Poly(butylene terephthalate) resin composition

A technology of polybutylene terephthalate and resin composition, which is applied in the field of polybutylene terephthalate resin composition, can solve problems such as strength reduction, and achieve the effect of suppressing the reduction of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

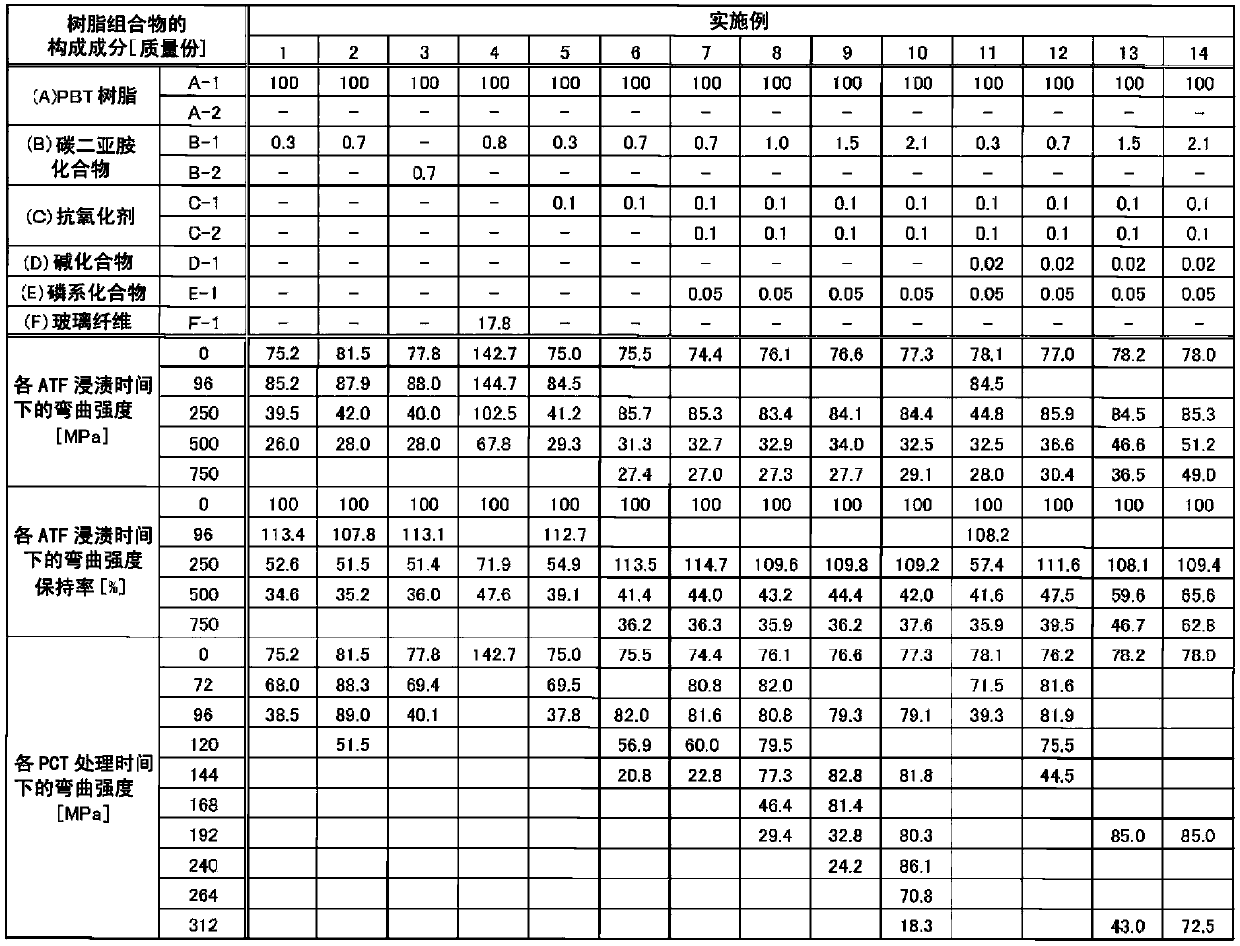

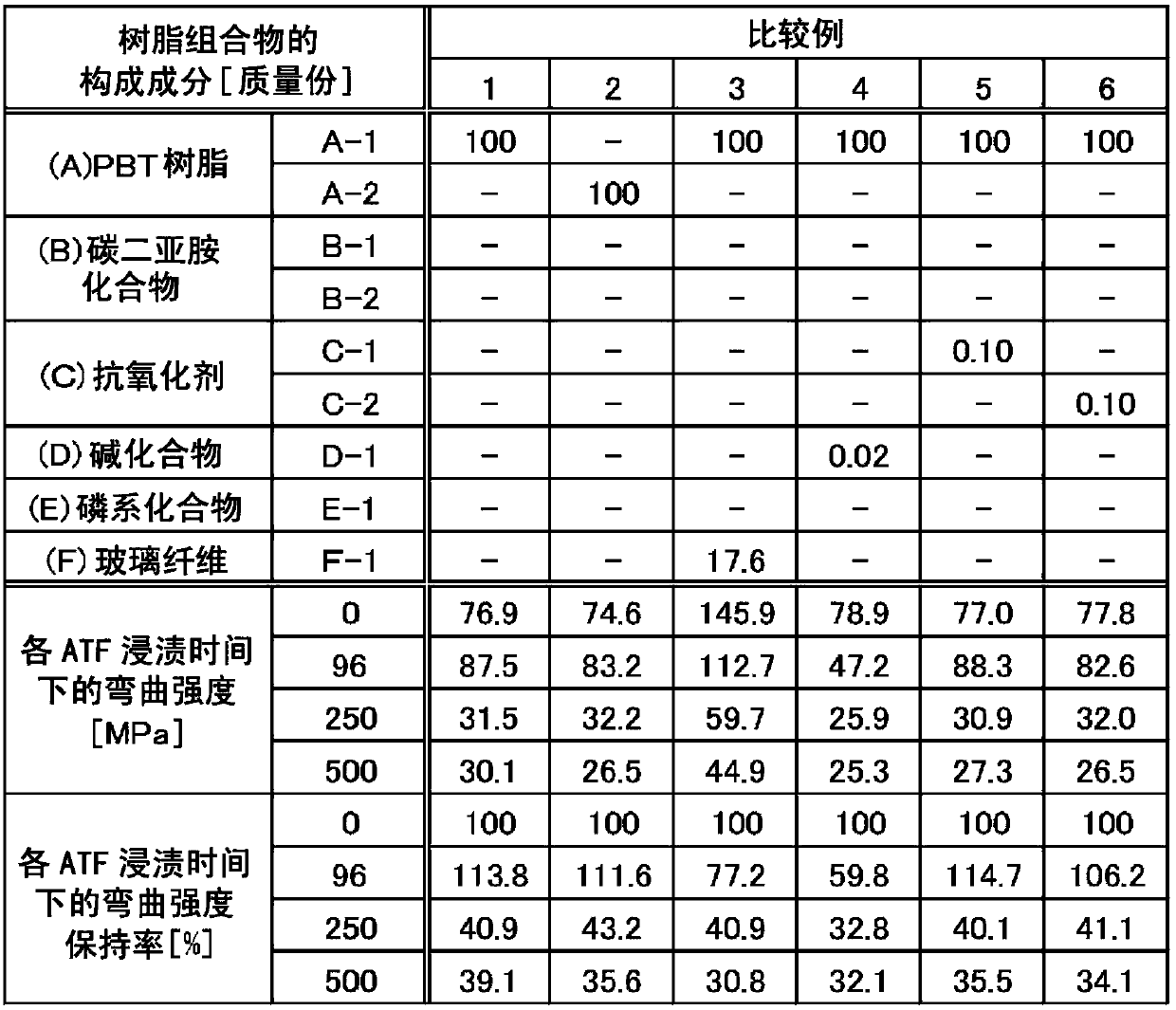

Embodiment 1~14、 comparative example 1~6

[0103] [Production of resin composition, production of molded products]

[0104] The components shown in the following Tables 1 to 2 were weighed and then dry-blended, melted and kneaded using a 30mmφ twin-screw extruder (manufactured by Nippon Steel Works, TEX-30) to produce pellets (barrel temperature 260°C, discharge rate 15kg / h, screw speed 150rpm).

[0105] Next, the prepared pellets were charged into an injection molding machine (J55AD manufactured by Nippon Steel Corporation) to prepare ISO tensile test pieces.

[0106] Here, as constituent components of the resin composition, the following were used.

[0107] (A) Polybutylene terephthalate (PBT) resin

[0108] ・(A-1) Manufactured by WinTech Polymer Ltd., intrinsic viscosity 0.83, amount of terminal carboxyl group 14meq / kg

[0109] ・(A-2) Manufactured by WinTech Polymer Ltd., intrinsic viscosity 1.14, amount of terminal carboxyl group 8meq / kg

[0110] (B) Carbodiimide compound

[0111] (B-1) Aromatic carbodiimide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com