Patents

Literature

332 results about "Ferric iron compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

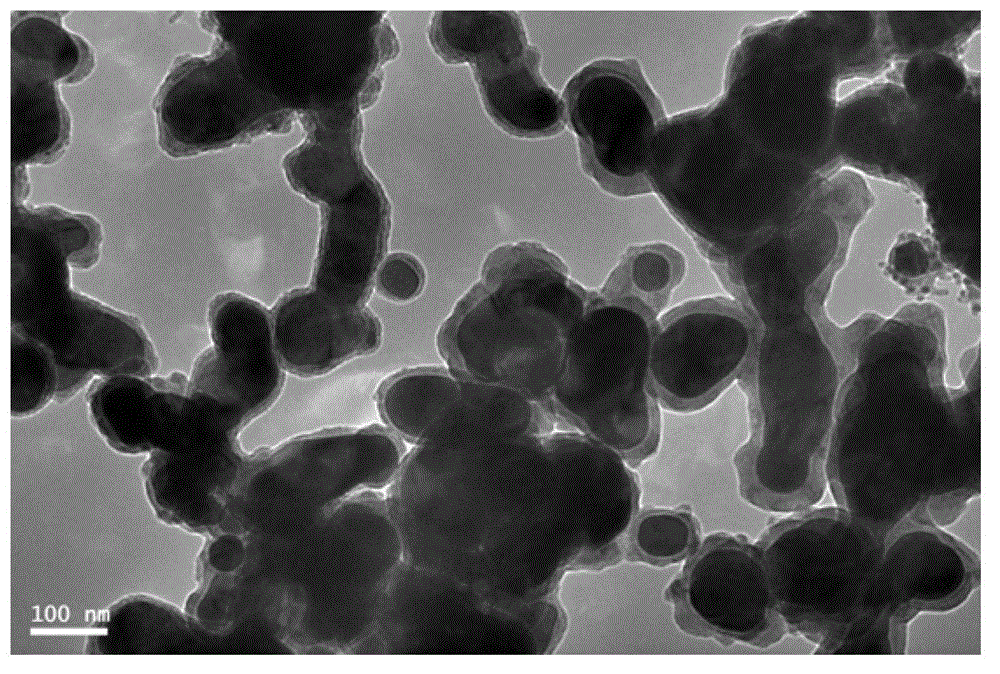

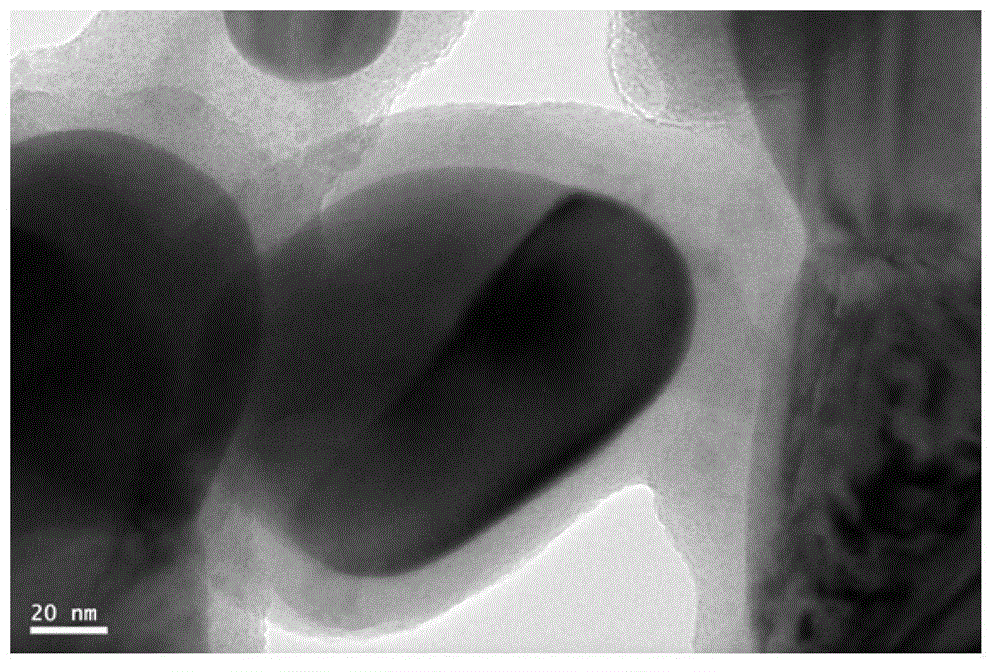

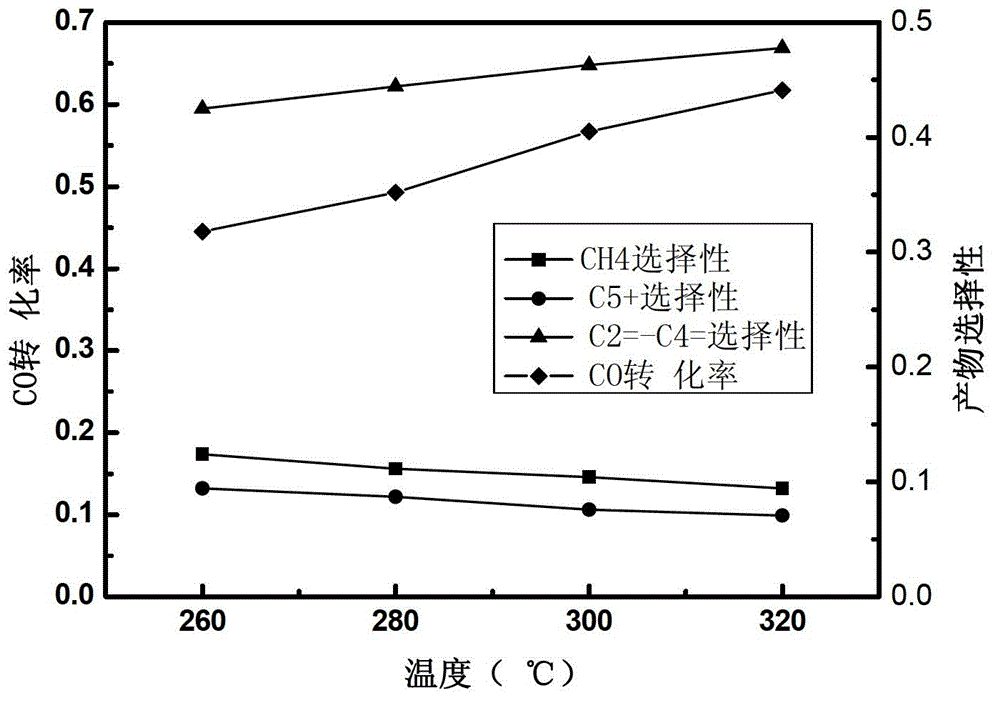

Preparation method and applications of catalyst used for preparing light olefin from synthesis gas

ActiveCN103331171AHigh activityImprove performanceHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasGas phase

The invention relates to a preparation method and applications of a catalyst which is used for preparing light olefin from synthesis gas directly and co-preparing gasoline. The preparation method comprises following steps: a molysite is taken as a precursor, and then the catalyst is obtained by pre-treatment with a carbon source, dispersion-mixing and modified vapor deposition which are all simple and easy to operate, wherein an iron-containing compound is taken as the active center of the catalyst, and the catalyst can be used for direct conversion of synthesis gas to light olefin and co-preparing of gasoline. Catalytic activity and economic cost of the catalyst enable that the catalyst can be applied in industrial production.

Owner:EAST CHINA UNIV OF SCI & TECH

Molding material, prepreg, fiber-reinforced composite material, fiber-reinforced composite material laminate, and process for production of fiber-reinforced molding base material

InactiveUS20130295806A1Economical efficiencyEconomical productivityPretreated surfacesWoven fabricsProduction rateFiber-reinforced composite

A molding material is provided including a composite having 1 to 50 wt % of (A) a bundle of continuous reinforcing fibers and 0.1 to 40 wt % of (B) a polyarylene sulfide prepolymer or (B′) a polyarylene sulfide; and 10 to 98.9 wt % of (C) a thermoplastic resin adhered to the composite; wherein the composite further has (D) a zero-valent transition metal compound or (E) a low-valent iron compound in an amount of 0.001 to 20 mol % based on the amount of sulfur atoms contained in the component (B) or (B′). A prepreg and a method of producing a fiber-reinforced molding base material is also provided. By using the molding material according to the present invention which exhibits excellent economic efficiency and productivity, a molded article having excellent mechanical characteristics can be easily produced.

Owner:TORAY IND INC

Method for preparing carbon coated lithium ferrous phosphate composite material including metal conductive agent

InactiveCN1649189AImprove electronic conductivityImprove protectionElectrode manufacturing processesPhosphatePhosphoric acid

This invention relates to a preparation method for LiFe PO4 / M / C compound positive material, the precursor of Li-Fe-PO4-M is synthesized with Li salt, Fe compound, phosphate, silver salt and organic acid as the raw materials by the sol-coagel method. Then the precursor mixed with pyrogenic-decomposed in inert atmosphere to get LiFePO4 / M / C compound positive material.

