Vacuum pump

A vacuum pump and structure technology, applied in the field of improving the reliability of rotor damage countermeasures, can solve the problems of reducing the impact force and torque of the encapsulation shell, insufficient, low reliability, etc., to reduce the impact force, improve the reliability and strengthen the reliability. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

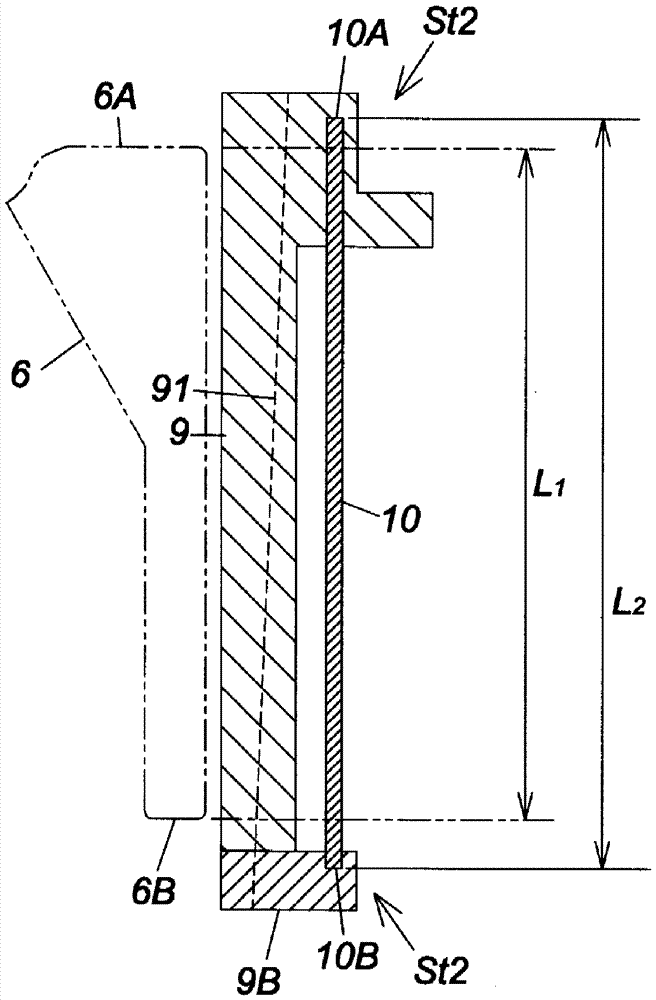

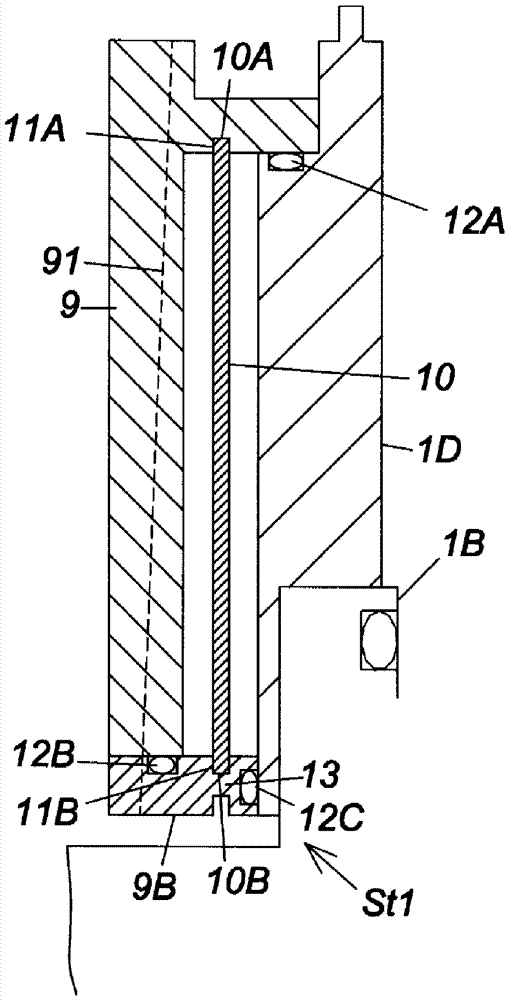

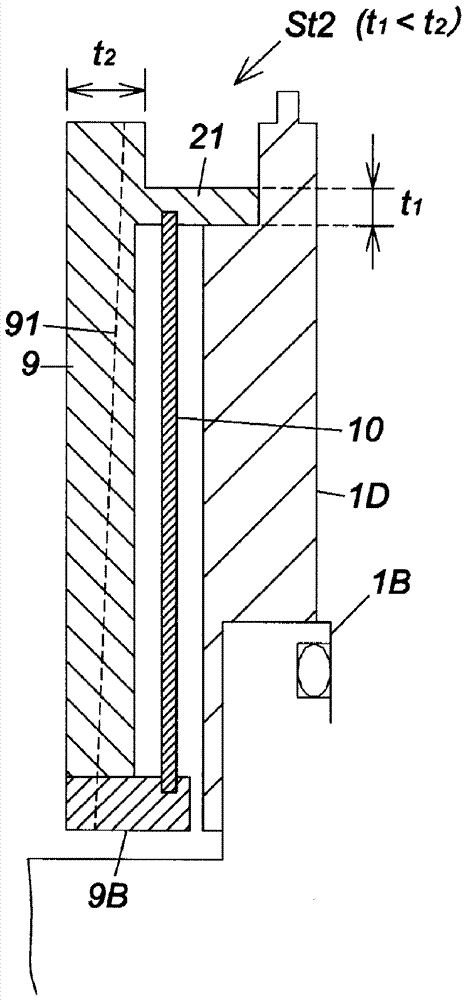

[0056] figure 1 is a cross-sectional view of a vacuum pump to which the present invention is applicable, figure 2 As the first embodiment of the present invention (corrosion-proof structure of high-strength parts), the figure 1 The vacuum pump to which the present invention is applied is an enlarged cross-sectional view of the stator (fixed member) near the screw groove exhaust portion. In addition, in these figures, in order to make the main part of the present invention easy to see, the hatching of the rotor section is omitted. This also applies to other drawings.

[0057] figure 1 The vacuum pump P1 includes: a housing 1; a rotor 6 disposed in the housing 1; a support unit SP that supports the rotor 6 so that it can rotate; a drive unit DR that drives the rotor 6 in rotation; Exhaust Mechanism for Exhausting Inhaled Gas, Wing Exhaust Pt for Inhaling and Exhausting Gas Through Rotary Wing 7 and Fixed Wing 8, and Screw Groove for Inhaling and Exhausting Gas Using Thread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com