Method and device for manufacturing automotive resin part

A technology for manufacturing devices and resin parts, which is applied to applications, household appliances, other household appliances, etc., to achieve the effects of suppressing deformation, suppressing strength reduction, and suppressing elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

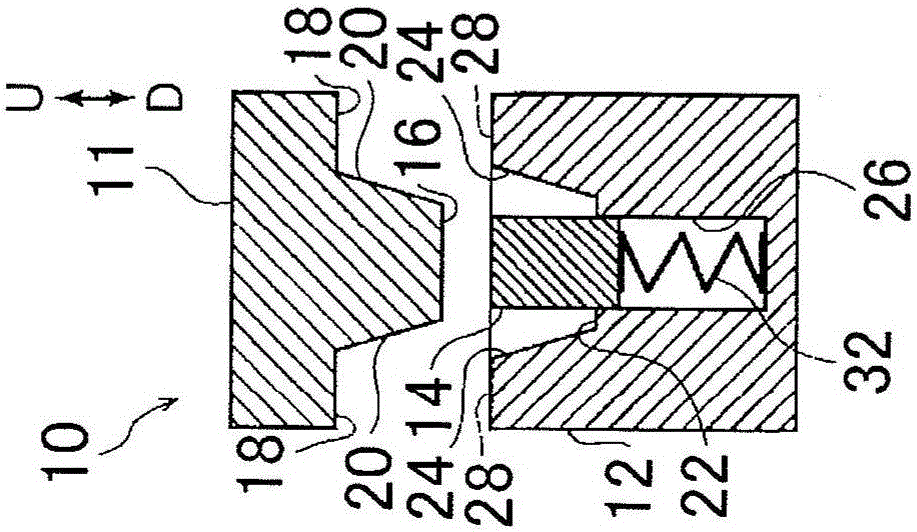

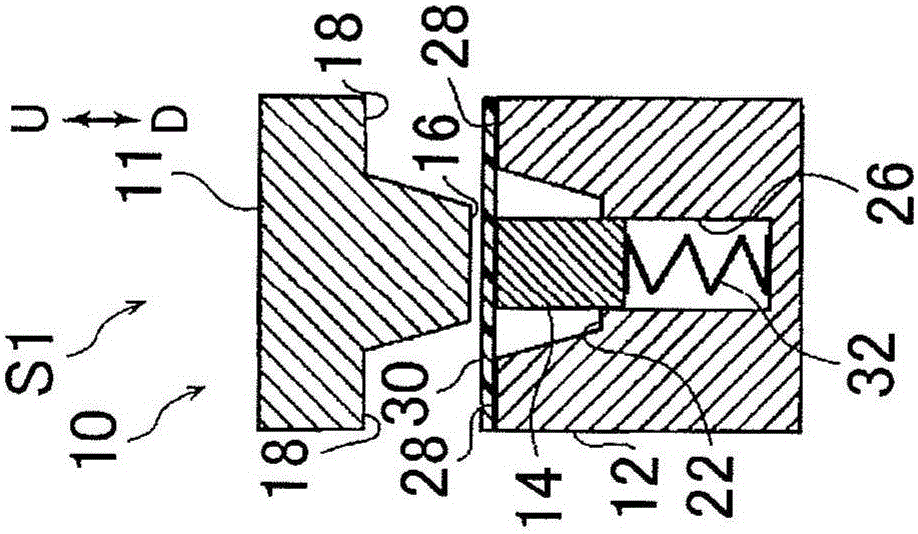

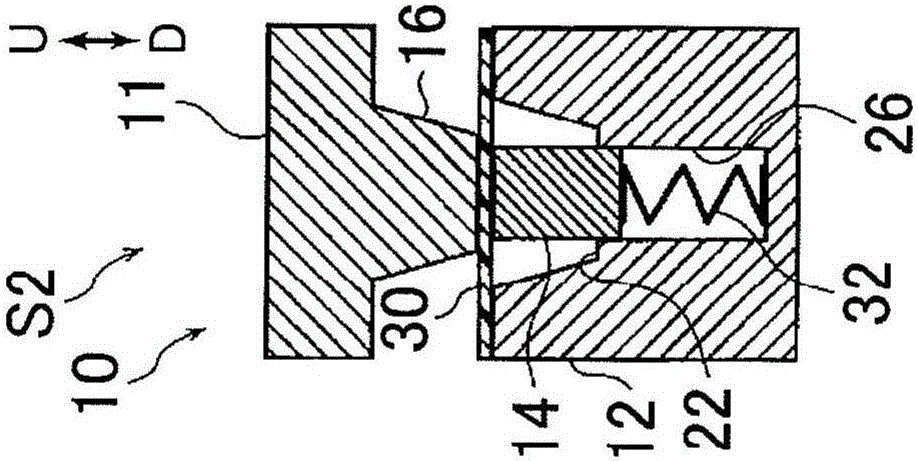

[0031] Embodiments of the present invention will be described below based on the drawings.

[0032] [Manufacturing equipment of the automotive resin department]

[0033] exist Figure 1A Among them, the manufacturing apparatus 10 of an automotive resin part according to this embodiment has an upper mold 11 as an example of a first mold, a lower mold 12 as an example of a second mold, and a movable block 14 .

[0034] The upper mold 11 is a mold having a convex portion 16 for molding, and is configured to be movable in a molding direction (arrow D direction) and a mold opening direction (arrow U direction). The convex portion 16 is formed to protrude downward from the base portion 18 to have, for example, a substantially trapezoidal cross section. The side wall portion 20 of the protrusion 16 is provided with a draft gradient.

[0035] The lower mold 12 is a die having a concave portion 22 for molding corresponding to the convex portion 16 and fixed to an unillustrated base. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com