Owner:ZHEJIANG UNIV

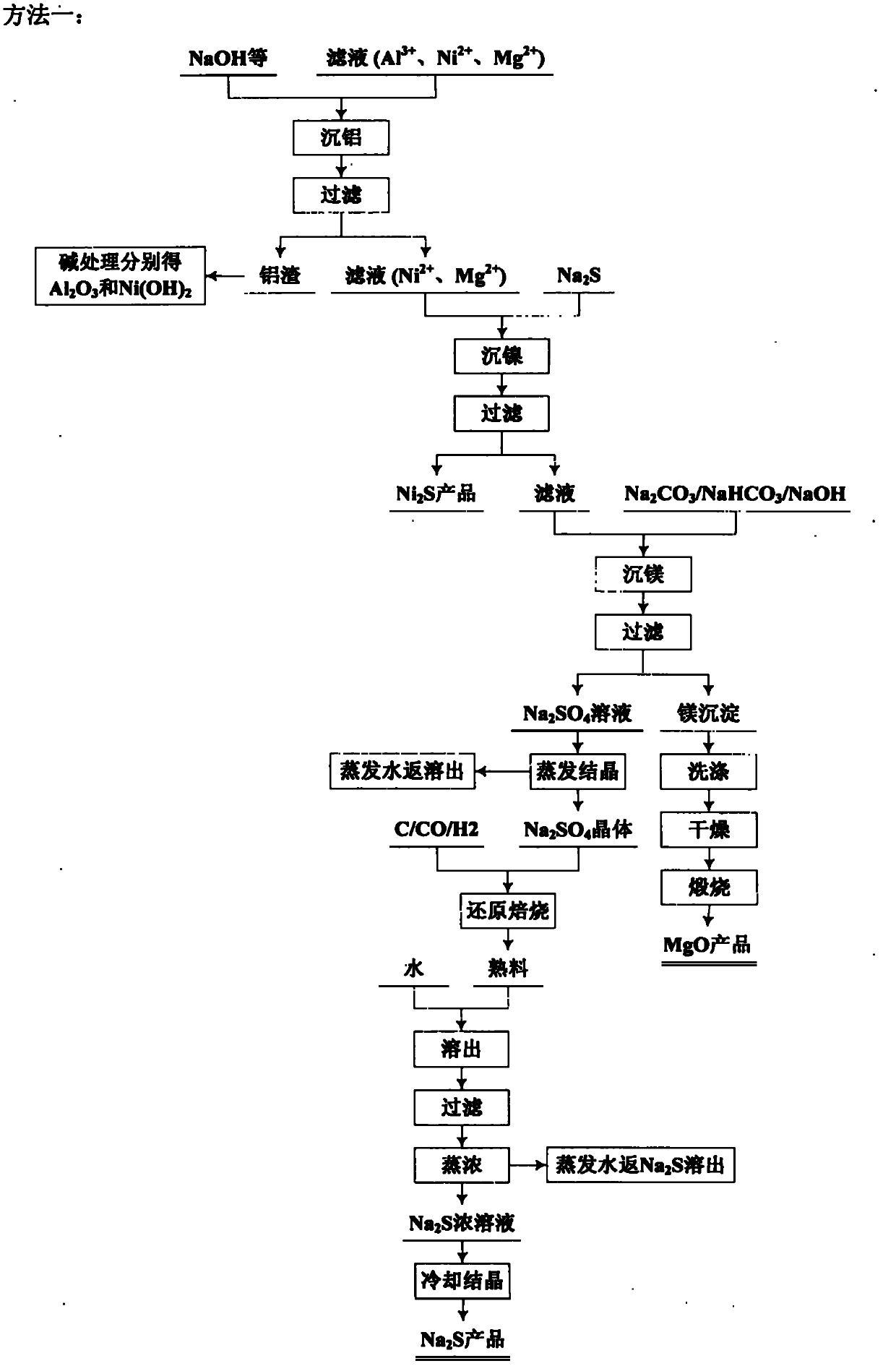

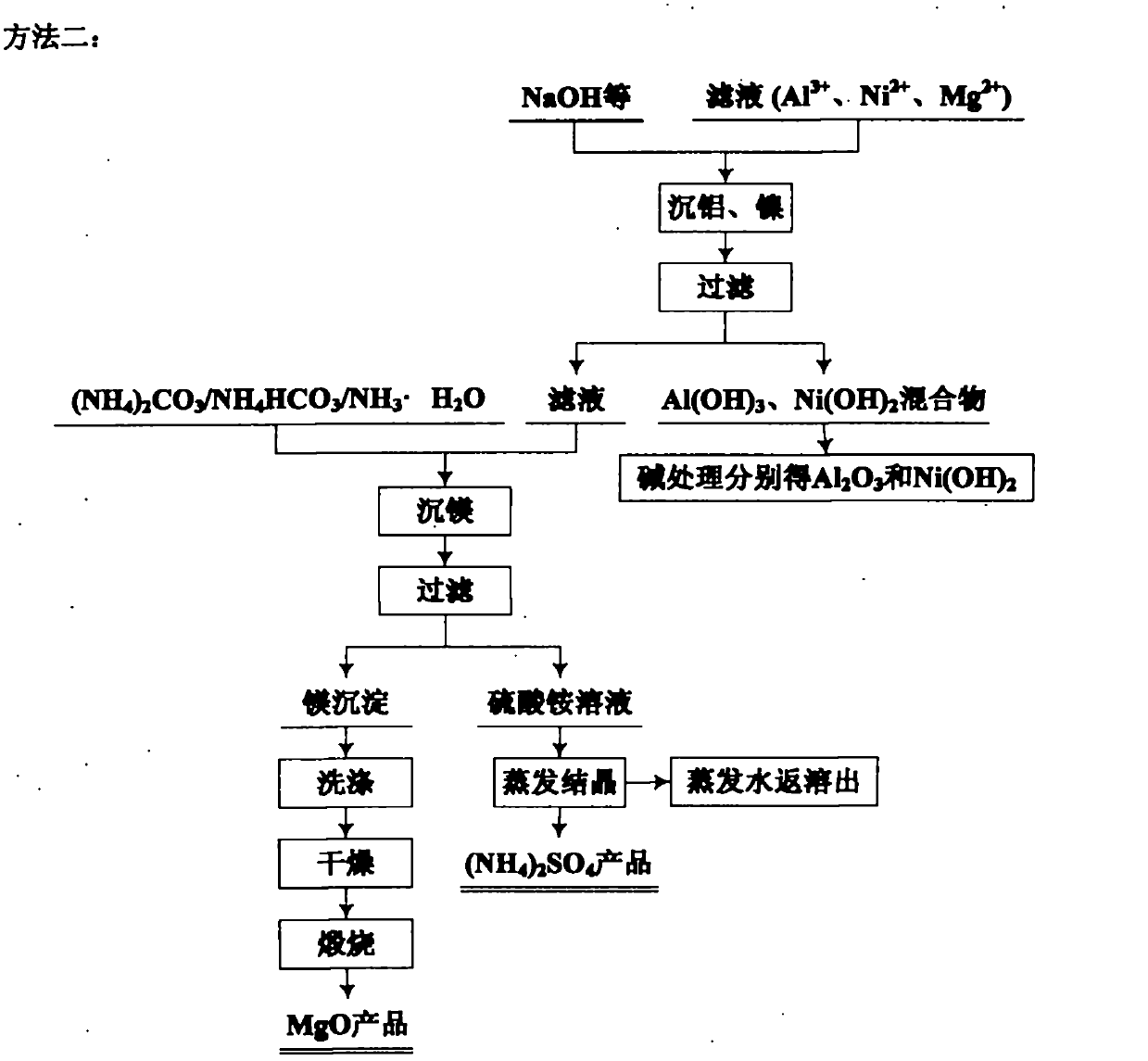

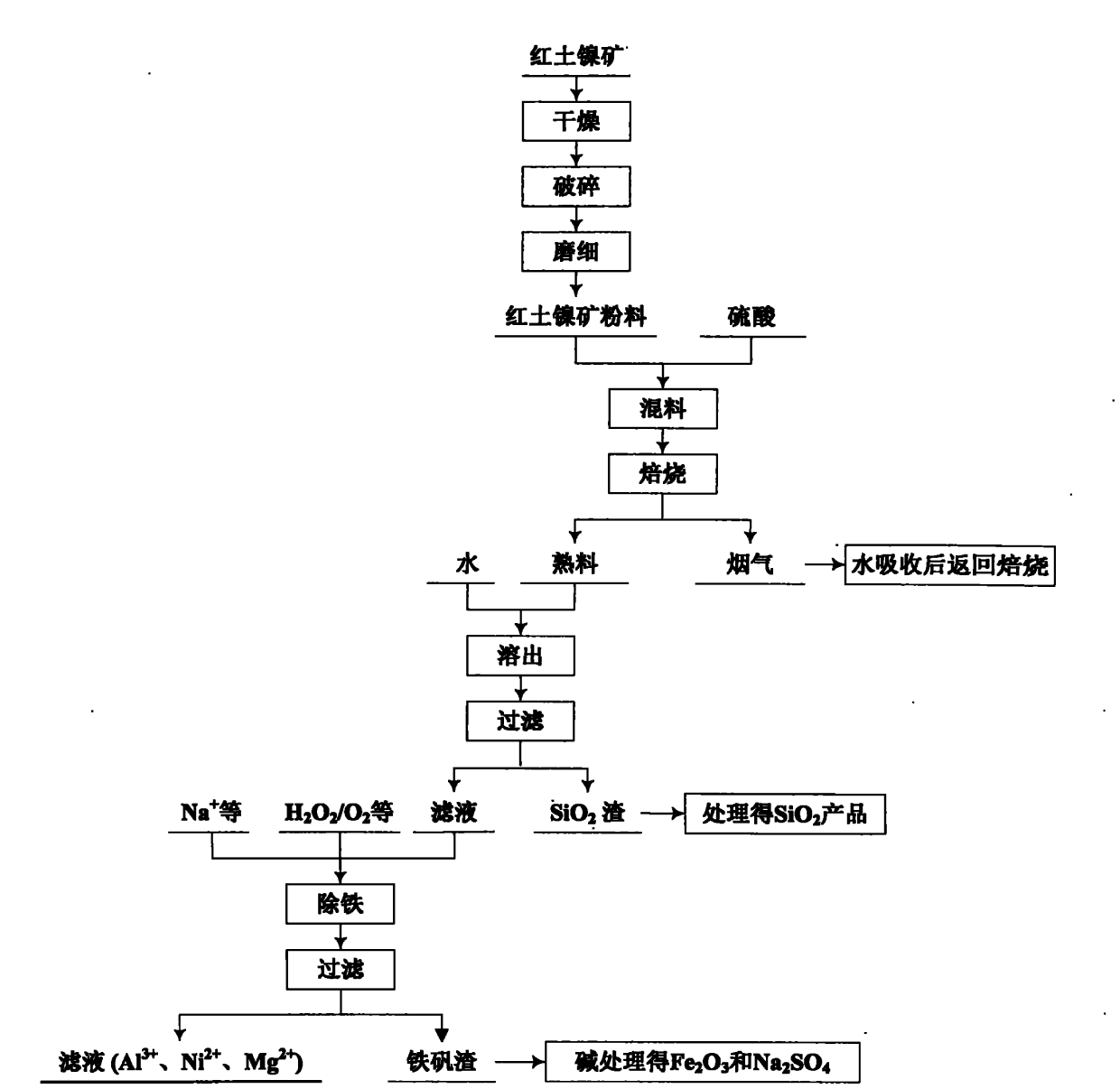

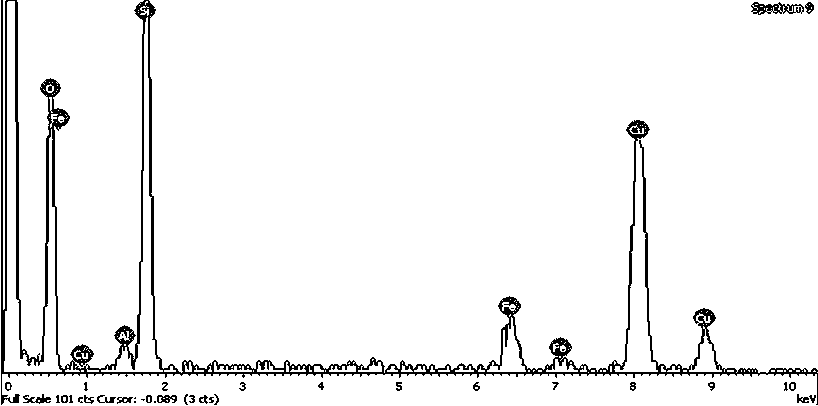

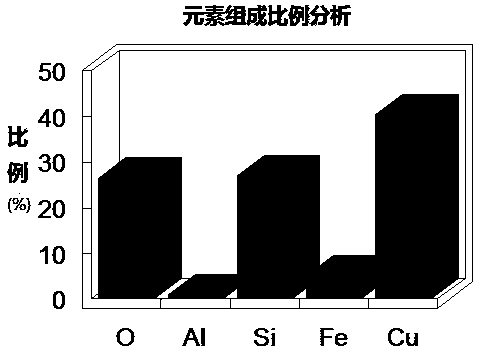

Comprehensive utilization method for laterite-nickel ore

The invention relates to an environmental-friendly comprehensive utilization method for a laterite-nickel ore, which comprises the following steps of: (1) grinding the laterite-nickel ore, mixing with sulfuric acid, roasting, dissolving out roasted clinker and filtering to obtain silicon dioxide and dissolution liquid; (2) deironing the dissolution liquid to obtain liquid No.2 and filter residue (iron compounds), wherein the liquid No.2 comprises aluminum, nickel and magnesium and can be treated by the step (3) or (4); (3) precipitating the aluminum in the liquid No.2 by using alkali, filtering, precipitating the nickel in filtrate by using sodium sulfide, filtering, precipitating the magnesium by using the alkali, and treating filter residue to obtain aluminum oxide, nickel hydroxide, nickel sulfide and magnesium oxide respectively; and (4) precipitating the aluminum and the nickel in the liquid No.2 by using the alkali, treating mixed slag containing the aluminum and the nickel by using the alkali to obtain aluminum hydroxide and nickel hydroxide products, and precipitating the magnesium in filtrate subjected to aluminum and nickel precipitation by using ammonia or ammonium saltto obtain a magnesium oxide product. The method is suitable for treating various laterite-nickel ores, three wastes (waste gas, waste water and waste residue) are not generated, and valuable components magnesium, nickel, iron, aluminum and silicon in the laterite-nickel ore are separated and extracted.

Owner:NORTHEASTERN UNIV

Synthetic ferro-aluminum spinel and its preparation method

InactiveCN1762895ALow priceSimple processAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPorosityAdhesive

The present invention relates to Fe-Al spinel and its preparation process. The technological scheme of the present invention is the Fe-Al spinel preparing process including the steps of: mixing Al containing compound and Fe containing compound in the molar Al / Fe ratio of 2 and adhesive in 1-6 wt% for 5-180 min; forming and drying at 90-120 deg.c for 20-30 hr; heating in carbon atmosphere and temperature raising speed of 0.5-10 deg.c / min at 1100-1700 deg.c for 5-600 min; and naturally cooling. The present invention has the advantages of simple technological process, low reaction temperature and cheap material. Under the sintering temperature, all the Al and Fe components are converted into FeAl2O4, and the sintered product has apparent porosity lower than 5 %.

