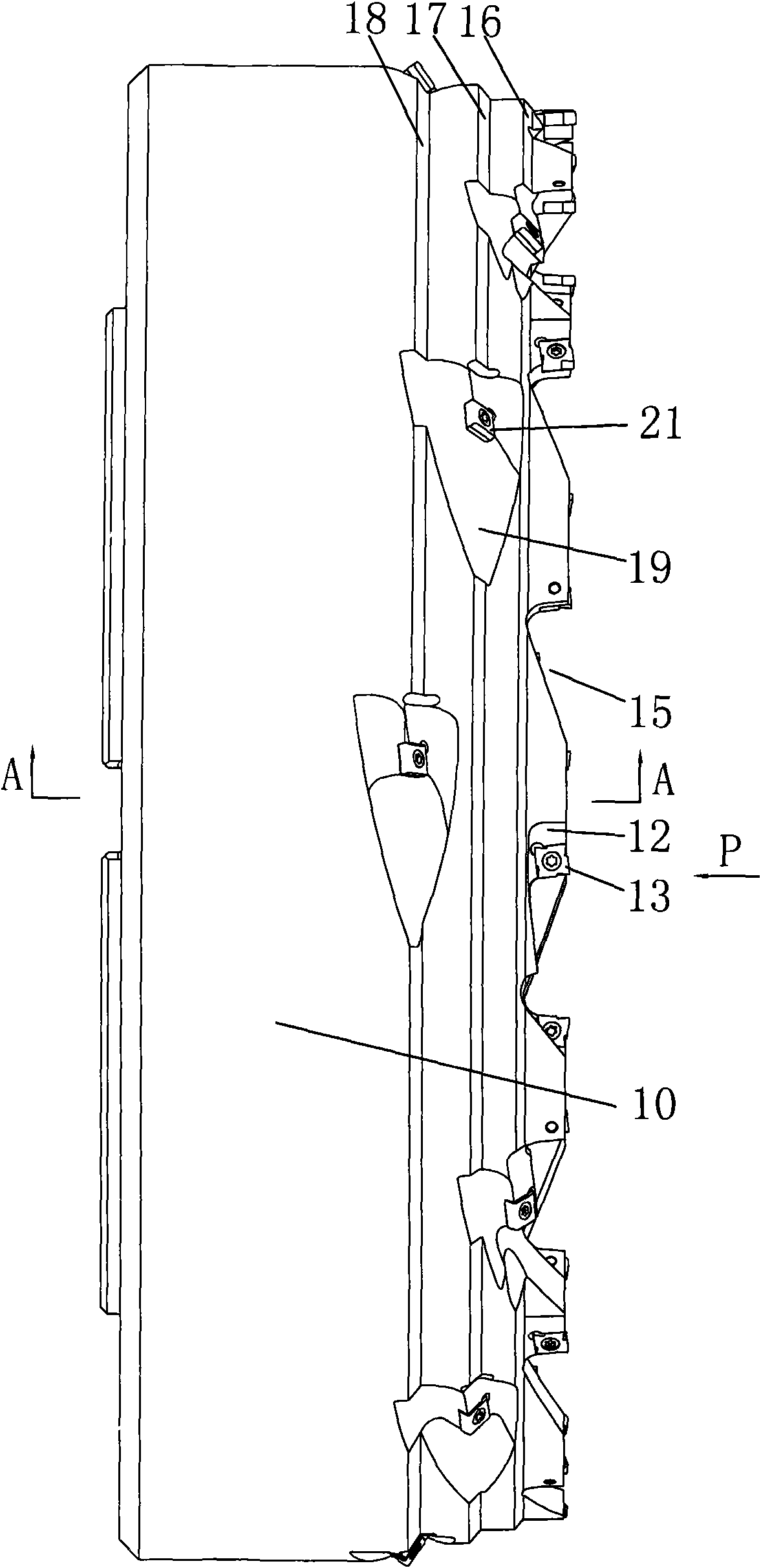

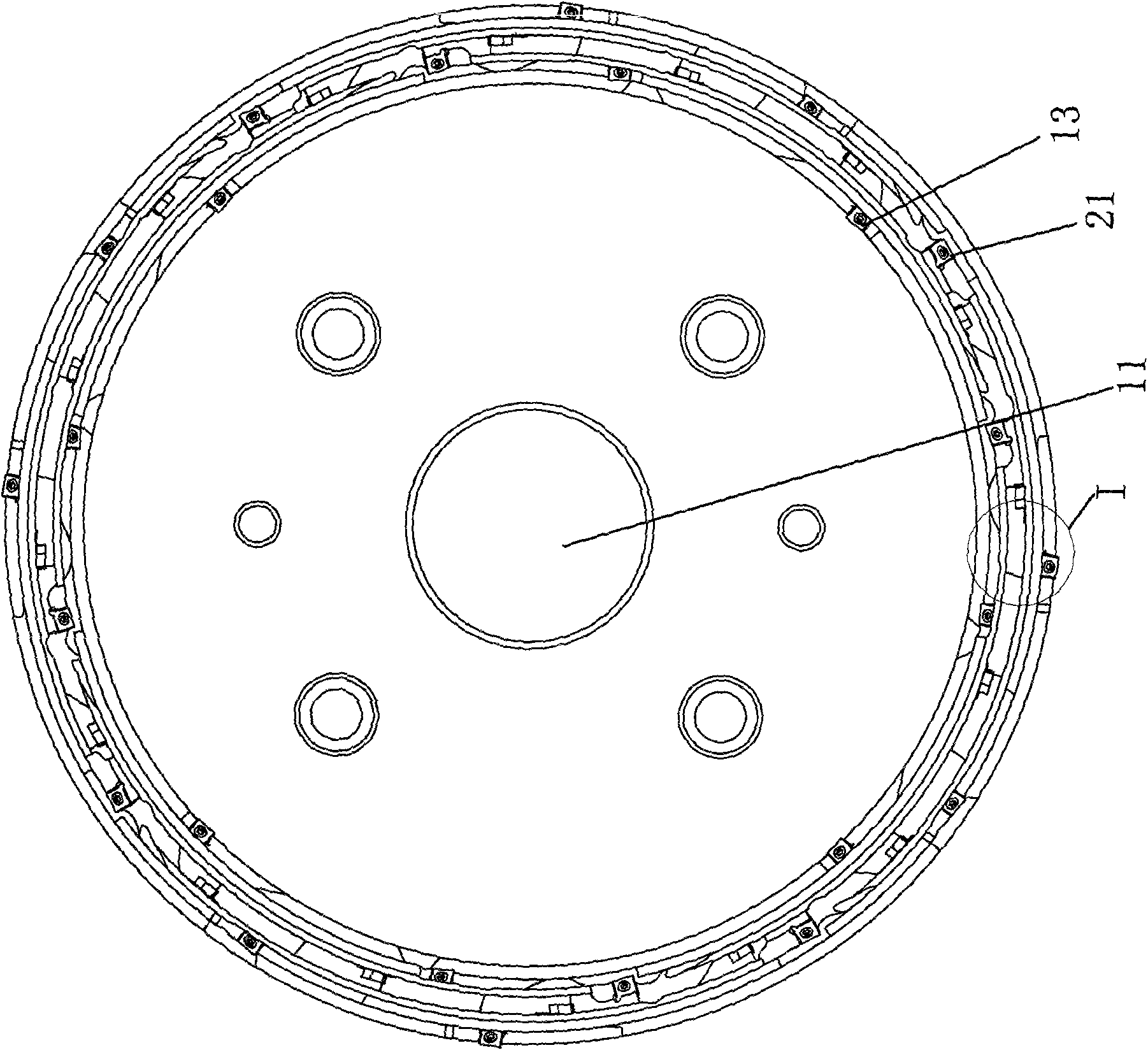

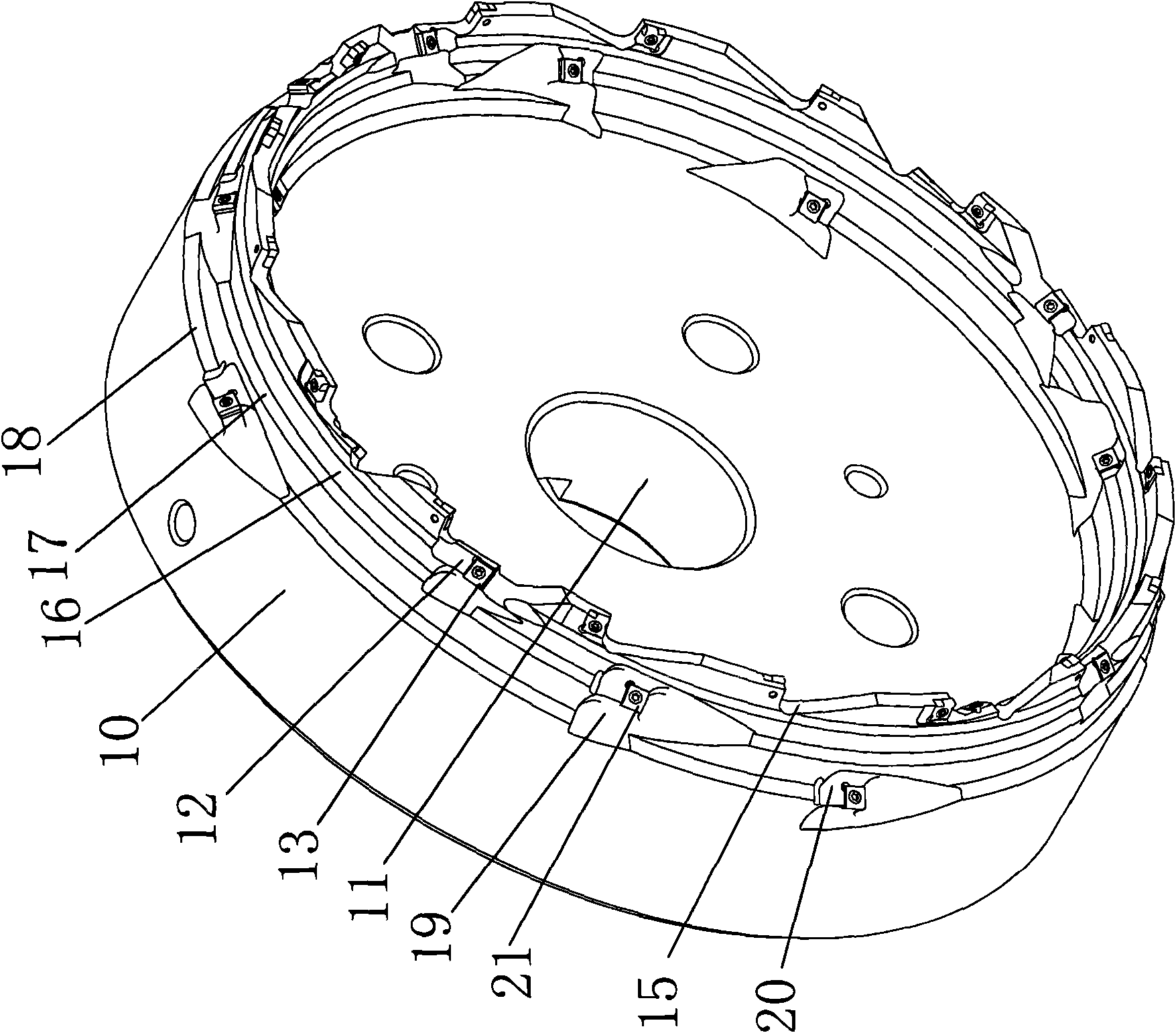

[0034] refer to Figure 1 to Figure 7 , The steam turbine rotor blade root arc groove rough milling cutter of the present invention includes a cylindrical cutter body 10, and the center of the cutter body is provided with a shaft hole 11 for installing a rotating shaft. A plurality of blade holders 12 with notches are arranged at intervals on the same circumference of the upper end surface of the cutter body, each blade holder 12 is an extension body from the upper end surface of the cutter body, and two blade holders are separated by arc-shaped chip removal grooves 15, so that the blade seats are arranged at intervals. A face cutting blade 13 is fixed in the notch of each blade seat 12, and the end face cutting blade 13 is fixed on the blade seat 12 by screws, and the end face cutting blade 13 on the blade seat 12 is parallel to the cutter bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com