Patents

Literature

30results about How to "Reduced inhibitory strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid crystal display device

InactiveUS6111559AReduce power consumptionLow luminance of backlightTelevision system detailsColor television detailsLiquid-crystal displayComputer science

A liquid crystal display apparatus having an amplitude detecting unit for detecting an amplitude of a supplied video signal; a liquid crystal display for displaying an image on a main surface based on the video signal; a backlight for giving off light with a luminance which can be freely set from the back surface of the liquid crystal display to the main surface; and a luminance setting unit for variably setting the luminance of the backlight based on the amplitude detected by the amplitude detecting unit.

Owner:SONY CORP

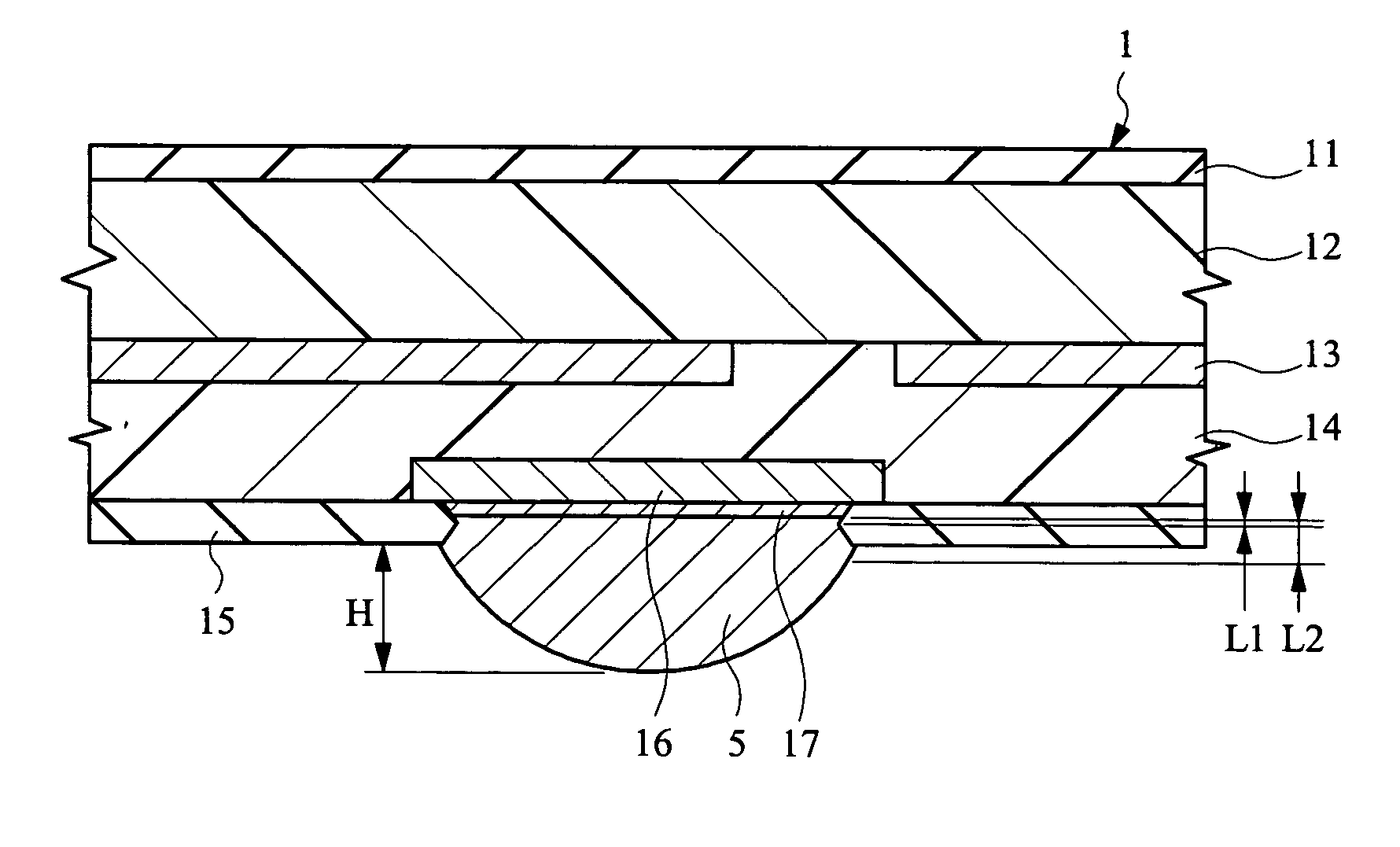

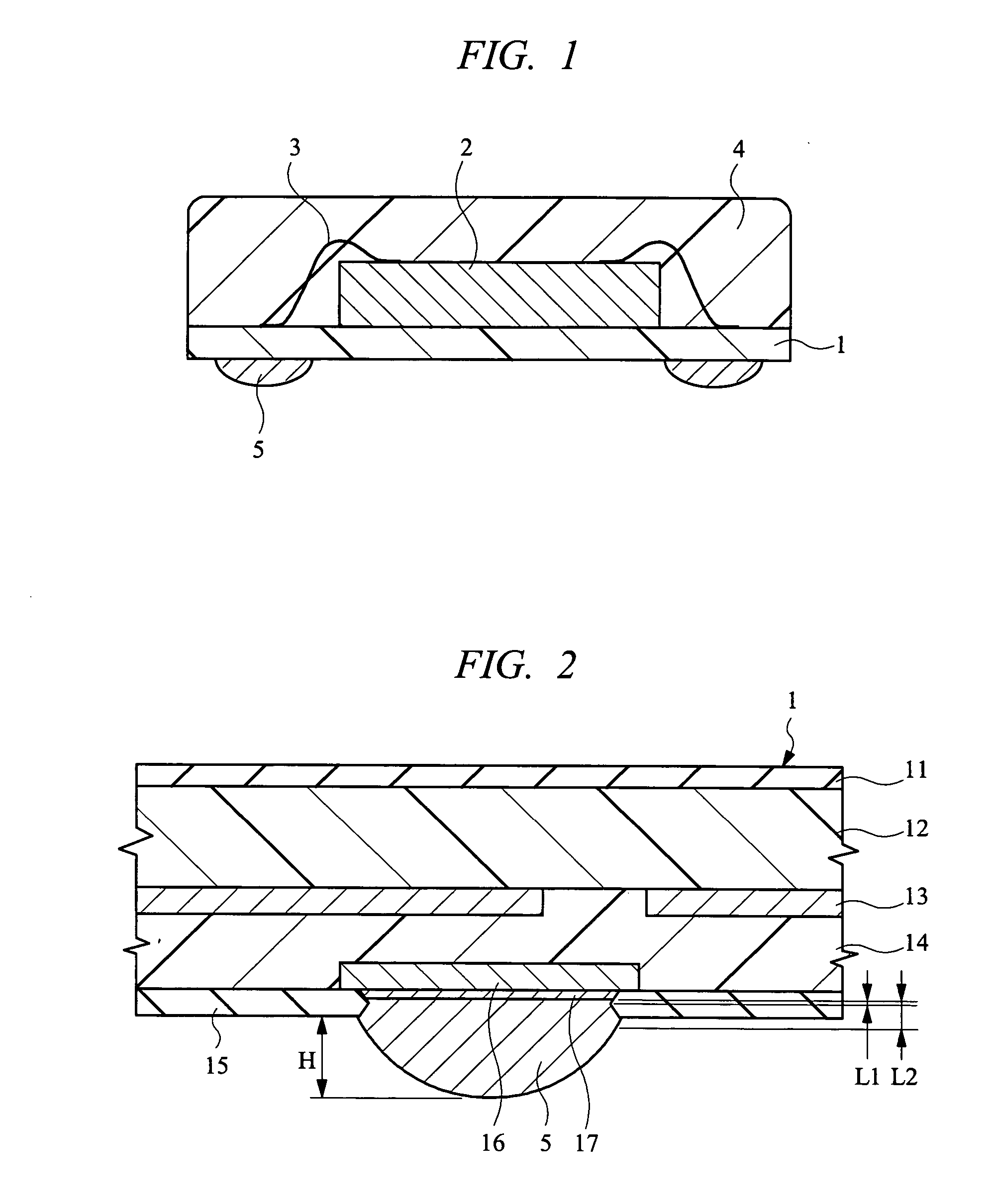

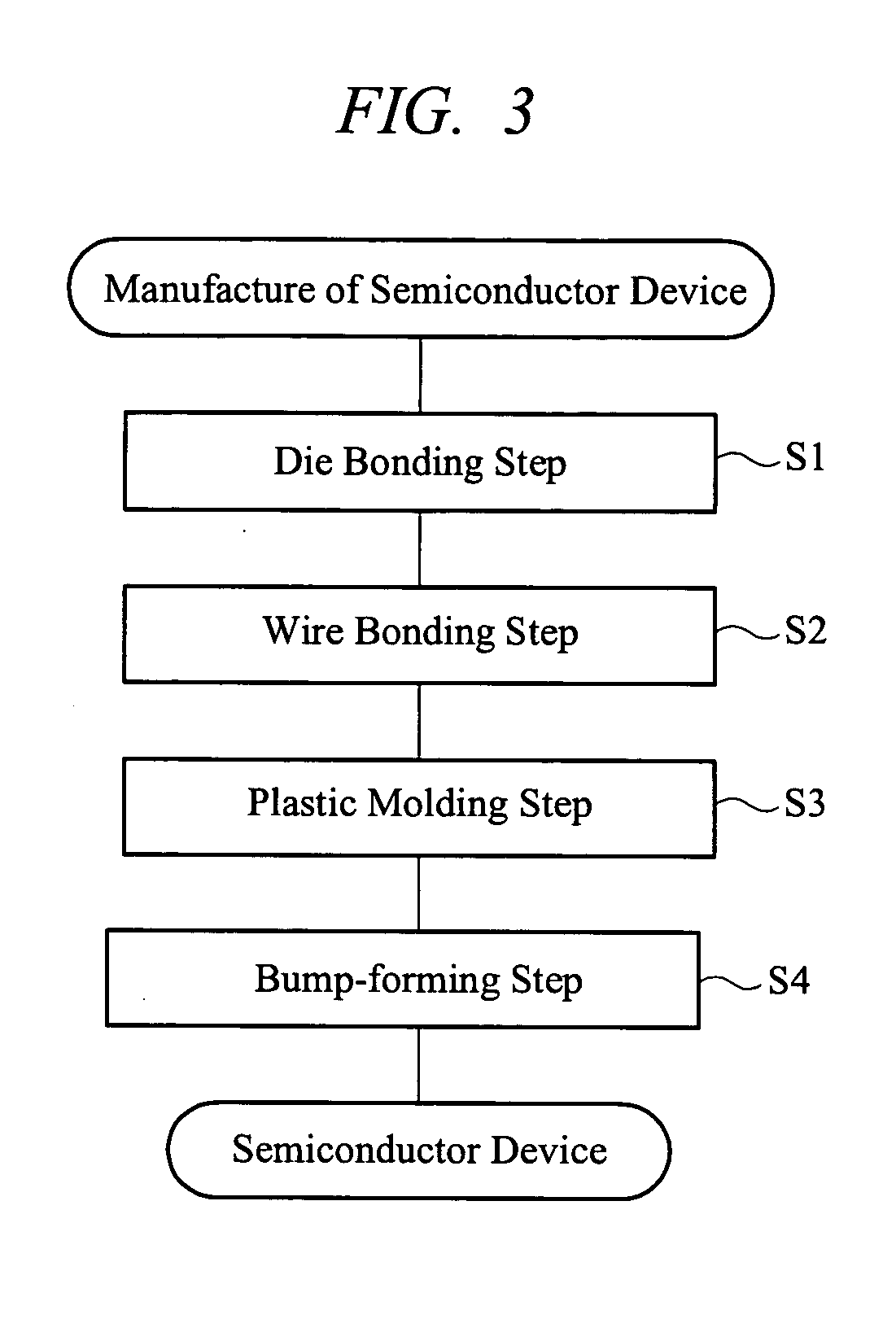

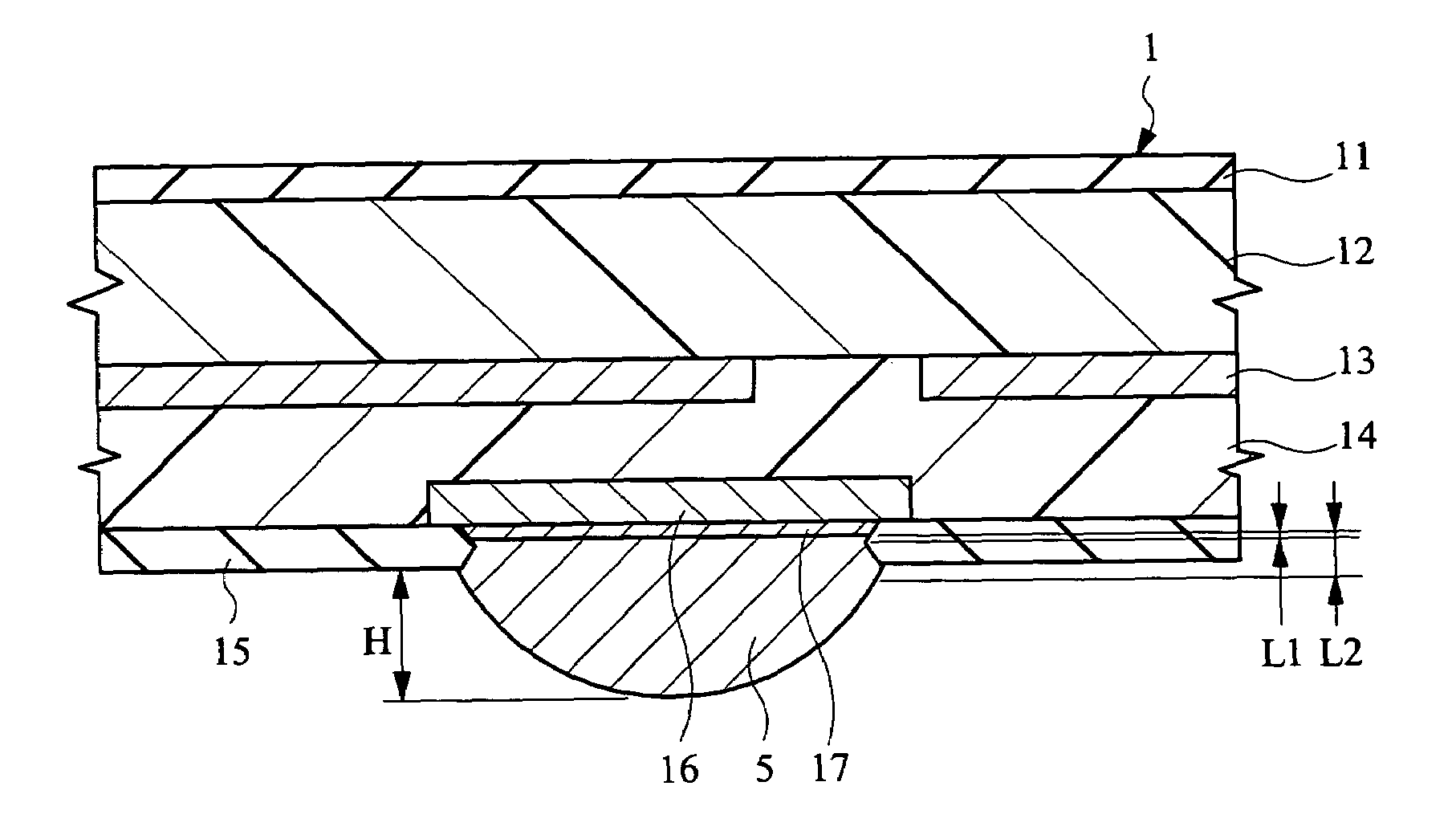

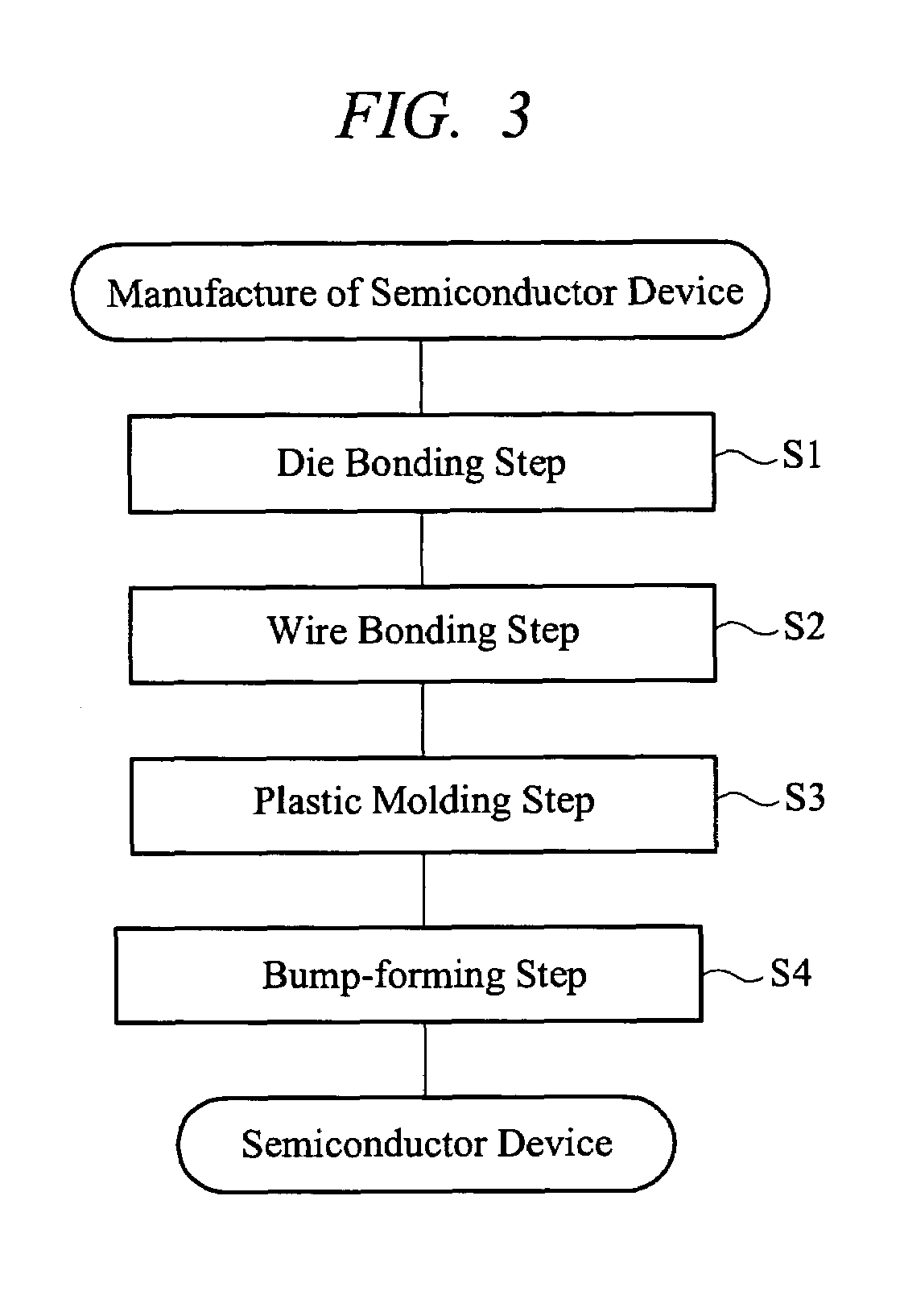

Semiconductor device and manufacturing method thereof

InactiveUS20060151877A1Inhibit reduction of strengthImprove thermal fatigue lifePrinted circuit assemblingSemiconductor/solid-state device detailsDevice materialCombined use

In order to inhibit the connection failure due to the degradation of the connection interface strength of the electrode pad and the warp thereof in the semiconductor device having an electrode pad, a metal layer formed on the electrode pad, and a metal bump formed on the metal layer, in the present invention, gold (Au) is contained in the metal layer, the metal bump is made of solder mainly made of Sn and designed to have an average height H of 100 μm or less per unit area in the electrode pad, and the concentration of Au of the metal layer dissolved in the solder is set to 1.3×10−3 (Vol %) or less. More preferably, the metal bump contains palladium (Pd), and the solder coating for forming the metal bump on the electrode pad is performed by using the dipping and the paste printing in combination.