Owner:WUHAN UNIV OF SCI & TECH

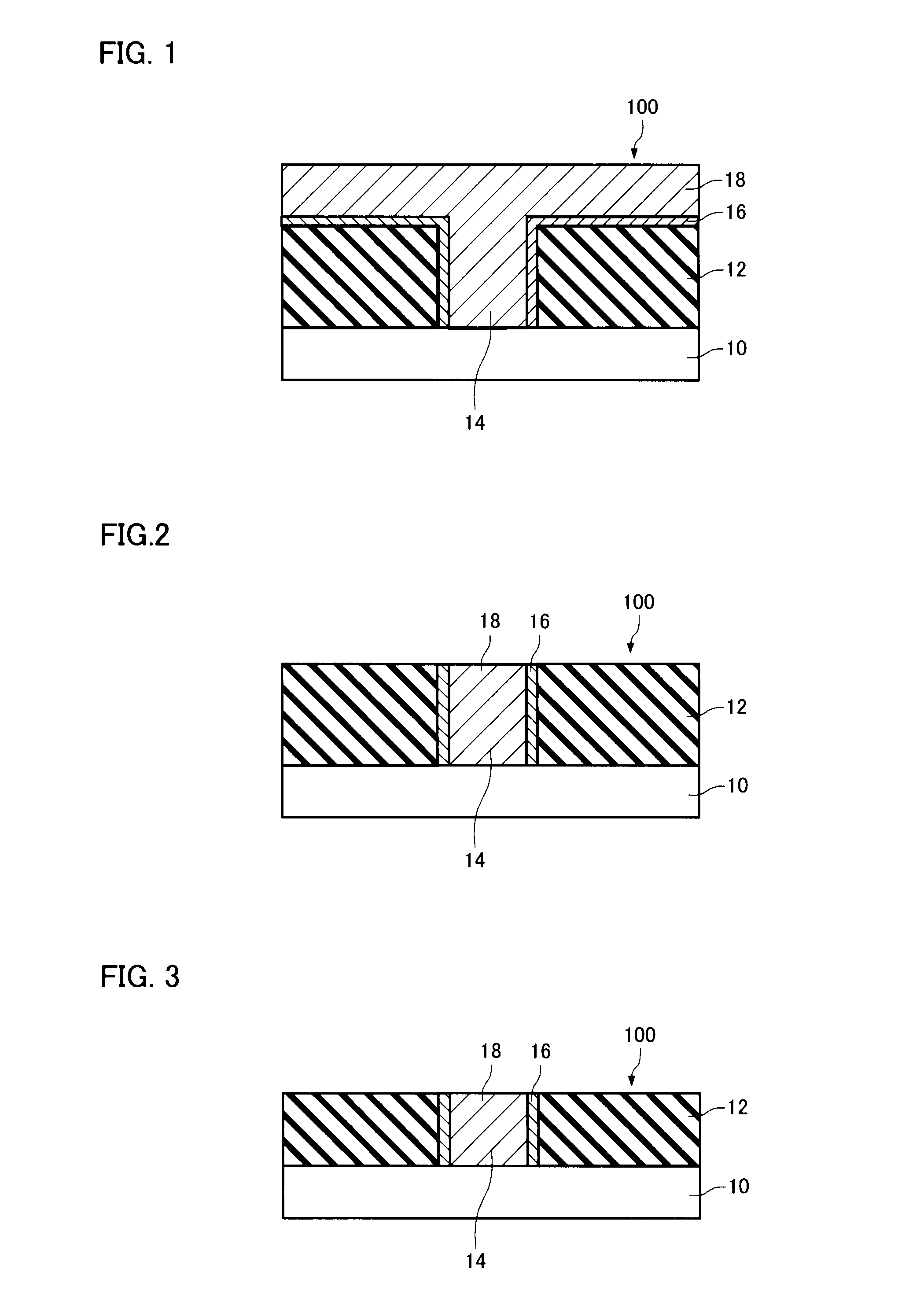

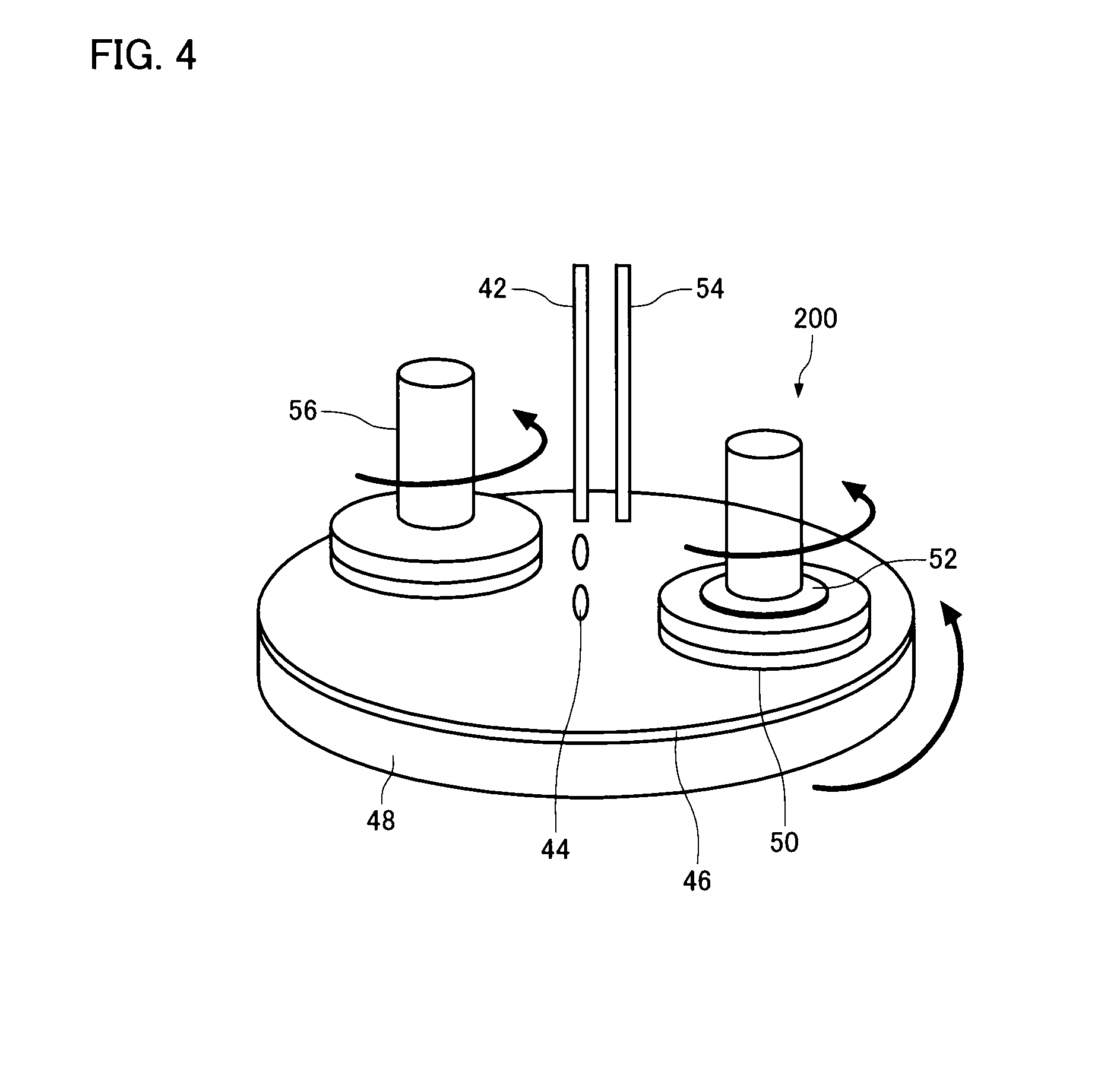

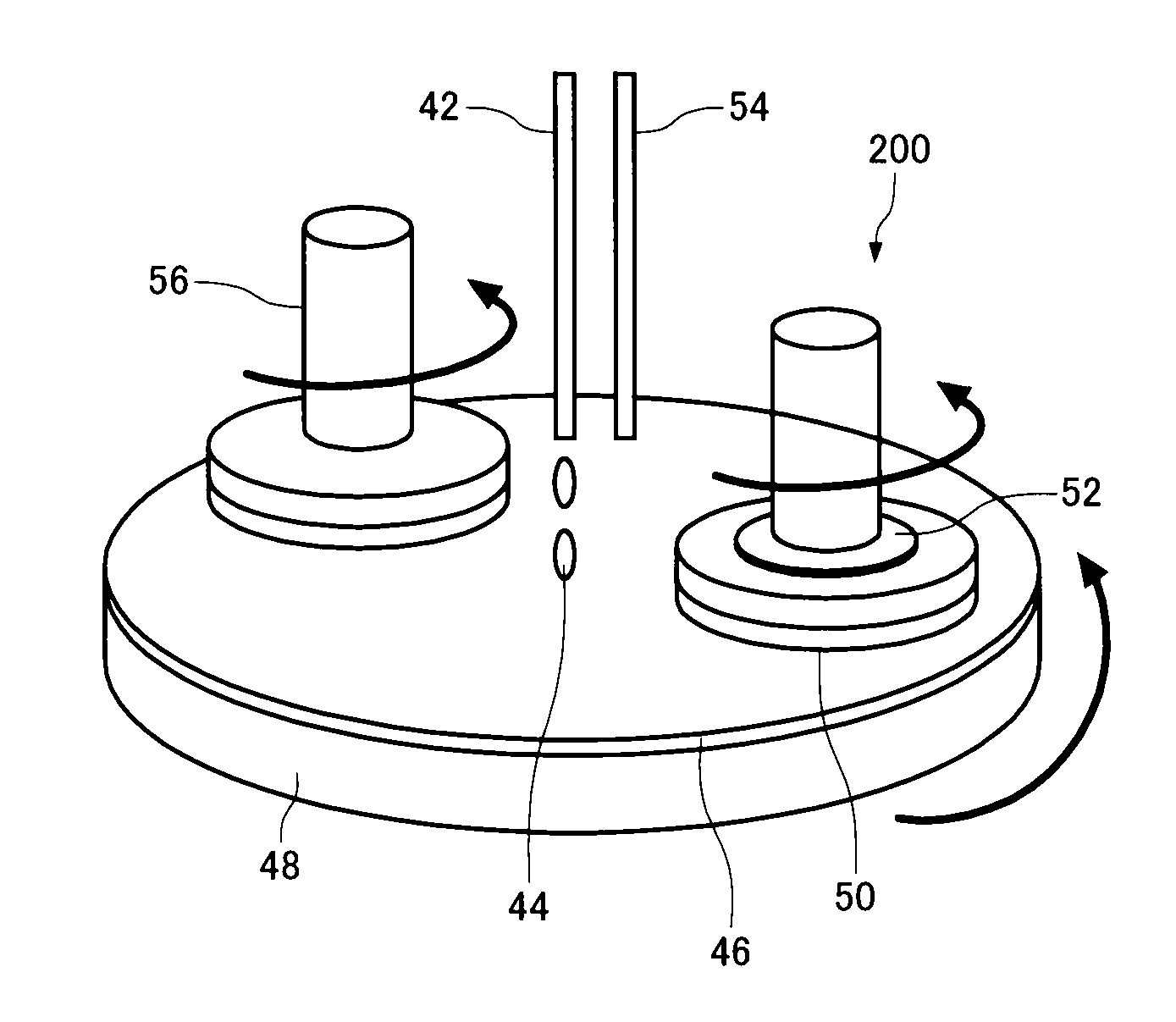

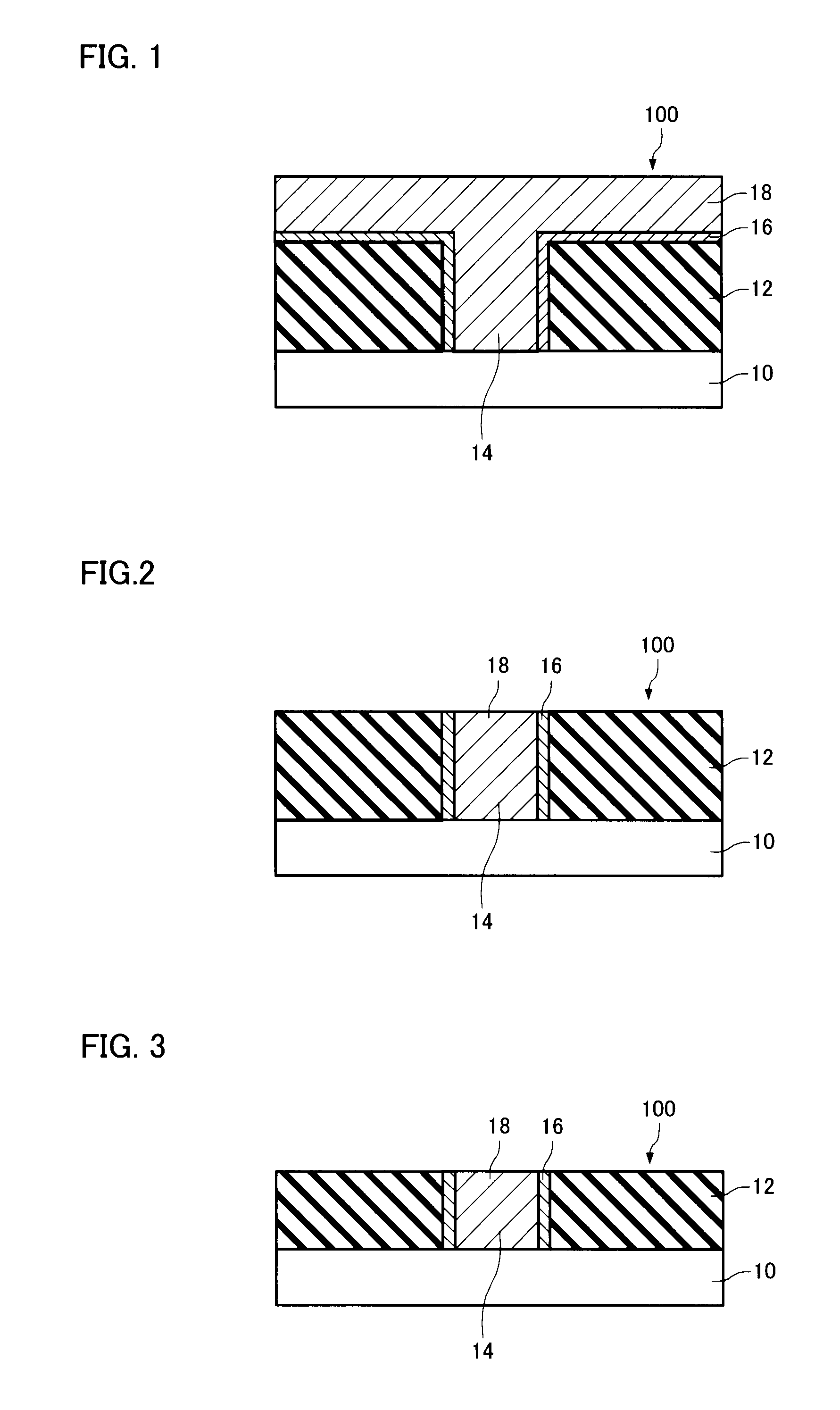

Chemical mechanical polishing aqueous dispersion and chemical mechanical polishing method

ActiveUS20100075501A1Other chemical processesDecorative surface effectsColloidal silicaSilica particle

A chemical mechanical polishing aqueous dispersion is used to polish a polishing target that includes an interconnect layer that contains tungsten. The chemical mechanical polishing aqueous dispersion includes: (A) a cationic water-soluble polymer; (B) an iron (III) compound; and (C) colloidal silica particles. The content (MA) (mass %) of the cationic water-soluble polymer (A) and the content (MB) (mass %) of the iron (III) compound (B) satisfy the relationship “MA / MB=0.004 to 0.1”. The chemical mechanical polishing aqueous dispersion has a pH of 1 to 3.

