Chrome copper alloy, preparation method and application

A chrome-copper alloy and alloy technology, applied in the field of chrome-copper alloy and its preparation, can solve problems such as difficulty in punching through holes, low production yield, broken drill bits and damaged billets, etc., so as to improve quality and production feasibility, High hardness, the effect of reducing cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

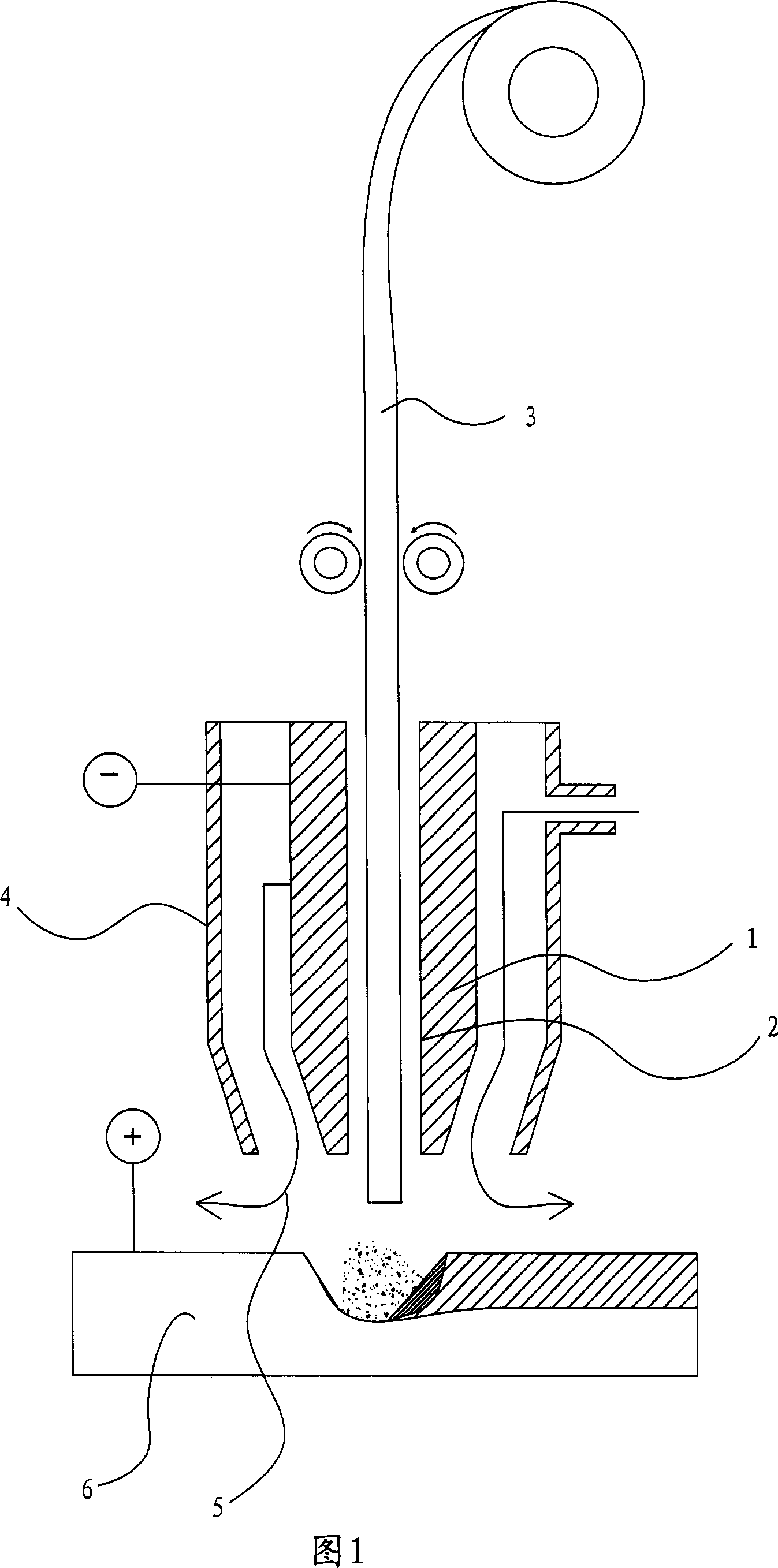

Method used

Image

Examples

