Mold material, method for producing same, method for producing mold, and method for regenerating recovered refractory aggregate

A manufacturing method and refractory technology, applied in the fields of mold material and its manufacture, manufacture of mold, and regeneration of reclaimed refractory aggregate, can solve labor-intensive, coated sand adhered to casting products, poor disintegration of mold Sufficient and other problems, to achieve the effect of excellent filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

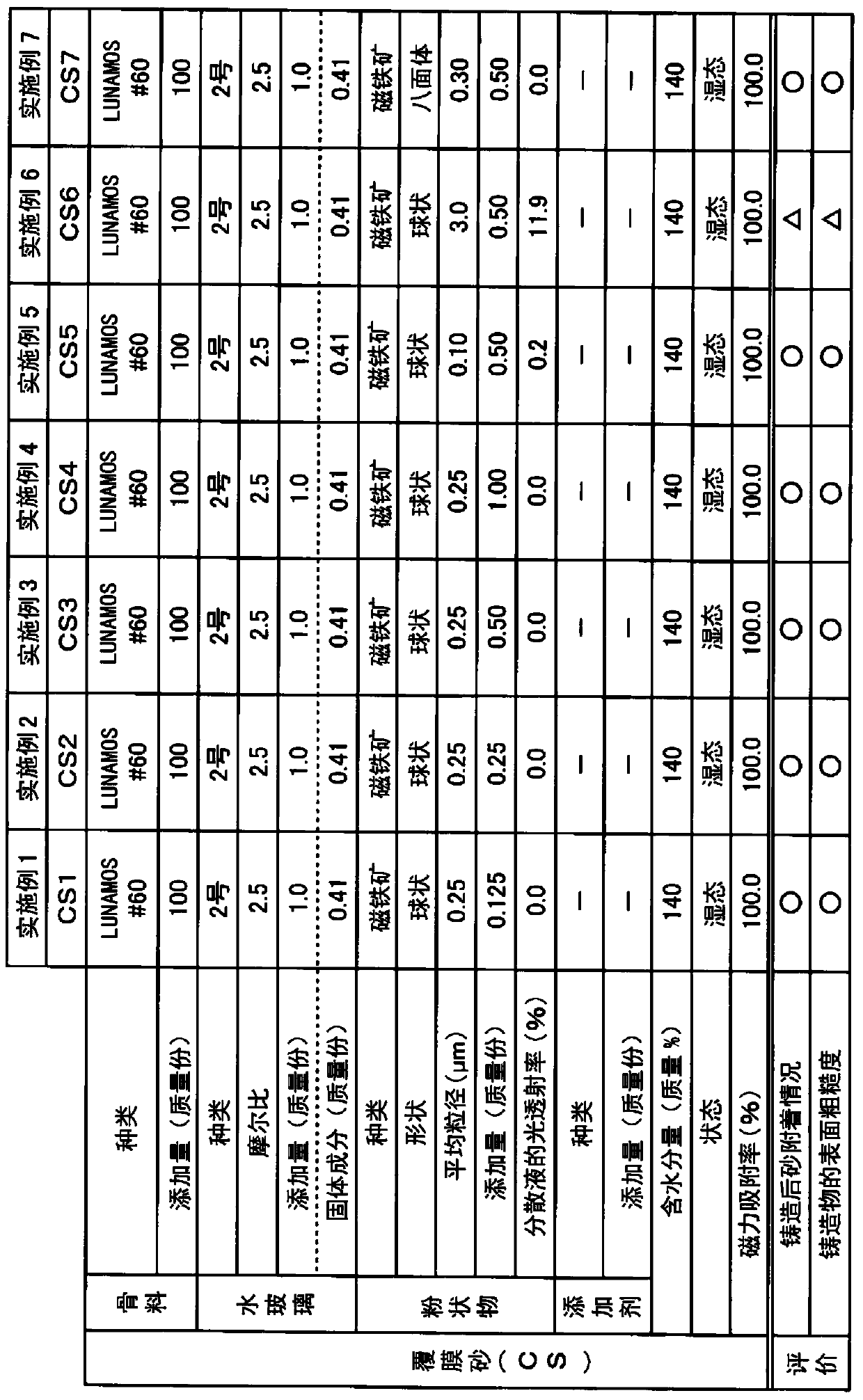

[0119] Hereinafter, some examples of the present invention are shown, and the present invention will be explained more concretely. It goes without saying that the present invention is not limited at all by the description of these examples. In addition, unless otherwise indicated, "%" and "part" shown in the following description are mass basis. In addition, in the following examples and comparative examples, the average particle diameter of the powder, the light transmittance of the dispersion liquid of the powder, the moisture content of the coated sand (CS) as the mold material, and the Measurement or evaluation of the magnetic adsorption rate, the state of sand adhesion when casting with each CS (adhesion state of CS), and the surface roughness of the casting surface.

[0120] (1) Average particle size of powder

[0121] For the average particle diameter of the powder, use the Microtrac particle size distribution measuring device (product name: MT3200II) manufactured by N...

manufacture example 1

[0146] As the refractory aggregate, commercially available artificial sand for foundry, LUNAMOS#60 (trade name, manufactured by Kao Quaker Co., Ltd.), and commercially available No. 2 sodium silicate (trade name, manufactured by Fuji Chemical Co., Ltd.) were prepared. , SiO 2 / Na 2 Molar ratio of O: 2.5, solid content: 41.3%) as water glass used as a water-soluble inorganic binder, and a powder of magnetite (spherical, average particle diameter: 0.25 μm) to be used as an iron-containing compound ). Add magnets in an amount equivalent to 0.125 parts per 100 parts of aggregate (LUNAMOS#60) to water glass in an amount equivalent to 1.0 parts (solid content: 0.41 parts) per 100 parts of aggregate (LUNAMOS #60) ore powder, and mixed to form a liquid mixture, 100 parts of the aggregate (LUNAMOS#60) was directly put into a Shinagawa-type universal mixer (5DM-r type, manufactured by DALTON CORPORATION) at room temperature, and the above-mentioned prepared The liquid mixture (the po...

manufacture example 2

[0148] Except that the addition amount of the powder of magnetite was 0.25 parts, a wet mold material: CS2 was obtained in the same procedure as in the above-mentioned Production Example 1. As a result of calculating the water content of the obtained CS2, it was an amount corresponding to 140% by mass of the solid content of water glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com