Owner:JSR CORPORATIOON +1

An a aqueous solution comprising an iron compound, an amino acid and a reducing agent

InactiveUS6306201B1Prevent oxidationEffectively actInorganic/elemental detergent compounding agentsBiocideCorrosionDisease

This invention relates to a bivalent iron compound comprising a bivalent iron salt, an amino acid and a reducing material. It is known that bivalent iron salts exhibit specific effects in wide applications, for example, agricultural applications such as modification of soil quality, fishing applications such as quality preservation of fishes, medical applications such as treatment of diseases and industrial applications such as prevention of metal corrosion and purification of waste water and exhaust gas. However, the conventional bivalent iron salts suffer a problem that they cannot exhibit such effect for extended periods. This invention was successful in chemically stabilizing the bivalent iron salts by adding amino acids and reducing materials so as to sustain the effects inherent in the bivalent iron salts and to enable utilization thereof in industrial applications.

Owner:I B E

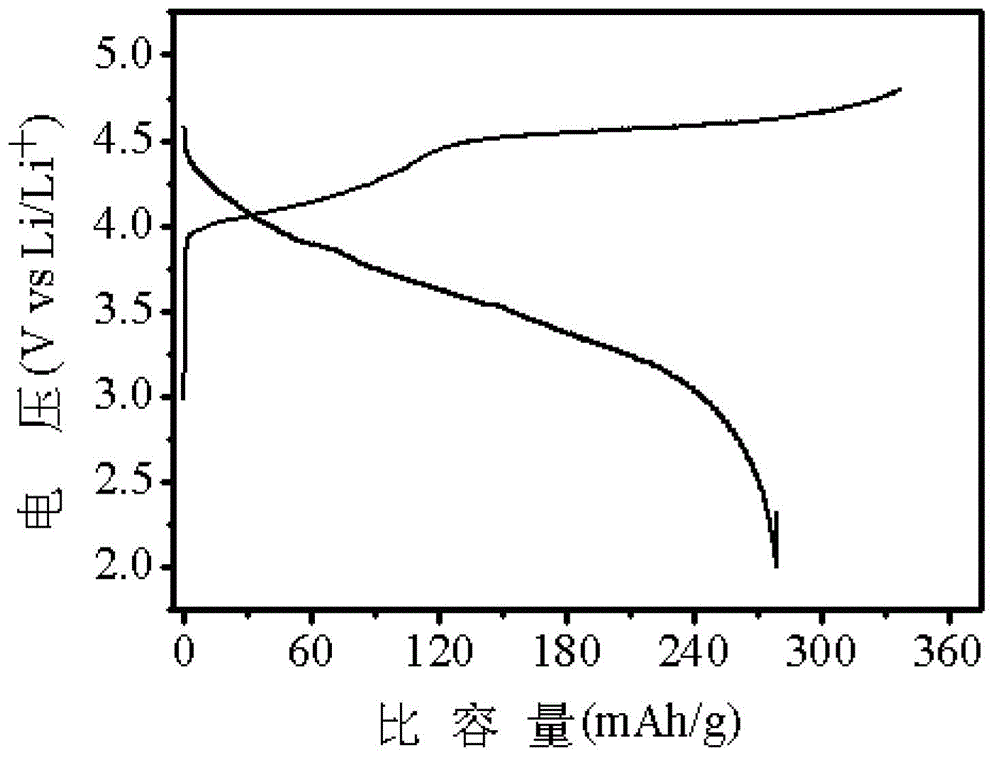

Lithium-rich manganese-based anode material and method for manufacturing same

ActiveCN102916169AImprove featuresUniform structureCell electrodesSecondary cellsPtru catalystActive agent

The invention discloses a lithium-rich manganese-based anode material and a method for manufacturing the same. The method includes steps of (a), providing mixed solution containing lithium compounds, nickel compounds and manganese compounds, optional titanium compounds, optional iron compounds, optional cobalt compounds or an optional combination of the titanium compounds, the ion compounds and the cobalt compounds; (b), adding complexing agents, catalysts and surfactants into the mixed solution to form pre-coagulated substances; and (c), calcining the pre-coagulated substances to obtain the lithium-rich manganese-based anode material Li[LixNiaMnbM1-a-b-x]O2 or a combination of lithium-rich manganese-based anode materials. The complexing agents, the catalysts and the surfactants are used for forming the pre-coagulated substances, the complexing agents contain resorcinol and formaldehyde, in the molecular formula of the lithium-rich manganese-based anode material, the M represents Ti, Fe, Co or a combination of the Ti, the Fe and the Co, the x is larger than 0 and is smaller than or equal to 0.4, the a is larger than 0 and is smaller than or equal to 0.5, the b is larger than or equal to 0.33 and smaller than or equal to 0.6, and a result of 1-a-b-x is larger than or equal to 0. The lithium-rich manganese-based anode material is of a multi-channel porous structure, is small in grain size, uniform in grain distribution, advanced in porosity and stable in electrochemical performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