Embodiment Construction

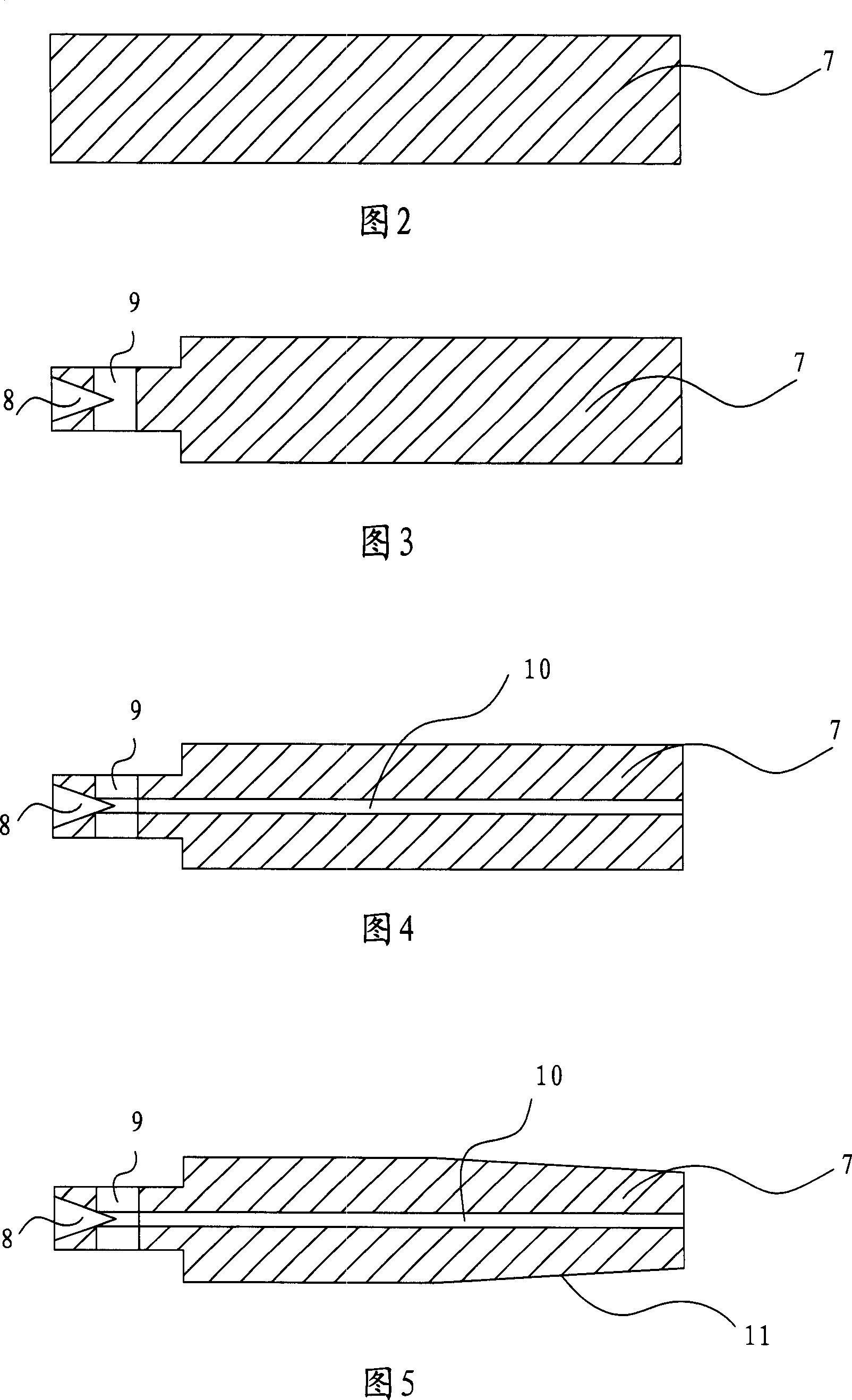

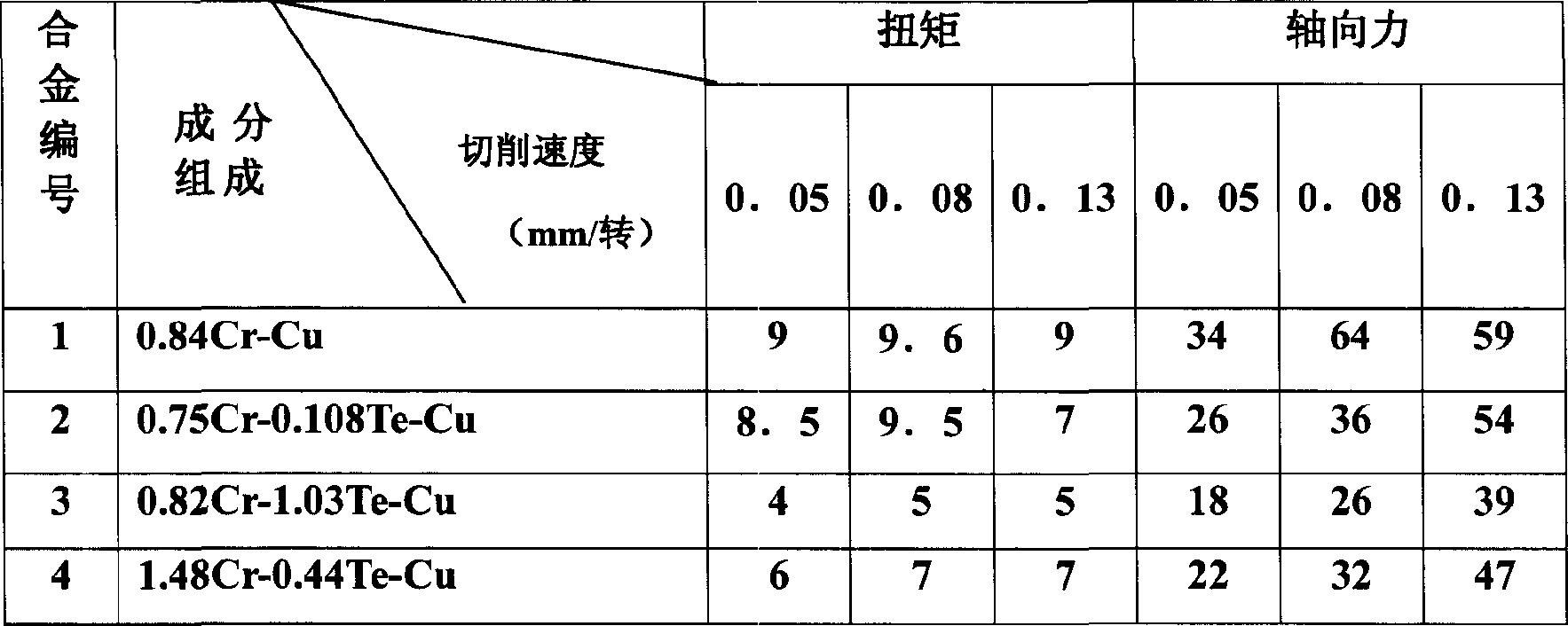

[0025] The inventors used the chromium copper (Cr: 0.84% by weight) used in the original contact tip and the invented product to form the four test samples in Table 1. First, 4 kinds of billets of test samples were cast and hot-extruded into rods with a diameter of 32 mm. Then, it was heat-retained at 960°C for about 1 hour for solution treatment, and stretched into a rod with a diameter of 25 mm and a length of 50 mm. After aging treatment at 455°C for about 3 hours, the desired sample is obtained. The HV hardness and electrical conductivity of the four samples after the aging treatment are shown in Table 1. The Te addition amount is in the range of 0.01-1.0% by weight, the electrical conductivity is slightly lower, and the HV hardness is slightly increased.

[0026] 【Table 1】

[0027] Alloy

serial number

Composition

HV hardness

1

0.84Cr-Cu

148

87

2

0.75Cr-0.108Te-Cu

151

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com