Owner:RENESAS ELECTRONICS CORP

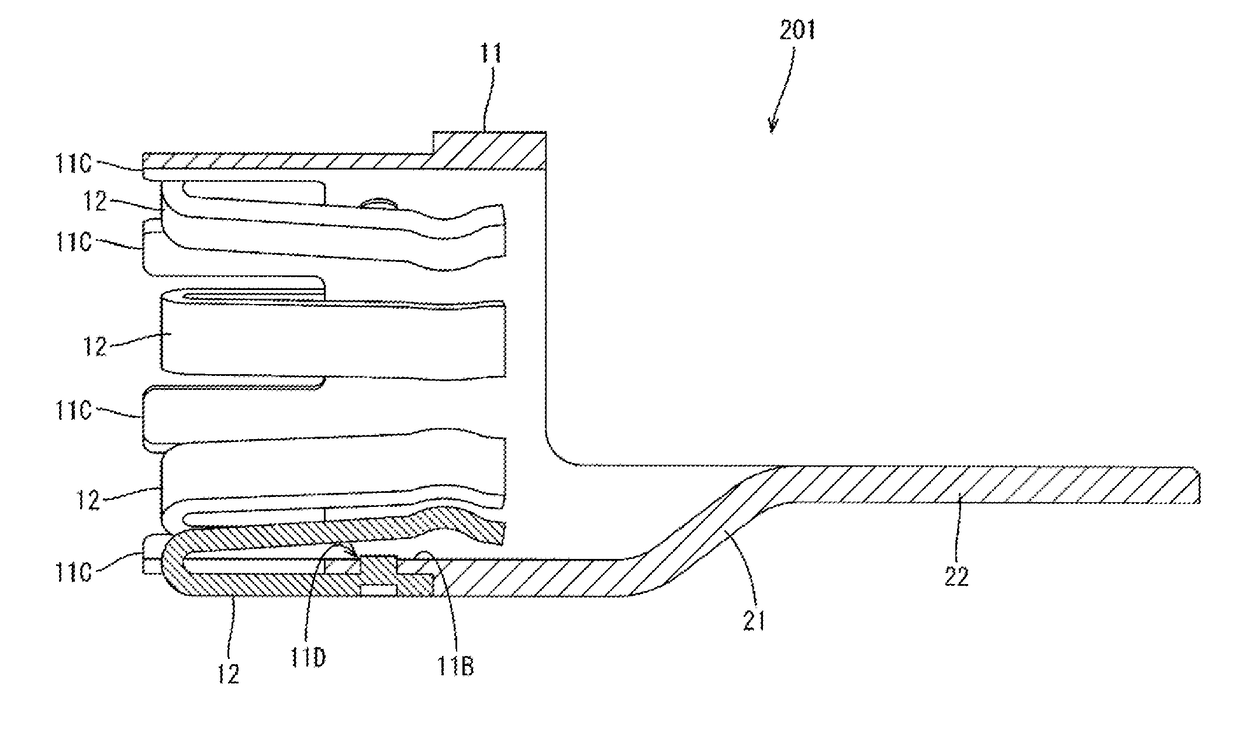

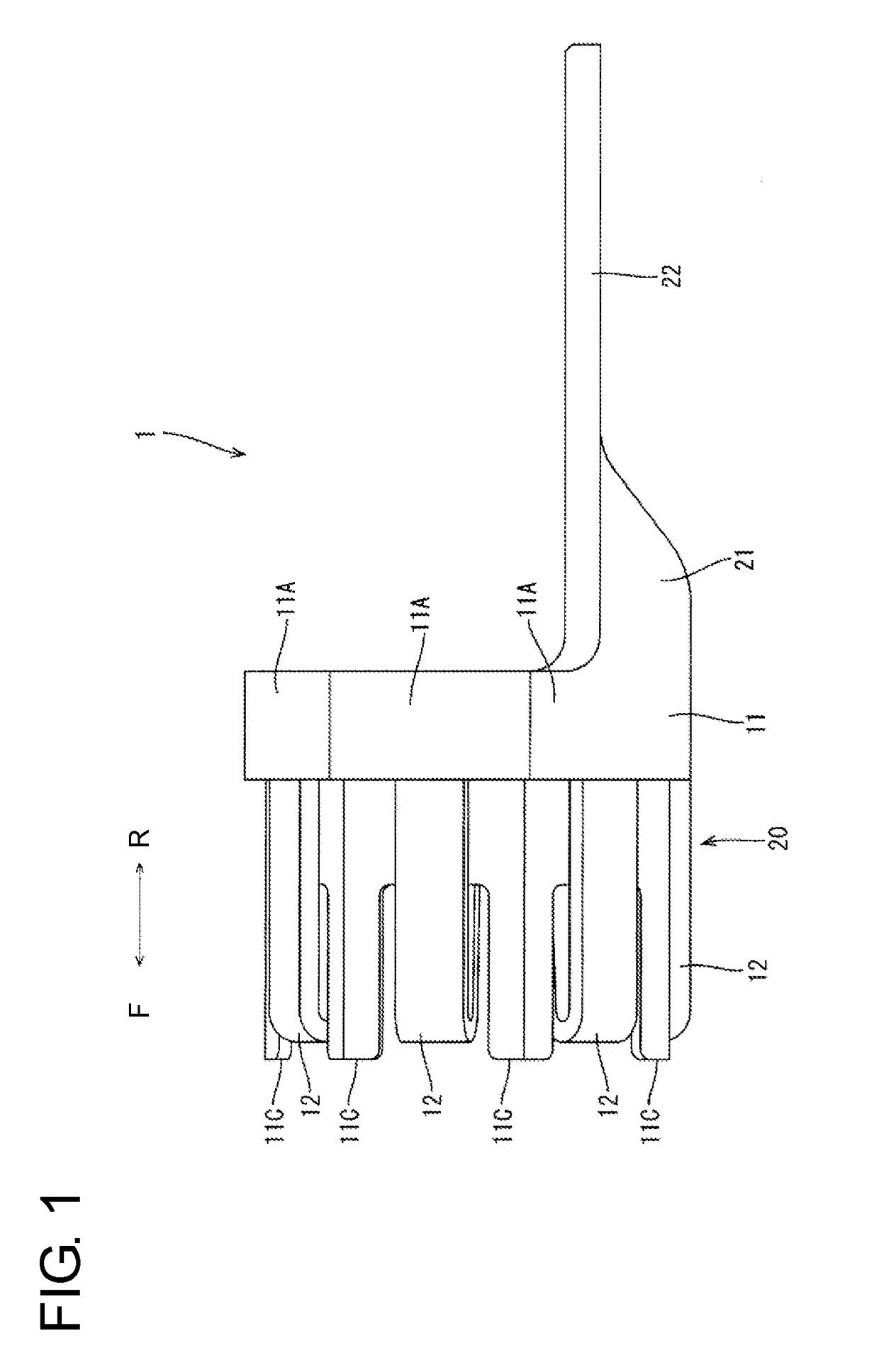

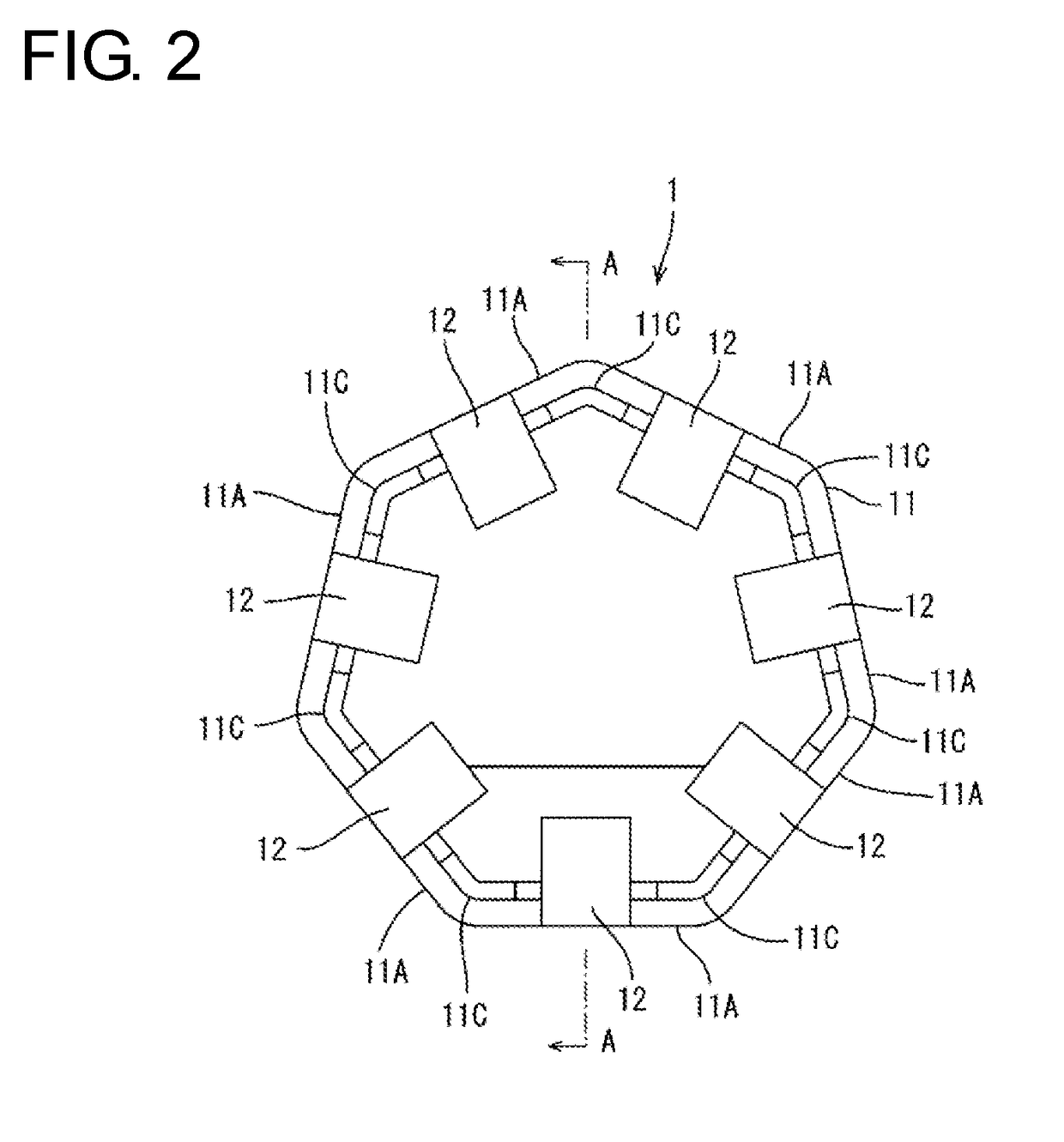

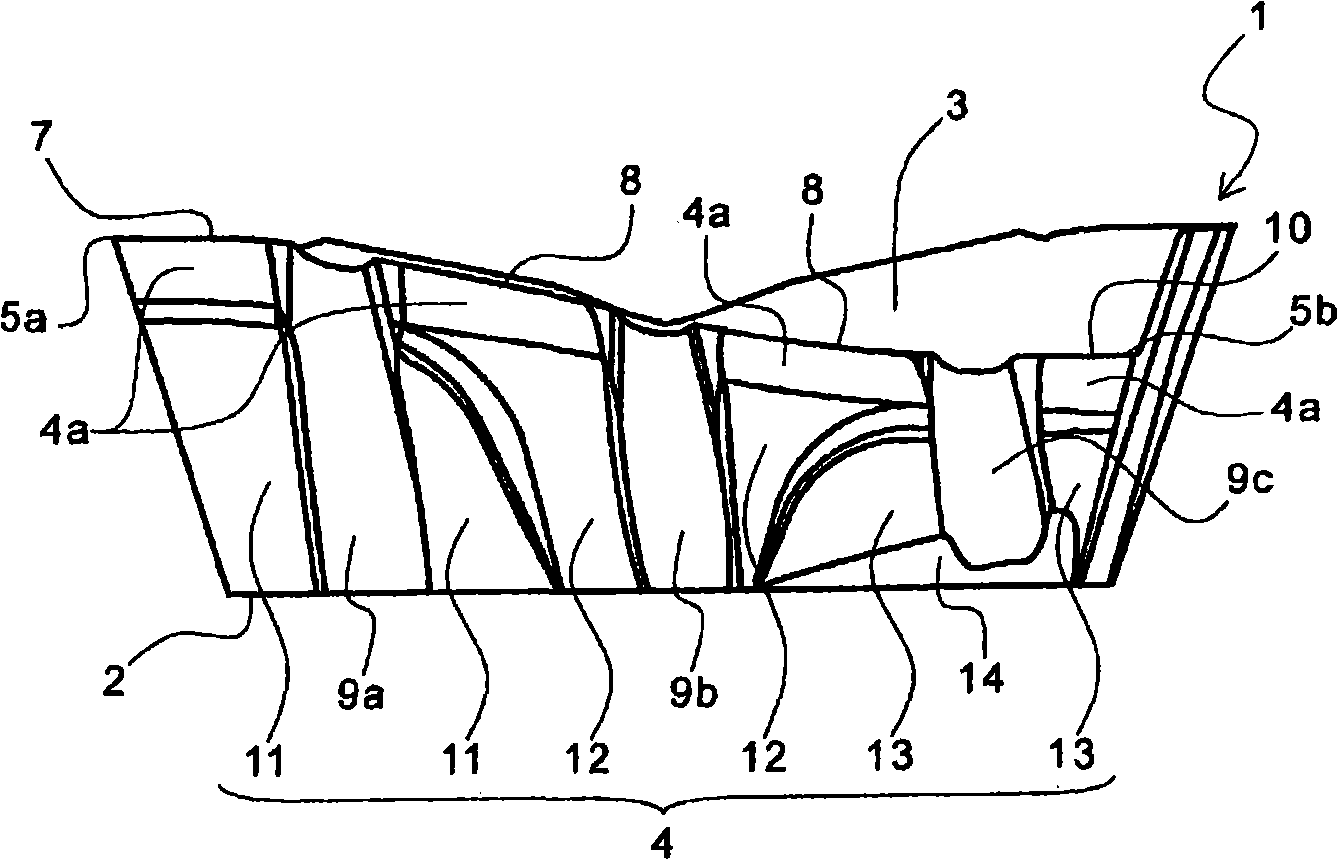

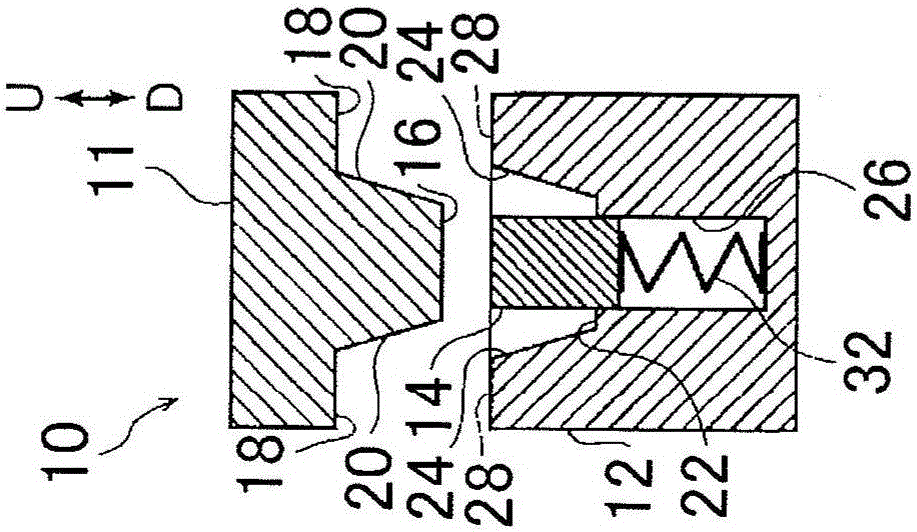

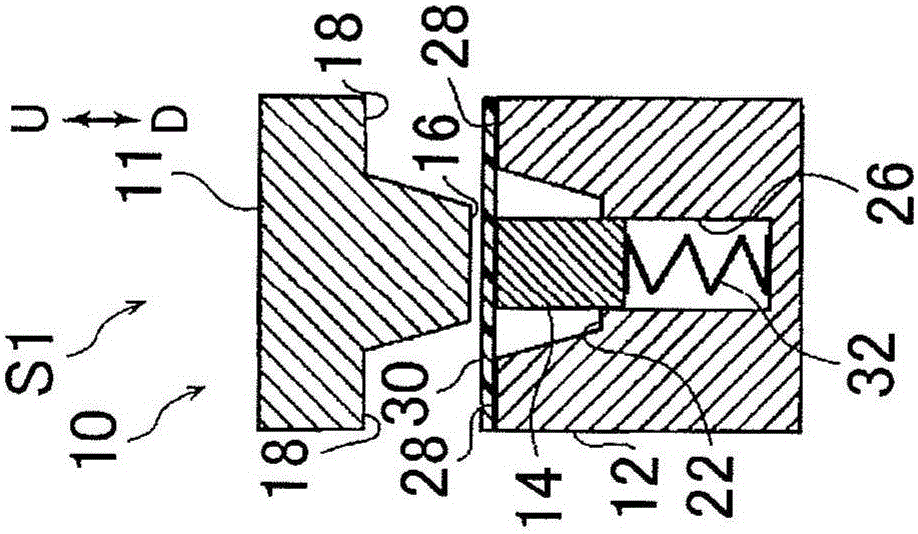

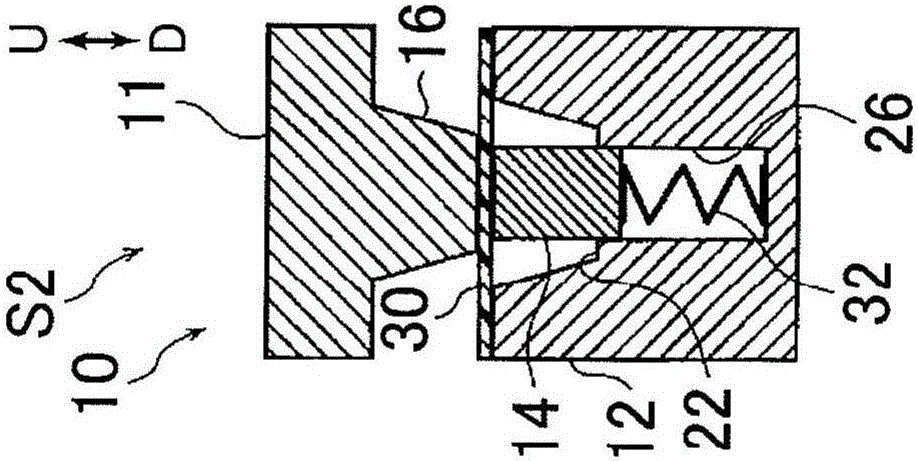

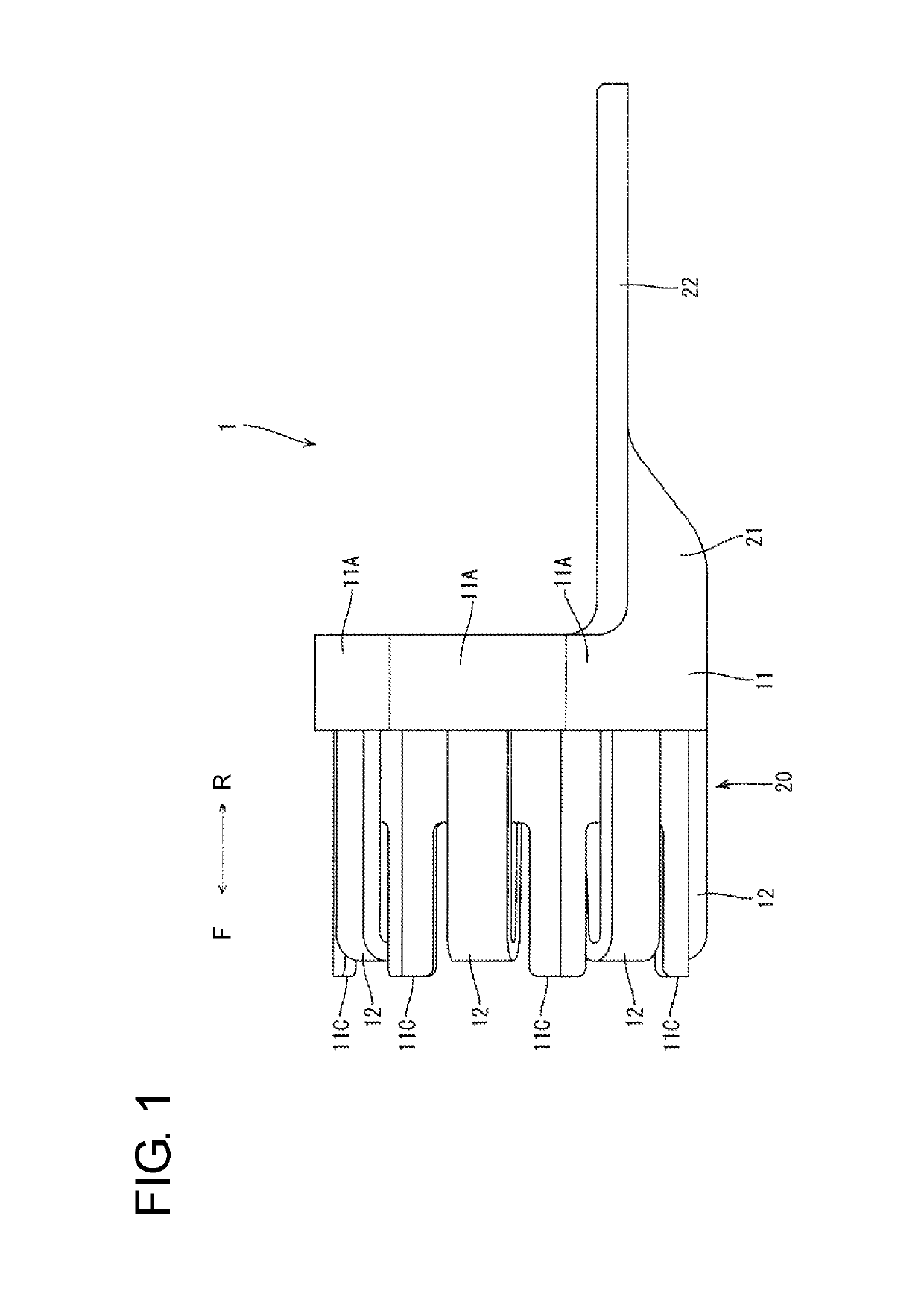

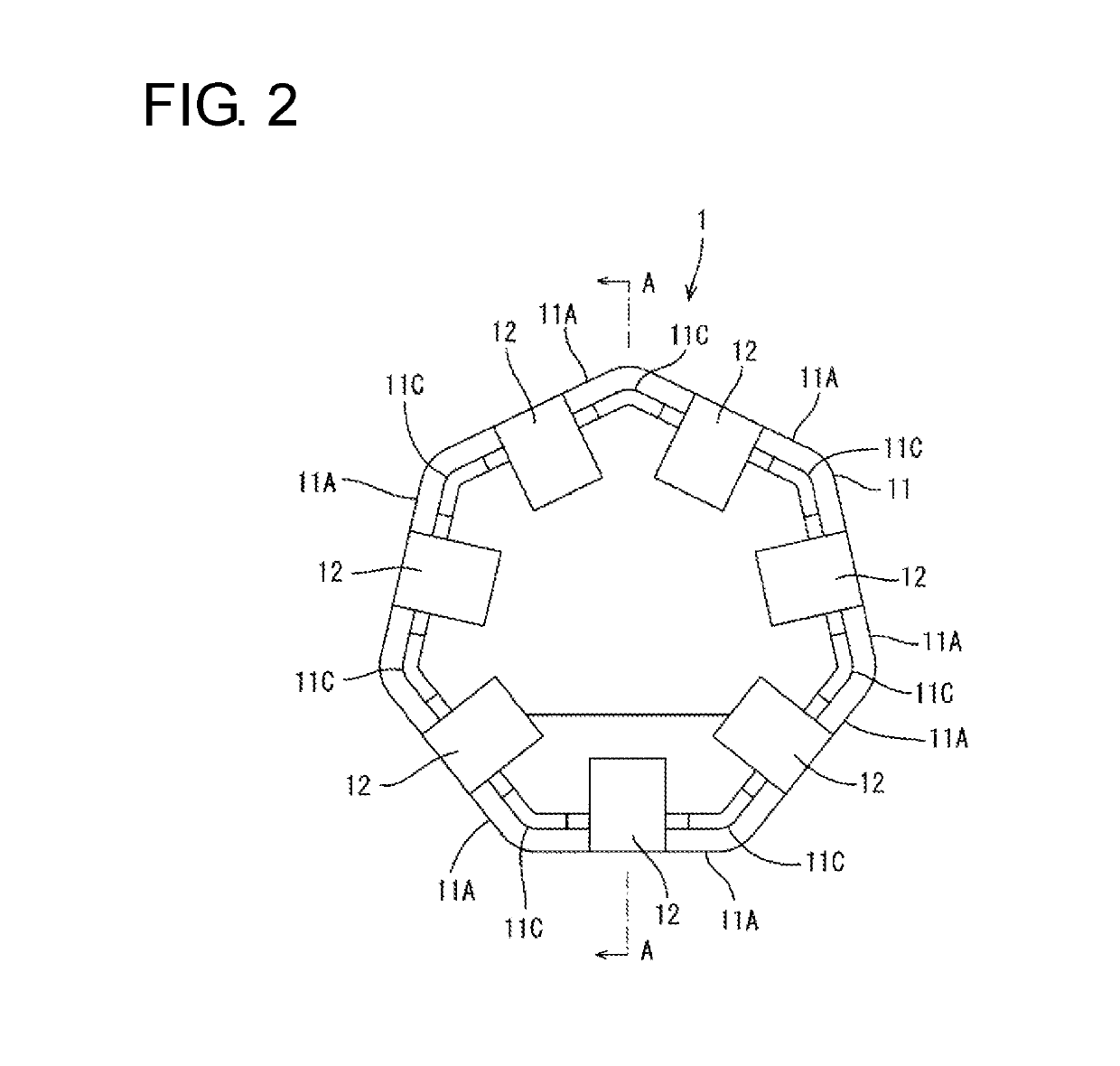

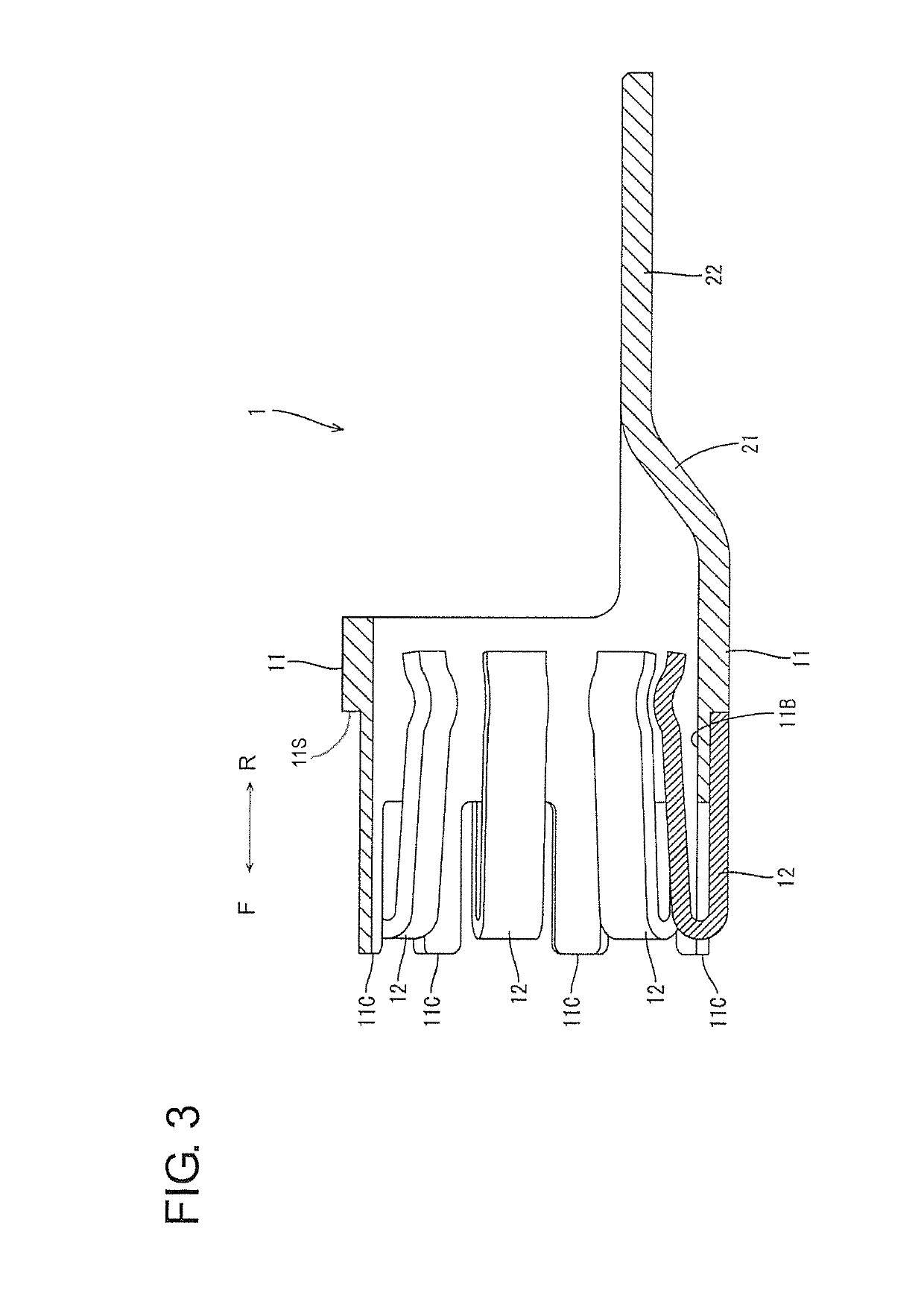

Method for manufacturing female terminal and female terminal

InactiveUS20180090900A1Reduced strengthLow costContact member manufacturingCoupling contact membersEngineeringMetal

A method for manufacturing a female terminal (1) with a tubular portion (11) formed by bending a metal plate into a tubular shape and resilient contact pieces (12) extending from the tubular portion (11) in an axial direction of the tubular portion (11), folded inwardly of the tubular portion (11) and configured to resiliently contact a mating terminal inside the tubular portion (11) includes a joining step of joining metal members thinner than the metal plate to the metal plate, and a forming step of bending the metal members joined to the metal plate and forming the metal members as the resilient contact pieces.

Owner:AUTONETWORKS TECH LTD +2

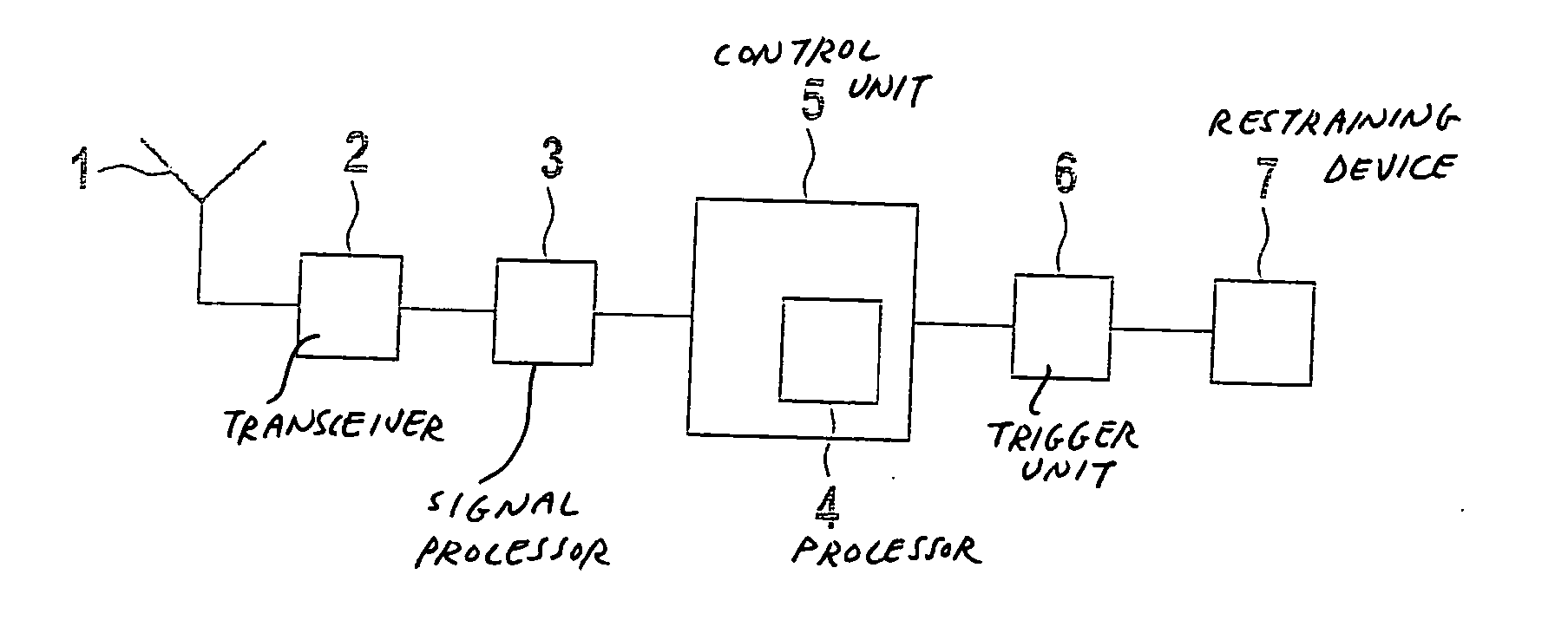

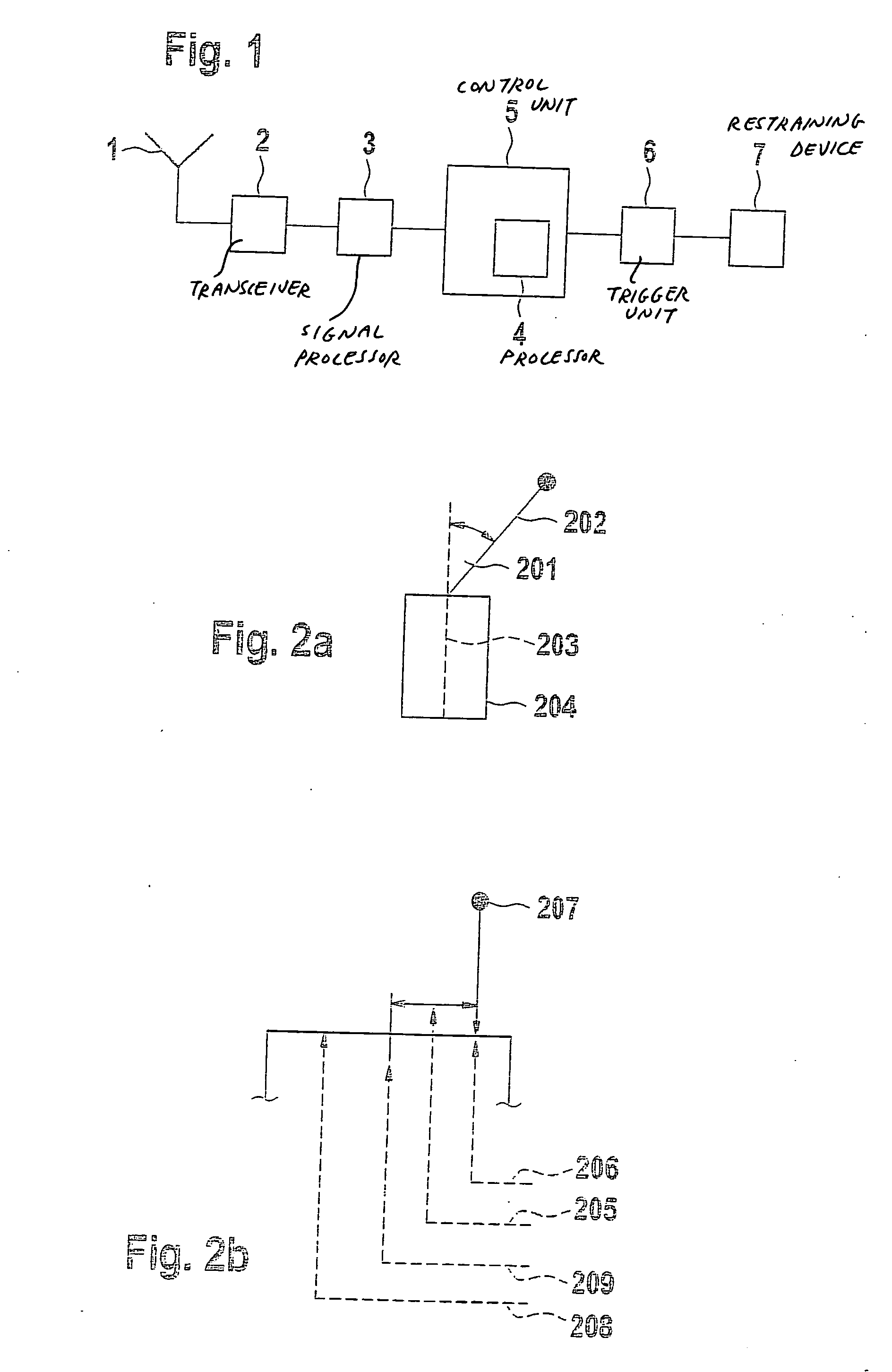

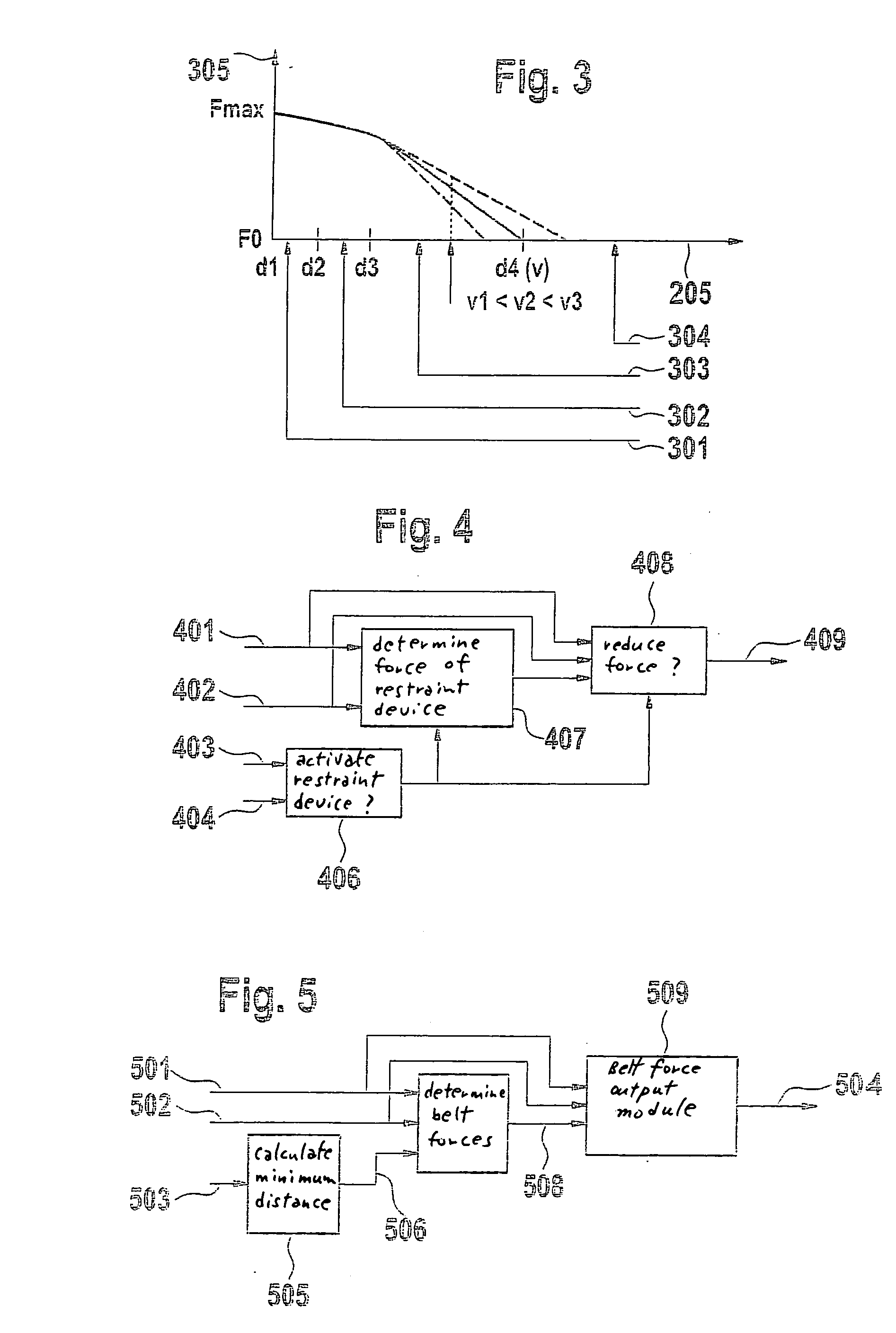

Method and device for actuating a restraining means in a vehicle

InactiveUS20050252708A1Little strengthEasy to wearBelt retractorsPedestrian/occupant safety arrangementEngineeringCollision probability

A method and a device for triggering a restraining device in a vehicle are provided. At least one parameter that is representative of the probability of a collision of the vehicle with an obstacle is determined and the restraining device is triggered when such a collision probability is recognized. The intensity of the triggering of the restraining device is a function of the value of the at least one parameter.