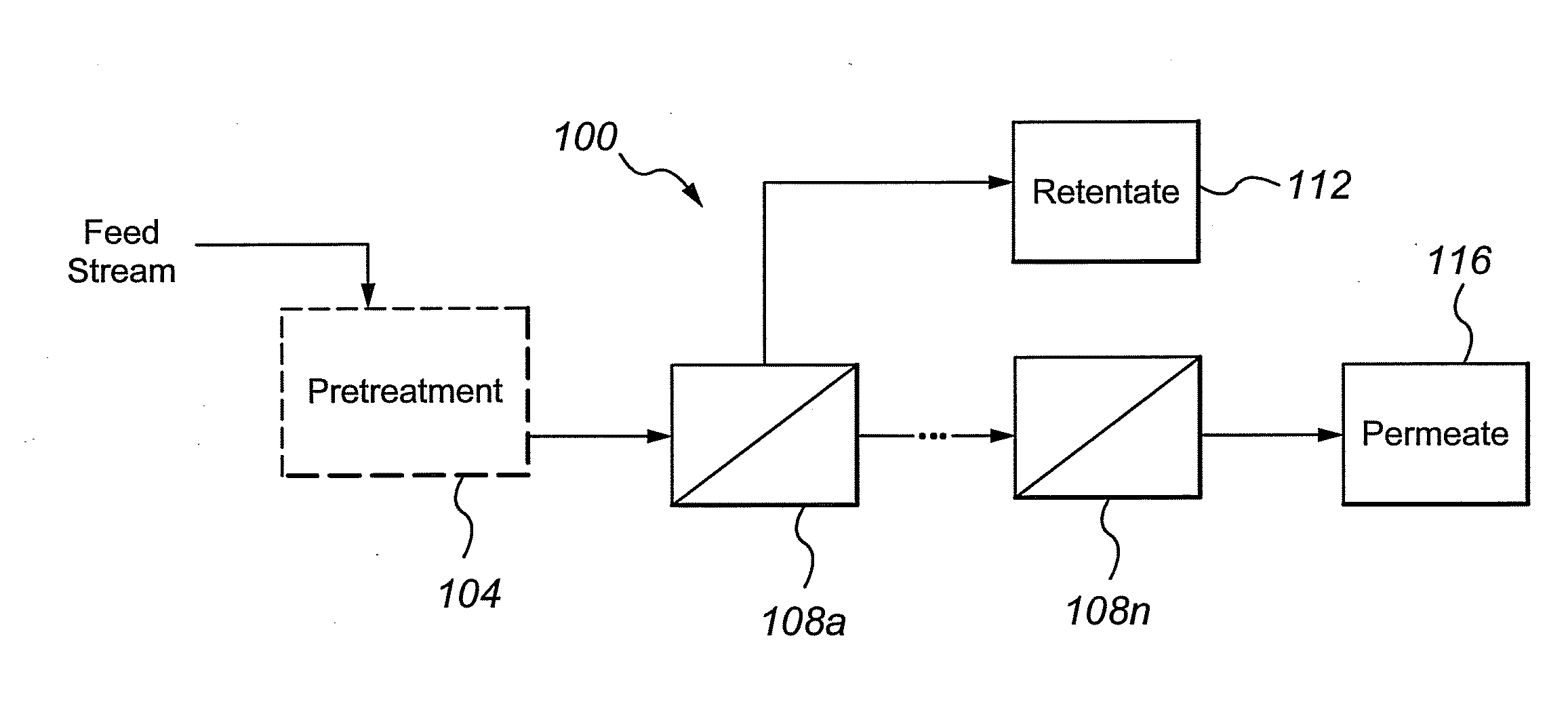

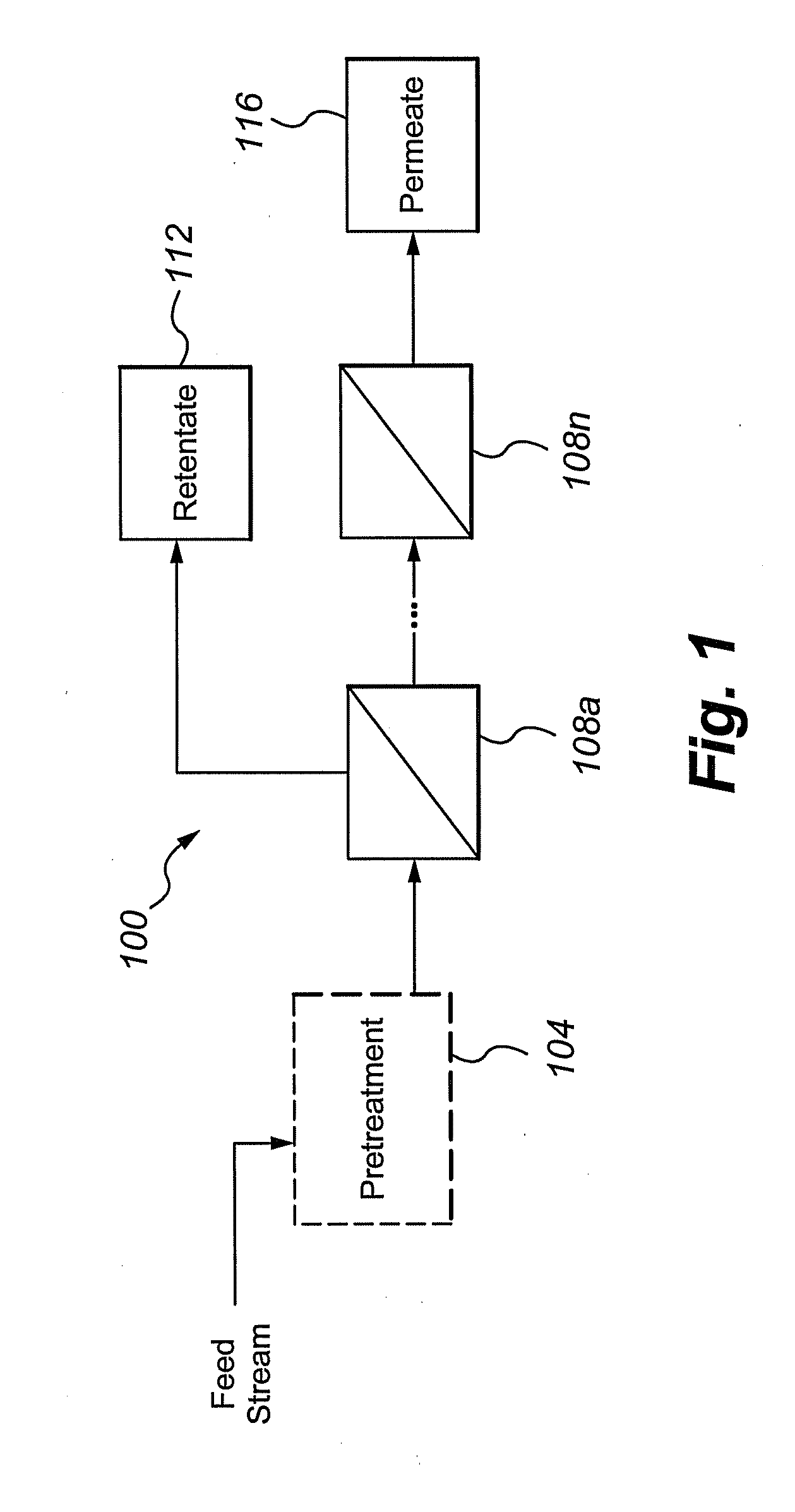

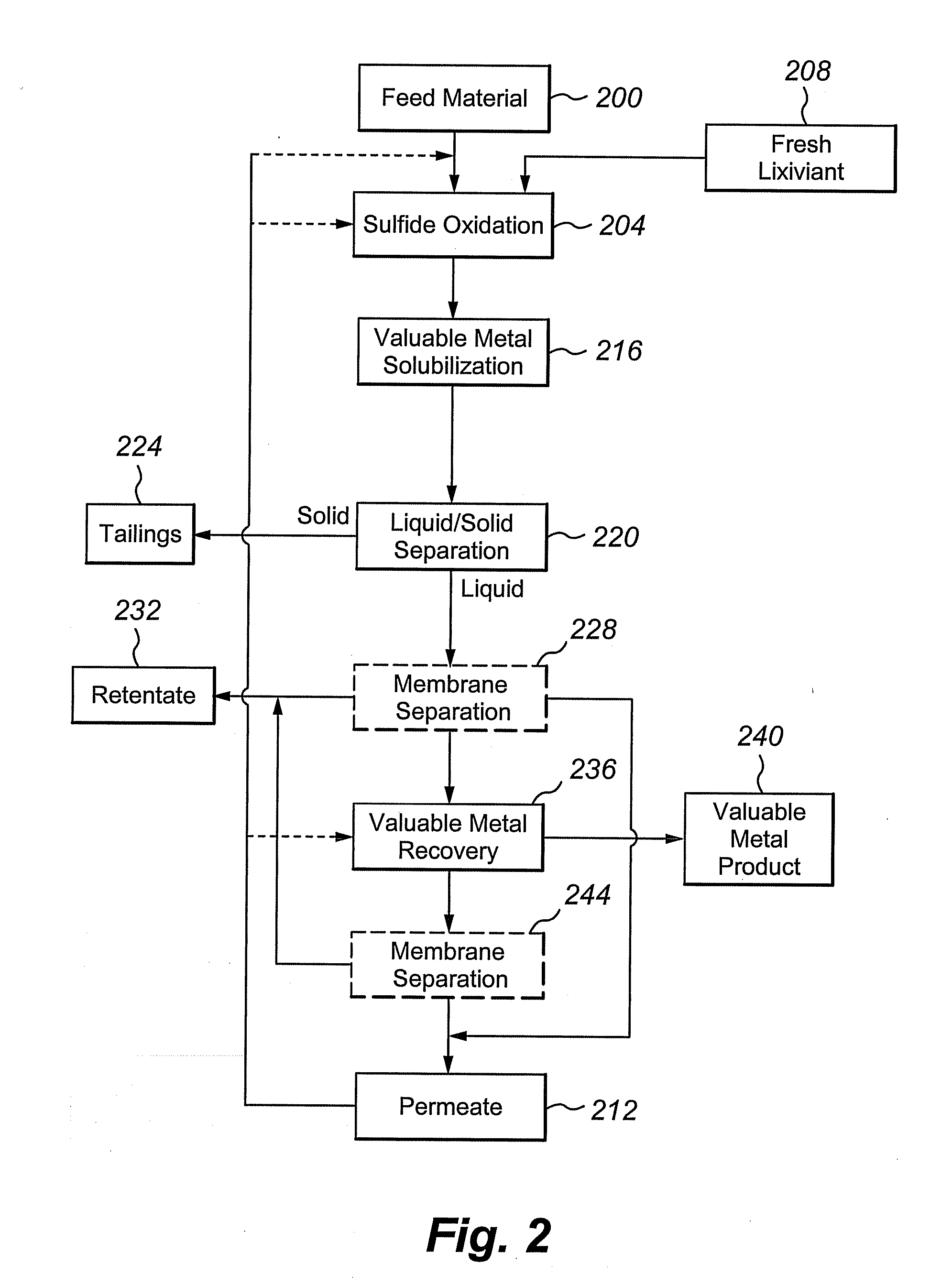

Multivalent iron ion separation in metal recovery circuits

InactiveUS20080069748A1High sulfide sulfur oxidation rateReduce electricity costsSolvent extractionFerrous oxidesPhysical chemistryFerric ion

Owner:HW PROCESS TECH

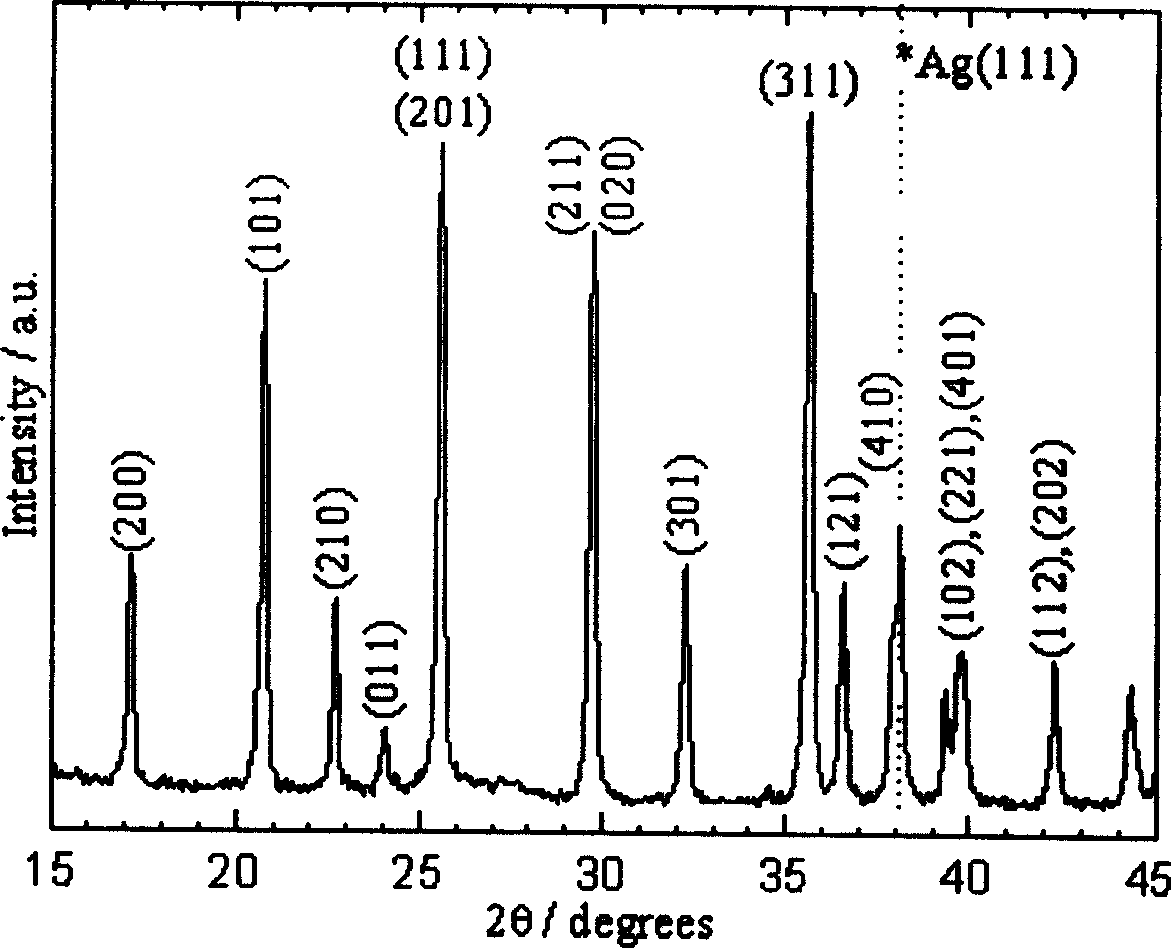

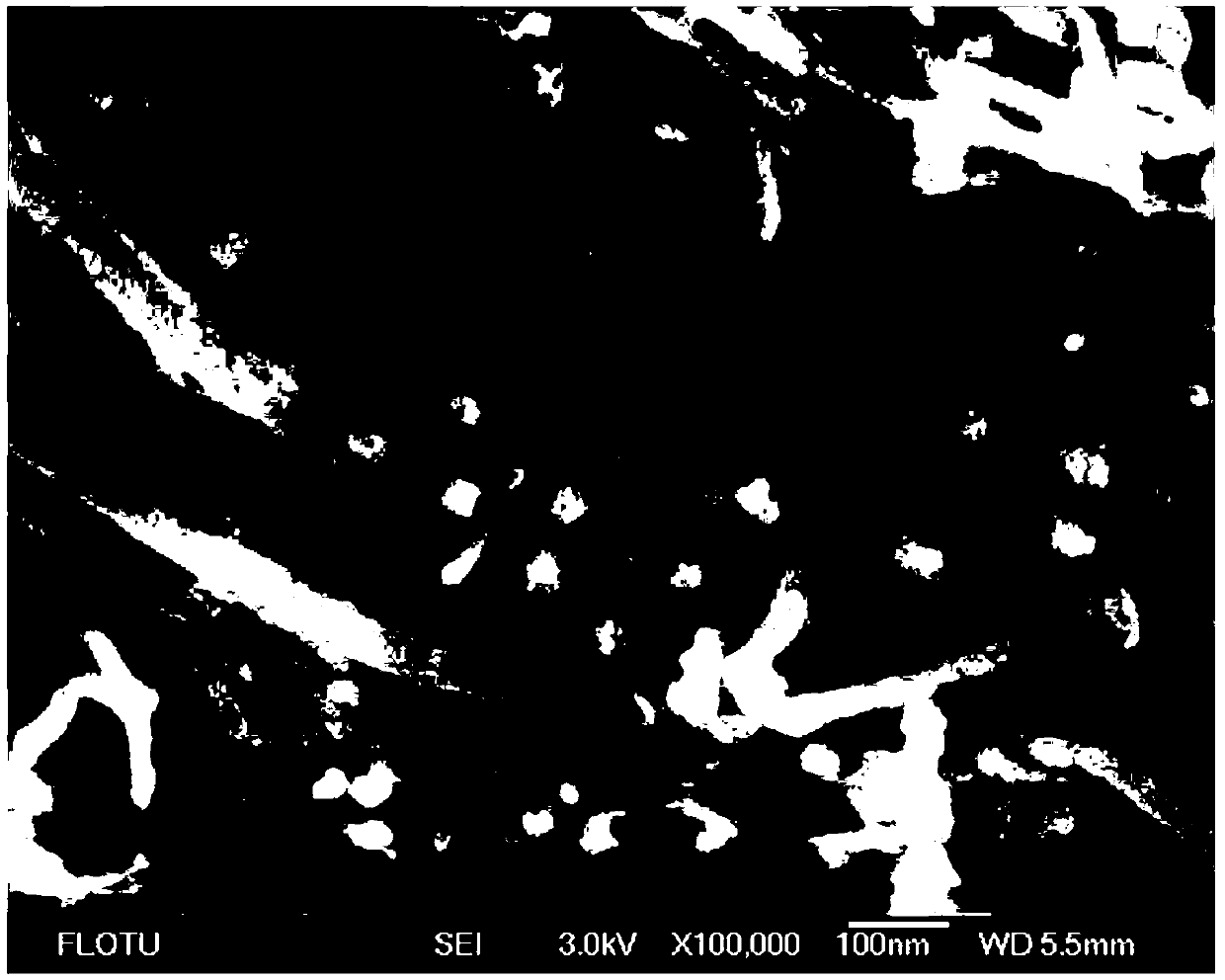

Ferromagnetic particles and process for producing the same, and anisotropic magnet, bonded magnet and compacted magnet

ActiveUS20140001398A1High purityReadily produce stable FeNitrogen-metal/silicon/boron binary compoundsInorganic material magnetismViewpointsIron oxyhydroxide

The present invention relates to ferromagnetic particles capable of exhibiting a high purity and excellent magnetic properties from the industrial viewpoints and a process for producing the ferromagnetic particles, and also provides an anisotropic magnet, a bonded magnet and a compacted magnet which are obtained by using the ferromagnetic particles. The ferromagnetic particles comprising an Fe16N2 compound phase in an amount of not less than 80% as measured by Mössbauer spectrum and each having an outer shell in which FeO is present in the form of a film having a thickness of not more than 5 nm according to the present invention can be produced by subjecting iron oxide or iron oxyhydroxide having an average major axis diameter of 40 to 5000 nm and an aspect ratio (major axis diameter / minor axis diameter) of 1 to 200 as a starting material to dispersing treatment to prepare aggregated particles; subjecting the iron compound particles passed through a mesh to hydrogen reducing treatment at a temperature of 160 to 420° C.; and then subjecting the resulting particles to nitridation treatment at a temperature of 130 to 170° C.

Owner:TOHOKU UNIV

Method for synthesizing ferrous aluminum spinel

The invention relates to a method for synthesizing ferrous aluminum spinel, belonging to the technical field of fireproofing materials. The method comprises the following steps of: mixing ferrous compound and aluminiferous compound according to the mol ratio of Fen<+> to Al<3+> of 1:2, additionally adding a binding agent accounting for 1-6 percent of the weight of the mixture, mixing, pressing, drying and sintering under the nitrogen atmosphere at the temperature of 1300-1700 DEG C, and keeping the temperature for 2-12 hours. The invention has the advantages of high synthetic purity, simple process and easy actualization.

Owner:SHANDONG SHENGCHUAN CERAMICS +3

Process, method, and system for removing heavy metals from fluids

InactiveUS20130306521A1Enhanced surface contactIncrease surface areaRefining with non-metalsRefining with metal saltsThioureaHydrazine compound

Trace amount levels of heavy metals such as mercury in crude oil are reduced by contacting the crude oil with a sufficient amount of a reducing agent to convert at least a portion of the non-volatile mercury into a volatile form of mercury, which can be subsequently removed by any of stripping, scrubbing, adsorption, and combinations thereof. In one embodiment, at least 50% of the mercury is removed. In another embodiment, the removal rate is at least 99%. In one embodiment, the reducing agent is selected from sulfur compounds containing at least one sulfur atom having an oxidation state less than +6; ferrous compounds; stannous compounds; oxalates; cuprous compounds; organic acids which decompose to form CO2 and / or H2 upon heating; hydroxylamine compounds; hydrazine compounds; sodium borohydride; diisobutylaluminium hydride; thiourea; transition metal halides; and mixtures thereof.

