Perforated plate, punch thereof and plastic working method and prediction method of mechanical behavior value

A technology of mechanical properties and perforated plates, which is applied in the field of car body components, can solve the problems that hinder the flexible use of perforated frame strength members, calculate the mechanical properties of perforated frames, and prolong the calculation time, so as to reduce weight, reduce tensile stress, and realize effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

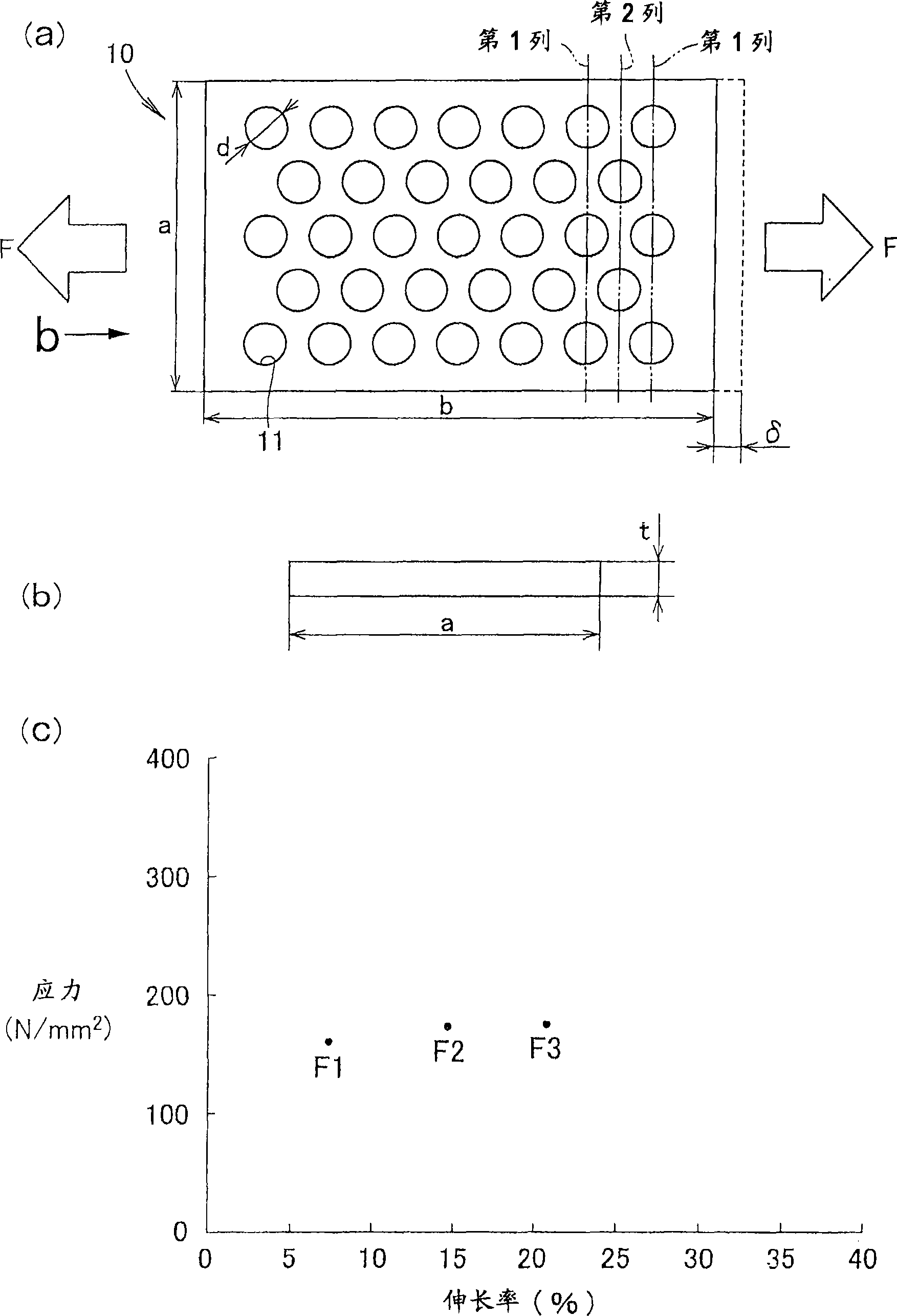

[0242] Experimental examples of the present invention are as follows. In addition, the present invention is not limited to the cases described in the experimental examples.

[0243] ○Punching machine specifications (common):

[0244] The diameter of the punch: 150mm

[0245] The shape of the front end of the punch: hemisphere or circular table

[0246] The diameter of the hole of the upper die: 153mm

[0247] The radius of the flange on the upper mold: 10mm

[0248] Axial force of the first cylinder: 100 tons

[0249] The diameter of the hole of the lower die: 160mm

[0250] Lubricant: lubricating oil

[0251] ○Soft steel plate:

[0252] Thickness: 1.0mm

[0253] Material: JIS G3131 SPHD

[0254] Number of samples: 6

[0255] ○Determination of drawing height:

[0256] The drawing height at the moment of fracture is taken as the "maximum drawing height". The maximum drawing heights obtained by investigating the six samples are shown in the tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com