High-strength steel sheet excellent in resistance to stress-relief annealing and low-temperature toughness

A high-strength steel plate, high-quality technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve problems such as toughness reduction, achieve excellent low-temperature toughness, and inhibit the effect of strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

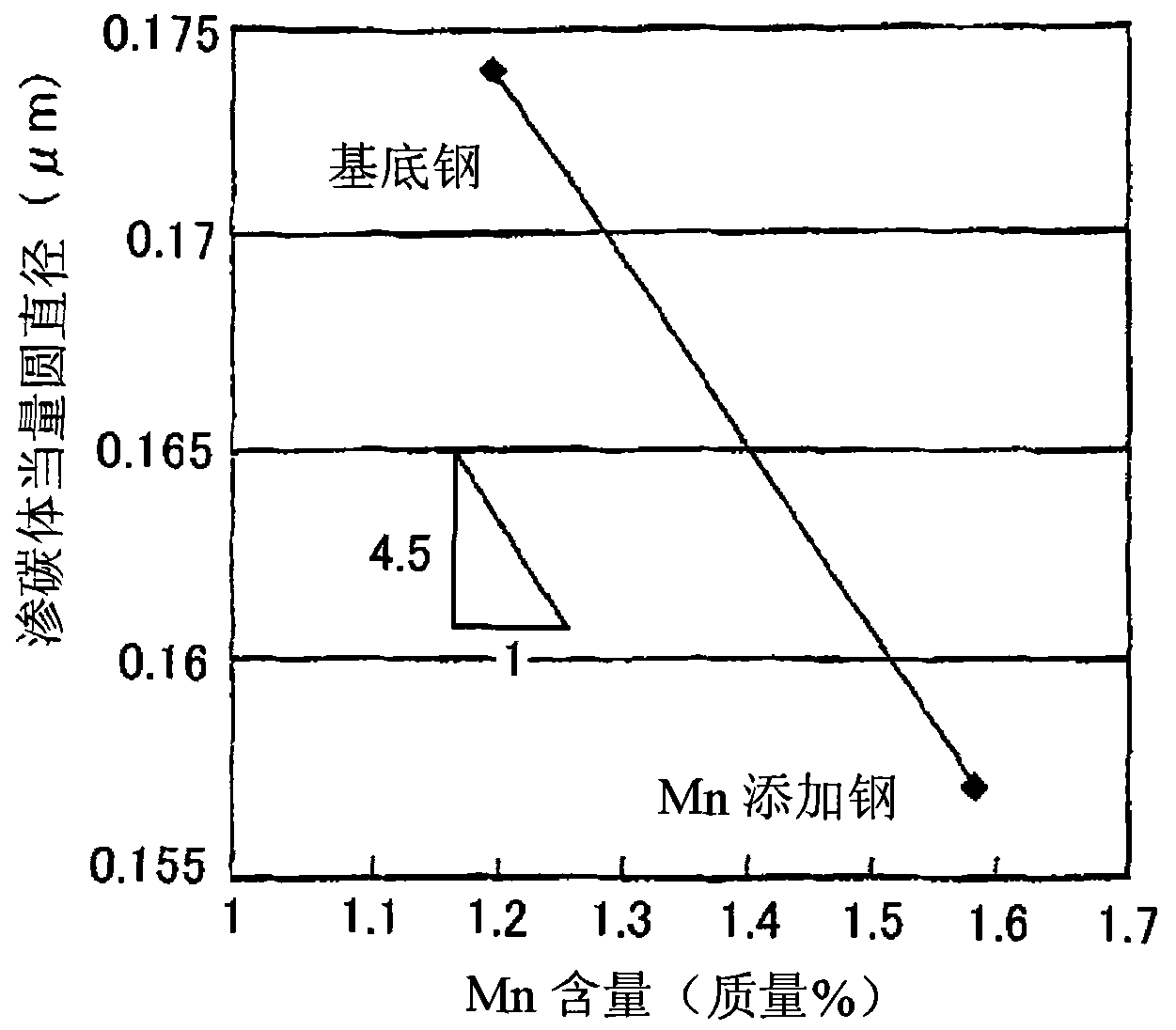

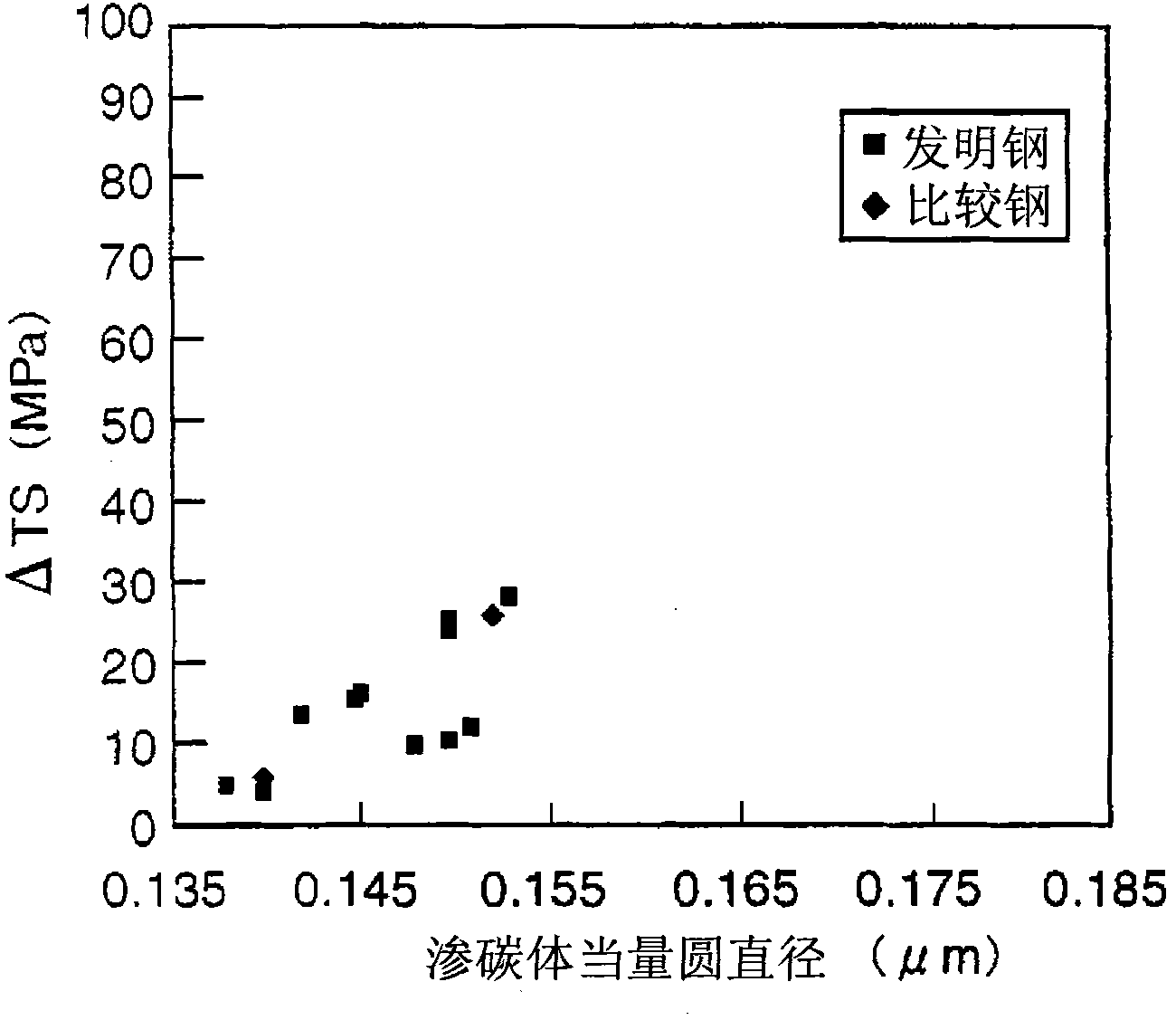

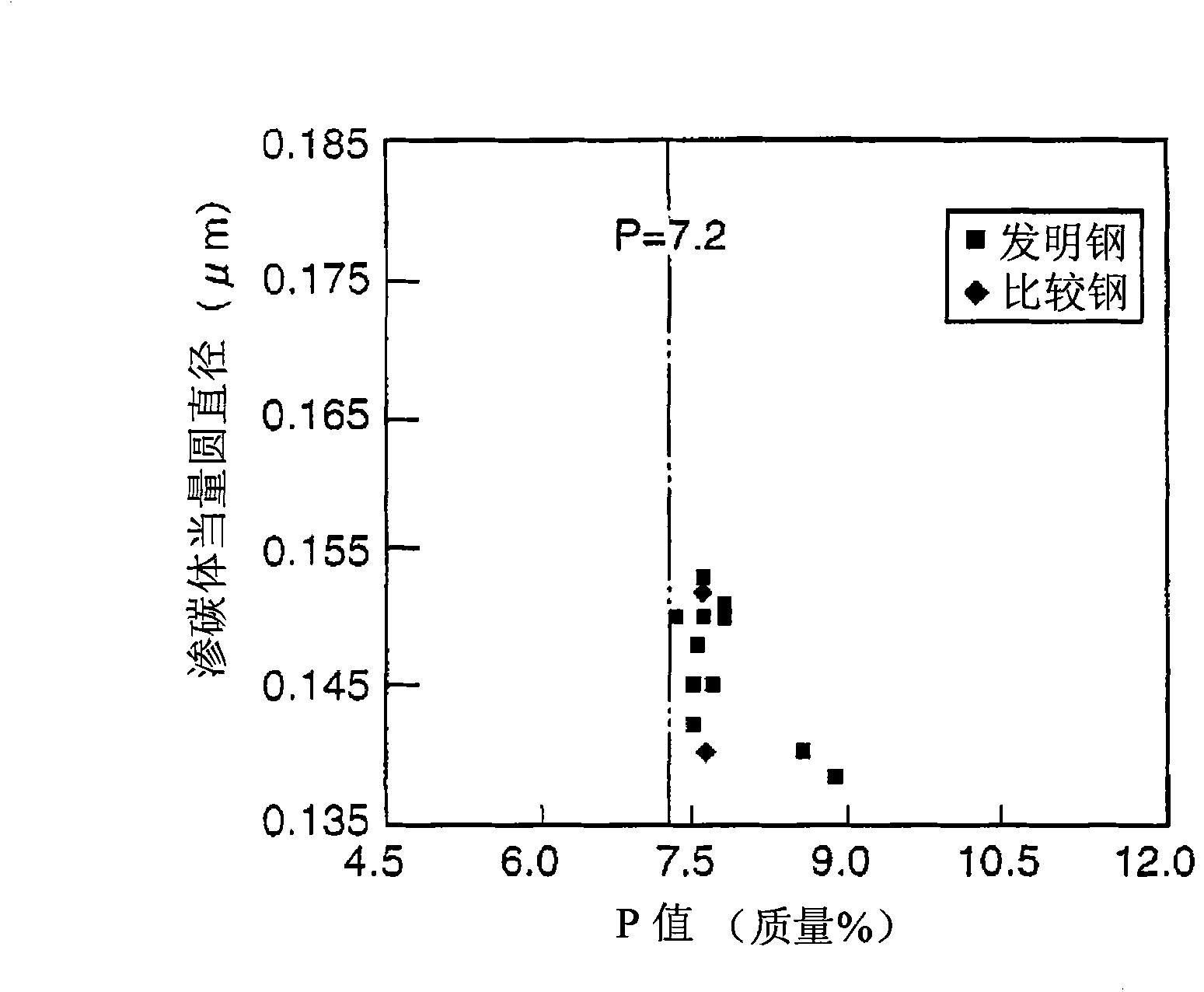

[0032] The inventors of the present invention have studied components that can maintain good weldability without causing a decrease in strength even after long-term SR treatment from various angles. As a result, it was found that as long as the chemical composition is properly controlled, and the content of Cr, Mn and V satisfies the relational expression of the above formula (1), it is possible to try to miniaturize the cementite and suppress the decline in strength. It can be seen that the technical significance. It should be noted that the present applicant has previously filed an application for the present invention (Japanese Patent Application No. 2006-338933). First, the reason for deriving the above expression (1) is as follows.

[0033] As precipitation strengthening, there is known a strengthening method in which a large amount of fine precipitates are dispersed in the matrix, and the magnetic flux pinning effect (Japanese: Pinzhime effect) of the dislocations gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com