Owner:CHEVROU USA INC

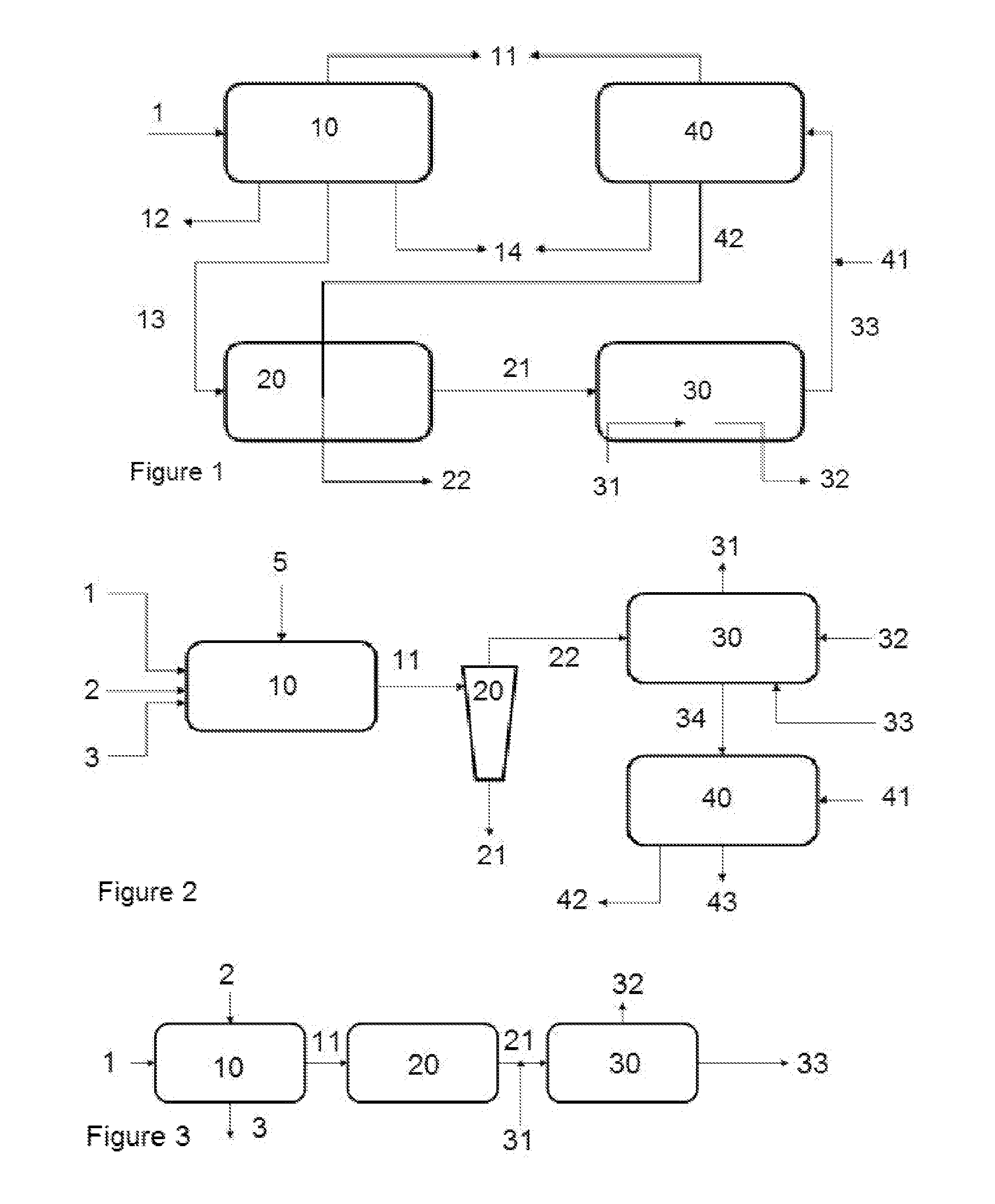

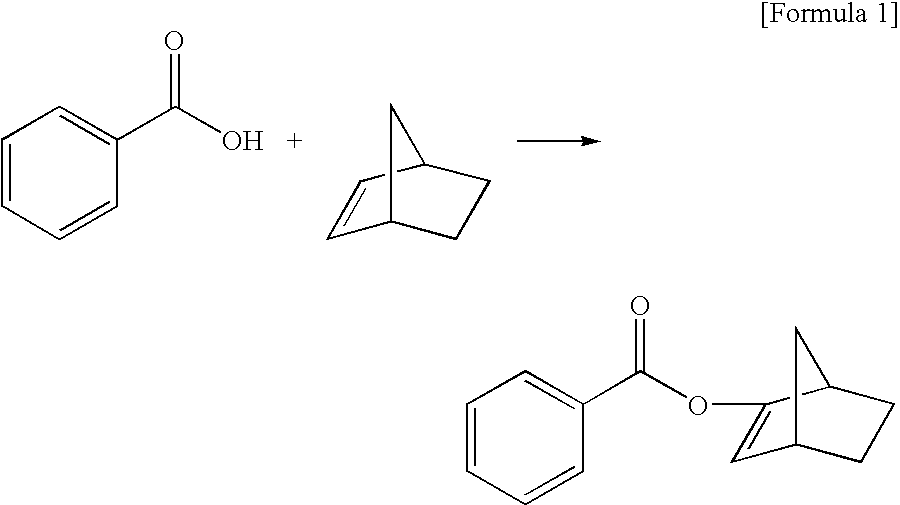

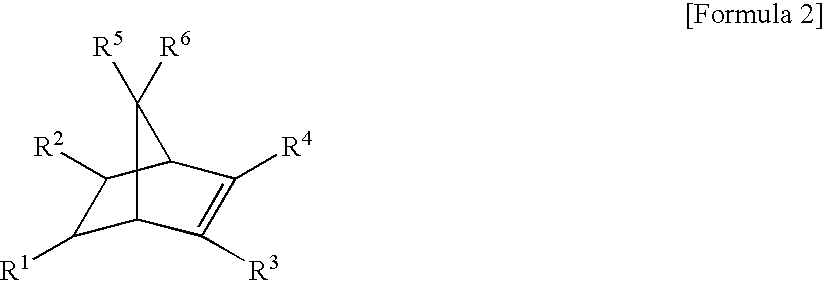

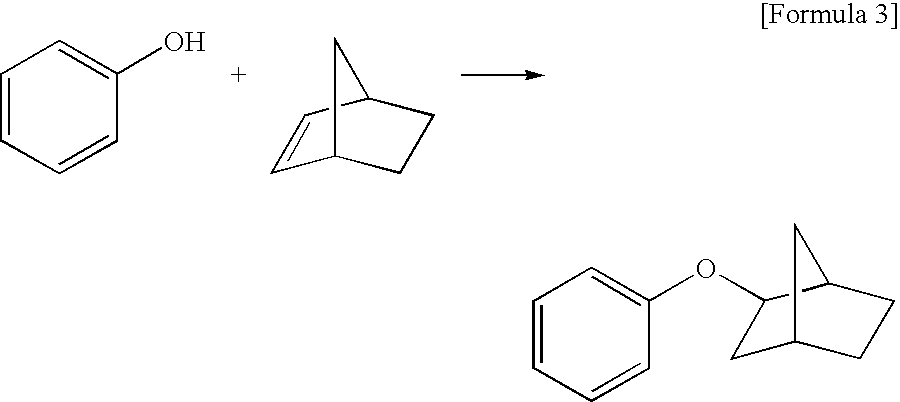

Process for Production of Carboxylic Acid Ester or Ether Compound

InactiveUS20090012324A1Easy to operateEconomical to useOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholNickel compounds

Disclosed is a process for production of a carboxylic acid ester from a carboxylic acid and an olefin or production of an ether compound from an alcohol and an olefin at low cost and with high yield in an industrially advantageous manner. The process comprises the step of reacting a carboxylic acid with an olefin to yield a corresponding carboxylic acid ester or reacting an alcohol with an olefin to yield a corresponding ether compound. In the process, a catalyst comprising a combination of (i) at least one metal compound selected from an iron compound, a cobalt compound and a nickel compound and (ii) an acidic compound is used.

Owner:NAT INST OF ADVANCED IND SCI & TECH

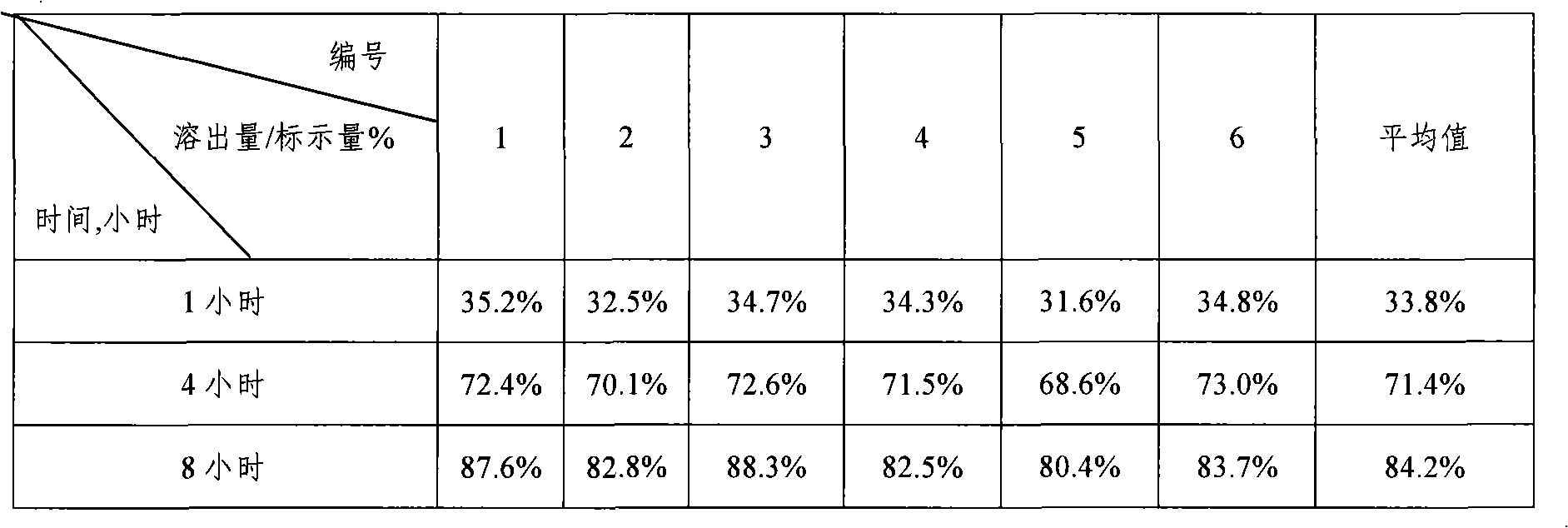

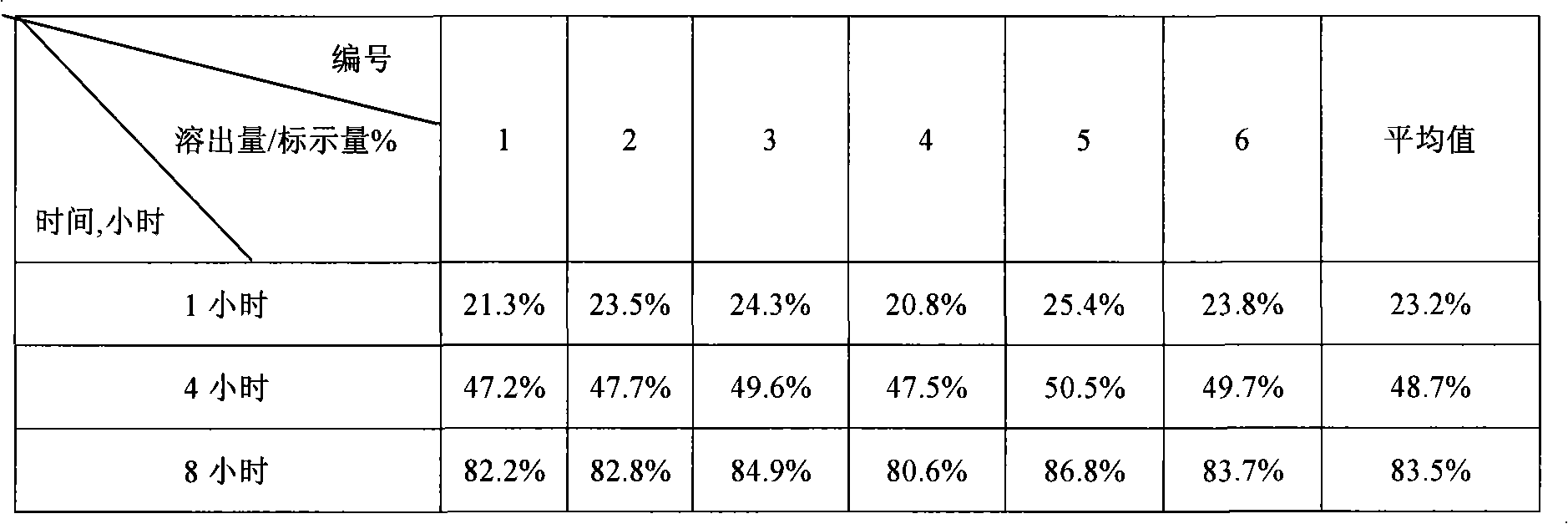

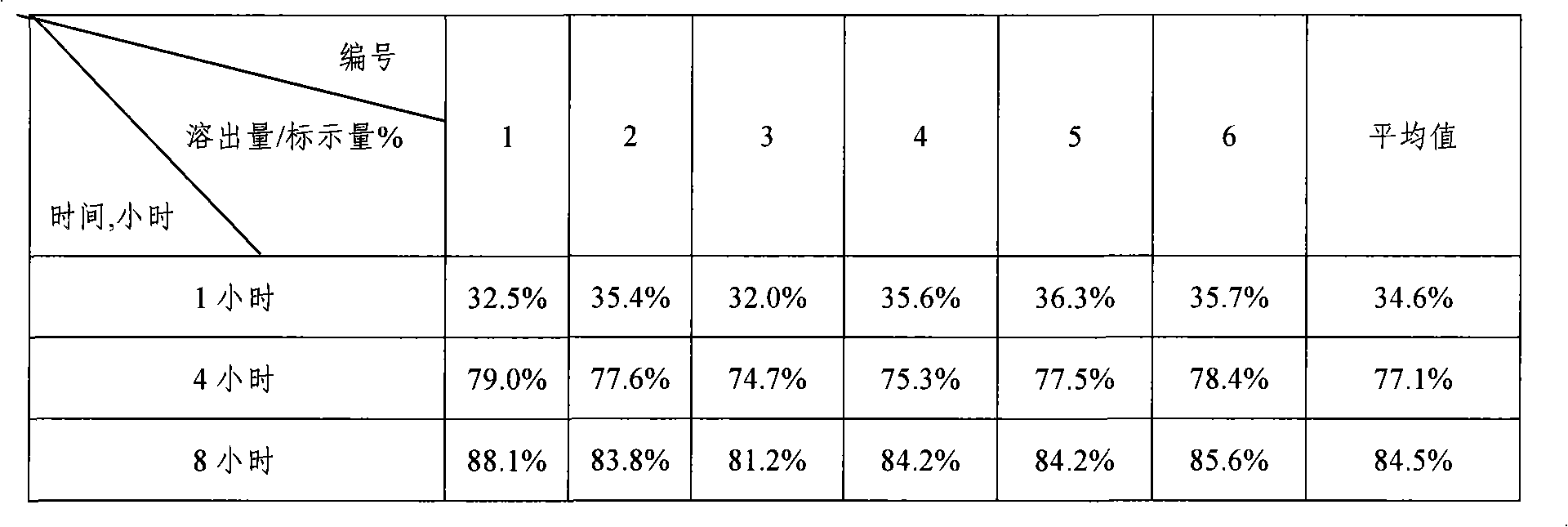

Double-layer sustained release tablets for compensating iron and preparation thereof