Owner:ROBERT BOSCH GMBH

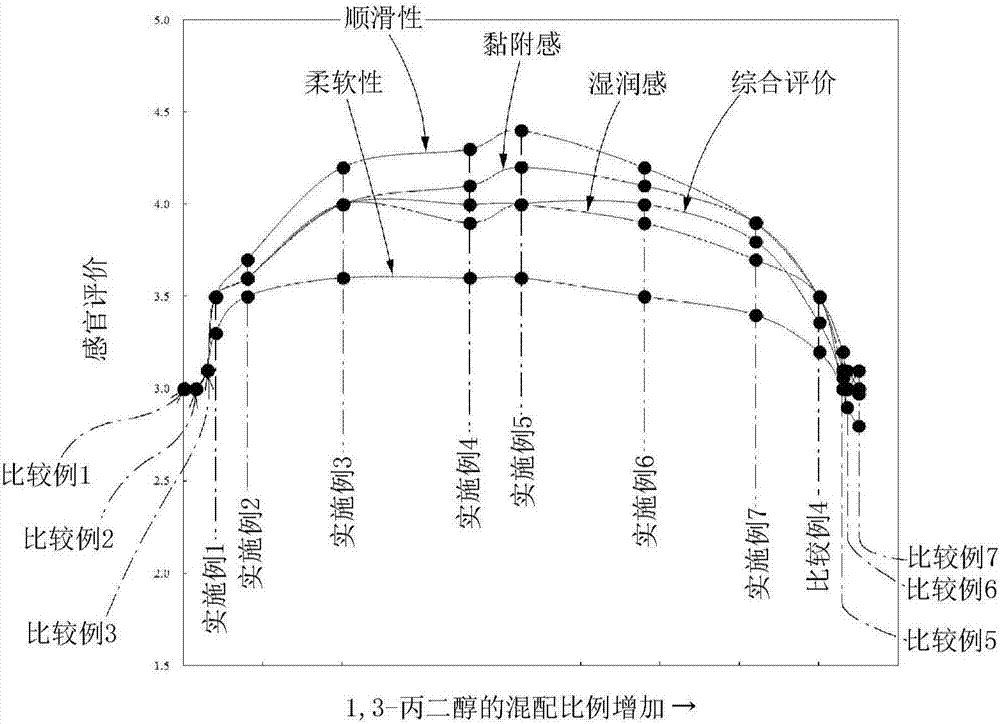

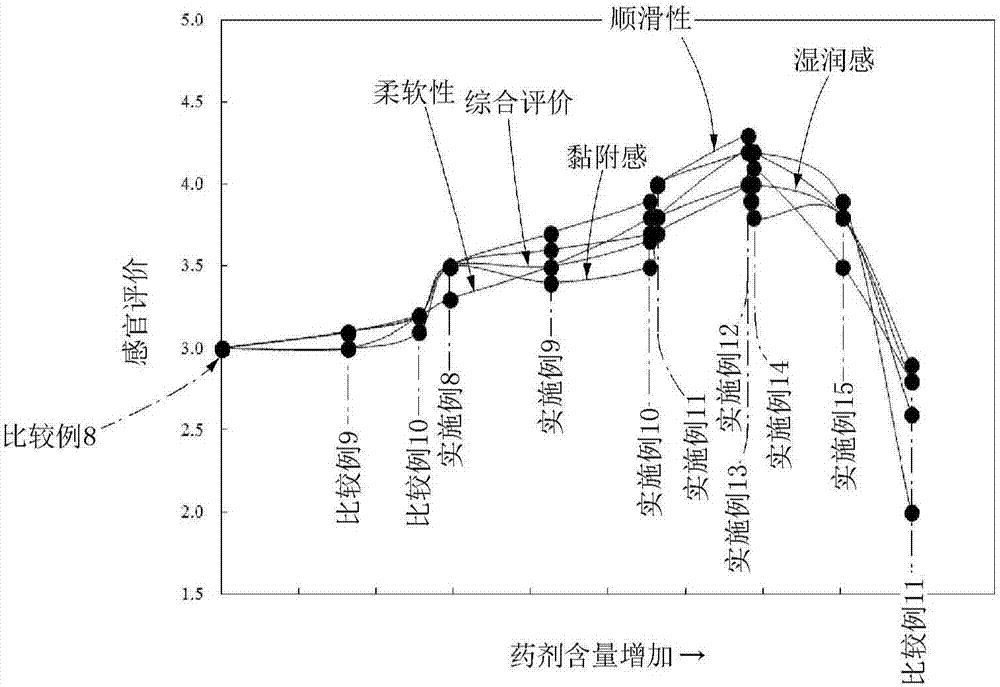

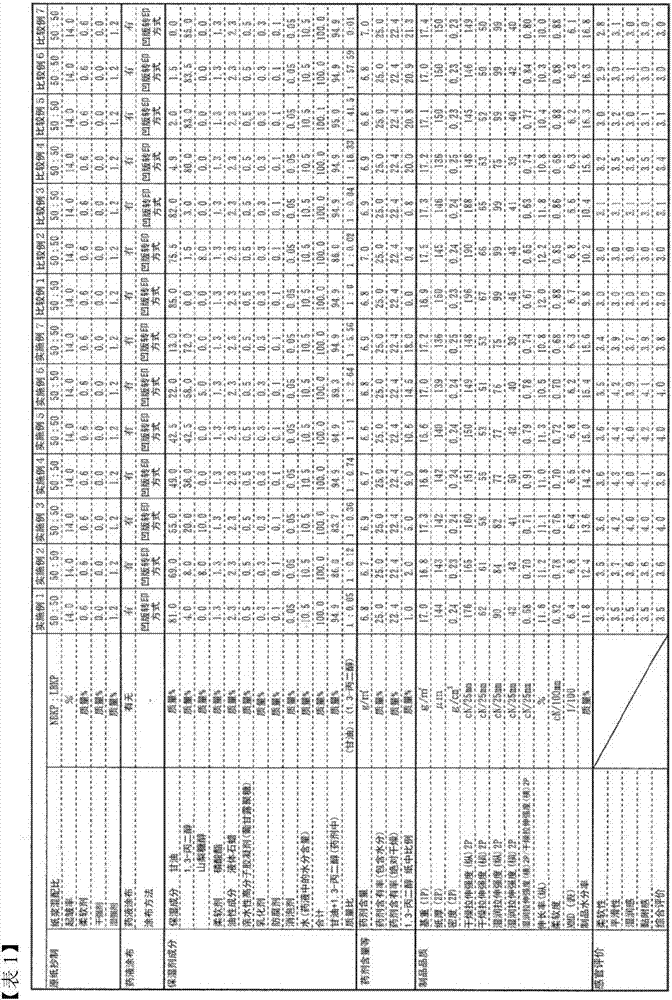

Tissue paper

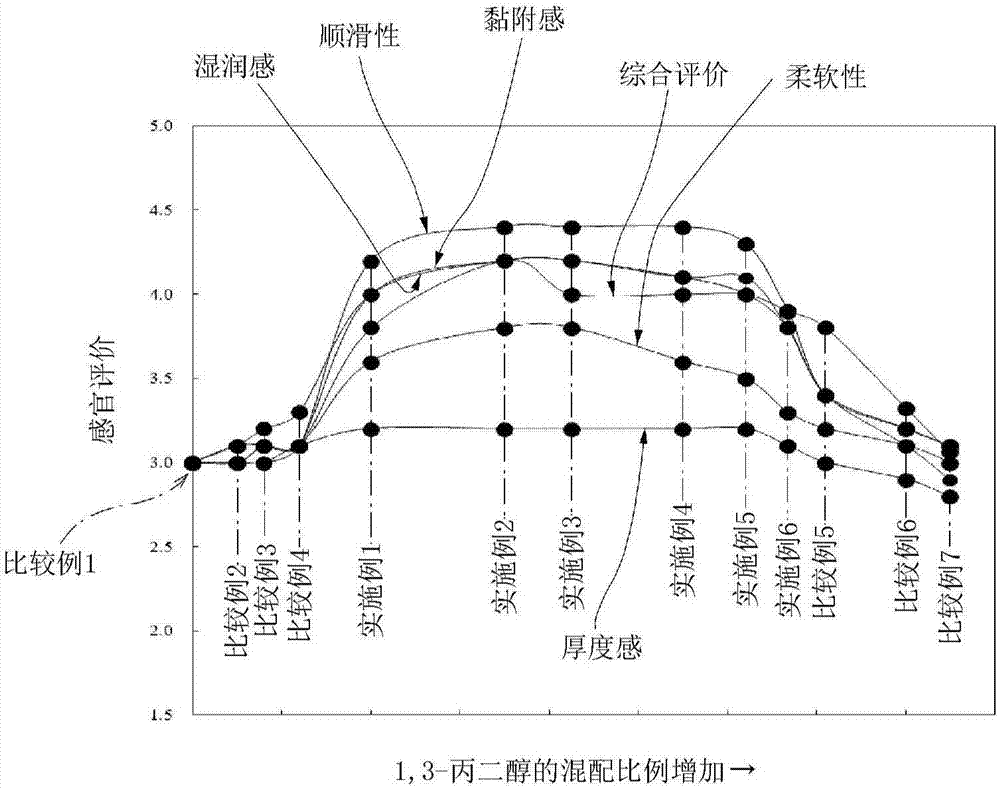

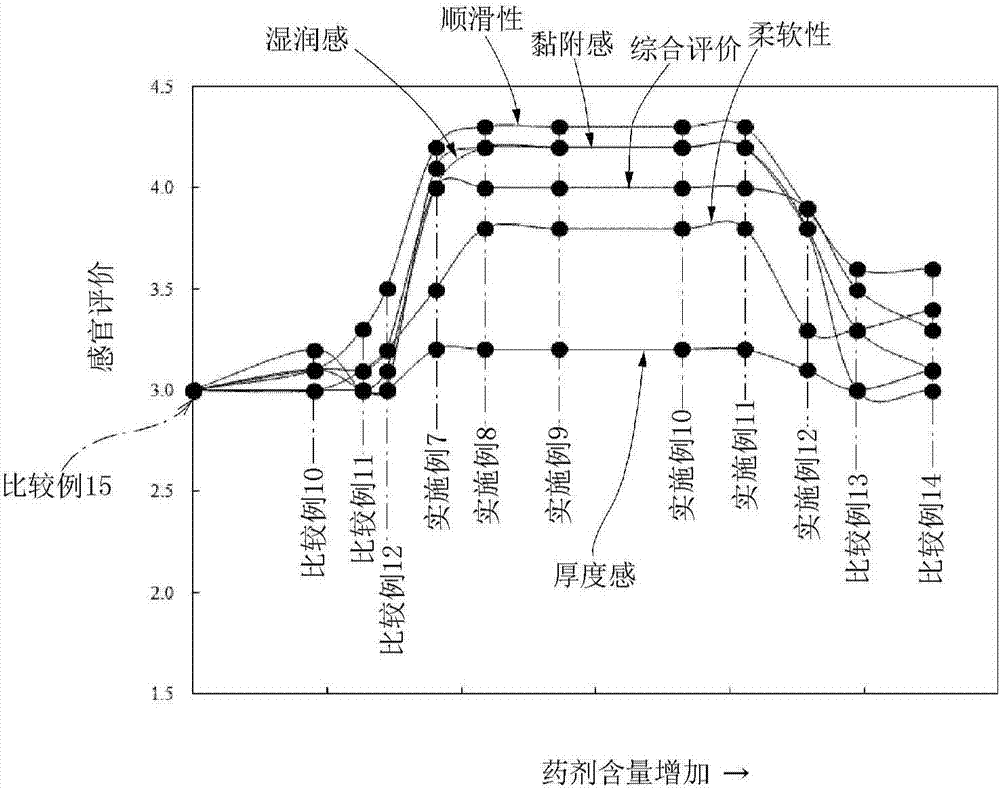

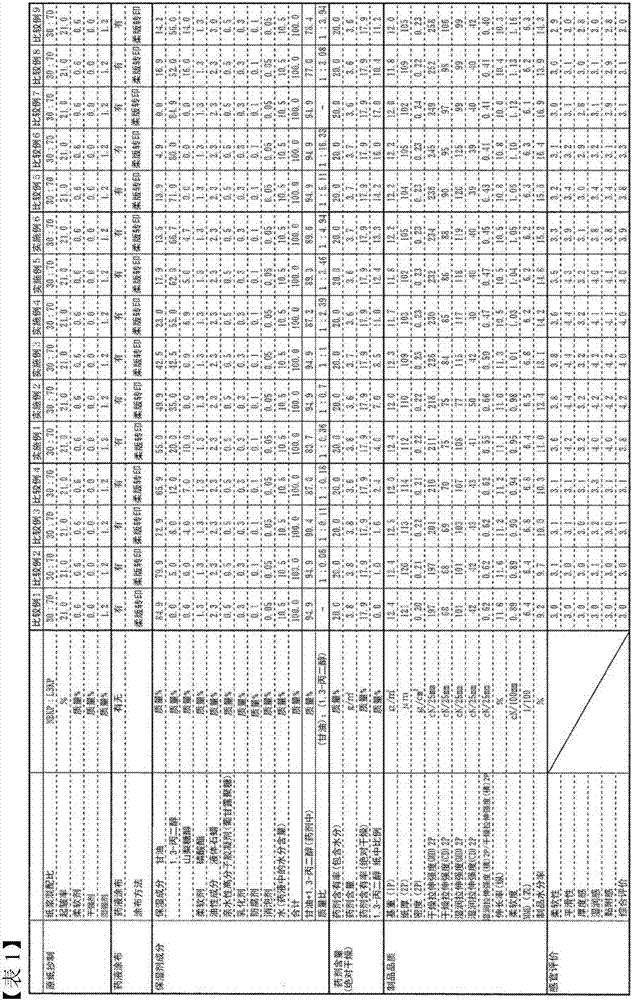

ActiveCN107105947AHigh "flexibility"Excellent moistureCosmetic preparationsToilet preparationsGlycerolPropanediol

To provide a tissue paper having excellent moistness and high smoothness. A two-ply tissue paper characterized by: the basis weight per ply being 15-18 g / m<2>; the two-ply paper thickness being 135-160 [mu]m; and containing 2.9-8.0 g / m<2> inclusive of a chemical which contains glycerol and 1,3-propanediol in a total amount of 83.7 mass% or more and in which the ratio by mass of glycerol to 1,3-propanediol is higher than 1:0.04 and not higher than 1:5.58.

Owner:DAIO PAPER CORP

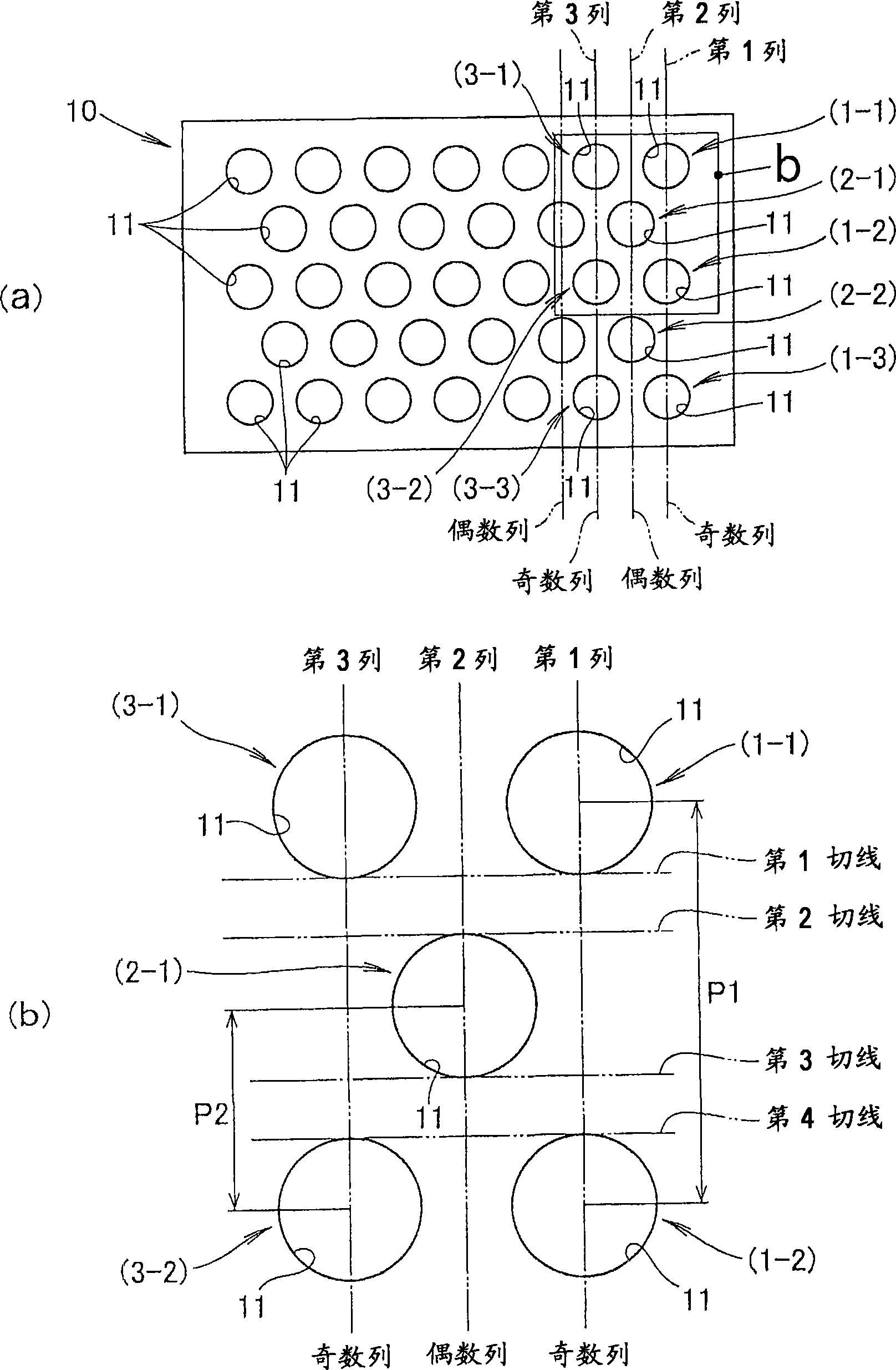

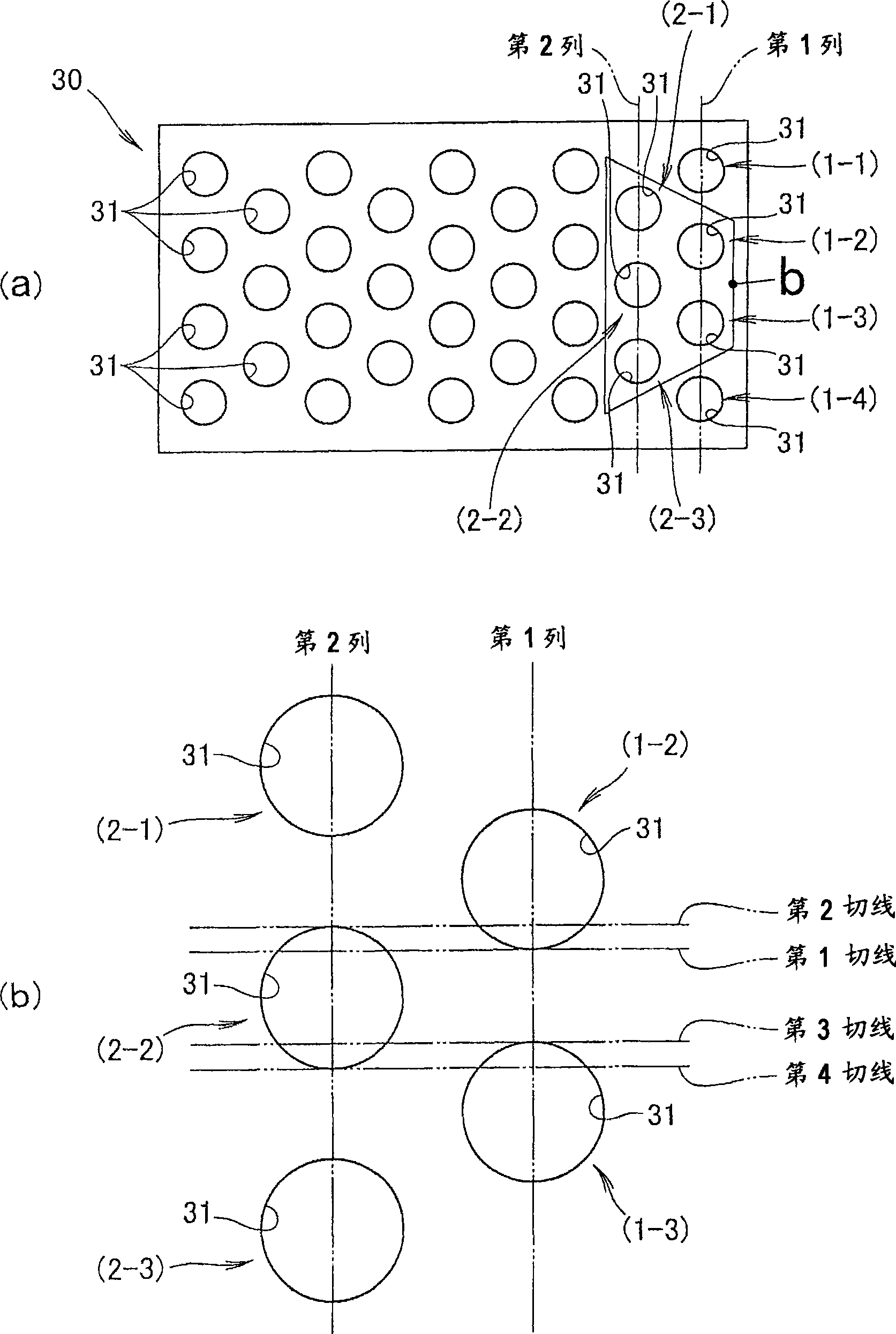

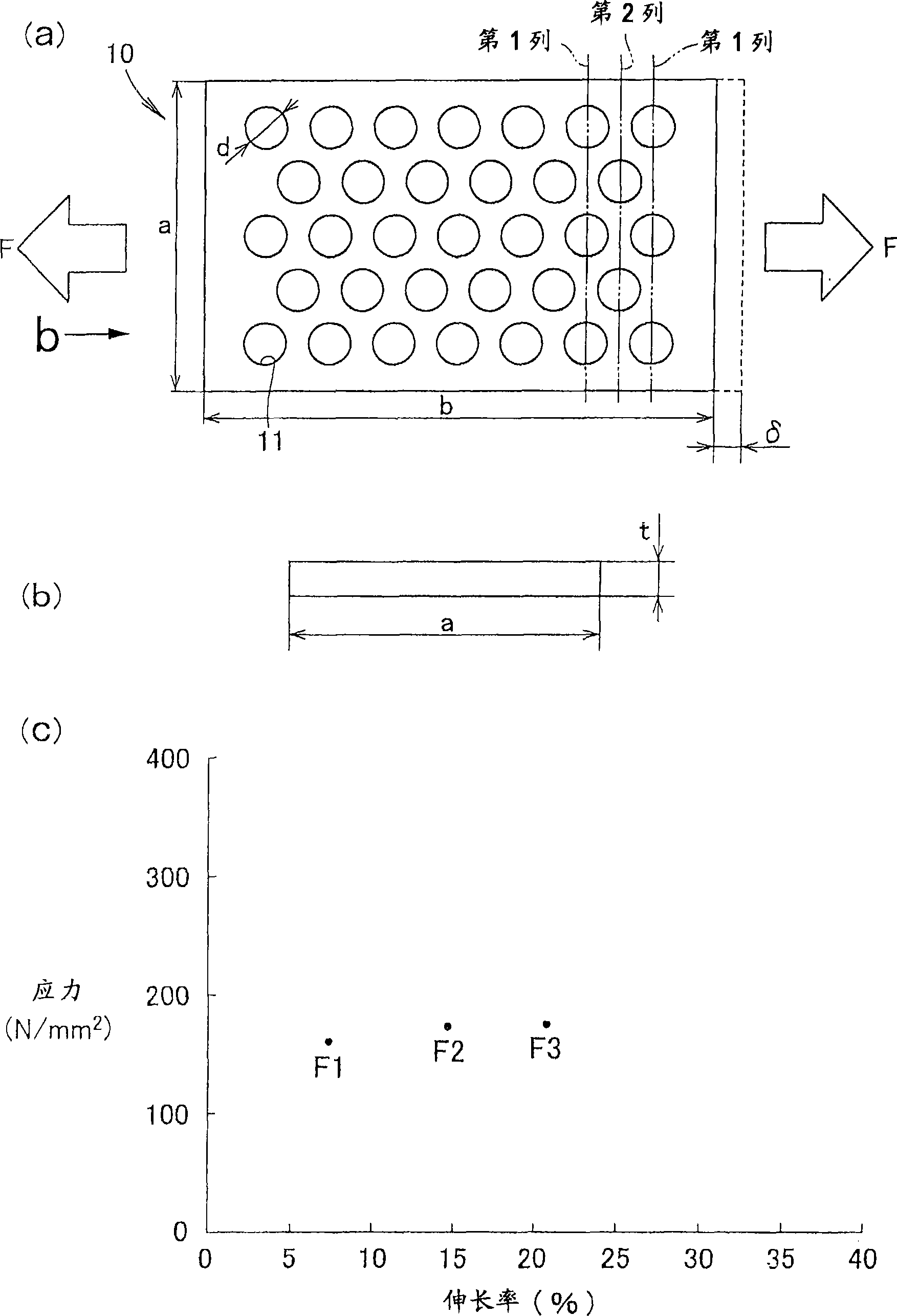

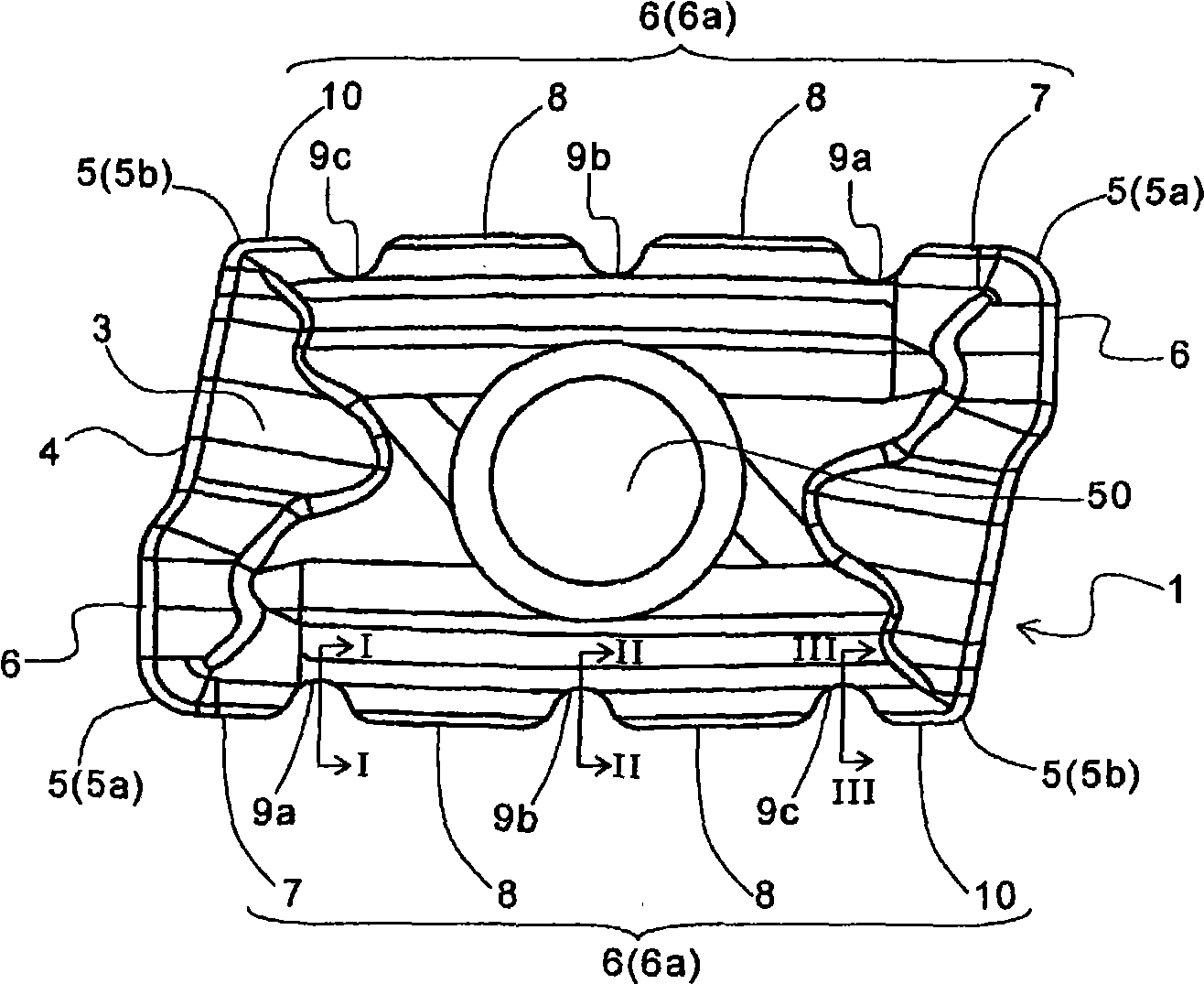

Perforated plate, punch thereof and plastic working method and prediction method of mechanical behavior value

InactiveCN101423071AReduced inhibitory strengthReduce weightUnderstructuresStructural/machines measurementPunchingBand shape

The present invention provides a perforated plate, a method for processing punching holes and a plastic working method for the perforated plate, as well as a method for predicting mechanical property value of tapping frames. The structure of the perforated plate is that in a sheet-shaped component with stretching force in a direction, multirow well group is configured in interleaving shape in thedirection, and two adjacent rows are separated with each other through a belt-shaped portion with a prescribed width.

Owner:HONDA MOTOR CO LTD

Cutting insert, cutting tool using the same, and cutting method

InactiveCN101522350AReduce cutting resistanceReduced inhibitory strengthTransportation and packagingMilling cuttersMechanical engineeringRidge

A cutting insert has a cutting edge formed at a ridge between an upper face and a side face. The side face has grooves running from the side face to the upper face to divide the cutting edge. A clearance angle in each groove is formed so that the angle is greater from one end of the cutting edge toward the other end, and as a result, the cutting insert has small cutting resistance and excellent cutting performance. Of the grooves, the groove nearest the one end of the cutting edge is preferably formed so that its width is greater from the upper face toward the lower face of the cutting insert.

Owner:KYOCERA CORP

Semiconductor device having a particular electrode structure

InactiveUS7211892B2Reduced inhibitory strengthImprove thermal fatigue lifePrinted circuit assemblingSemiconductor/solid-state device detailsMetallurgyPalladium

