High-strength steel sheet excellent in resistance to stress-relief annealing and low-temperature joint toughness

A stress relief annealing, high-strength steel plate technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problem of low-temperature toughness reduction of HAZ, and achieve the effect of suppressing the reduction of strength and excellent low-temperature joint characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Hereinafter, the present invention is described in more detail through the examples, but the following examples do not limit the nature of the present invention, and can also be appropriately changed and implemented within the scope of being able to meet the purpose of the foregoing and the following, and these are all included in the technology of the present invention. within range.

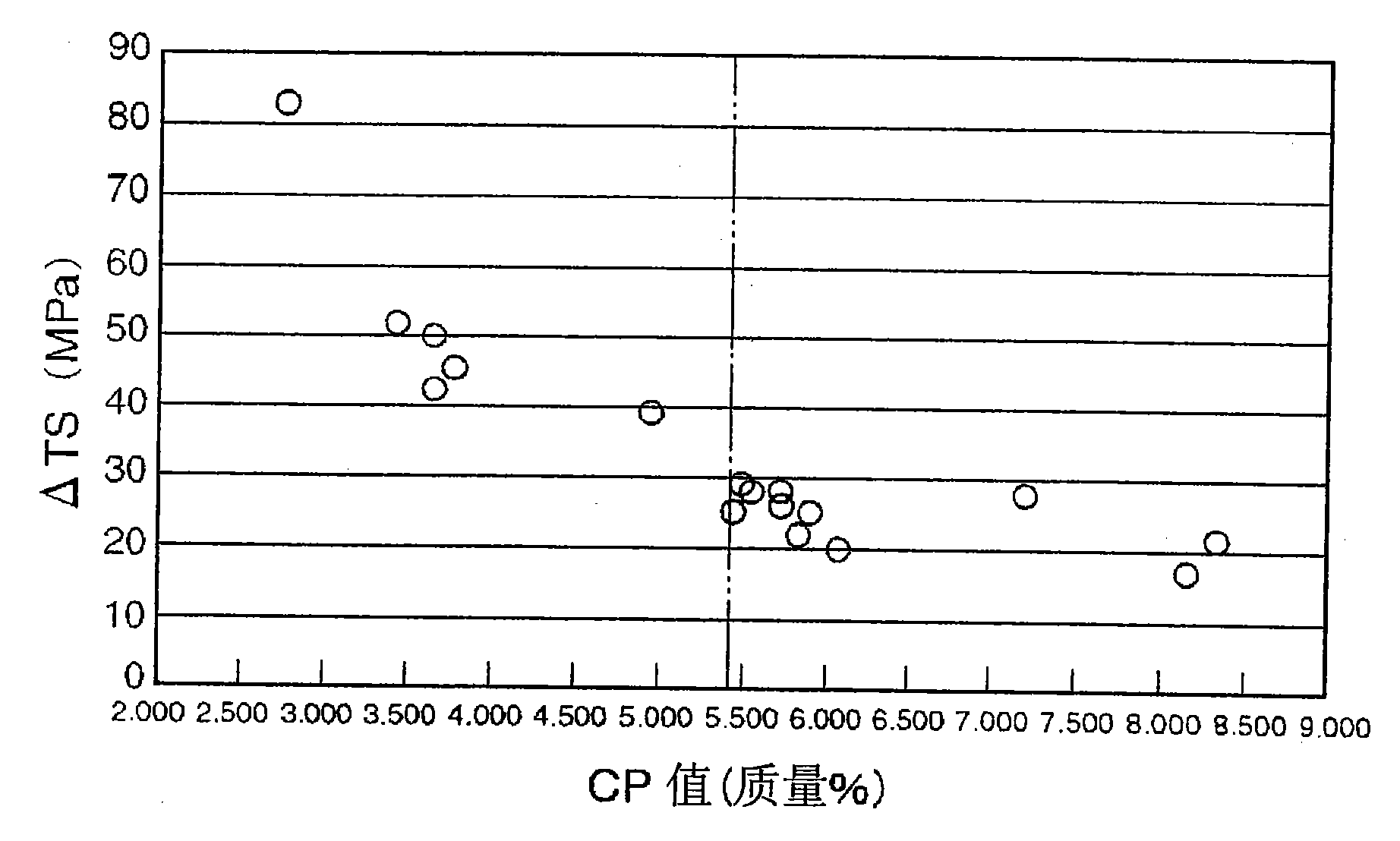

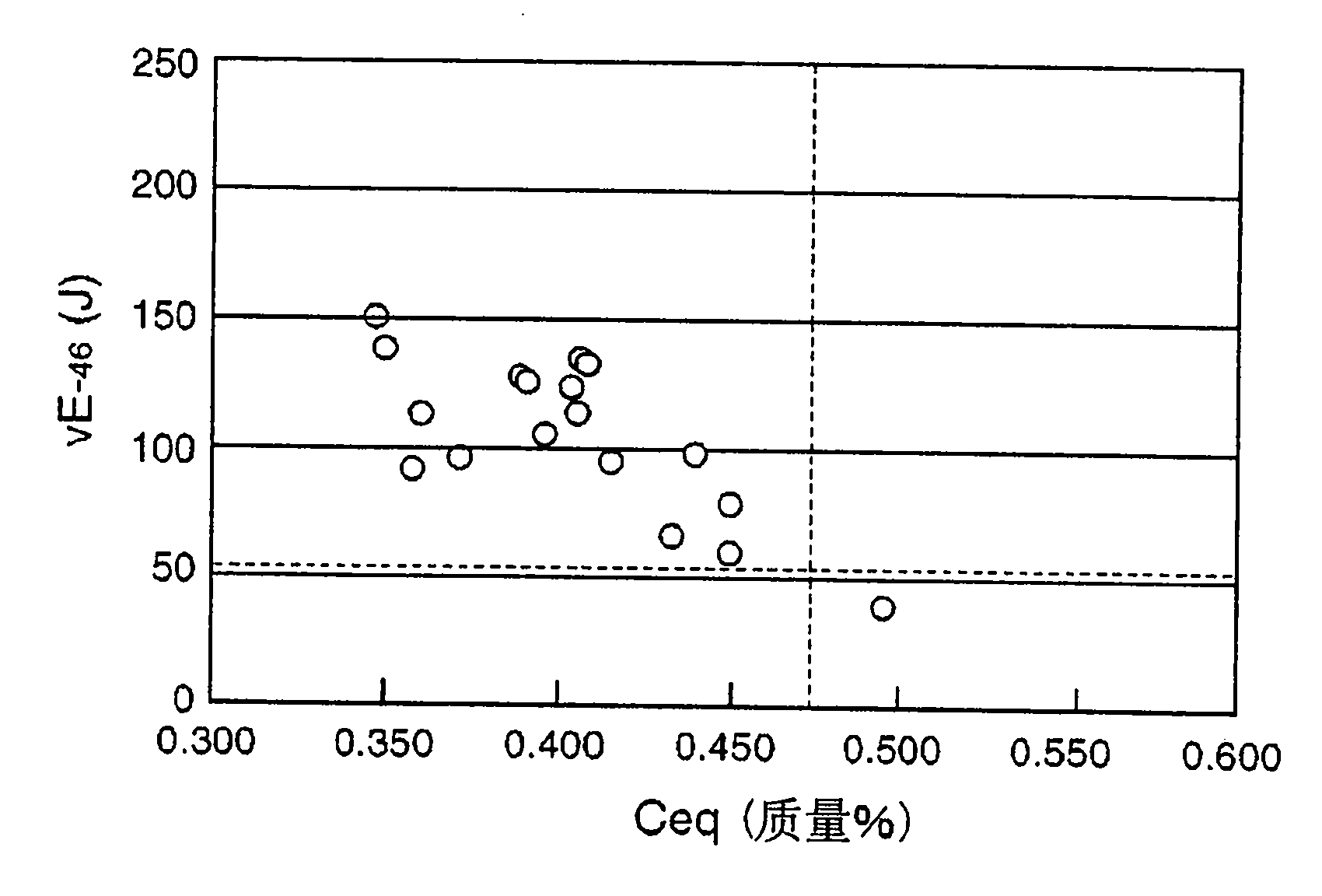

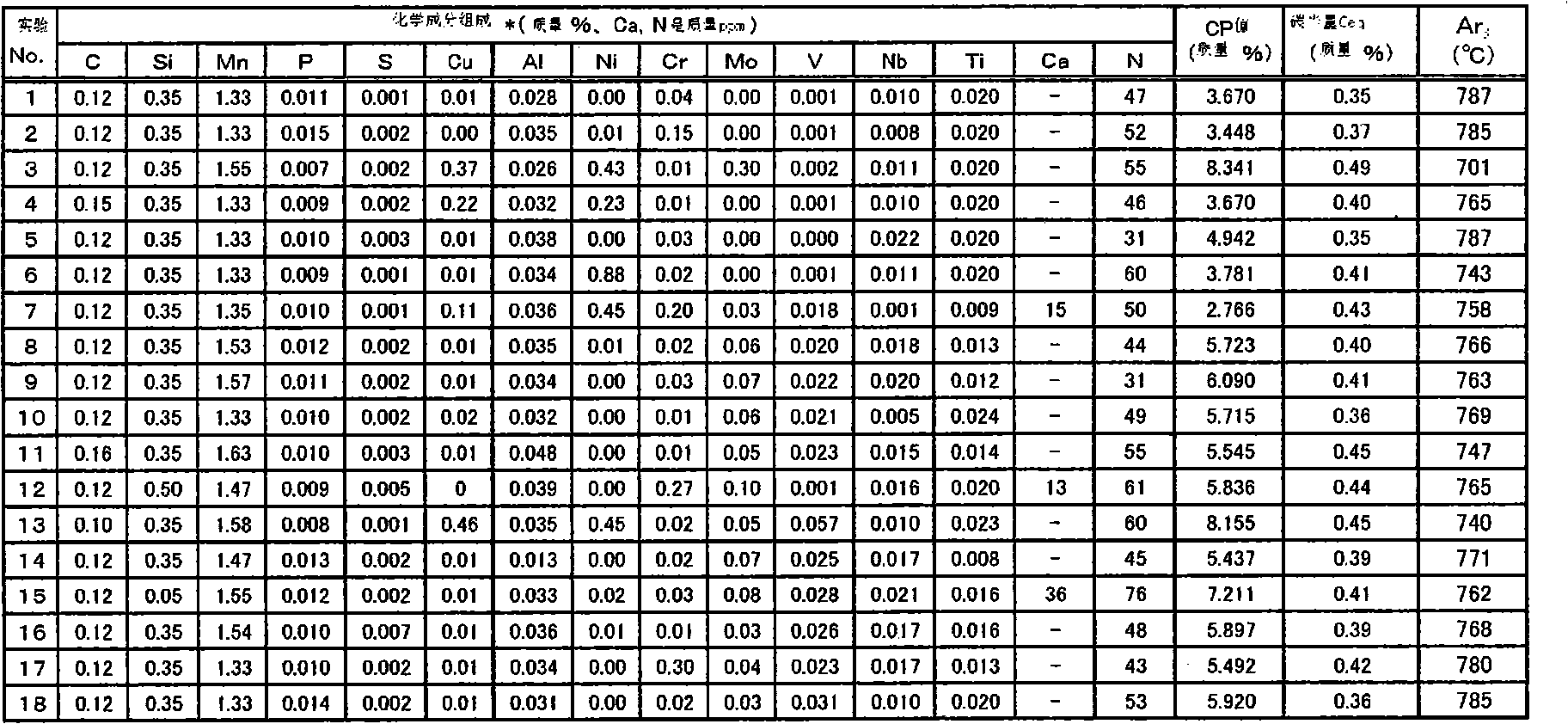

[0061] Among the various chemical compositions shown in Table 1 below, converter smelting and continuous ingot casting were carried out, and Ar 3 Rolling is completed at a temperature equal to or higher than the transformation point, and accelerated cooling (cooling rate: about 3 to 30° C. / second) is performed from this temperature to produce various steel sheets. Each of the obtained steel sheets was subjected to SR treatment at 615° C. for 23 hours (the value of P in the above formula (3) was 18.97).

[0062] Also in Table 1, the Ar of each steel grade is also shown 3 These values ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com