ActiveCN101322778AEasy to prepareImprove nutritional statusHeavy metal active ingredientsOrganic active ingredientsSustained Release TabletNutritional status

The invention relates to a double-layer sustained release tablet for supplementing iron, the double-layer sustained release tablet consists of a sustained release layer and a quick release layer laminating with each other at the weight ratio of 1:0.25-1:4; the sustained release layer consists of an iron-containing compound, a sustained release framework, an adhesive, a lubricant and a filler; the quick release layer consists of a traditional Chinese medicine for enriching the blood and / or invigorating vital energy, a filler, a disintegrating agent, an adhesive and a lubricant; the quick release layer can also be added with vitamins. In the double-layer sustained release tablet, by arranging the iron-containing compound in the sustained release layer and the traditional Chinese medicine in the quick release layer, the iron element is released slowly and uniformly, which increases the absorption rate, avoids gastrointestinal reaction caused by high-content iron; meanwhile the double-layer sustained release tablet supplements iron element and the traditional Chinese medicine which has the functions of enriching the blood and invigorating vital energy, thus fully improving the nutritional status caused by iron deficiency anemia and improving iron supplementing effect.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

Composition For Electrode, Electrode And Battery

ActiveUS20080096109A1Large capacityGood repeated charge-discharge cycle characteristicFinal product manufactureActive material electrodesMethacrylateSlurry

Disclosed is a composition for electrode comprising (i) a positive electrode active material comprising an iron compound and carbon, and (ii) a copolymer (P) prepared by copolymerization of acrylic acid esters and / or methacrylic acid esters, with an α,β-unsaturated nitrile compound. Also disclosed is an electrode comprised of an active material layer made of the composition for electrode, and a collector. This electrode can be produced by mixing the positive electrode active material, the copolymer (P), a solvent and an optional thickener, by a mixer to prepare an electrode composition slurry with solid content of 40-90% by weight, coating a collector with the electrode composition slurry, and then, removing the solvent from the thus-formed coating. Further disclosed a battery provided with the electrode.

Owner:ZEON CORP

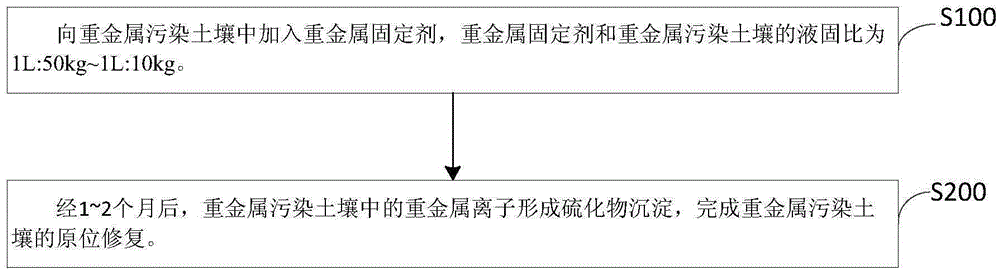

Heavy metal fixing agent and in-situ repair method for heavy metal contaminated soil

ActiveCN105363773AAchieve immobilizationReduce the binding forceContaminated soil reclamationPlant rootsSoil science

The invention discloses a heavy metal fixing agent and an in-situ repair method for heavy metal contaminated soil. The heavy metal fixing agent comprises sulphur-containing compound solution and an iron-containing compound, wherein iron element in the iron-containing compound is mixed with the sulphur-containing compound solution in a solid-liquid ratio of 1kg: 20L to 1kg: 1L to obtain the heavy metal fixing agent. According to the heavy metal fixing agent, the liquid-solid ratio of the iron-containing compound to the sulphur-containing compound solution is proper, the mass concentration of the sulphur-containing compound solution is reasonable, and trithione triazine trisodium salt can form a stable vulcanization-chelation coprecipitate with heavy metal ions in soil, thus achieving the effect of fixing heavy metals; and the iron-containing compound is conducive to weaken combination of plant root system secretion and the heavy metals in soil, and stabilize the effect of fixing the heavy metals. The heavy metal fixing agent is capable of fixing the many heavy metal ions in soil simultaneously, high in the stability of fixing for the heavy metals, and capable of reducing the contents of the heavy metals in soil in a short time.

Owner:湖南中金岭南康盟环保科技有限公司

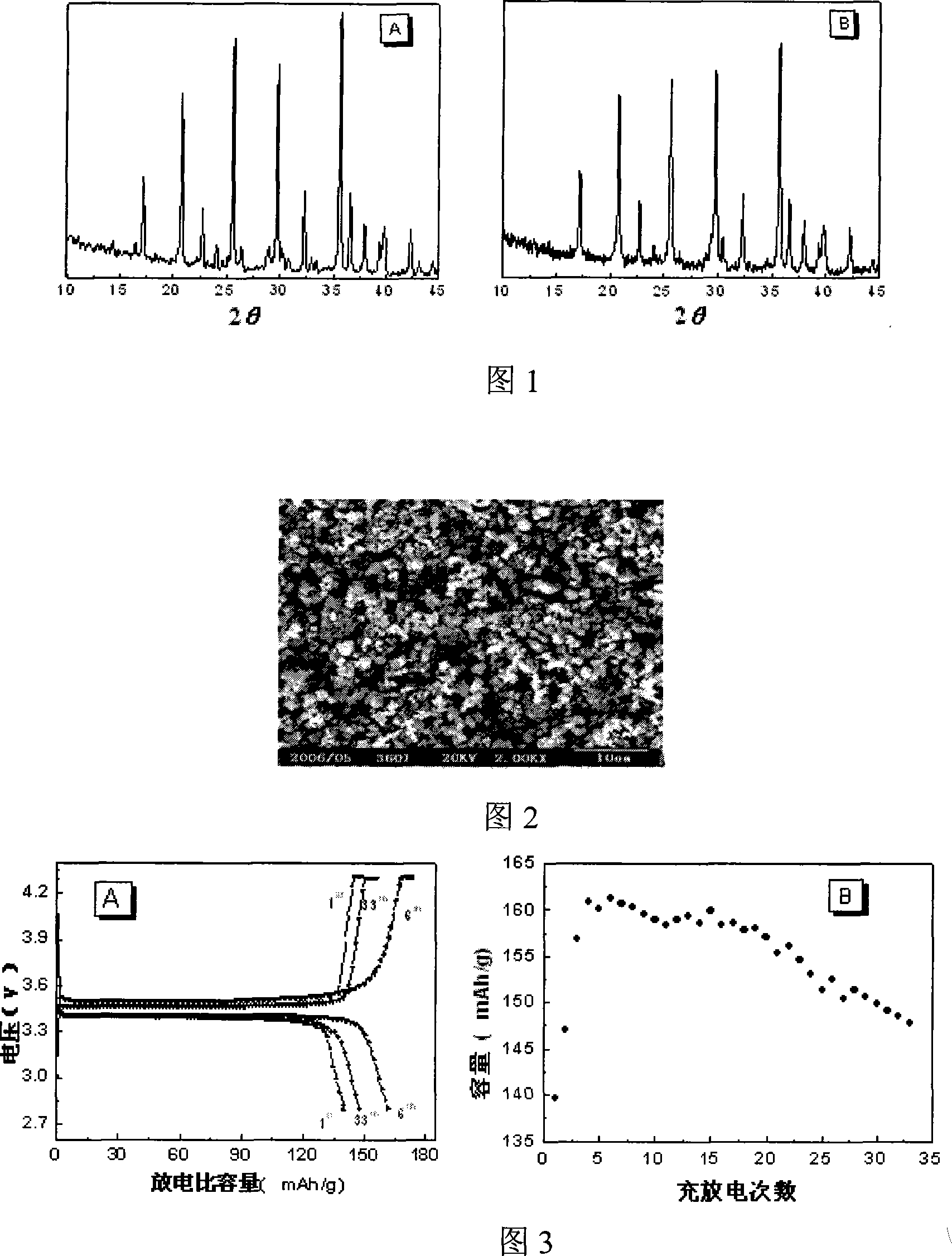

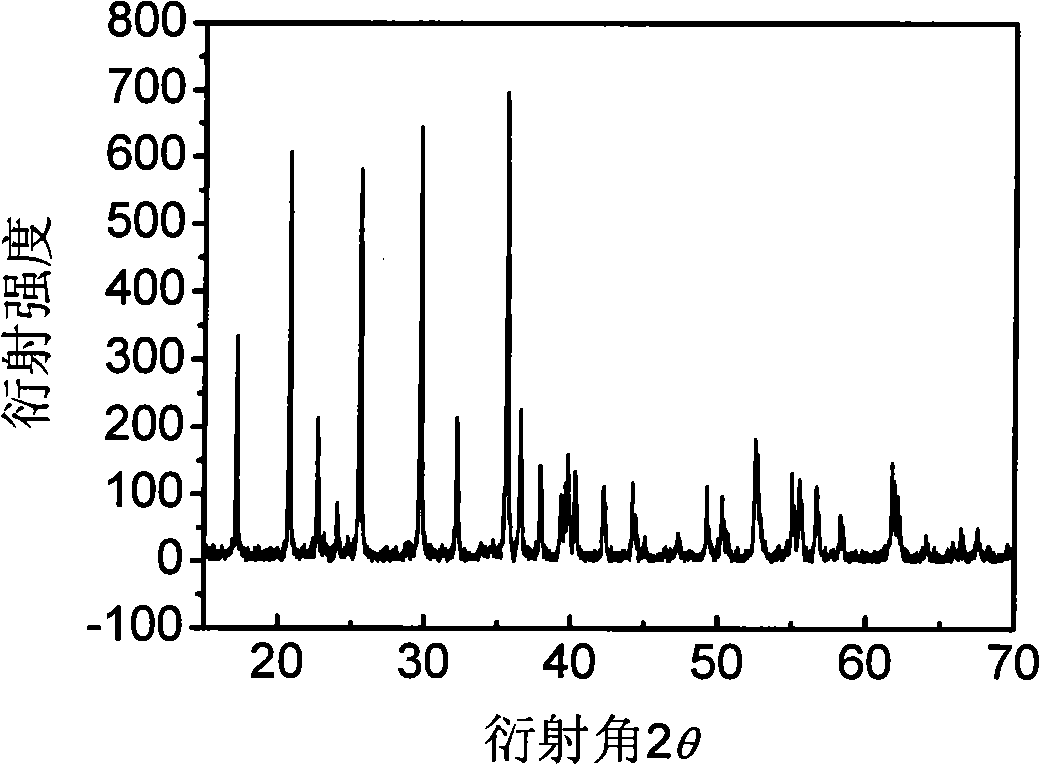

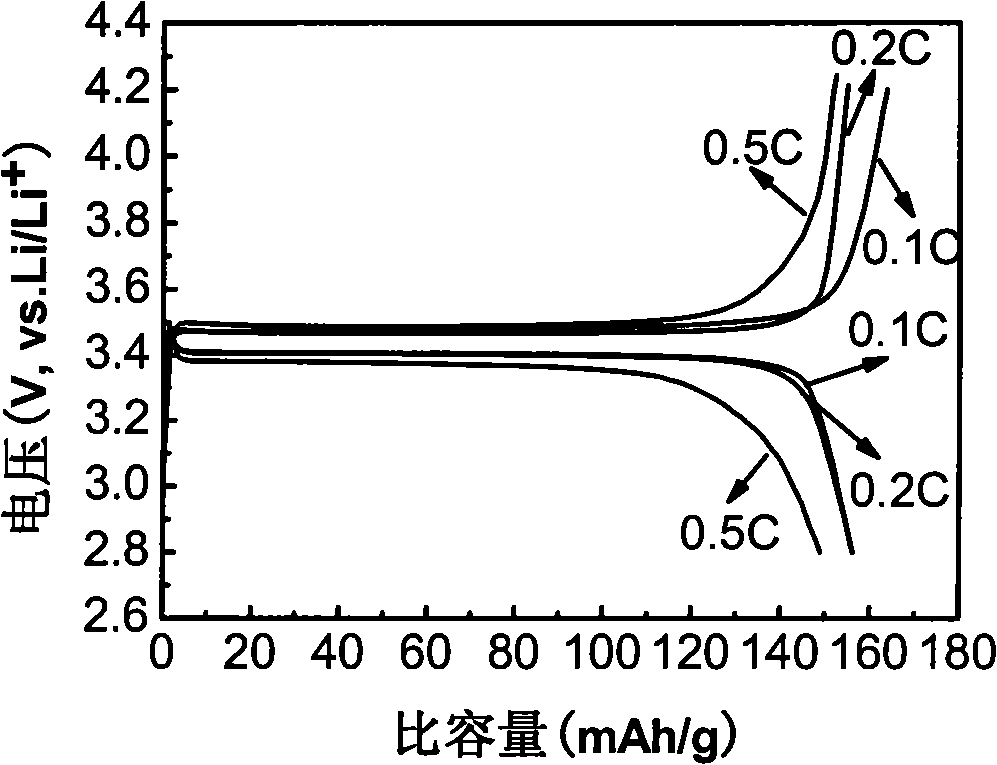

Lithium iron carbonate material prepared by vacuum carbon reduction and method

InactiveCN101070149ALower synthesis costHigh yieldCell electrodesPhosphorus compoundsChemical reactionPhosphate