Owner:RENESAS ELECTRONICS CORP

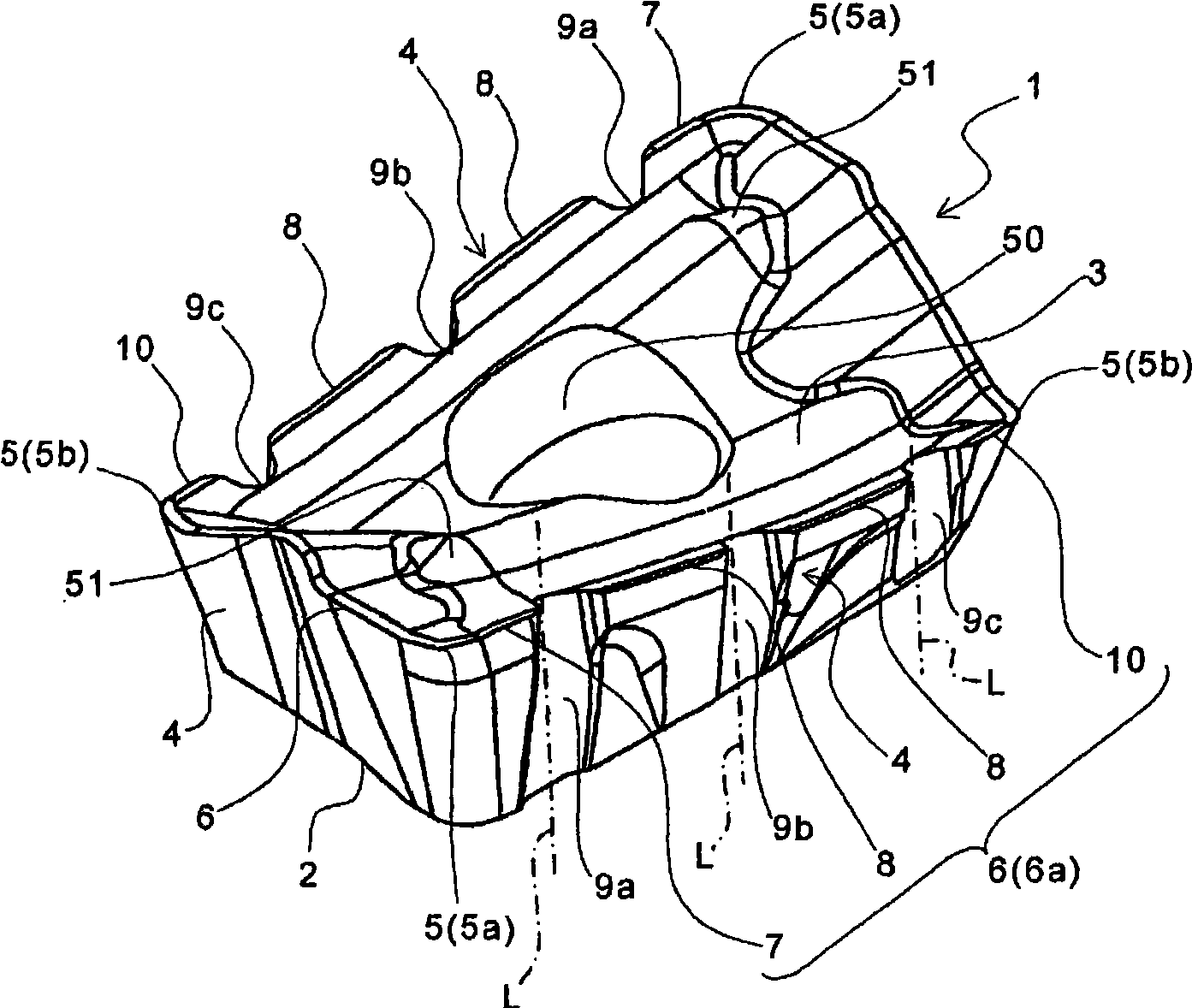

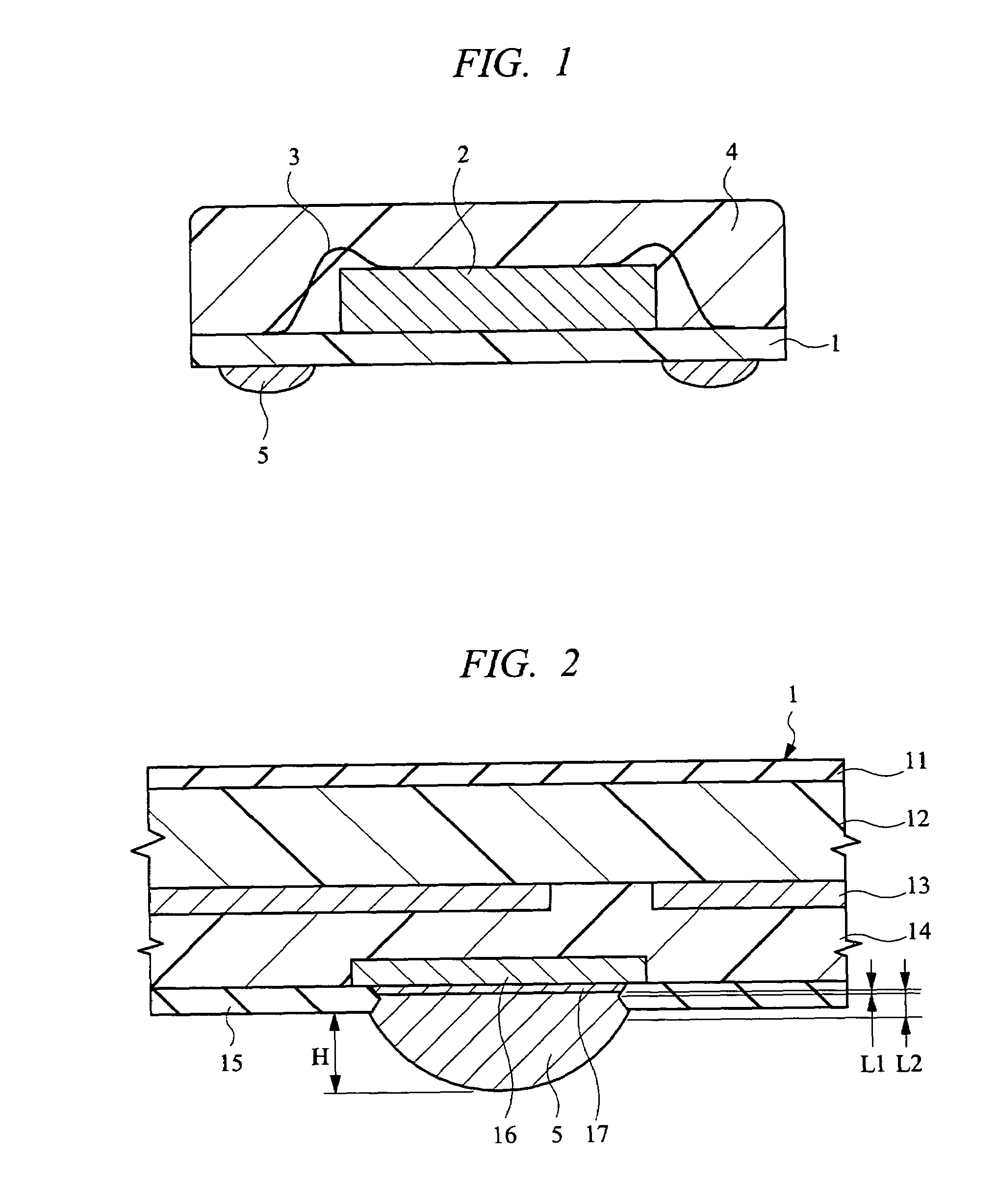

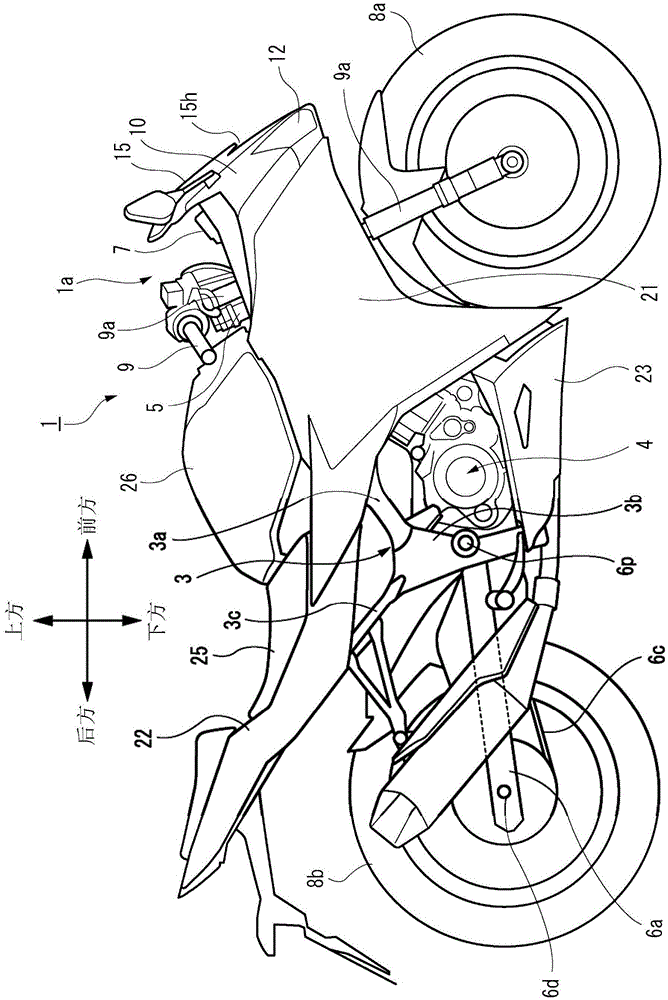

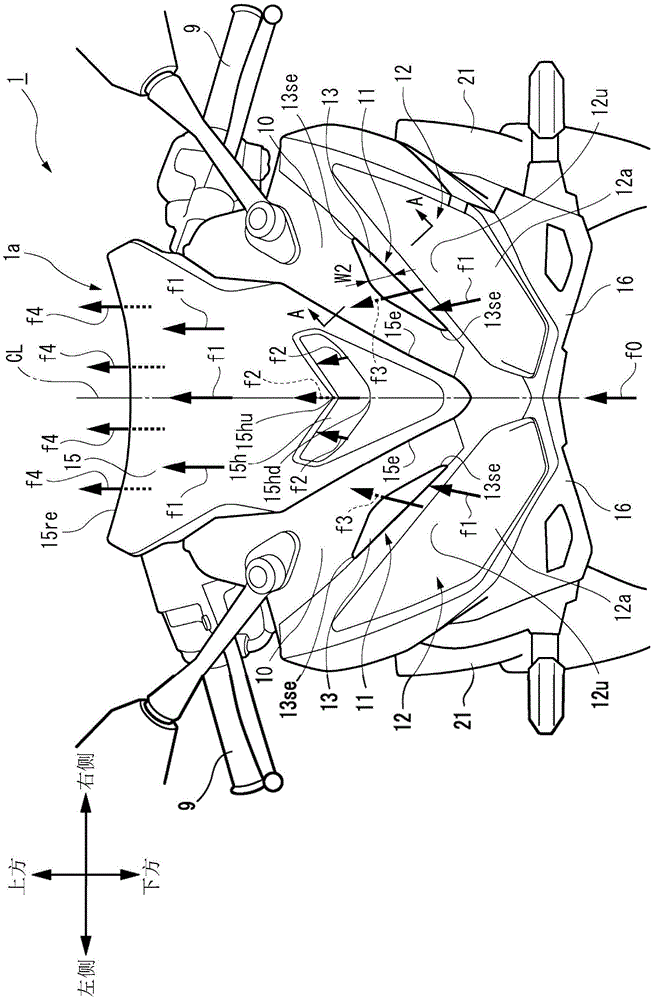

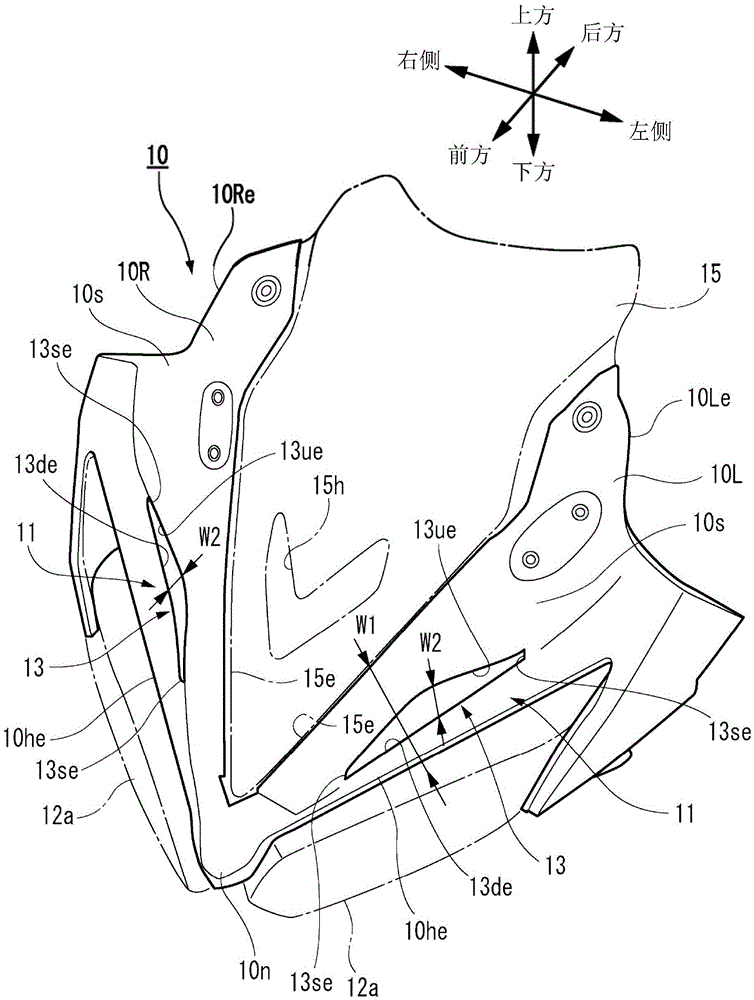

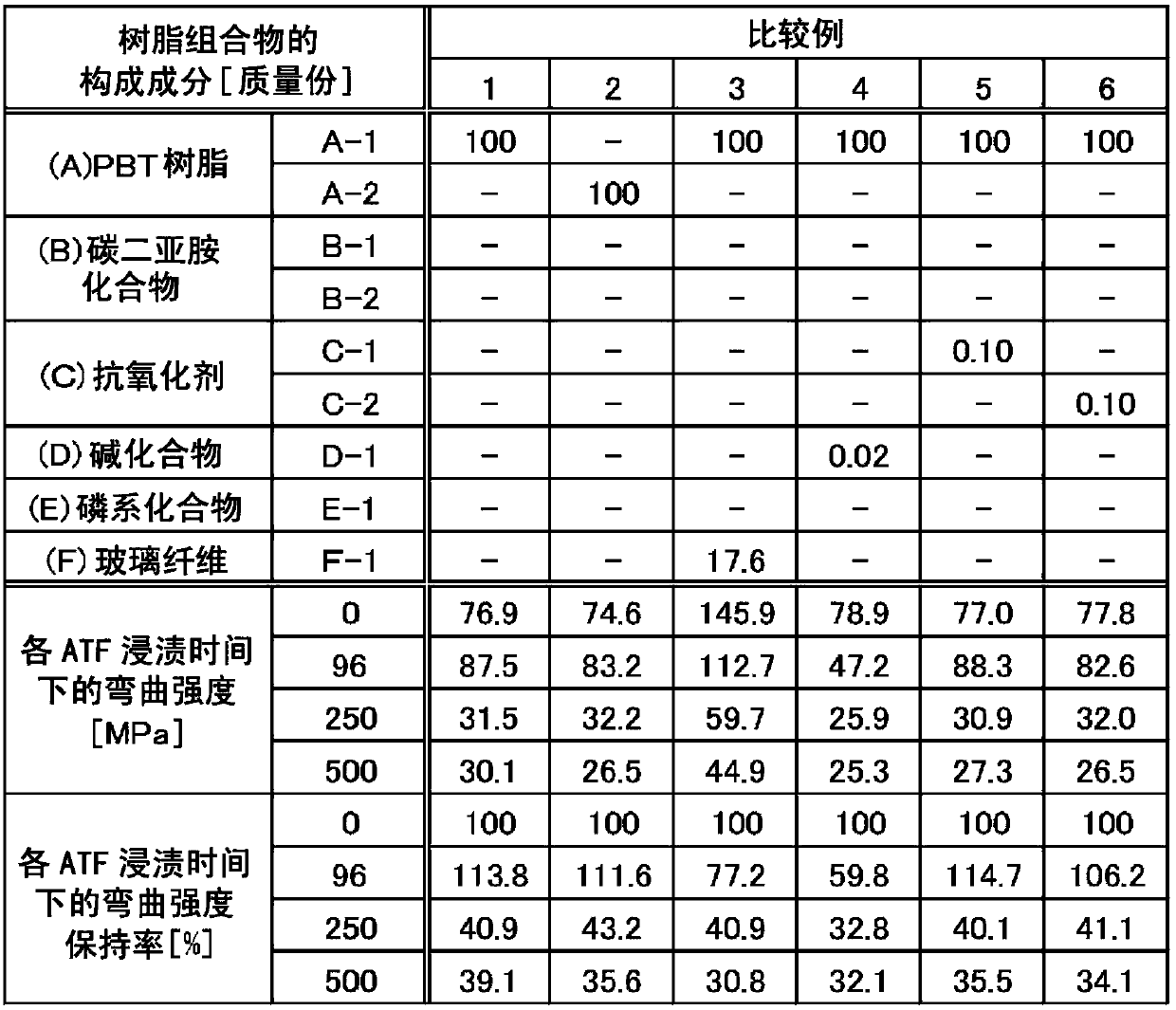

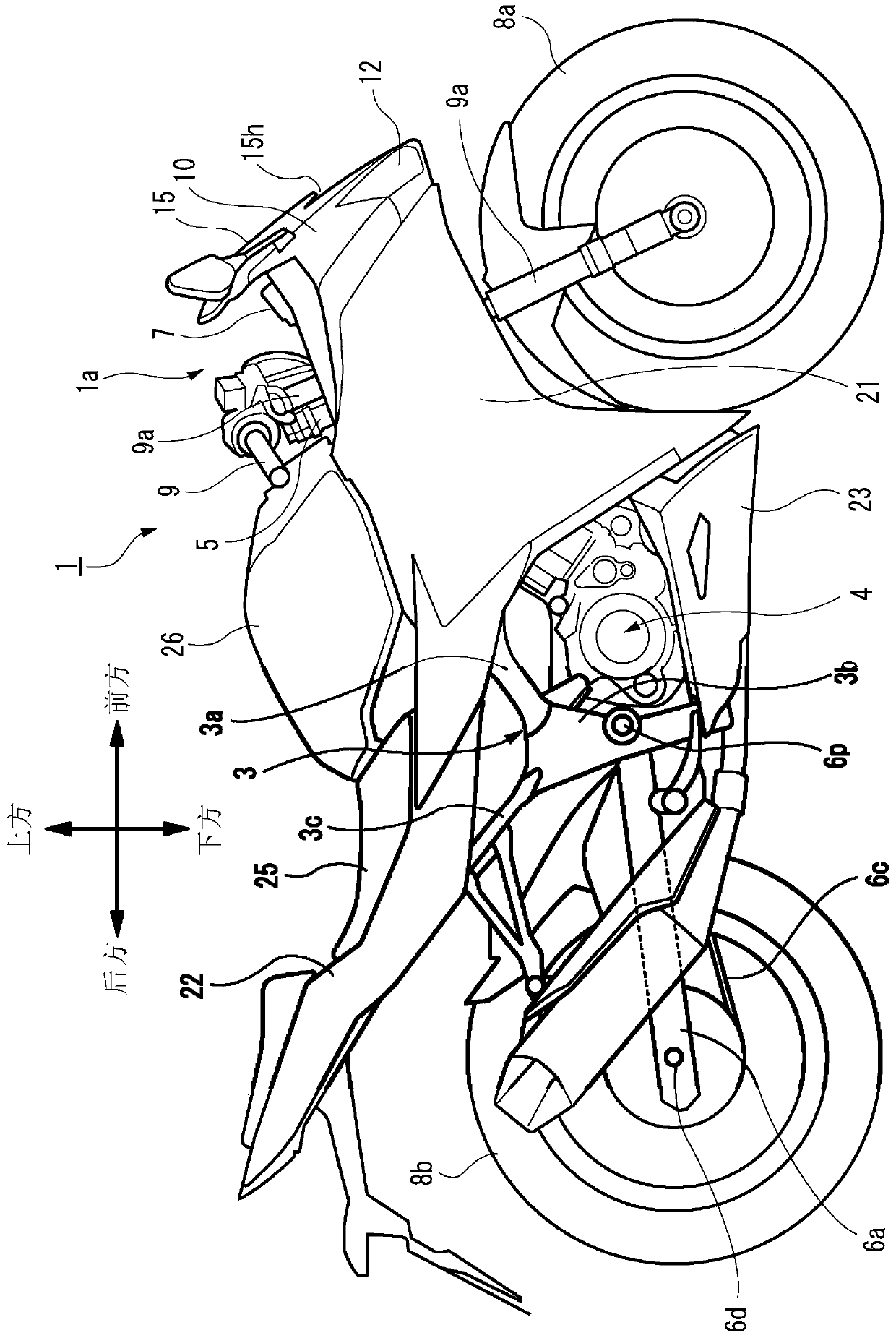

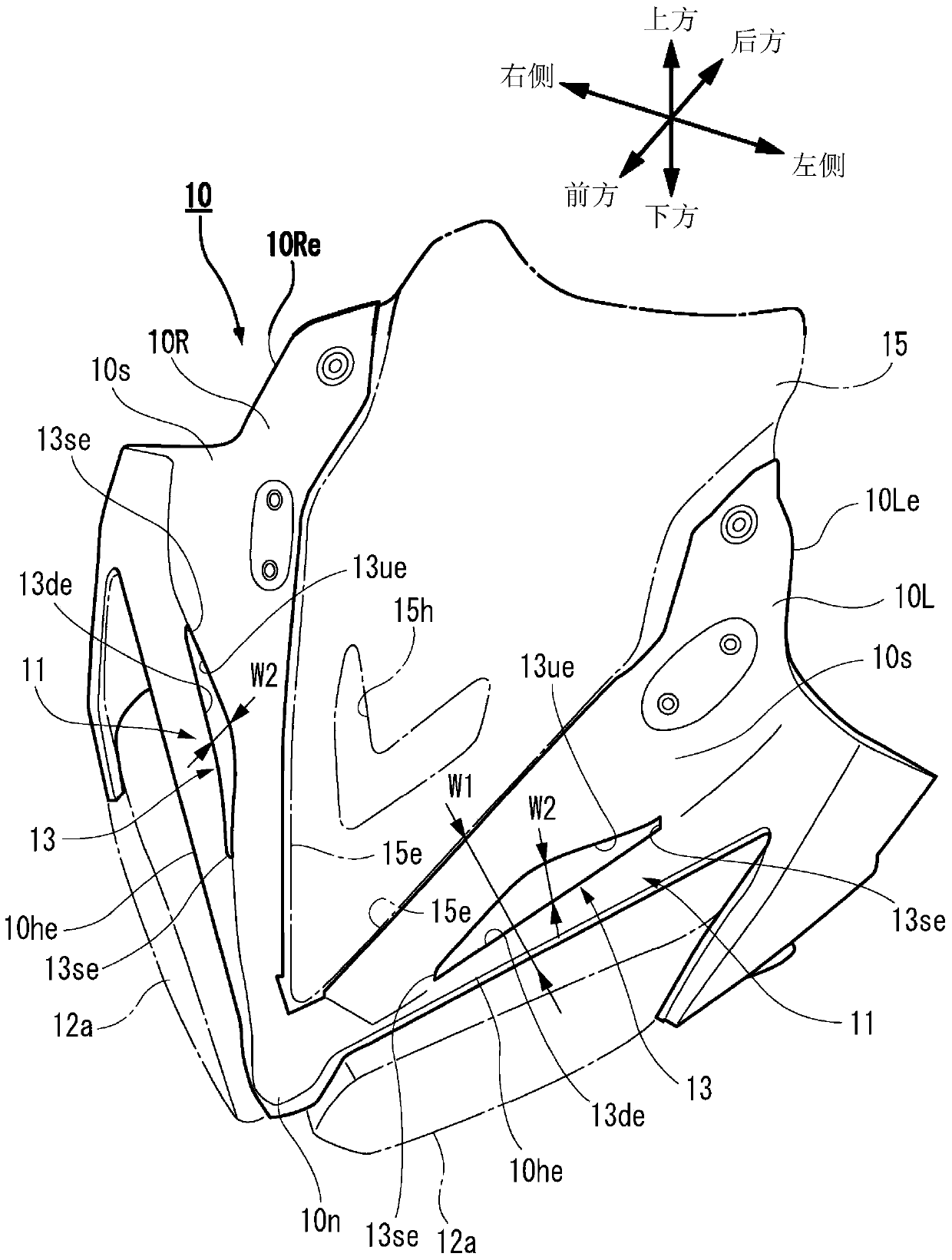

Front cover structure of automatic two wheel vehicle

The invention provides a front cover structure of an automatic two wheel vehicle. The front cover structure enables smooth flow of air on the front cover arranged on the front part of the vehicle. The front cover structure of the automatic two wheel vehicle (1) includes a head lamp 912) arranged on the front part of the vehicle, a front cvoer (10) arranged in a manner of surrounding the outer periphery of the head lamp (12), a protection shade (15) arranged on the upper side of the front cover (10). The front cover structure is characterized in that a concave part (11) sinking towards the inner side of the vehicle is formed in the front cover and between the head lamp (12) and the protection shade (15) and an opening enabling drive air to flow into the front cover is fromed in the concave part (11).

Owner:HONDA MOTOR CO LTD

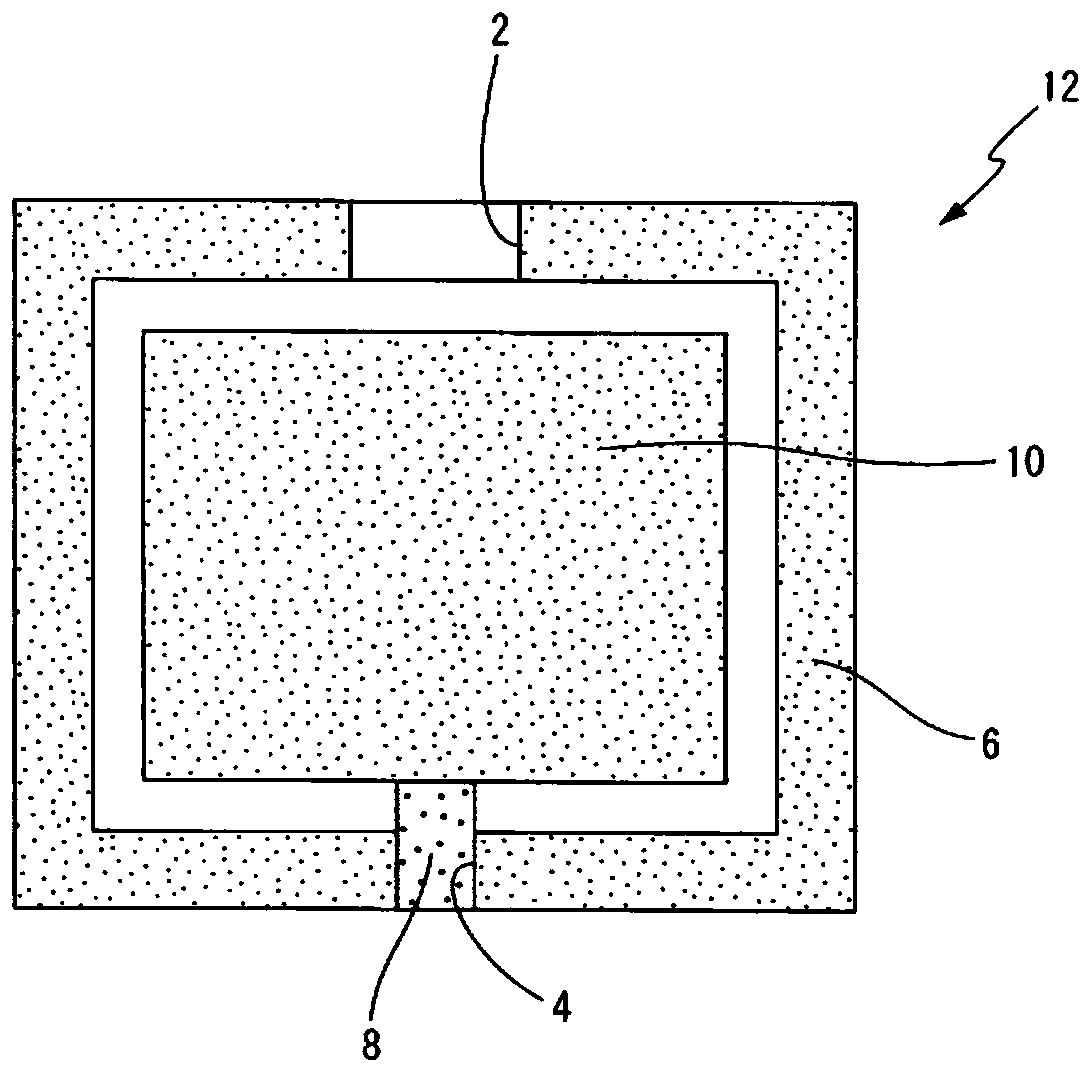

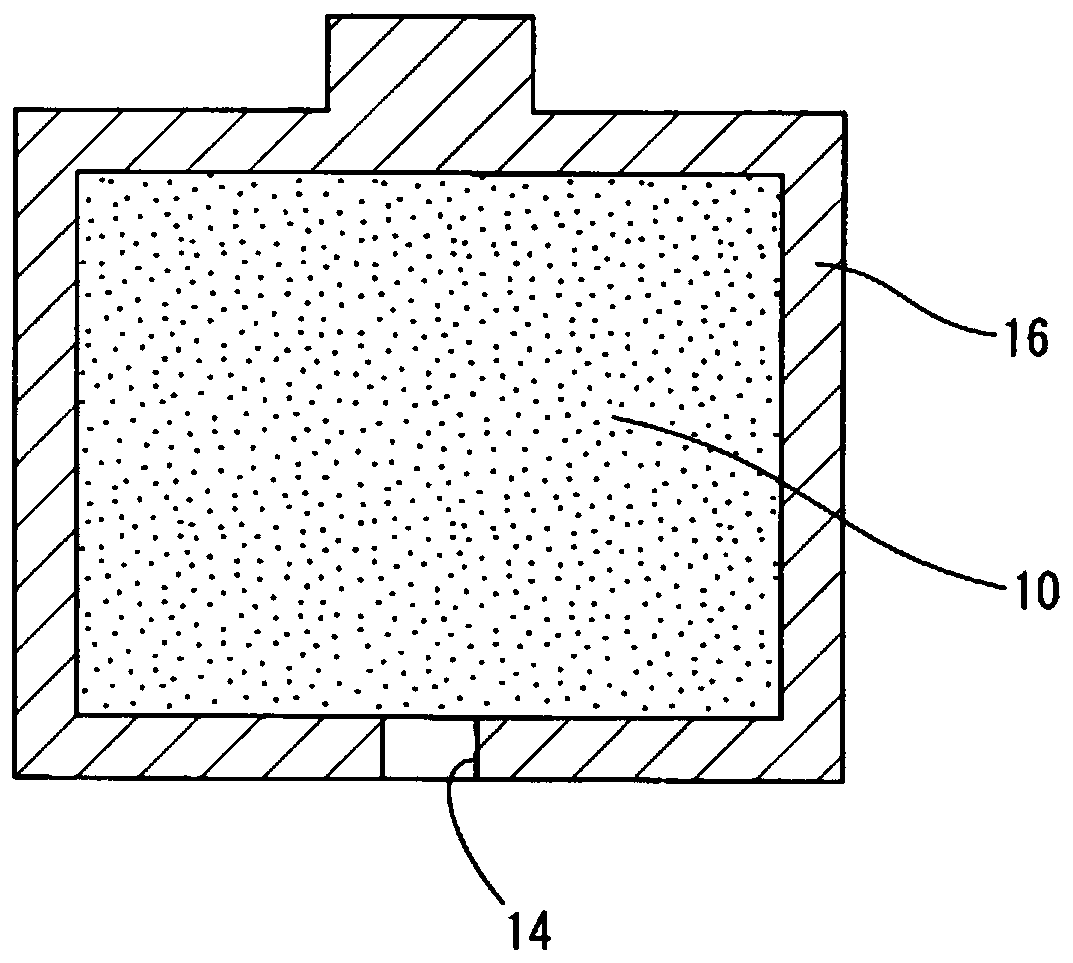

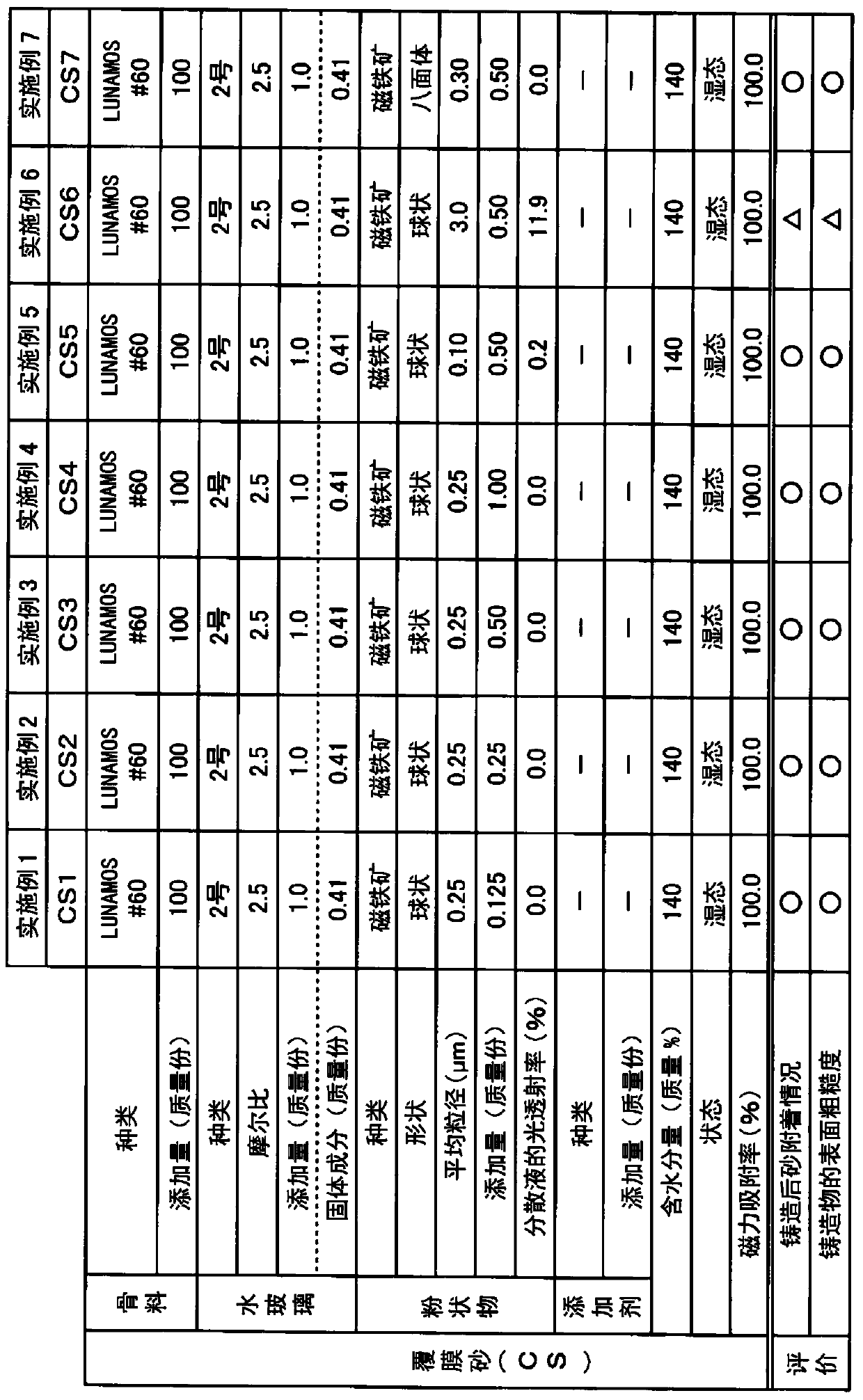

Mold material, method for producing same, method for producing mold, and method for regenerating recovered refractory aggregate

PendingCN110944768AEasy to fillEasy to separateFoundry mouldsFoundry coresPolymer scienceCasting mold

The present invention provides a mold material that enables a mold, which is a final product of the mold material, to suppress adhesion of the mold material and / or a solidified product thereof to a molded article, while having excellent mold strength and excellent mold fillability. The mold material is configured to contain at least (a) a refractory aggregate, (b) a water-soluble inorganic binderand (c) a powder of an iron-containing compound; and the powder of an iron-containing compound has an average particle diameter of 0.01 [mu]m or more but less than 50 [mu]m.

Owner:ASAHI YUKIZAI KOGYO CO LTD

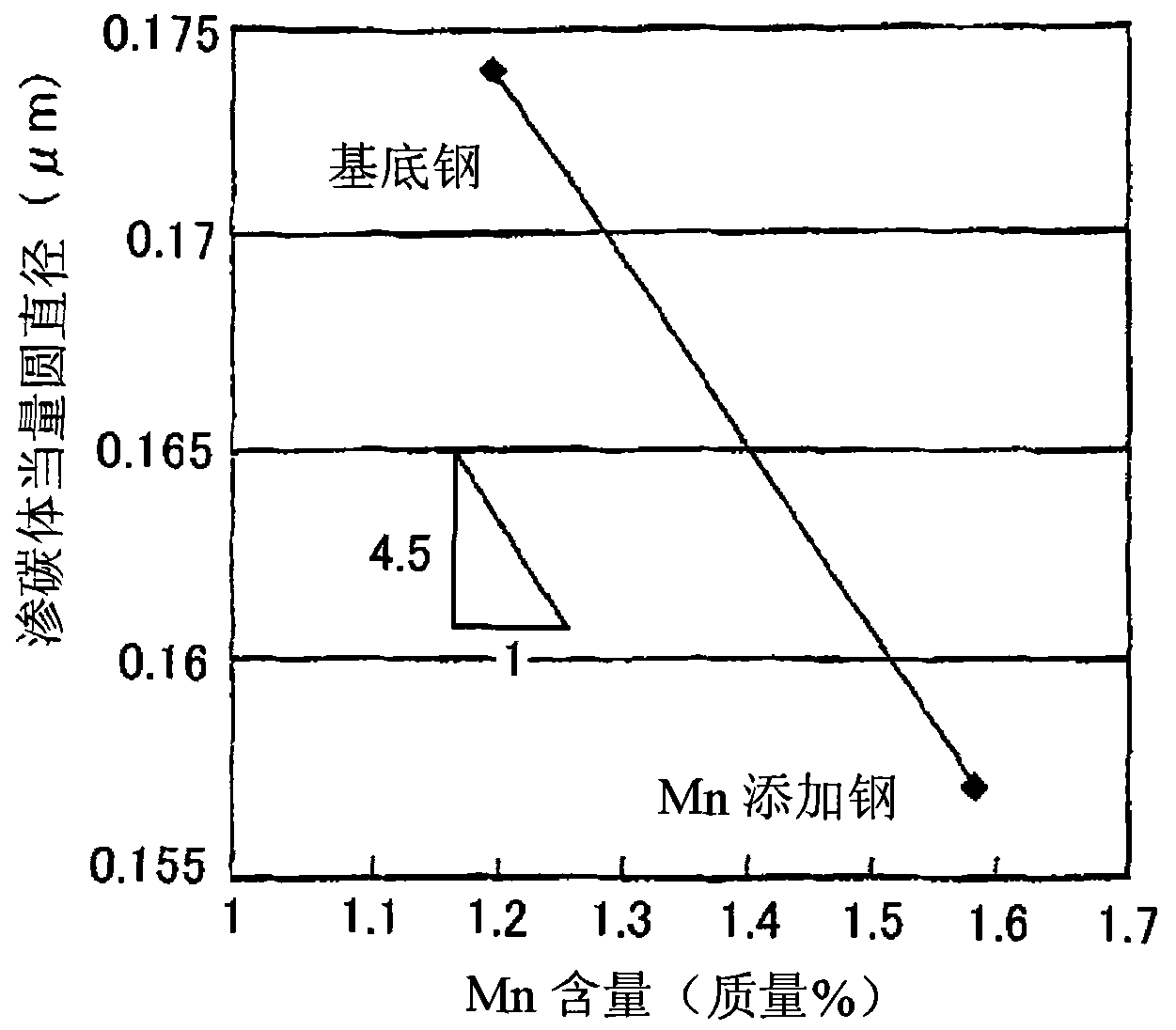

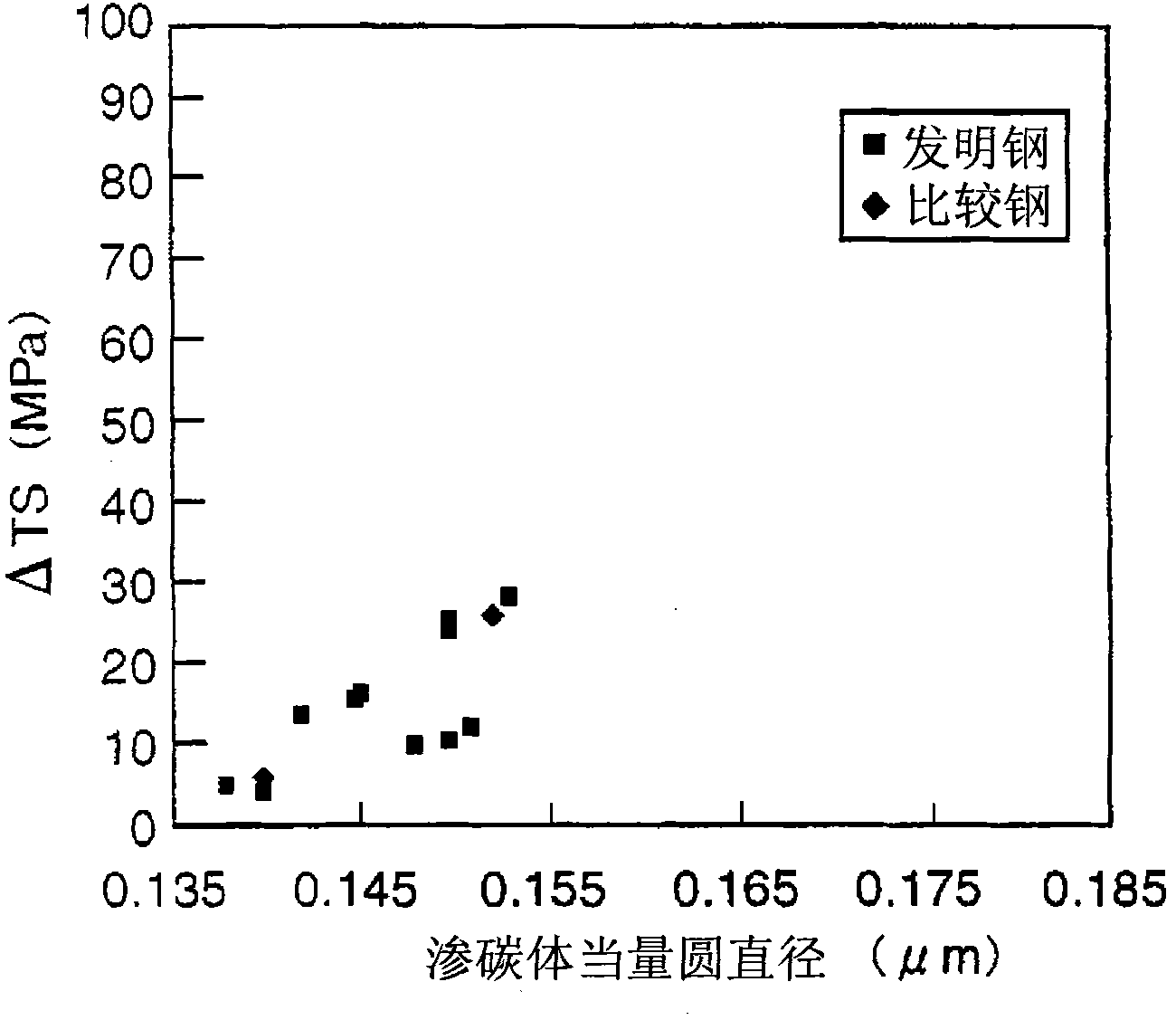

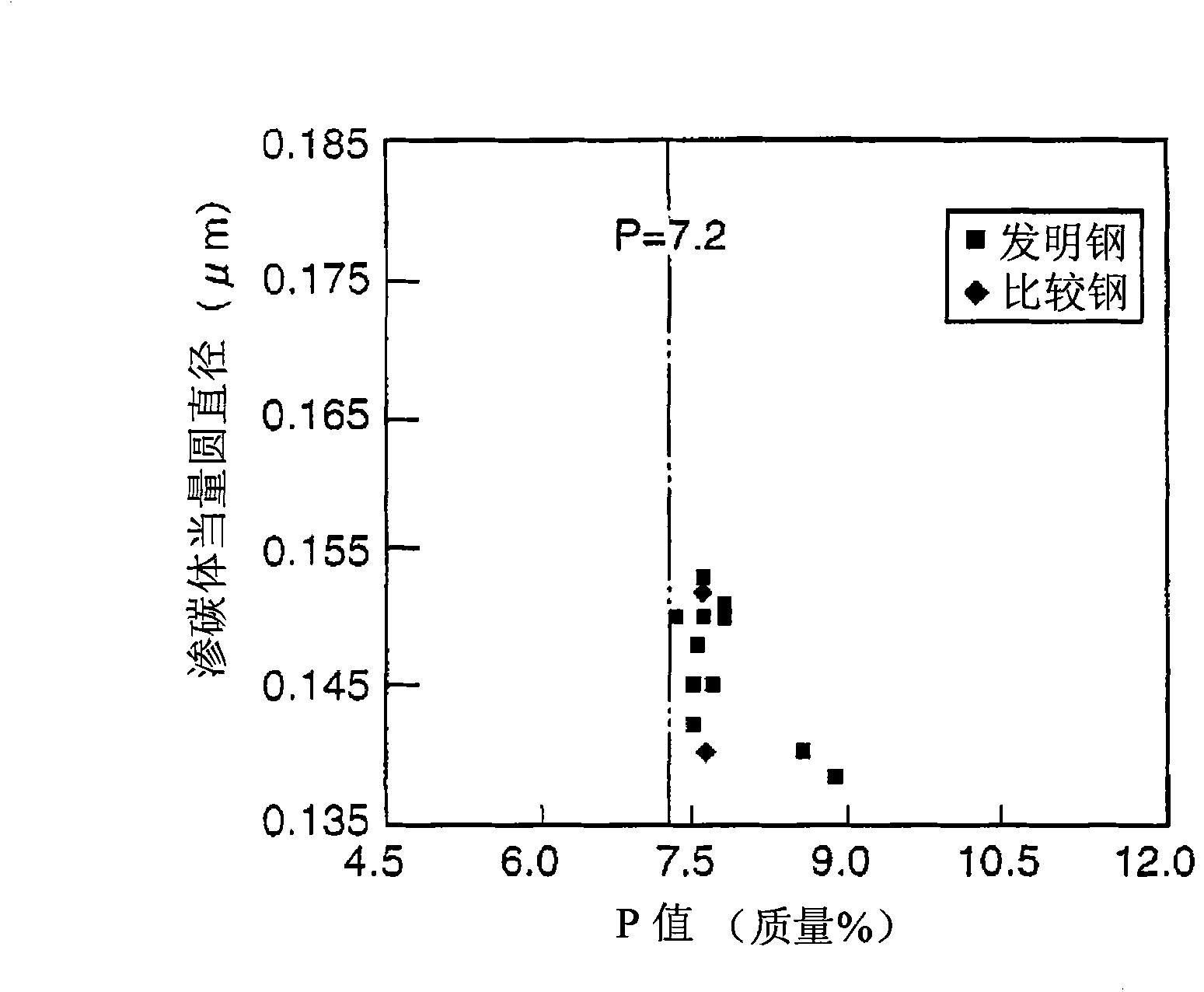

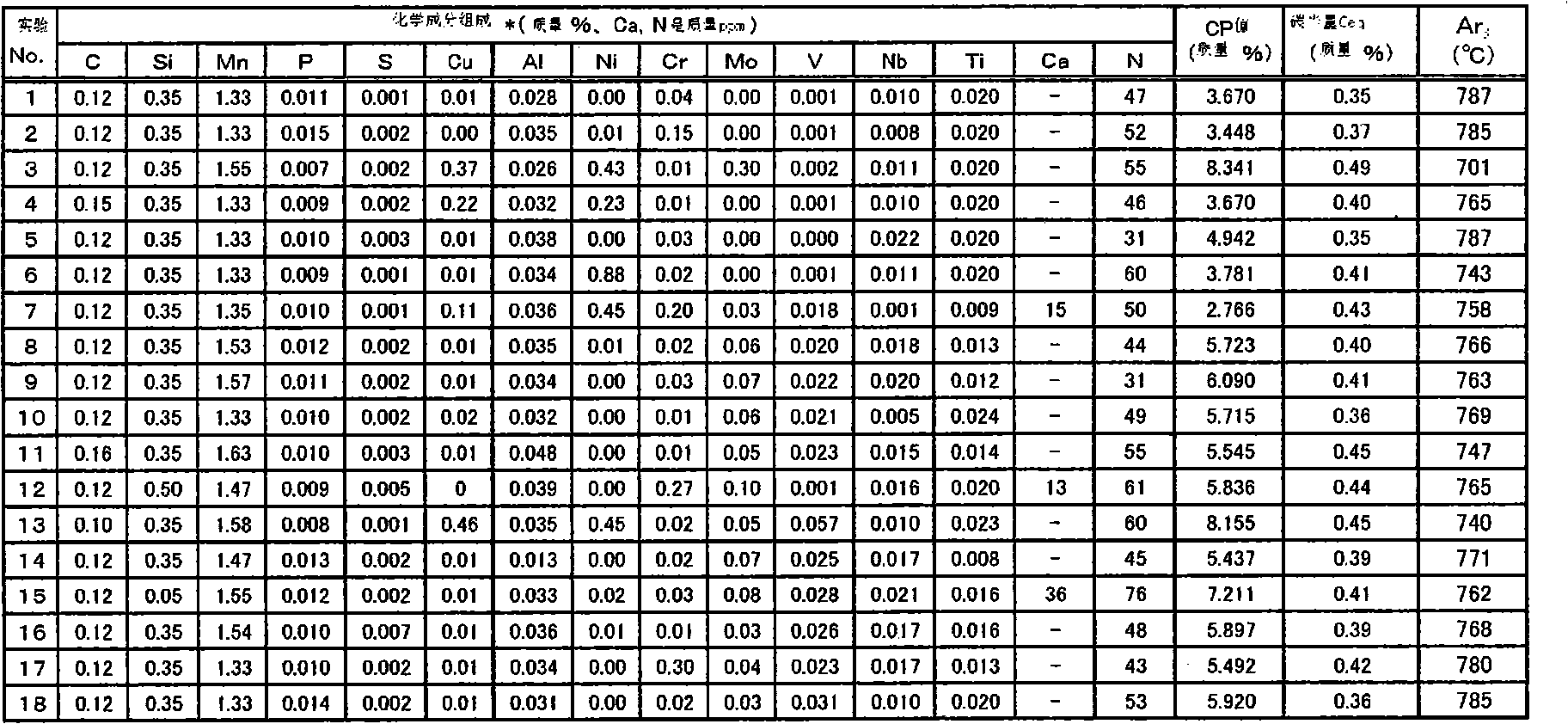

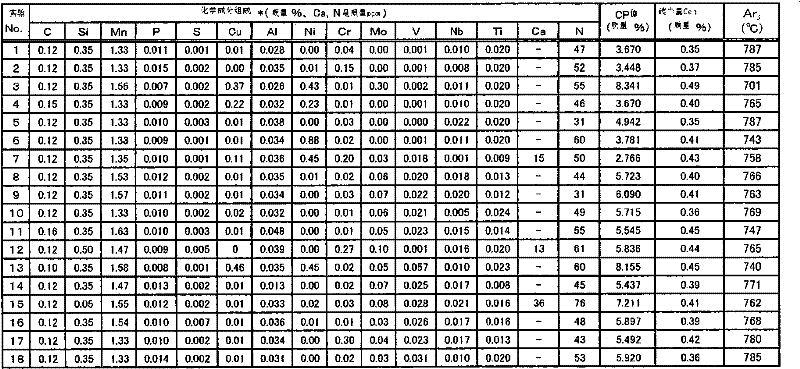

High-strength steel sheet excellent in resistance to stress-relief annealing and low-temperature toughness

InactiveCN101960033AReduced inhibitory strengthGood low temperature toughnessFurnace typesHeat treatment furnacesHigh intensityLong term stress

A high-strength steel sheet is provided which, even when subjected to long-term stress-relief annealing after welding, decreases little in strength (that is, has satisfactory resistance to stress-relief annealing) and which is excellent also in the low-temperature toughness of the base material and HAZ after the SR treatment. The high-strength steel sheet contains 0.05-0.18% carbon (in terms of mass%; the same applies hereinafter), 0.10-0.50% silicon, 1.2-2.0% manganese, 0.01-0.10% aluminum, 0.05-0.30% chromium, 0.008-0.025% titanium, and 0.01-0.05% vanadium, with the remainder being iron and incidental impurities. The content of phosphorus among the incidental impurities has been reduced to 0.008% or lower. The steel sheet satisfies a given relationship.

Owner:KOBE STEEL LTD

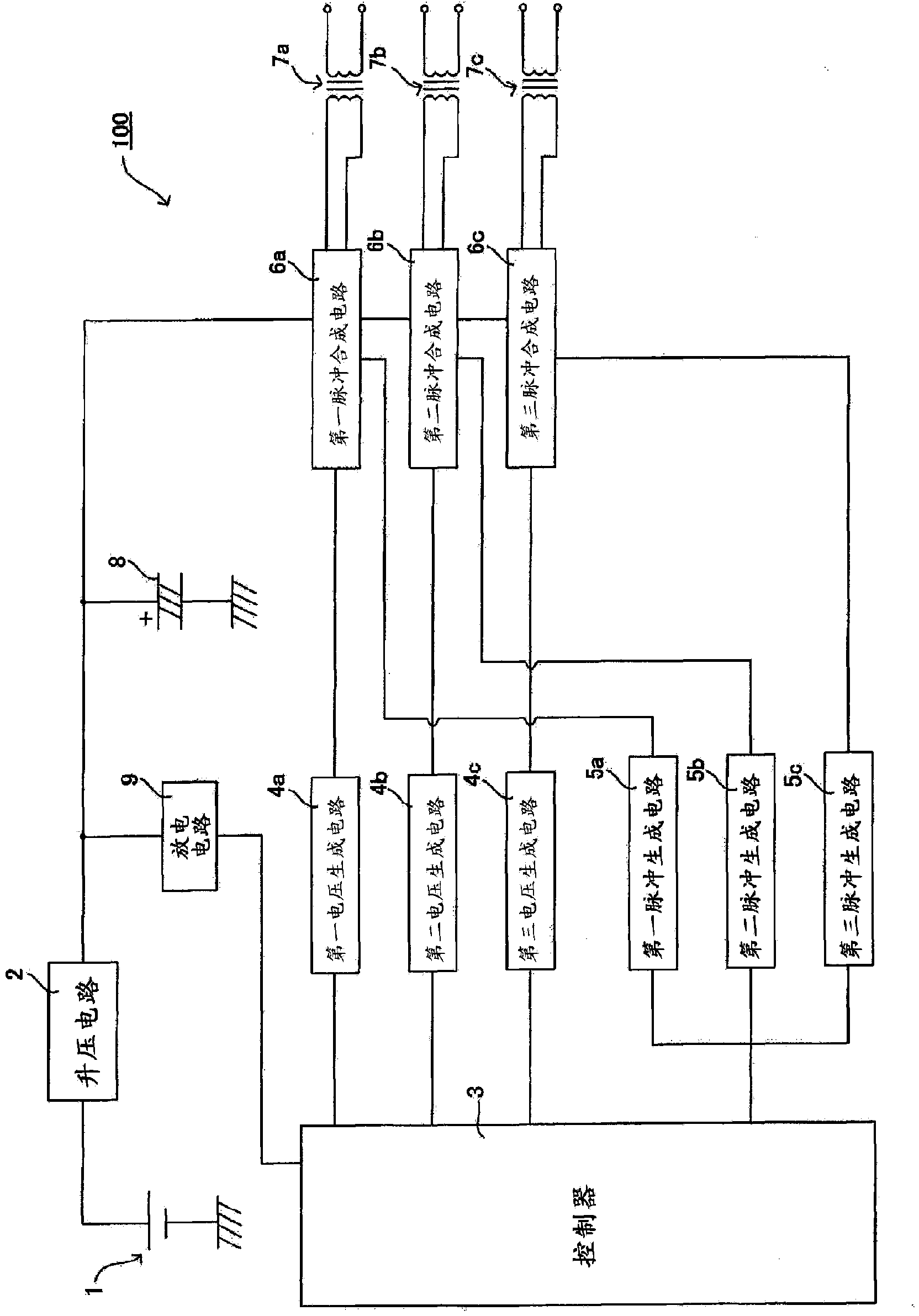

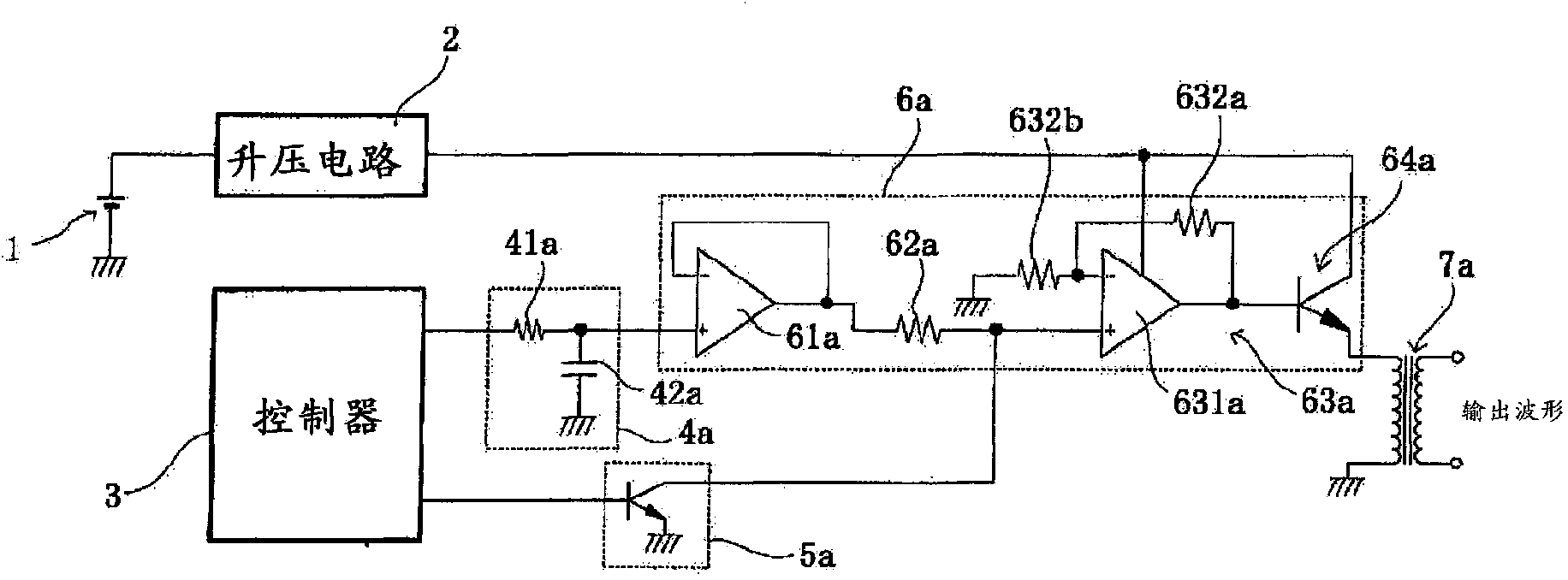

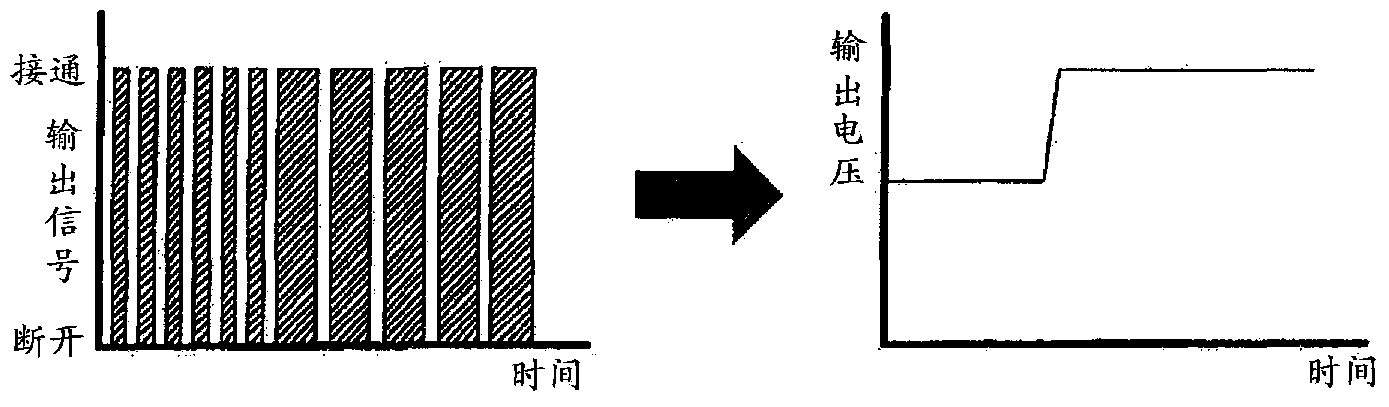

Electric stimulus signal generating device and muscular movement metabolism stimulating device

ActiveCN103547312AReduced inhibitory strengthReduce intensityElectrotherapyArtificial respirationSignal onVIT signals

Owner:HOMER ION LAB

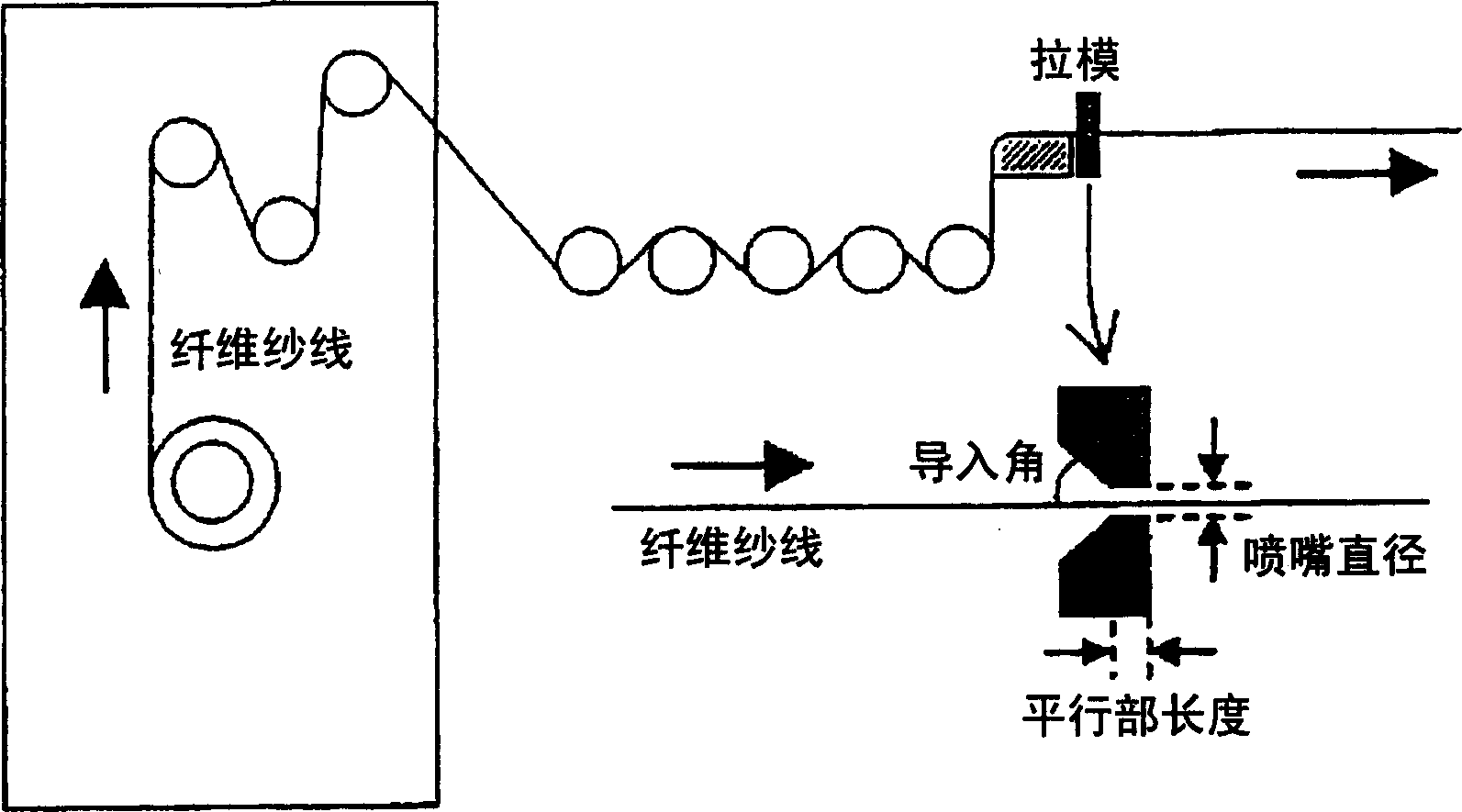

Method and device for manufacturing automotive resin part

InactiveCN105269718AReduced inhibitory strengthAvoid deformationDomestic articlesFiberPlastic materials

The invention relates to a method and device for manufacturing an automotive resin part. The method for manufacturing an automotive resin part includes: heating a fiber reinforced plastic material that uses a thermoplastic resin as a binder resin and arranging the fiber reinforced plastic material between a first die having a projected section for molding and a second die having a recessed section for molding that corresponds to the projected section; approaching the first die and the second die in a molding direction and holding the fiber reinforced plastic material by the projected section and a movable pad provided in the recessed section; and stacking the first die and the second die in the molding direction and press-molding the fiber reinforced plastic material while a state that the fiber reinforced resin material is held between the projected section and the movable pad is maintained by moving the movable pad along with movement of the projected section in the molding direction.

Owner:TOYOTA JIDOSHA KK

Tissue paper

ActiveCN107109802AHigh "flexibility"Less stickinessNon-macromolecular organic additionBathroom accessoriesGlycerolPropanediol

Owner:DAIO PAPER CORP

Method for manufacturing female terminal and female terminal

InactiveUS10290990B2Reduced strengthLow costContact member manufacturingCoupling contact membersEngineeringMetal

A method for manufacturing a female terminal (1) with a tubular portion (11) formed by bending a metal plate into a tubular shape and resilient contact pieces (12) extending from the tubular portion (11) in an axial direction of the tubular portion (11), folded inwardly of the tubular portion (11) and configured to resiliently contact a mating terminal inside the tubular portion (11) includes a joining step of joining metal members thinner than the metal plate to the metal plate, and a forming step of bending the metal members joined to the metal plate and forming the metal members as the resilient contact pieces.

Owner:AUTONETWORKS TECH LTD +2

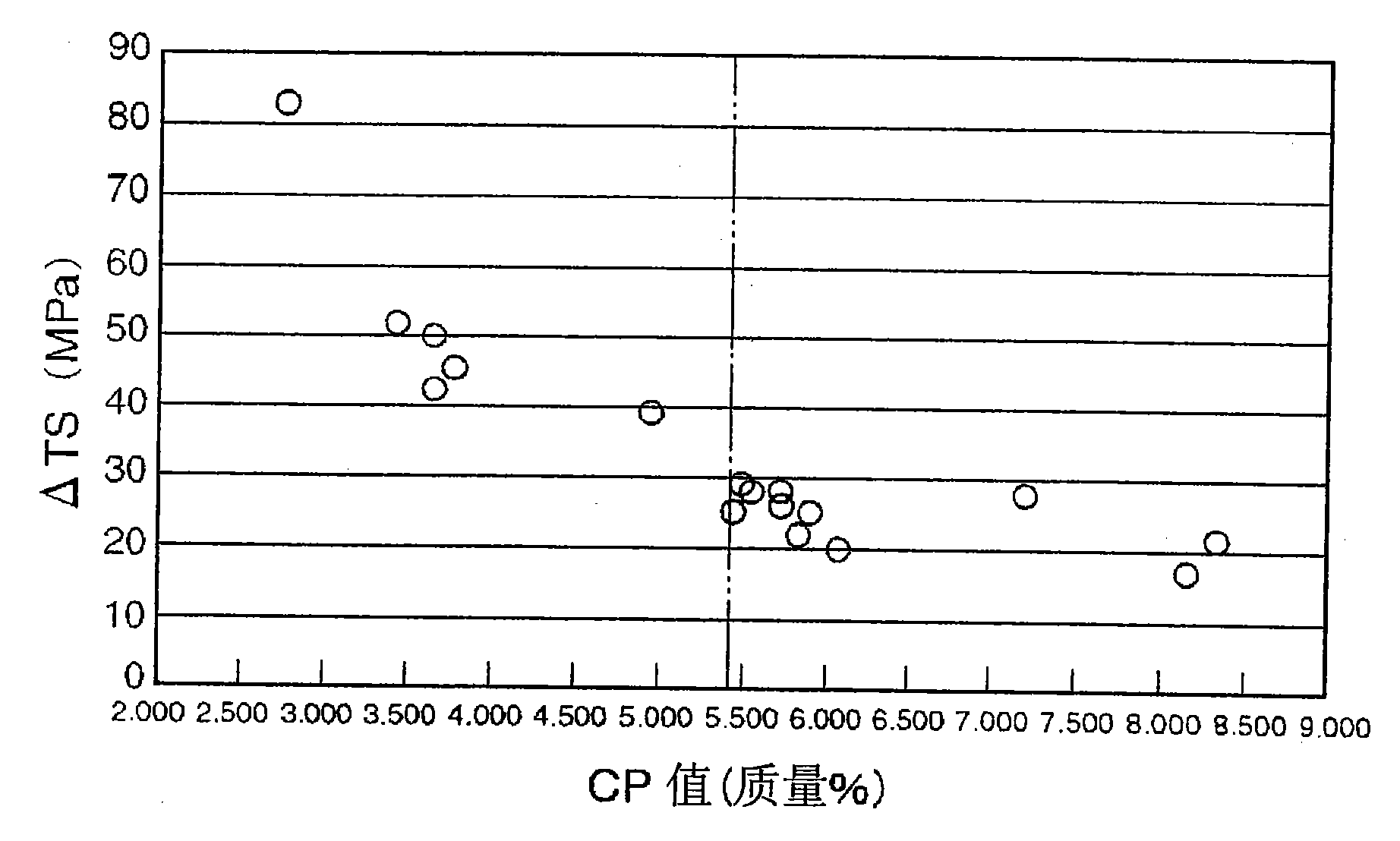

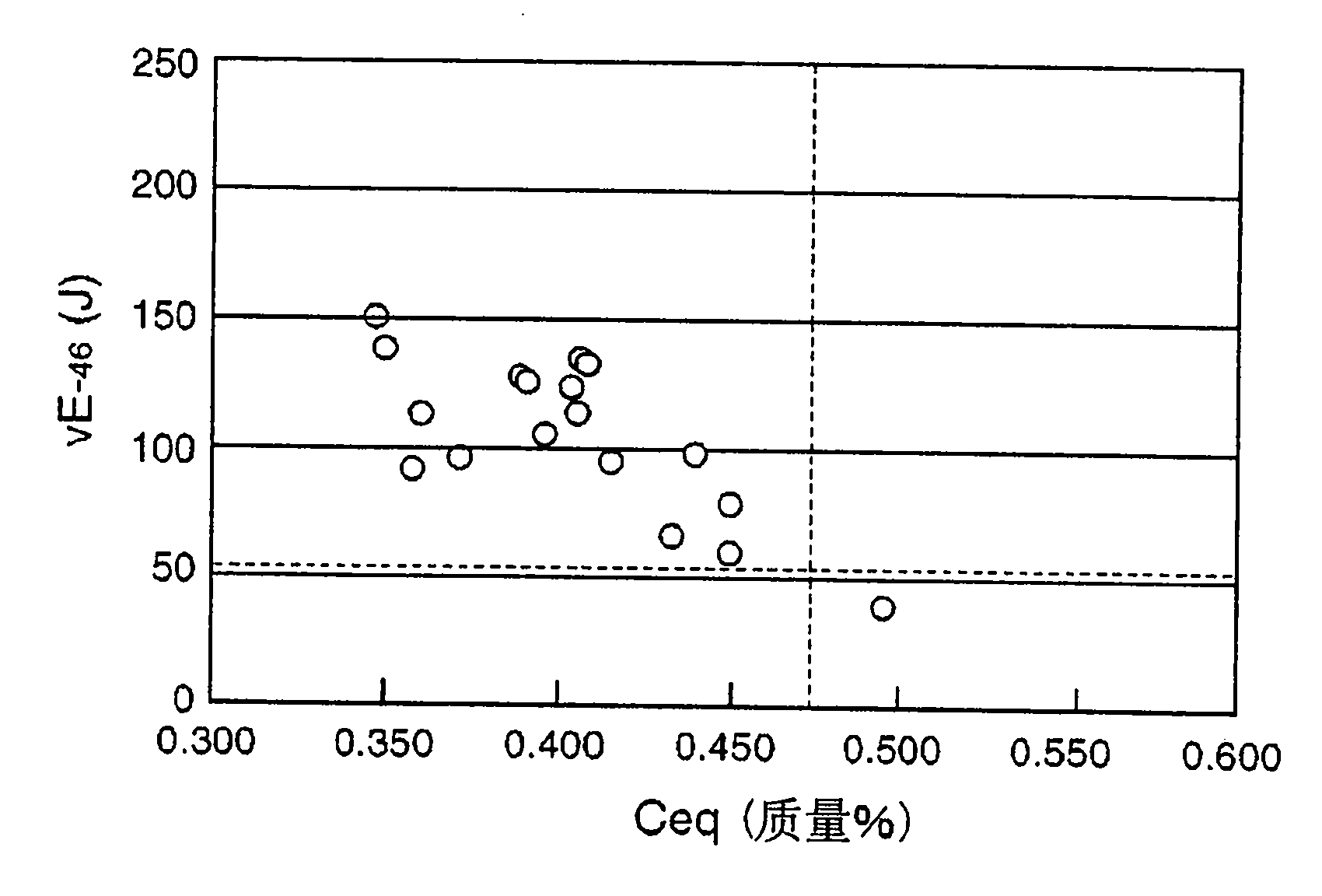

High-strength steel sheet excellent in resistance to stress-relief annealing and low-temperature joint toughness

InactiveCN101932743AImprove featuresReduced inhibitory strengthFurnace typesHeat treatment furnacesChemical compositionStress relief

Owner:KOBE STEEL LTD

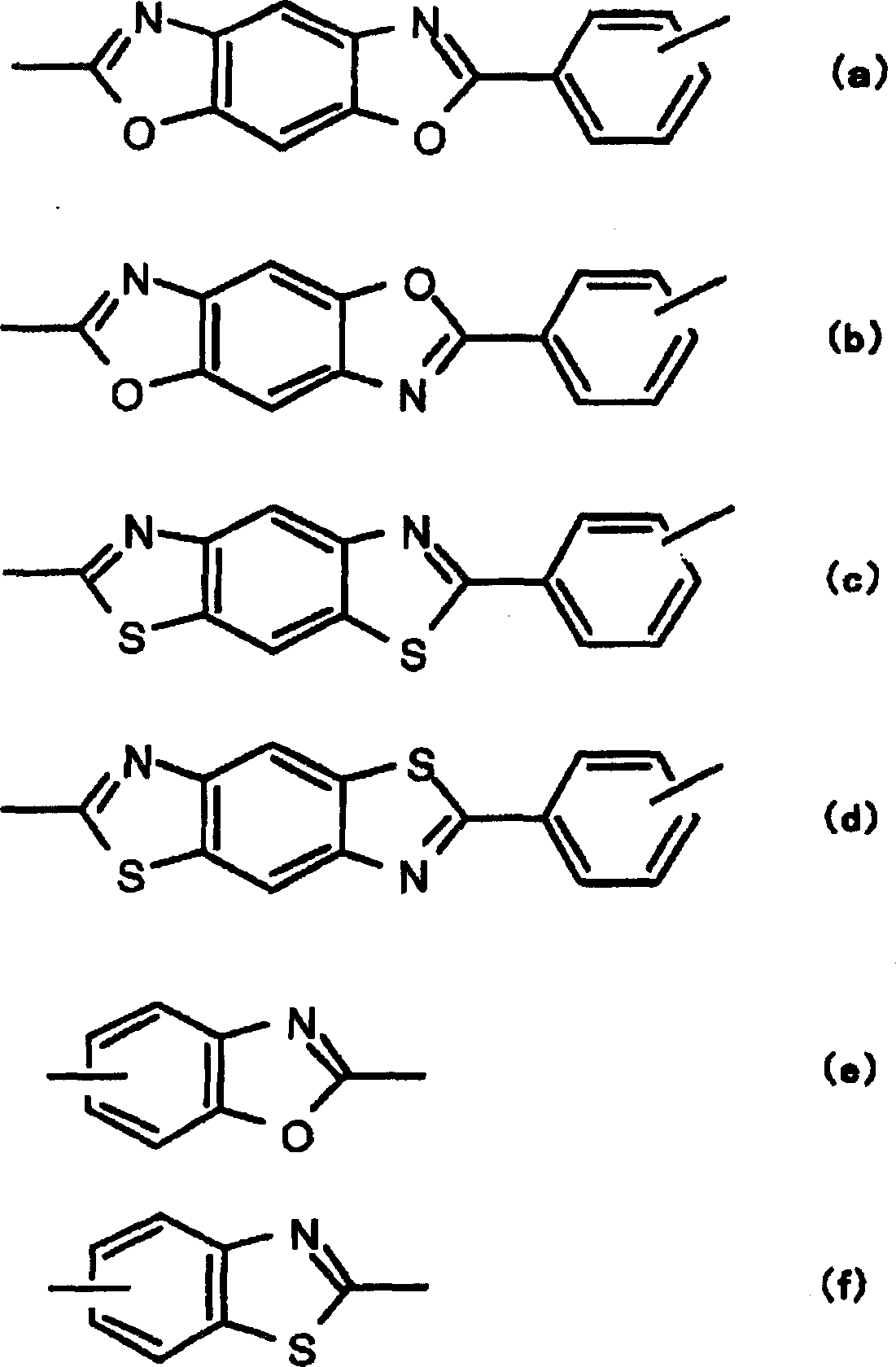

Polybenzazole fiber and article comprising the same

InactiveCN1890413AReduced inhibitory strengthIncreased durabilityMonocomponent synthetic polymer artificial filamentYarnHigh humidity

Polybenzazole fibers which have excellent durability under high-temperature high-humidity conditions even after threads thereof are damaged to develop a kink band in a post-processing step for a woven fabric, knitting, braid, rope, cord, etc. Also provided are articles comprising the fibers, especially a spun yarn, rubber-reinforcing material, fiber-reinforced composite material, woven or knit fabric, knifeproof material or bulletproof vest, rope, sailcloth, etc.

Owner:TOYO TOYOBO CO LTD

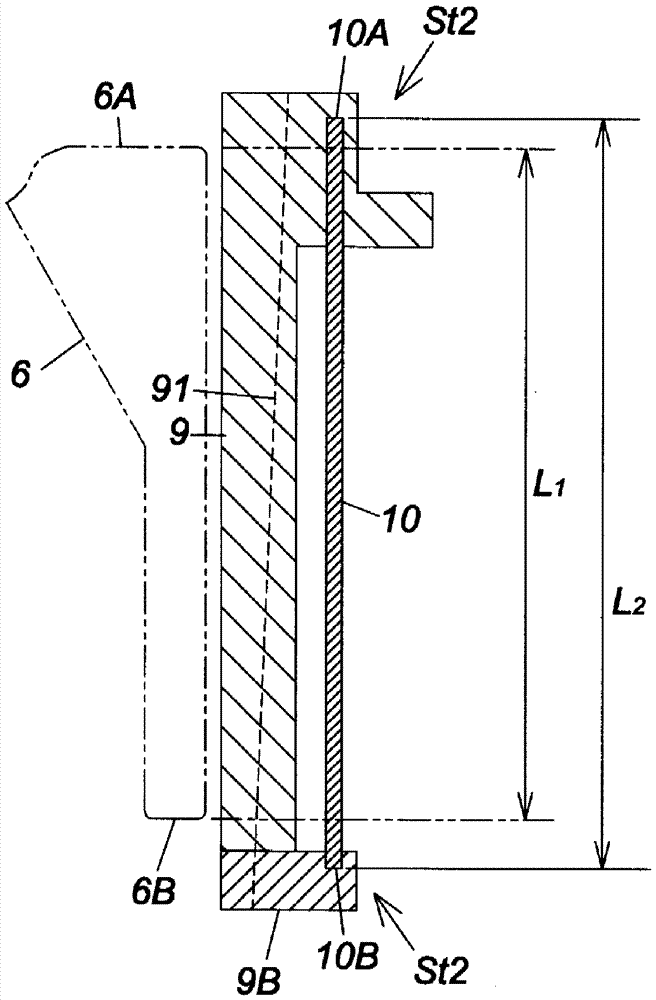

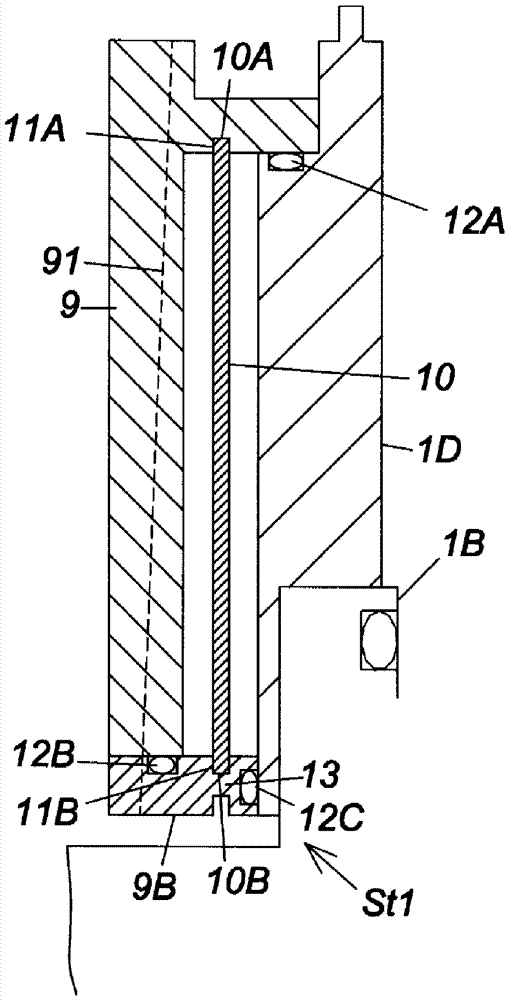

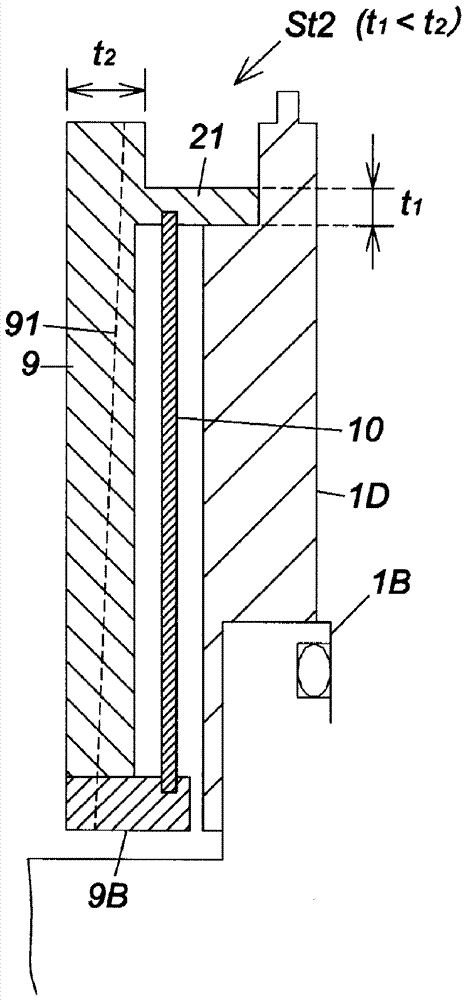

Vacuum pump

InactiveCN107152408AReduced inhibitory strengthImprove reliabilityAxial flow pumpsNon-positive displacement fluid enginesStatorEngineering

The invention provides a vacuum pump for improving the reliability of strategy for reducing rotator damage. In order to form a thread groove gas exhaust path in the peripheral side of a rotator, a fixing part, which is arranged on the inner peripheral side of an encapsulation shell (1(1A,1B)), comprises a thread groove gas exhaust part stator (9); in the peripheral side of the thread groove gas exhaust part stator (9), a high strength part (10), which is made of a material harder than the material of thread groove gas exhaust part stator (9), is installed; and in order to inhibit the corrosion, which is caused by corrosive components in the gas, on the high strength part (10), an anti-corrosion structure (St1) is arranged on the periphery of the high strength part (10).

Owner:EDWARDS JAPAN

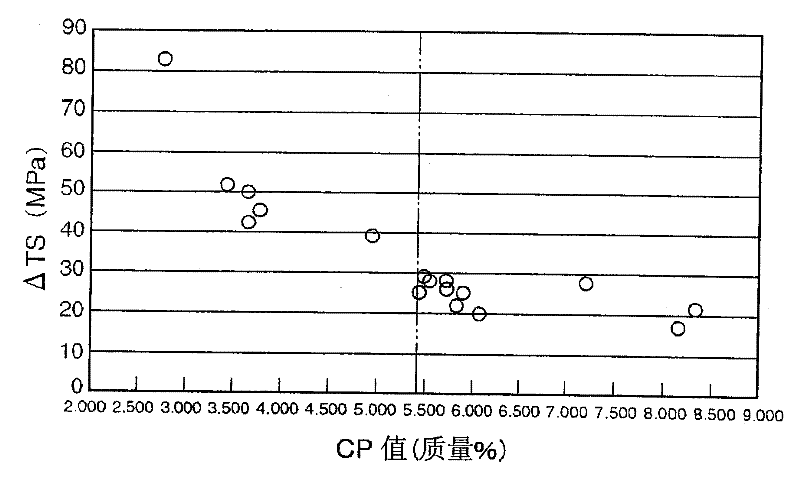

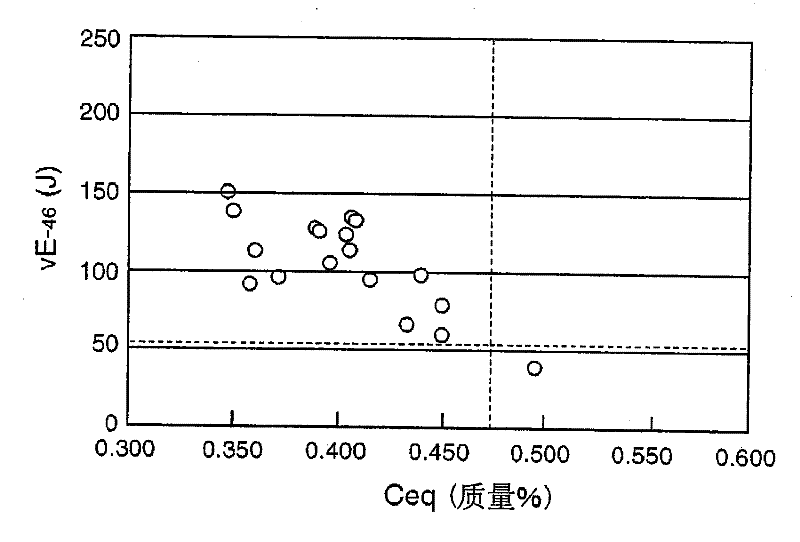

High-strength steel sheet excellent in resistance to stress-relief annealing and low-temperature joint toughness

InactiveCN101932743BImprove featuresReduced inhibitory strengthFurnace typesHeat treatment furnacesChemical compositionStress relief

A high-strength steel sheet is provided which, even when subjected to long-term stress-relief annealing after welding, decreases little in strength and which has satisfactory low-temperature HAZ toughness. The high-strength steel sheet has a chemical composition adequately regulated and has a CP value defined by the following equation (1) of 5.40% or higher and a carbon equivalent (Ceq) defined by the following equation (2) of 0.45% or lower. CP value = 125[Ti]+111[Nb]+60[V]+15[Mo] (1) ([Ti], [Nb], [V], and [Mo] indicate the contents (mass%) of Ti, Nb, V, and Mo, respectively.) Ceq=[C]+[Mn] / 6+([Cr]+[Mo]+[V]) / 5+([Cu]+[Ni]) / 15 (2) ([C], [Mn], [Cr], [Mo], [V], [Cu], and [Ni] indicate the contents (mass%) of C, Mn, Cr, Mo, V, Cu, and Ni, respectively).

Owner:KOBE STEEL LTD

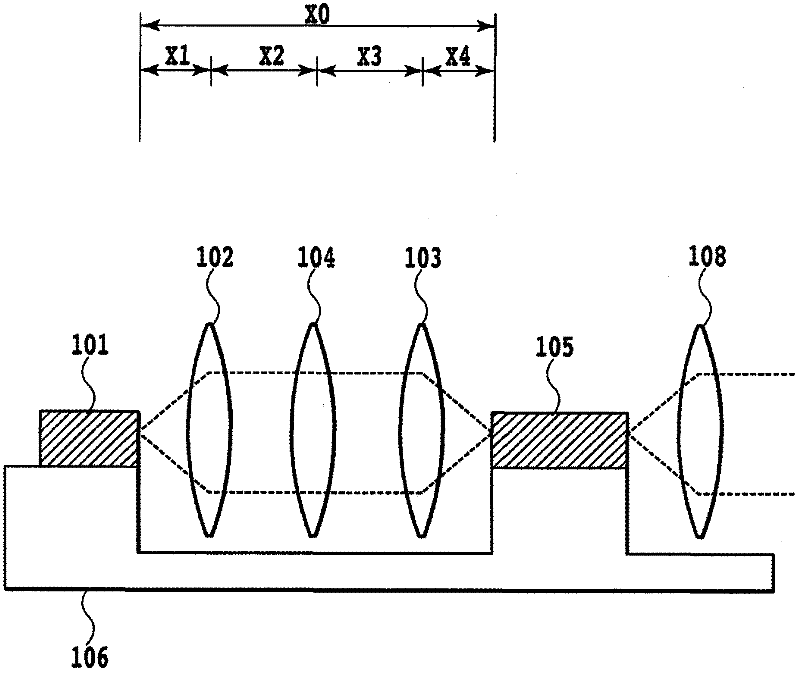

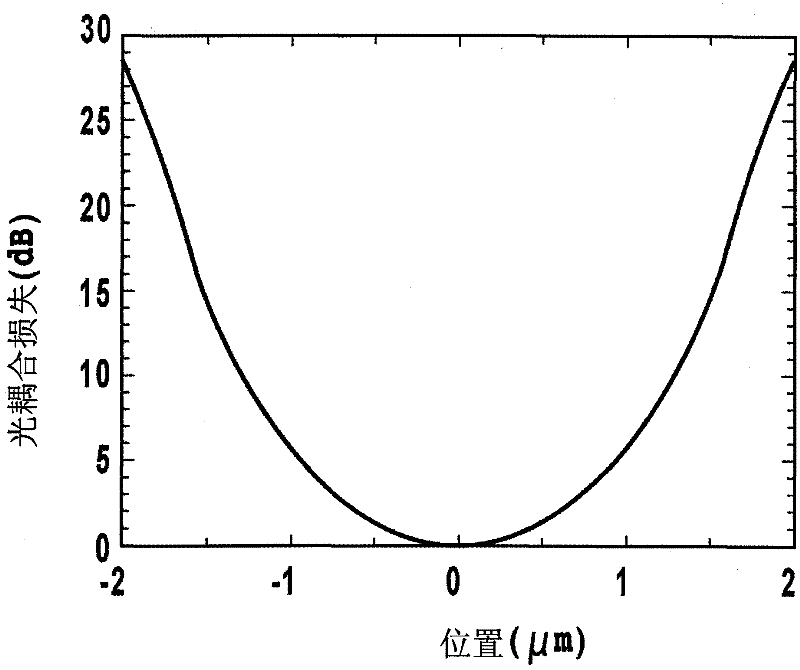

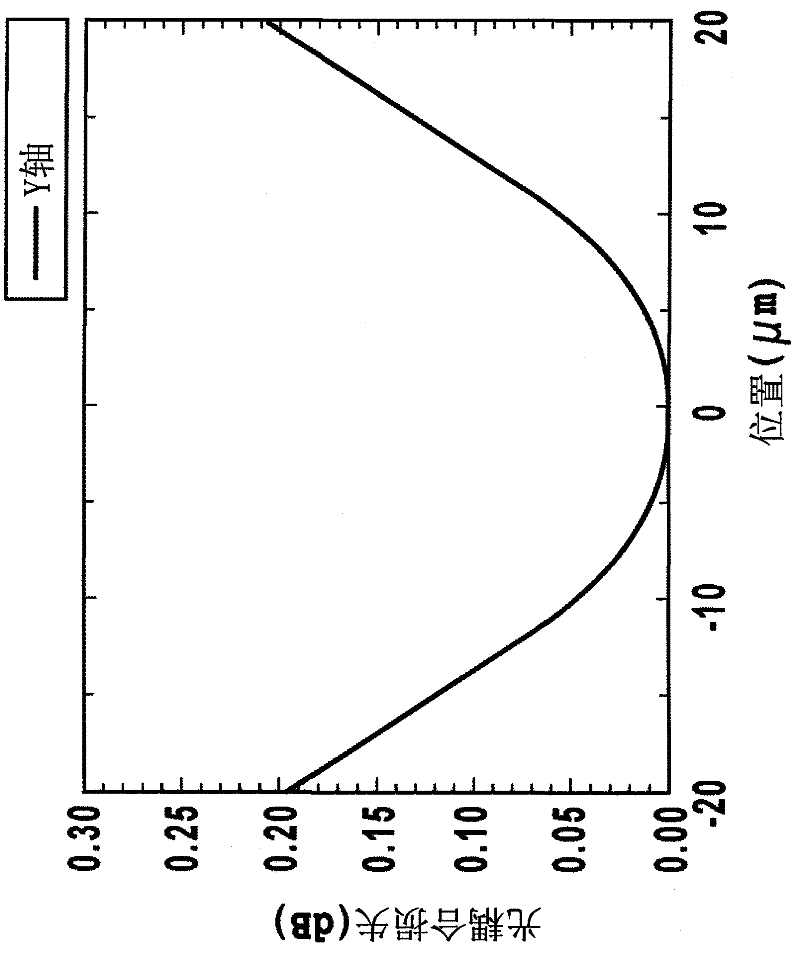

Optical semiconductor module and method for assembling the same

ActiveCN102177626AStable optical coupling efficiencyReduced inhibitory strengthLaser detailsSemiconductor laser optical deviceSemiconductorLaser

Owner:NIPPON TELEGRAPH & TELEPHONE CORP +1

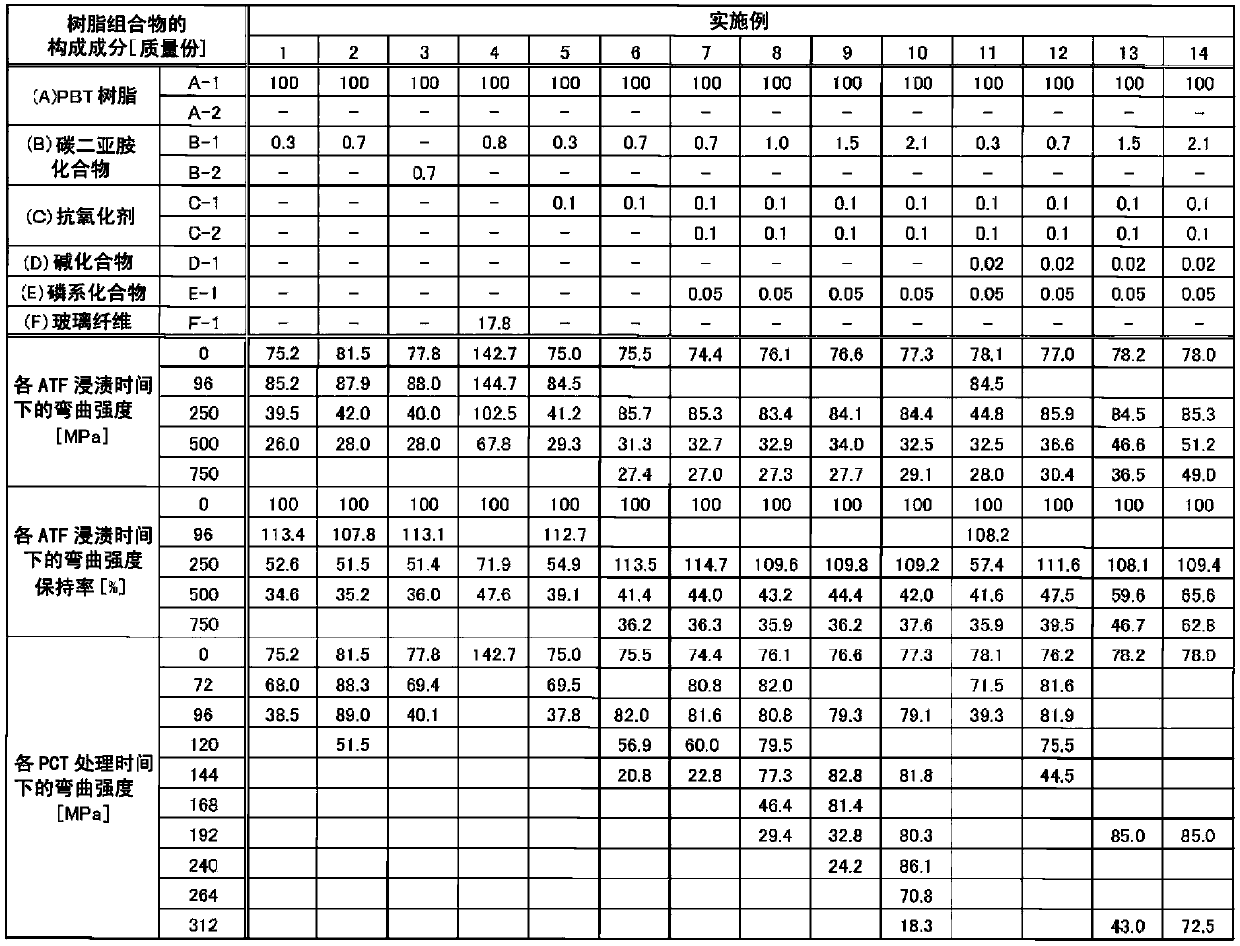

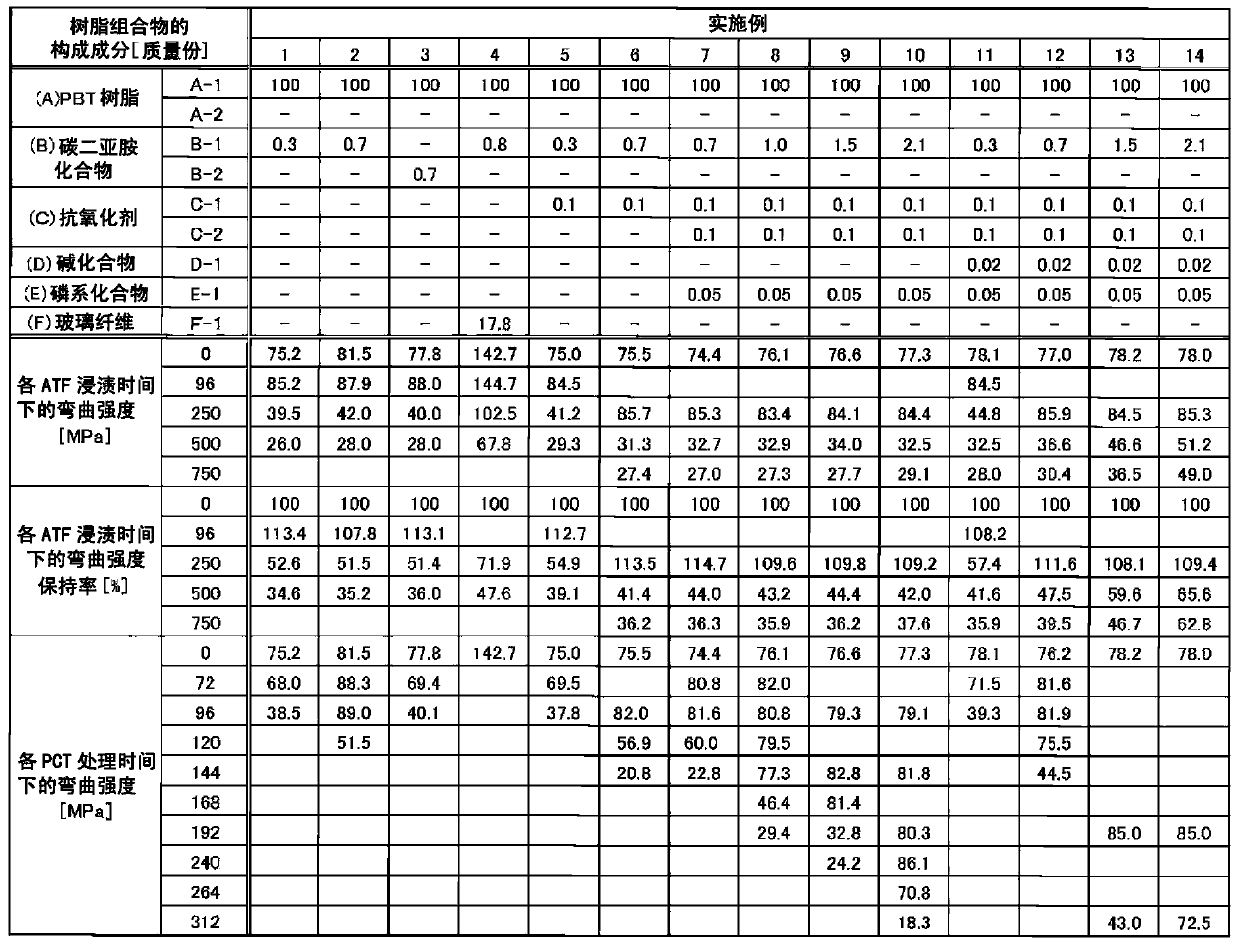

Poly(butylene terephthalate) resin composition

ActiveCN107922718AReduced inhibitory strengthPolytetramethylene terephthalatePolyethylene terephthalate

Provided is a resin composition which includes a poly(butylene terephthalate) resin excellent in terms of physical and chemical properties, etc. and which has excellent ATF resistance and is suitablefor use as molded articles to be used in contact with high-temperature automotive lubricating oils such as ATF. The poly(butylene terephthalate) resin composition according to the present invention comprises a poly(butylene terephthalate) resin and a carbodiimide compound and is for use in configuring molded articles to be used in contact with automotive lubricating oils, and the molded article has a tensile strength retention of 50% or higher after 250-hour immersion in a 150 DEG C automotive lubricating oil.

Owner:POLYPLASTICS CO LTD

Front cover structure of a motorcycle

The invention provides a front cover structure of an automatic two wheel vehicle. The front cover structure enables smooth flow of air on the front cover arranged on the front part of the vehicle. The front cover structure of the automatic two wheel vehicle (1) includes a head lamp 912) arranged on the front part of the vehicle, a front cvoer (10) arranged in a manner of surrounding the outer periphery of the head lamp (12), a protection shade (15) arranged on the upper side of the front cover (10). The front cover structure is characterized in that a concave part (11) sinking towards the inner side of the vehicle is formed in the front cover and between the head lamp (12) and the protection shade (15) and an opening enabling drive air to flow into the front cover is fromed in the concave part (11).

Owner:HONDA MOTOR CO LTD

Polybutylene terephthalate resin composition

Provided is a resin composition which includes a poly(butylene terephthalate) resin excellent in terms of physical and chemical properties, etc. and which has excellent ATF resistance and is suitable for use as molded articles to be used in contact with high-temperature automotive lubricating oils such as ATF. The poly(butylene terephthalate) resin composition according to the present invention comprises a poly(butylene terephthalate) resin and a carbodiimide compound, has a tensile strength retention of 50% or higher after 250-hour immersion in a 150ºC automotive lubricating oil, and is for use in configuring molded articles to be used in contact with automotive lubricating oils.

Owner:POLYPLASTICS CO LTD

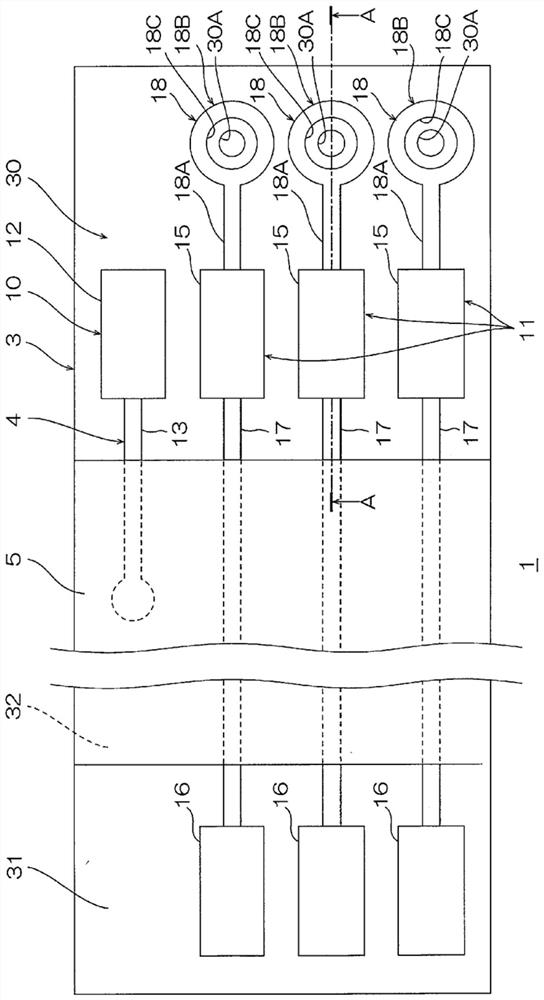

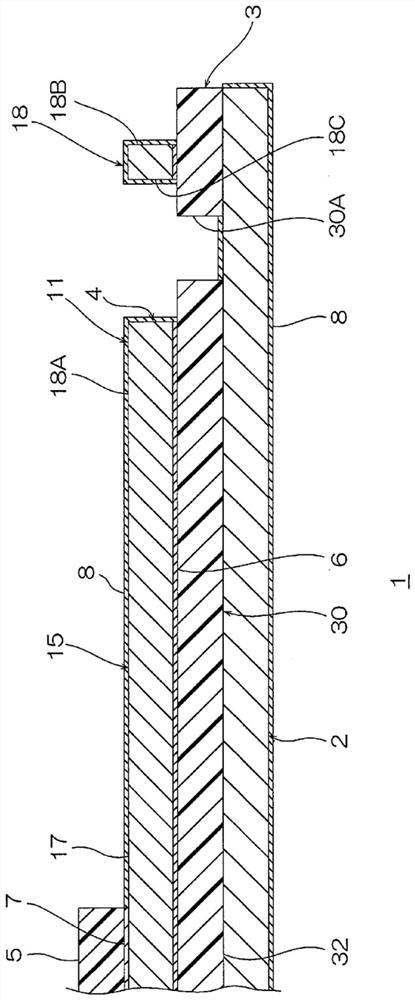

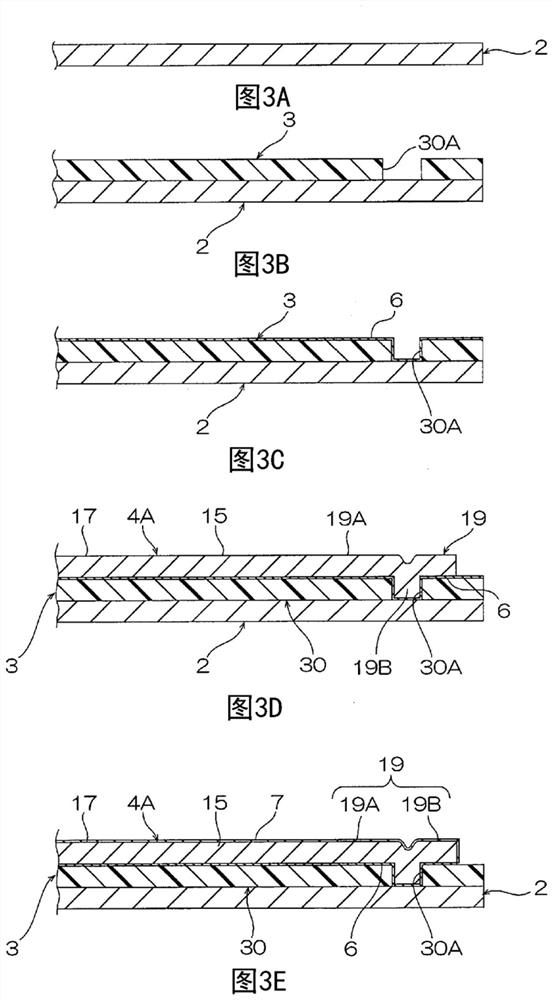

Wiring circuit board

PendingCN113826454AReduced inhibitory strengthEfficient preparationPrinted circuit aspectsPrinted circuit secondary treatmentElectrical conductorElectrical connection

This wiring circuit board 1 comprises: a metal support layer 2; a base insulating layer 3 disposed on one side in the thickness direction of the metallic support layer 2; and a conductor layer 4 disposed on one side in the thickness direction of the base insulating layer 3 and provided with first terminals 15 and ground lead remainder portions 18 electrically connected to the first terminal 15. The base insulating layer 3 is provided with through-holes 30A passing therethrough in the thickness direction. The ground lead remainder portions 18 comprise openings 18C extending so as to surround the respective through-holes 30A.

Owner:NITTO DENKO CORP

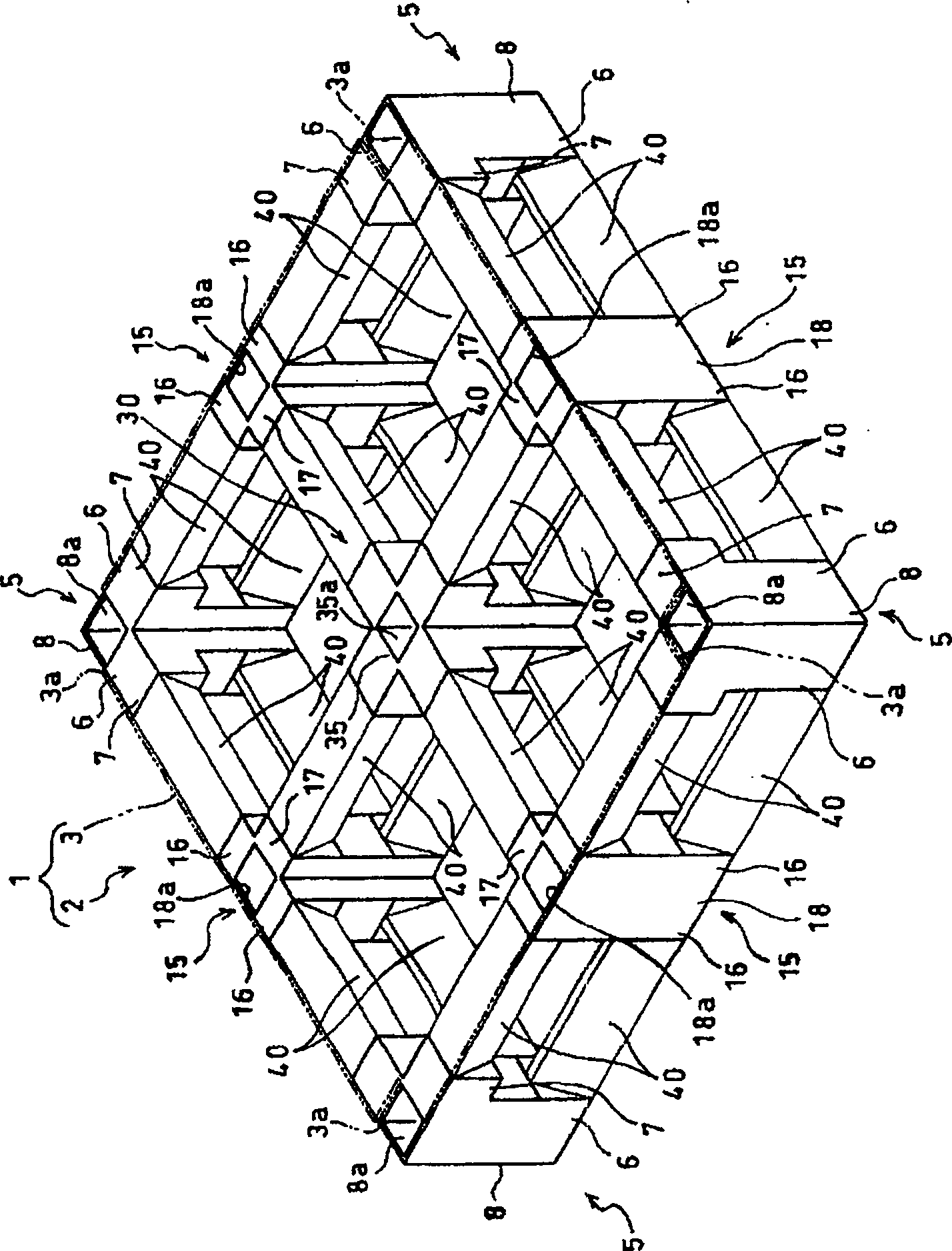

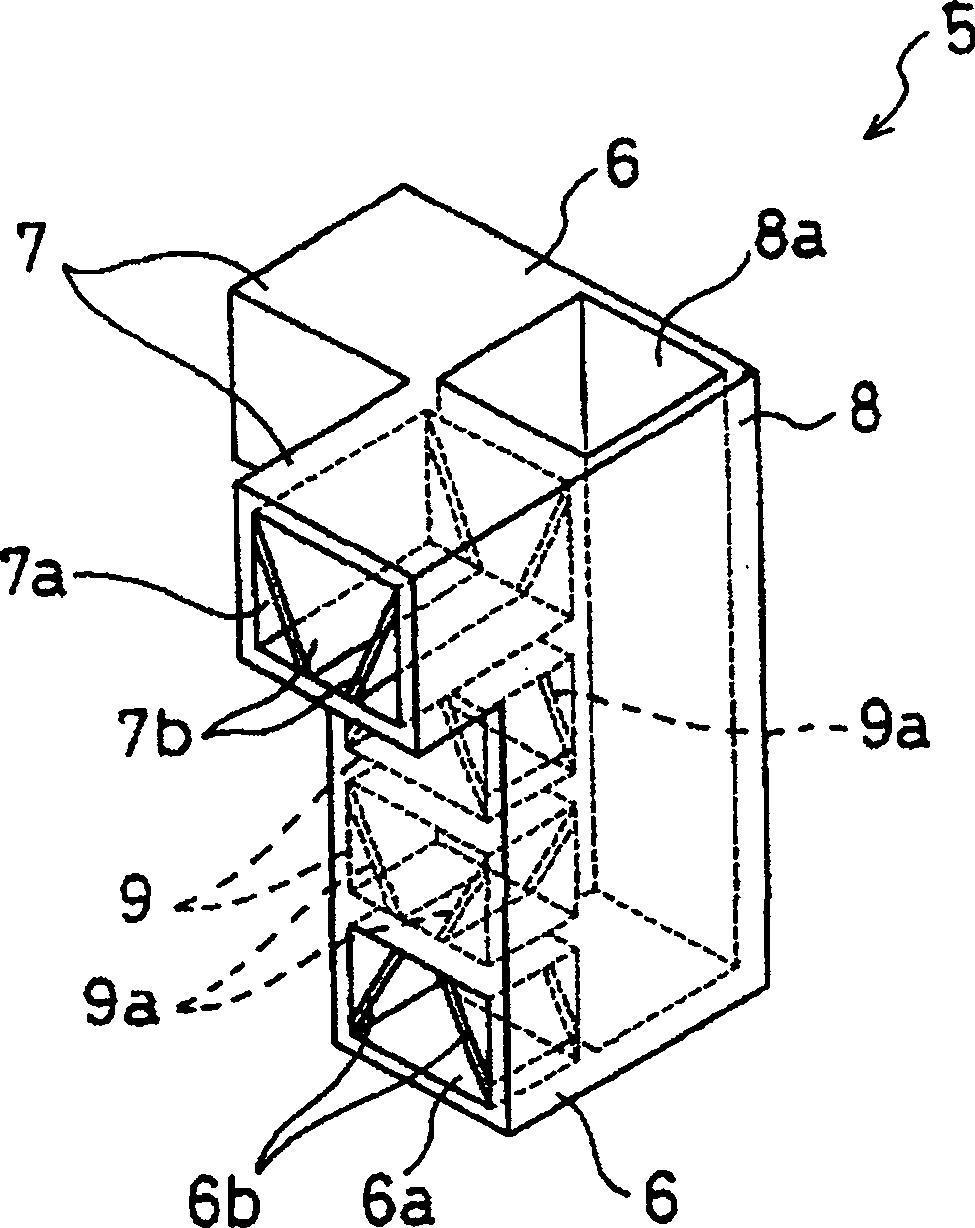

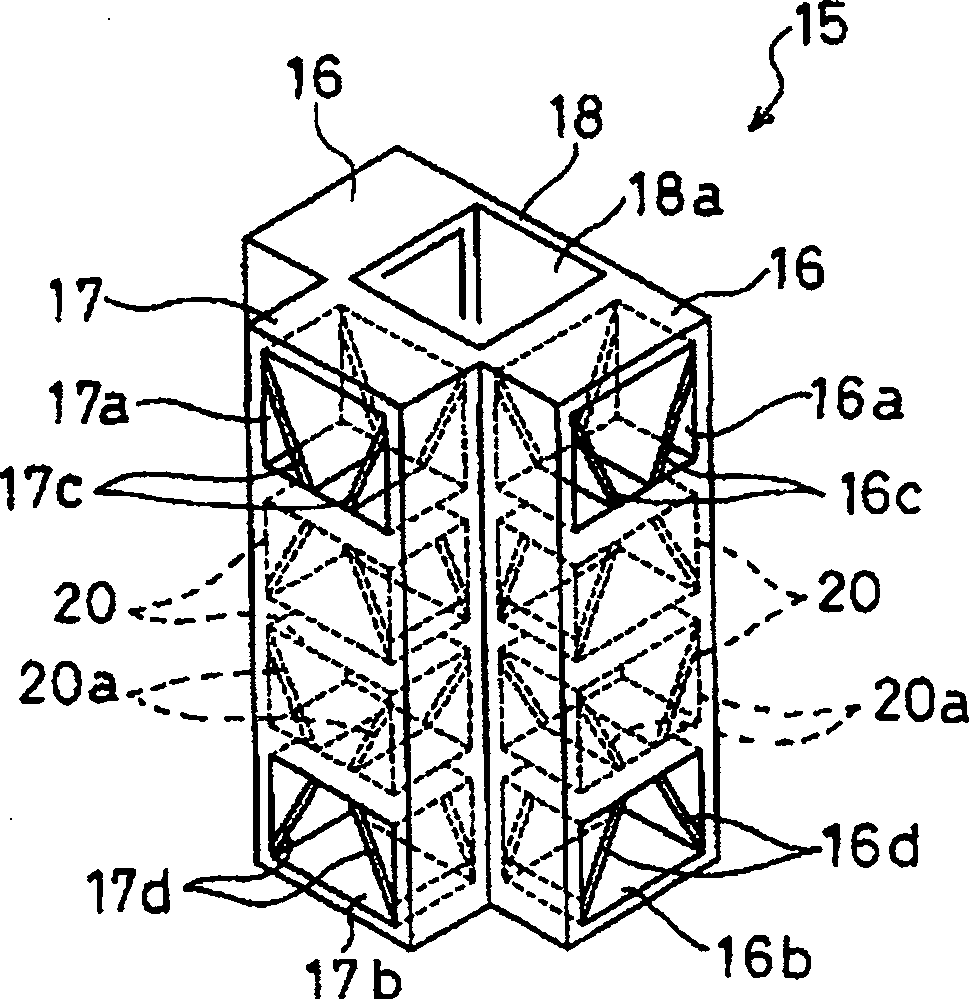

Resin pallet

A resin pallet, in which a plurality of resin blocks (5), (15), (30) are connected with a plurality of rod-shaped connecting members (40) to form a skeleton part (2), and each block ( 5), (15), and (30) are provided with a plurality of openings facing in different directions, and the connecting member (40) is inserted into these openings. A resin pallet (1) is formed by providing a flat plate (3) covering the frame portion (2).

Owner:日本秋子公司

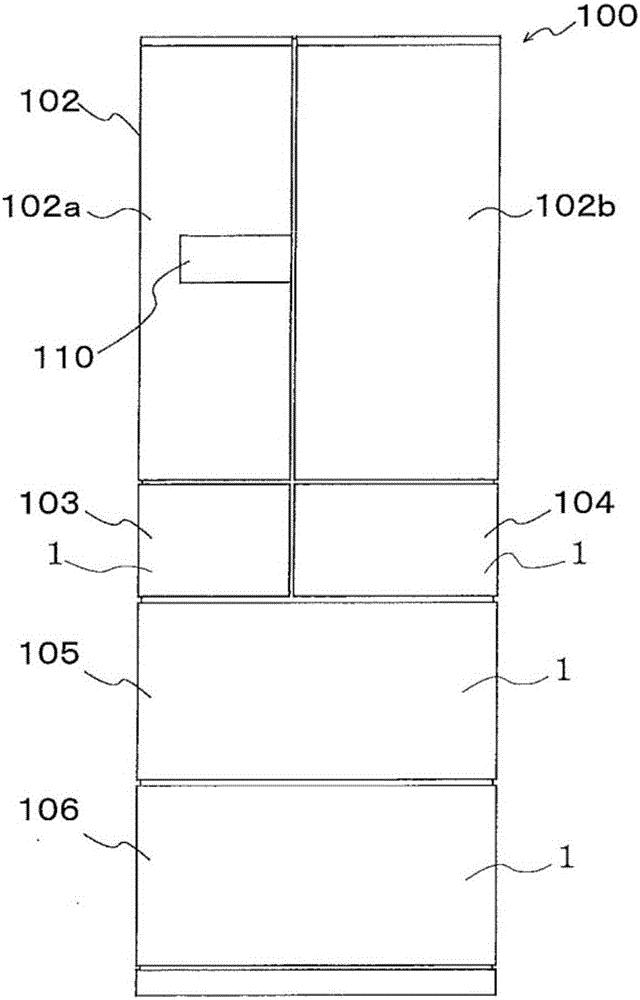

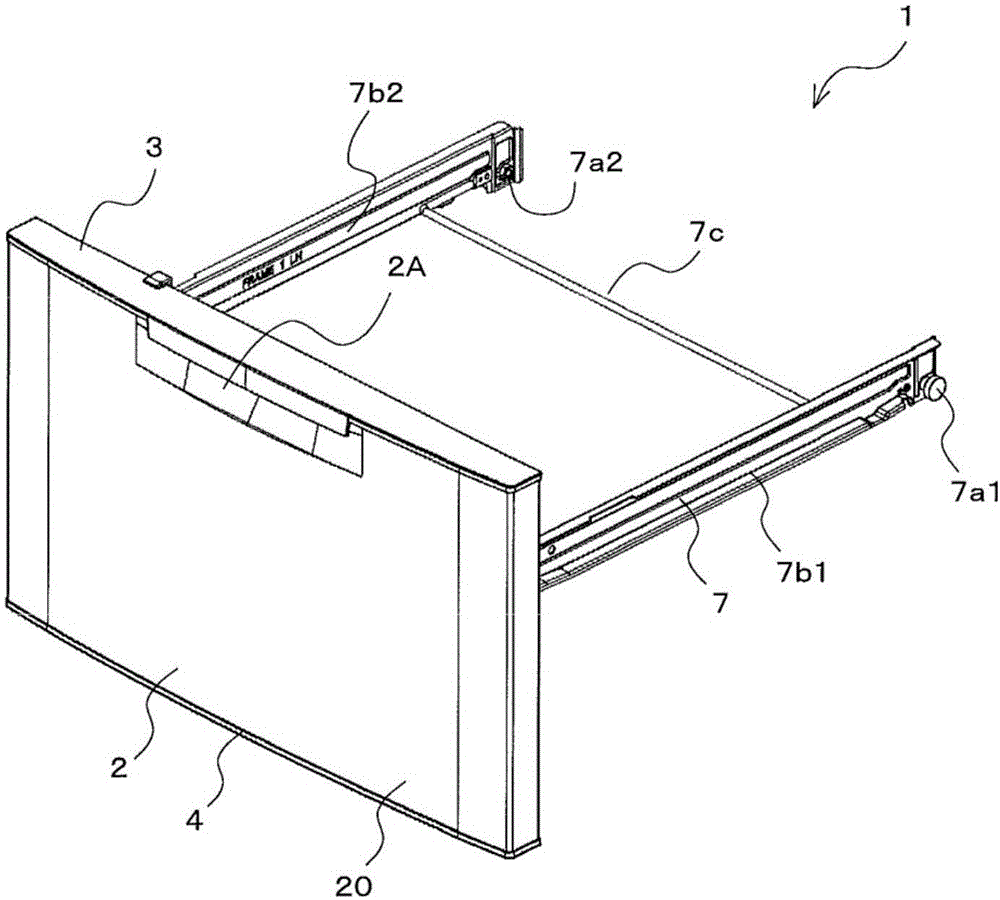

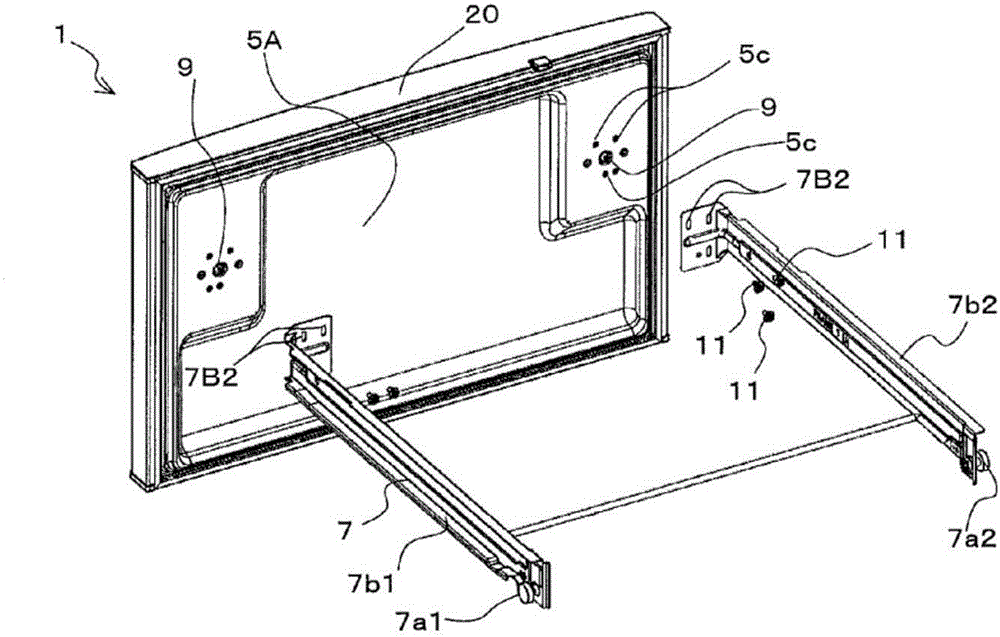

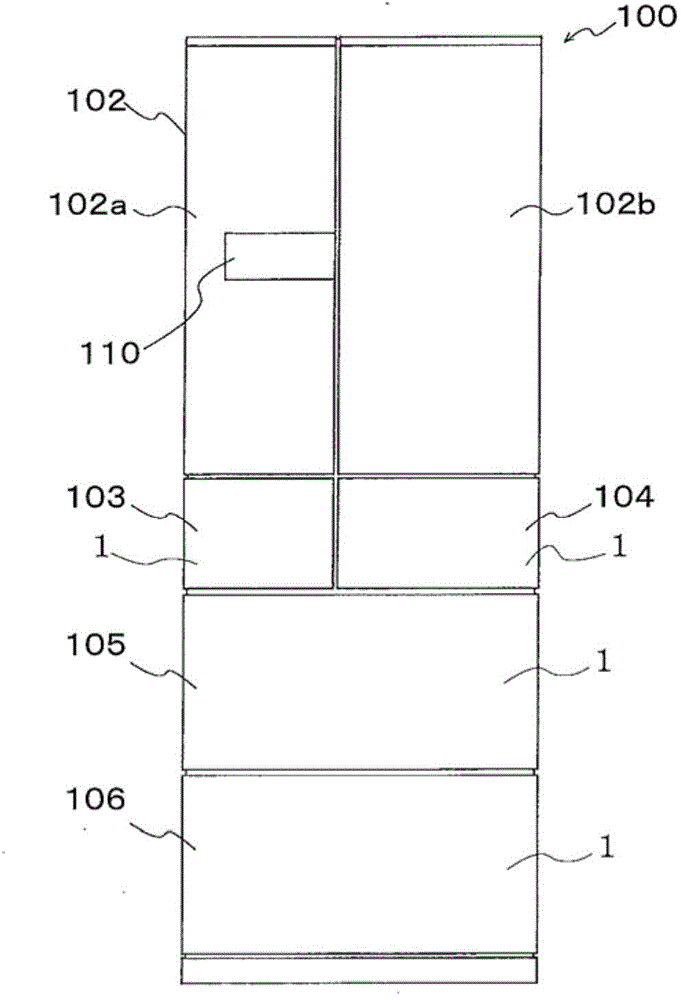

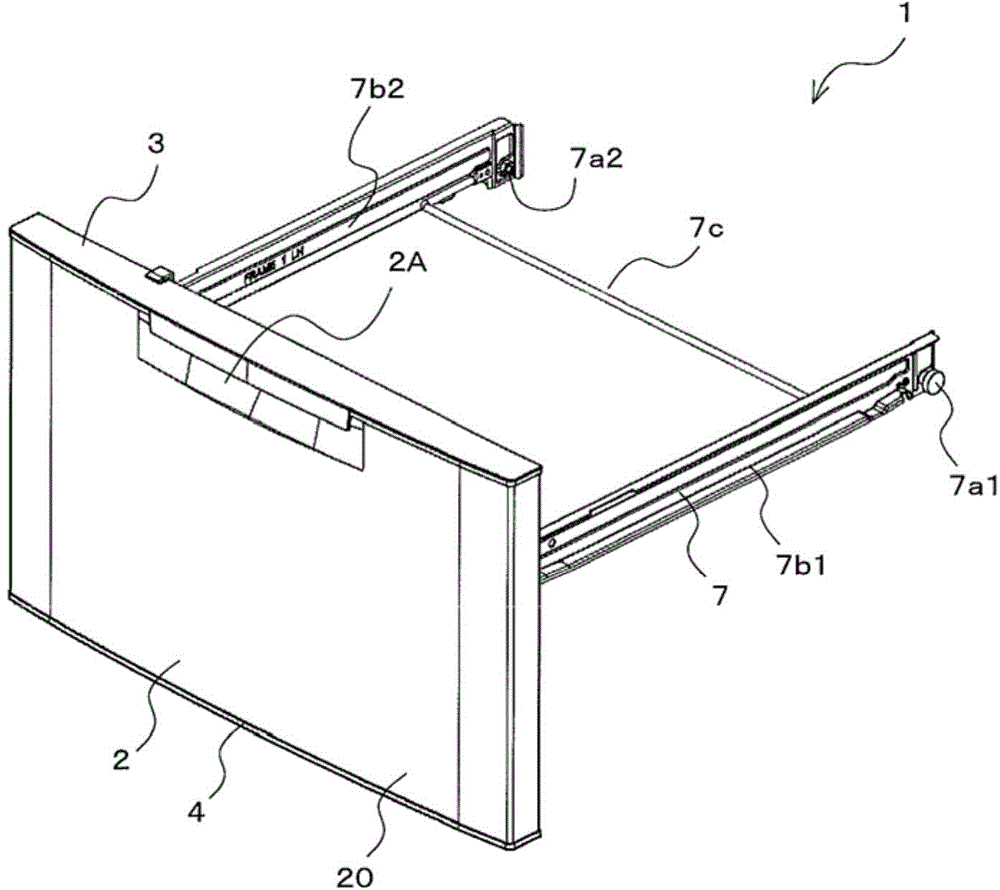

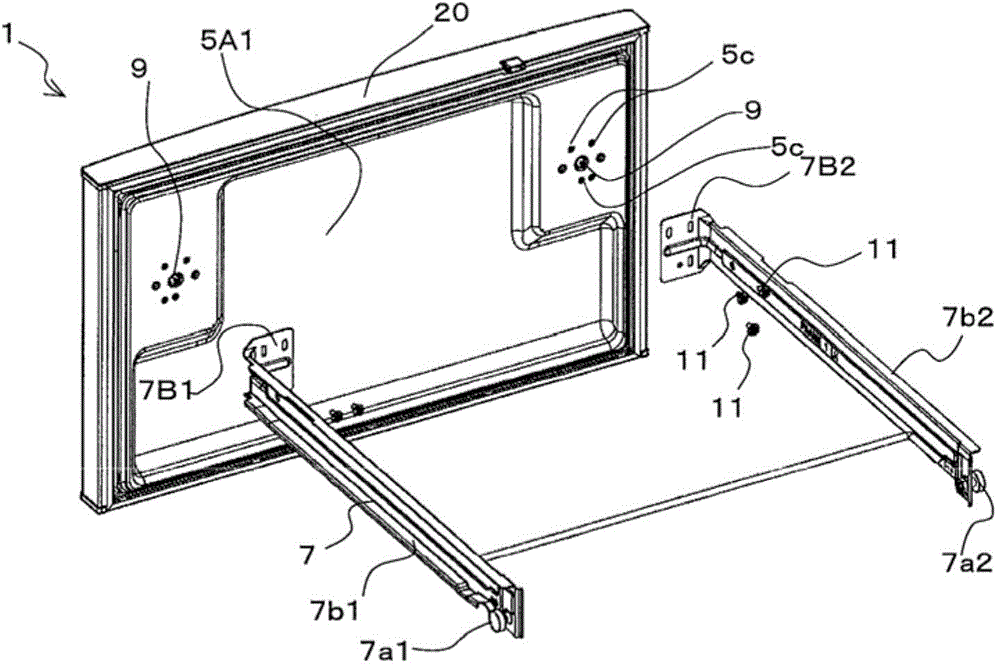

Refrigerator door and a refrigerator having the same

ActiveCN104344662BSuppression of manufacturing cost increaseReduced inhibitory strengthLighting and heating apparatusSupportEngineeringUltimate tensile strength

Owner:MITSUBISHI ELECTRIC CORP

Refrigerator door and refrigerator with same

ActiveCN104344662ASuppression of manufacturing cost increaseReduced inhibitory strengthLighting and heating apparatusSupportRefrigerator carUltimate tensile strength

Owner:MITSUBISHI ELECTRIC CORP

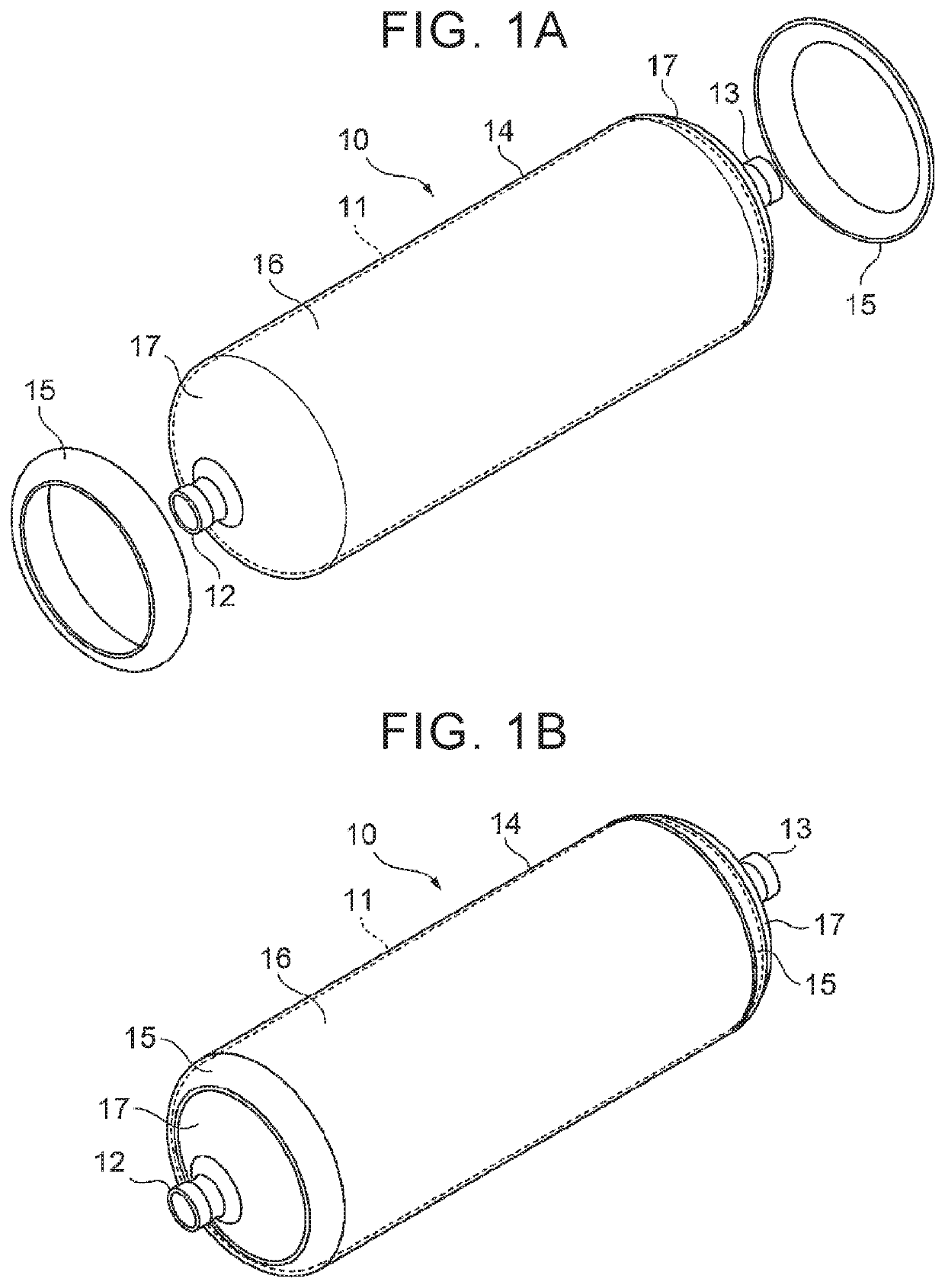

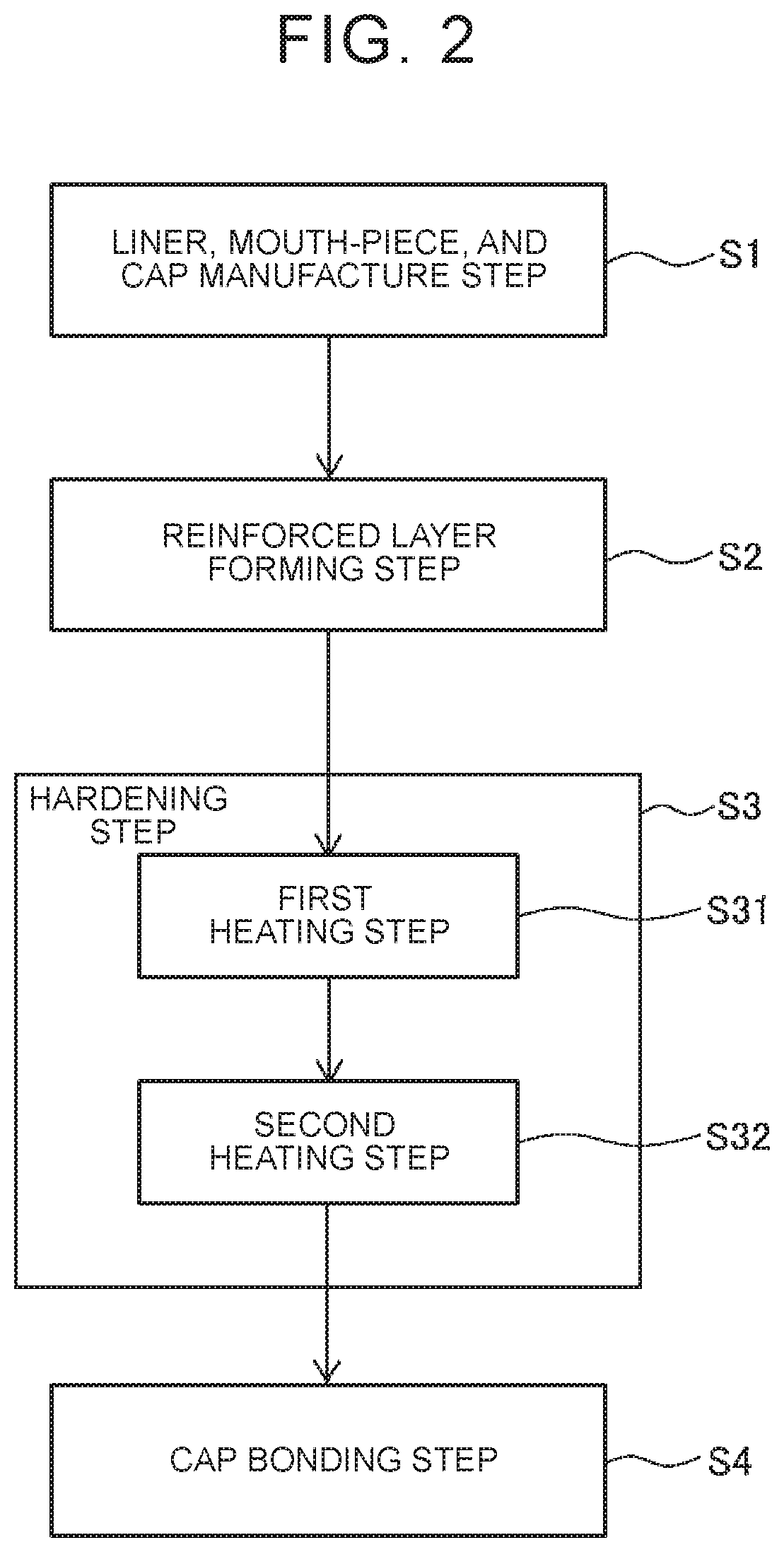

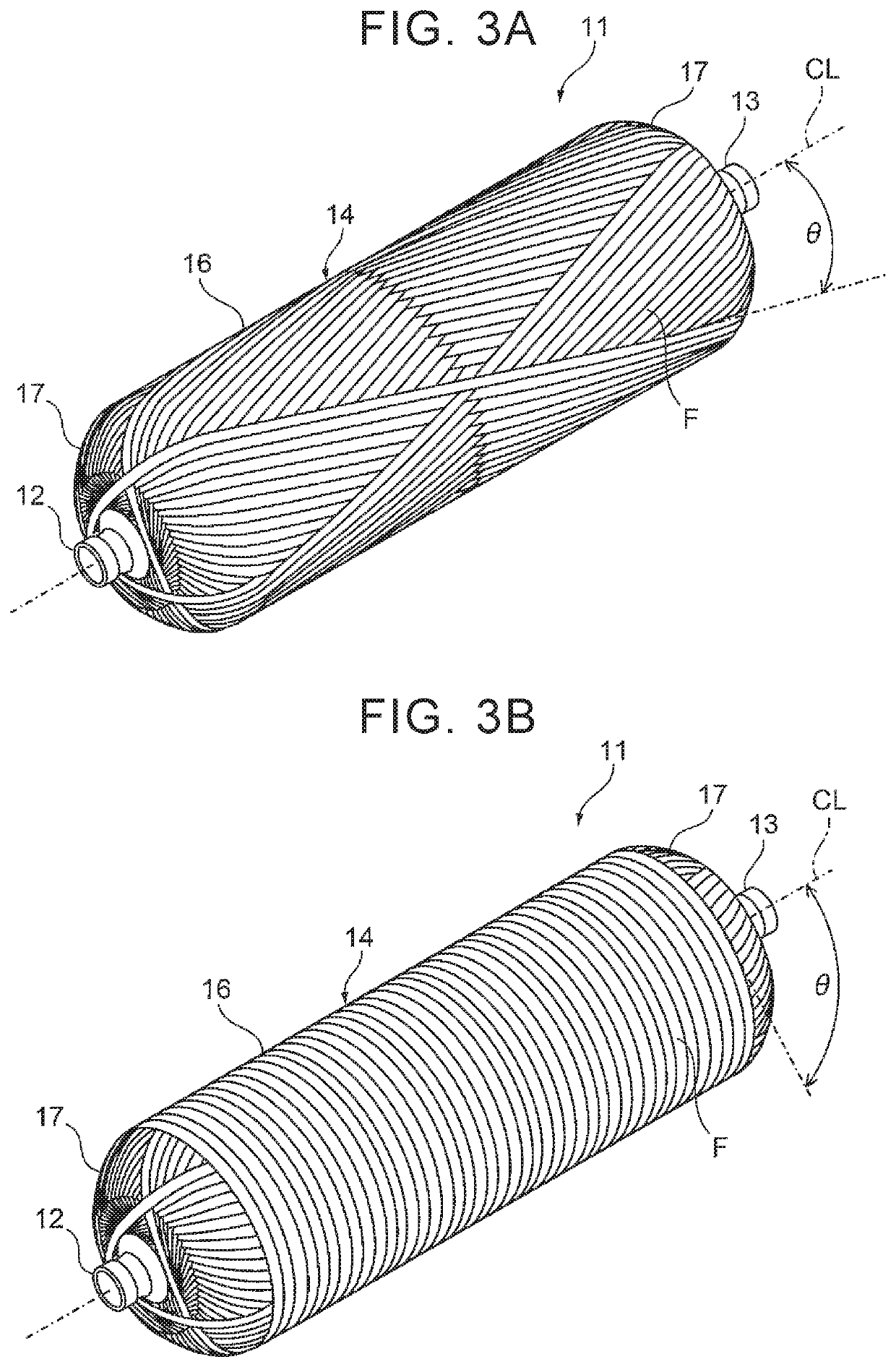

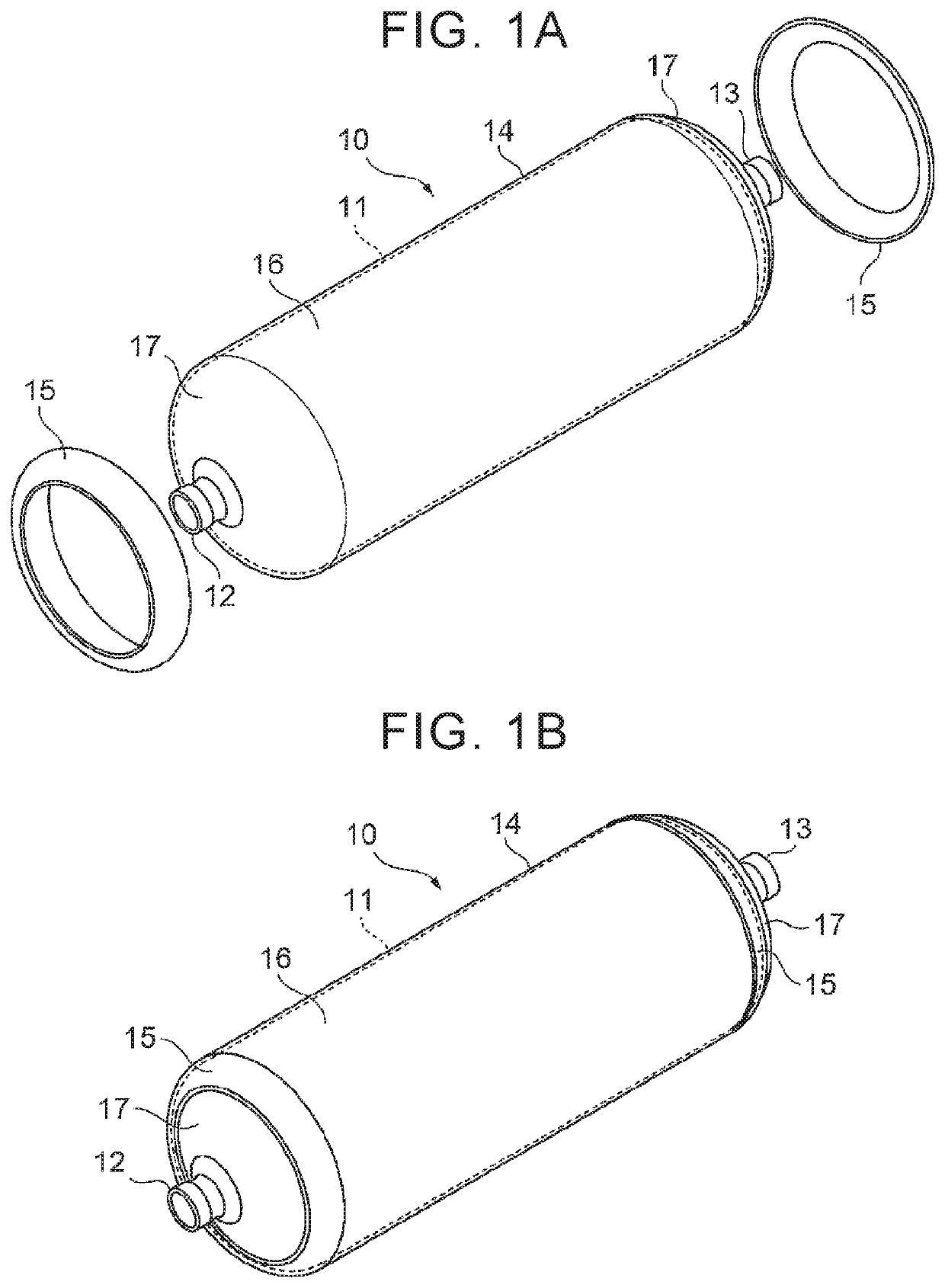

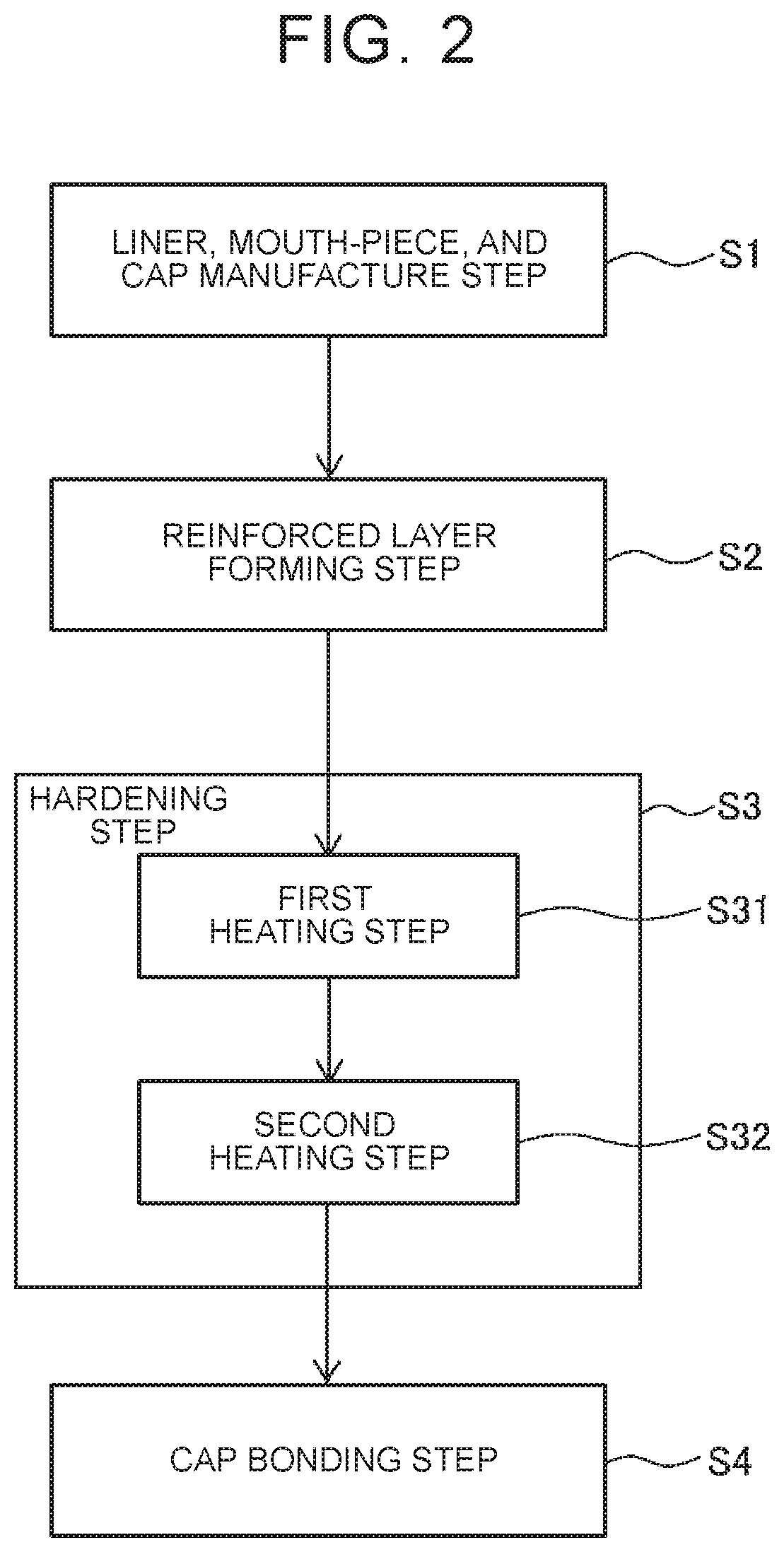

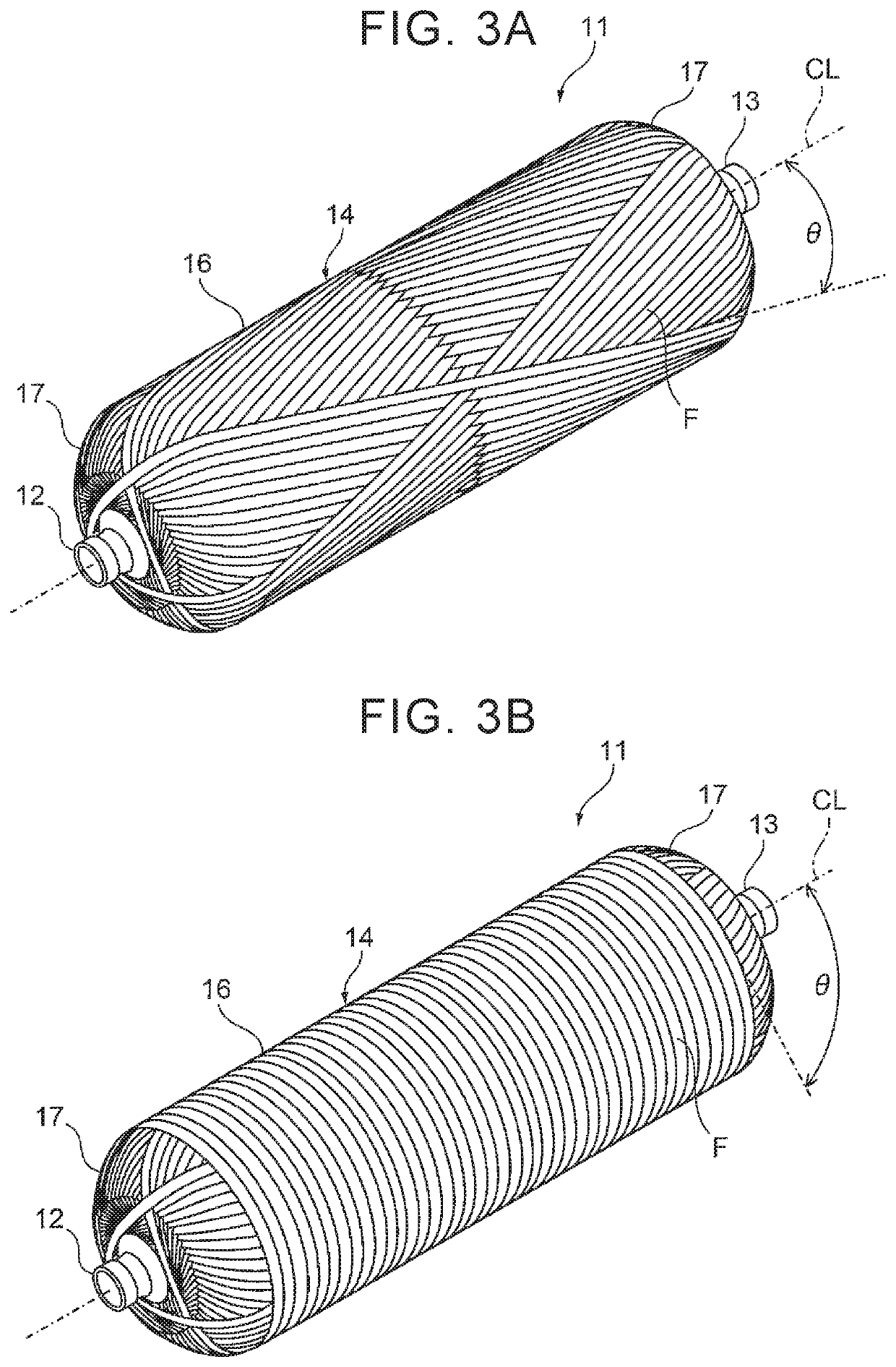

Manufacturing method for tank

ActiveUS20200282633A1Poor appearanceDecrease in qualityVessel manufacturingVessel wallsChemistryElectrically conductive

A manufacturing method for a high-pressure tank is a manufacturing method for a high-pressure tank including a reinforced layer formed such that an electrically conductive fiber bundle impregnated with thermosetting resin is wound around a liner. The manufacturing method includes: a step of preparing the tank in which the uncured reinforced layer is formed on the liner; a first heating step of heating the uncured reinforced layer by low-frequency induction heating so the thermosetting resin is softened; and a second heating step of, after the first heating step, heating the softened reinforced layer by high-frequency induction heating so that the softened reinforced layer is hardened.

Owner:TOYOTA JIDOSHA KK

Manufacturing method for tank

ActiveUS11148351B2Increase volumeProne to feverVessel manufacturingVessel wallsFiber bundleMechanical engineering

A manufacturing method for a high-pressure tank is a manufacturing method for a high-pressure tank including a reinforced layer formed such that an electrically conductive fiber bundle impregnated with thermosetting resin is wound around a liner. The manufacturing method includes: a step of preparing the tank in which the uncured reinforced layer is formed on the liner; a first heating step of heating the uncured reinforced layer by low-frequency induction heating so the thermosetting resin is softened; and a second heating step of, after the first heating step, heating the softened reinforced layer by high-frequency induction heating so that the softened reinforced layer is hardened.

Owner:TOYOTA JIDOSHA KK

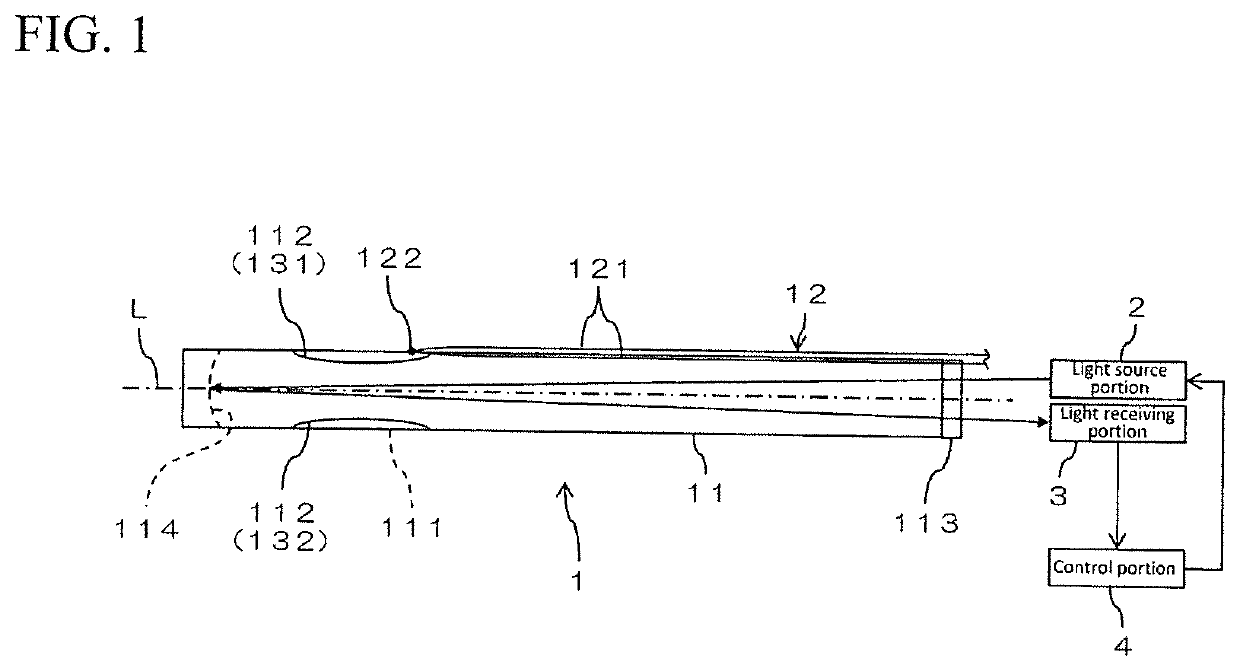

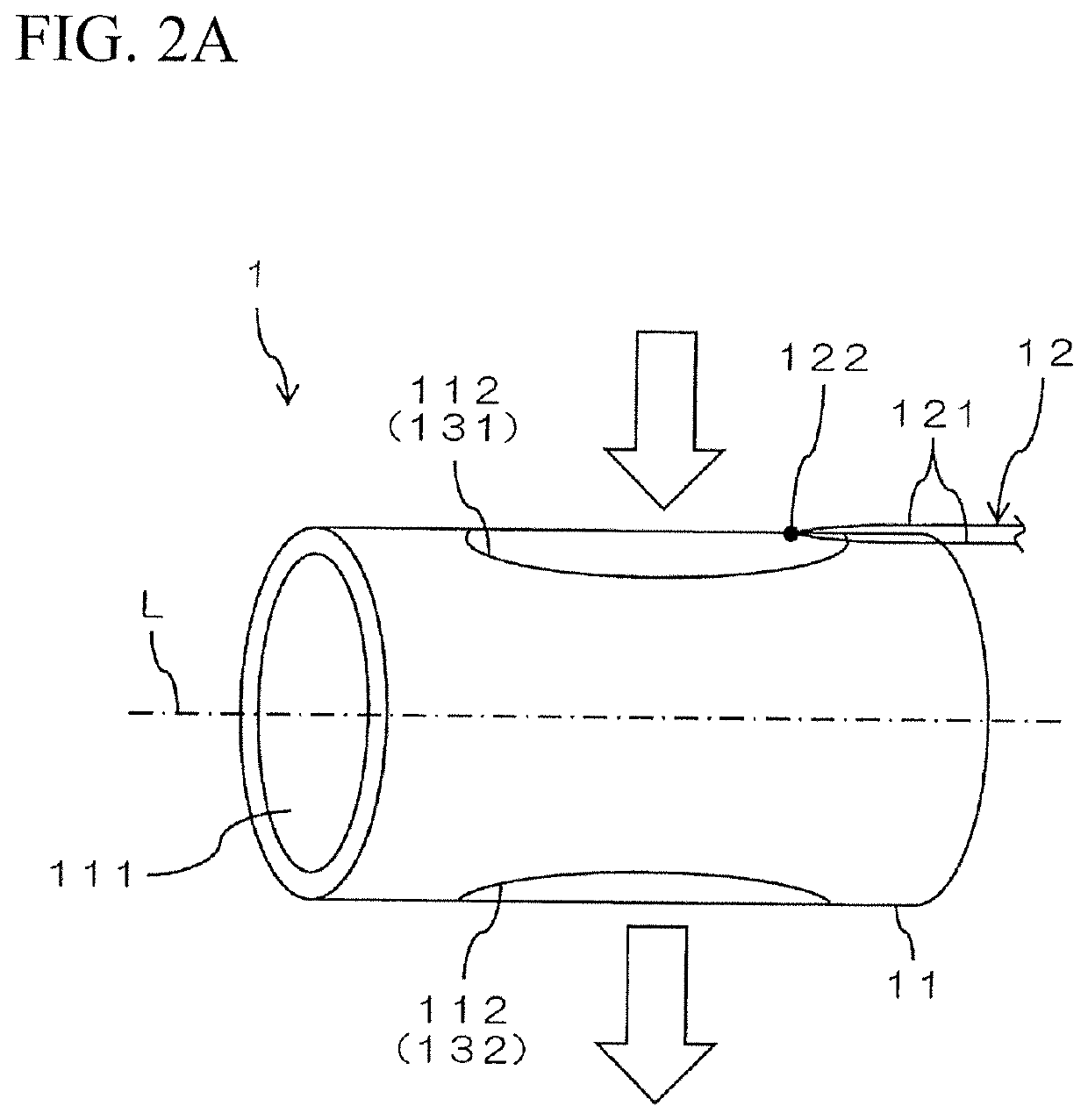

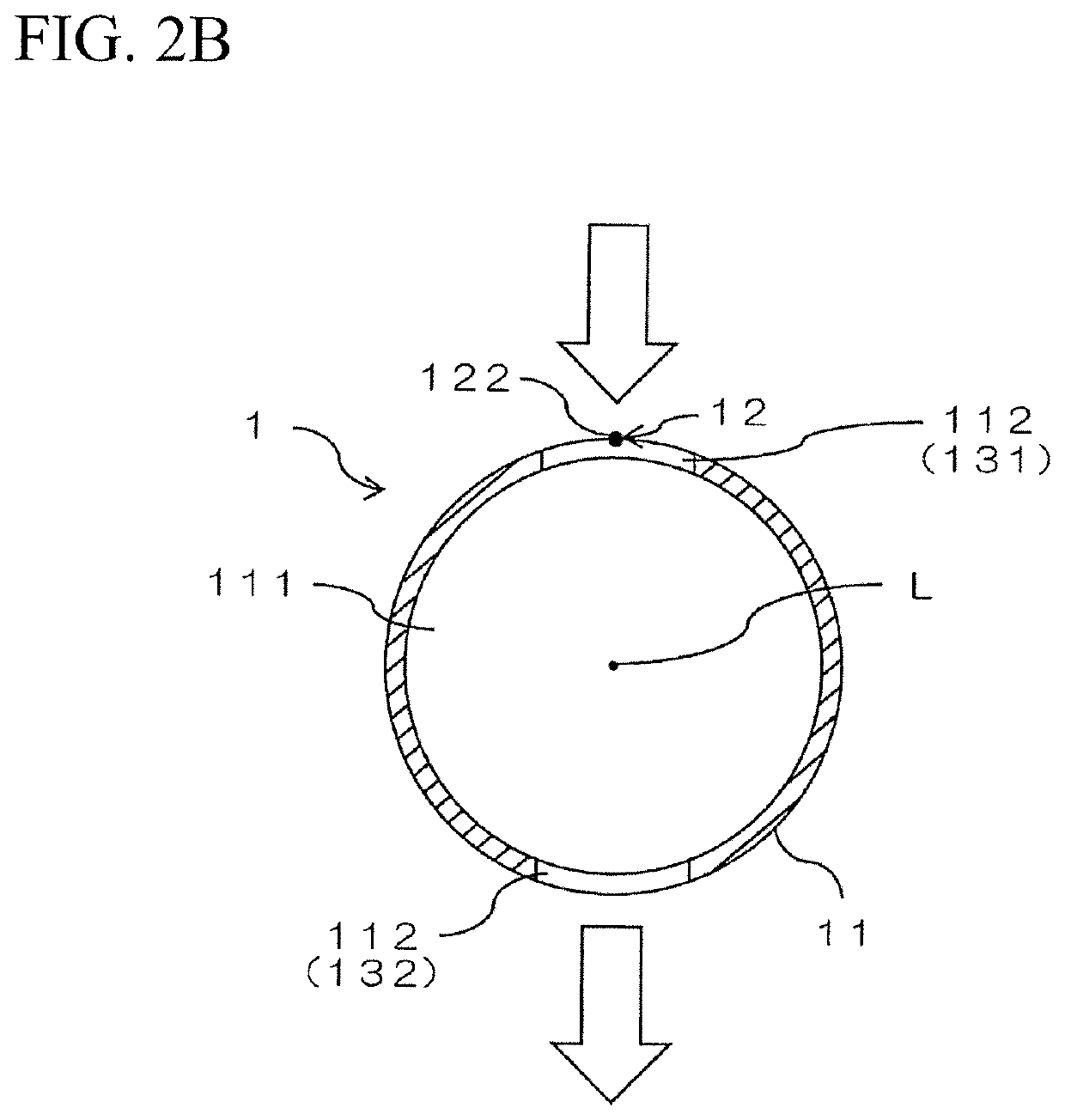

Flow cell and gas analyzing device having the same

InactiveUS20200088704A1Reduced strengthImprove responsivenessThermometers using electric/magnetic elementsRegenerative fuel cellsGas analysisInterior space

A flow cell has a tubular main body and a thermocouple. An internal space is formed in the main body, a plurality of opening portions allowing the internal space to communicate with an external portion is formed in a peripheral wall, and sample gas flowing from at least one of the plurality of opening portions passes through the internal space and flows out of the other opening portion. The thermocouple includes two metal wires which are integrally attached to the main body, and a joint part of the two metal wires is provided in the vicinity (proximate) of the opening portion closer to an upstream side of the sample gas in a distributing direction than a center axis line of the main body.

Owner:SHIMADZU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com