This invention relates to a kind of anode material and method used for reducing preparation of lithium iron phosphate by vacuum carbon. It uses cheap phosphate, iron compound and lithium compound as raw material, compound of cheap heavy metal as adulteration modifying agent, cheap and abundant activated carbon, acetylene black and graphite as reducing agent. Dealing with it using ball milling techniques and makes solid-phase chemical reaction under the vacuum condition, then get the anode material adulterating lithium iron phosphate which contains carbon. Lithium iron phosphate compounded in this invention has a stable performance, physical chemistry of products has a good homogeneity and consistency and a high productivity; lithium iron phosphate produced in this invention has a high tap density and electric specific votume, good discharging capability of high-current, stable electrochemistry circulation capability, and low local action, besides, it is easy to control content of tantalum adulterated. The tap density of lithium iron phosphate produced by this method is 1.63-2.04g / cu cm, the highest discharging specific votume is 161.3mAh / g.

Owner:HUBEI UEE ENERGY TECH CO LTD

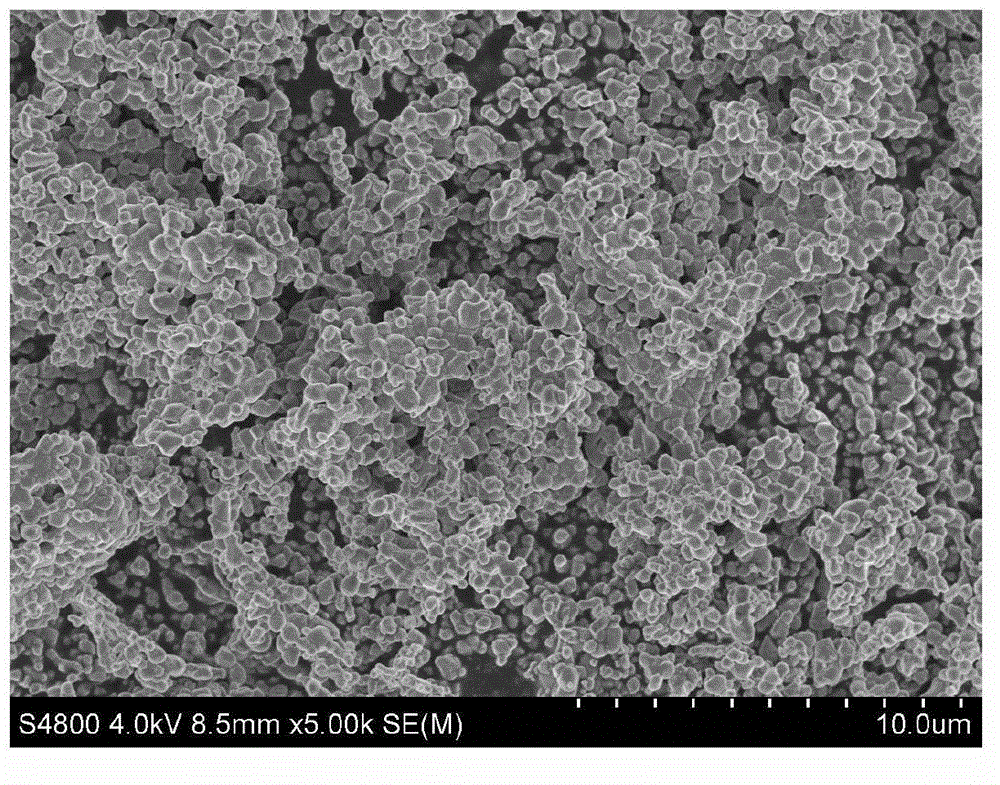

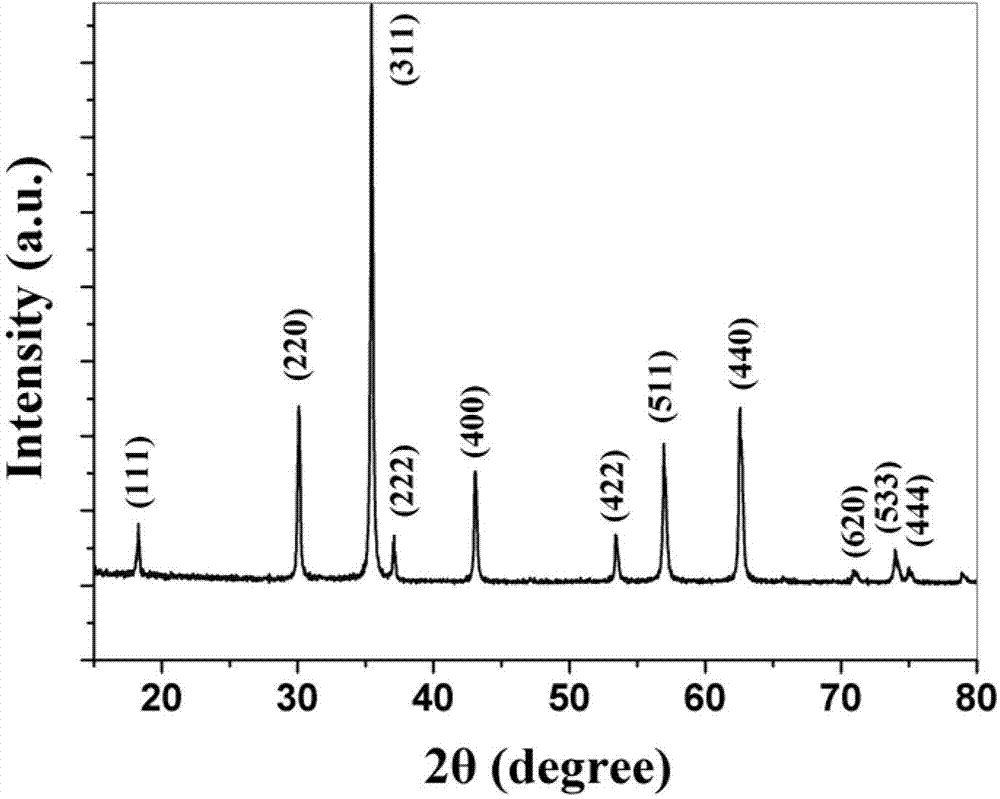

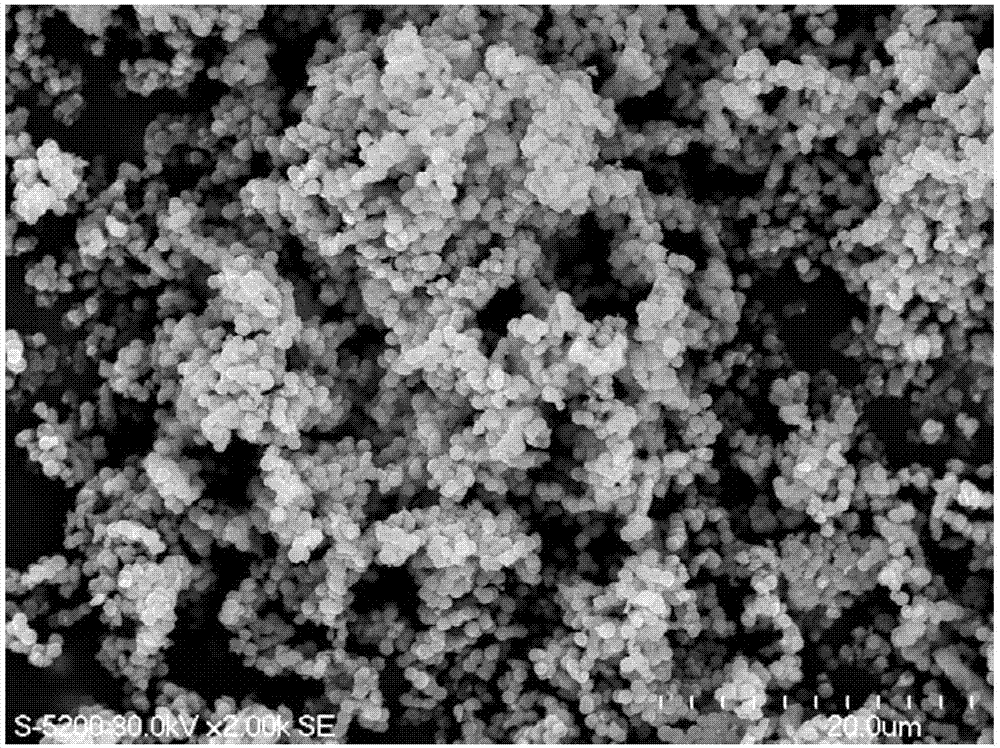

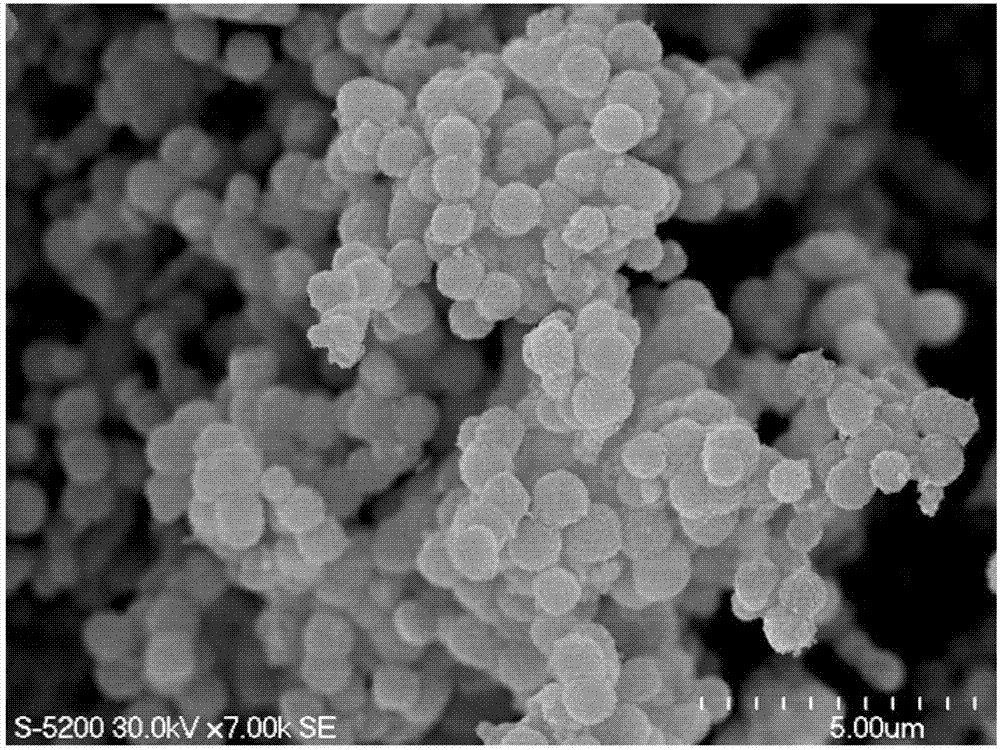

Carbon-nanotube-loaded multi-stage nanometer ferroferric oxide adsorbent and preparation method and application thereof

ActiveCN103007887AEffectively regulate growthPromote formationOther chemical processesAlkali metal oxides/hydroxidesFerric iron compoundNanotube

The invention discloses a carbon-nanotube-loaded multi-stage nanometer ferroferric oxide adsorbent and a preparation method and application of the carbon-nanotube-loaded multi-stage nanometer ferroferric oxide adsorbent. The adsorbent comprises a carbon nanotube and multi-stage nanometer ferroferric oxide loaded on the carbon nanotube, wherein the ferroferric oxide has the grain size of 30 to 80 nanometers and mass fraction of 25 to 35%. The preparation method of the adsorbent comprises the following steps in sequence: mixing the oxidized carbon nanotube with an organic reducing agent and an organic iron compound; transferring the mixture into a reacting kettle; thermally synthesizing through an in-situ solvent in an oil bath under an inert atmosphere at reaction temperature of 180 to 270 DEG C and pressure of 0.1 to 2.0 MPa; cooling the reacting product; washing; and drying in vacuum to obtain carbon-nanotube-loaded multi-stage nanometer ferroferric oxide adsorbent. The carbon-nanotube-loaded multi-stage nanometer ferroferric oxide adsorbent disclosed by the invention is high adsorbing performance and easy to separate and recovery; and the preparation method is simple and low in cost, and has a wide application prospect in the field of adsorbing heavy metal ions and organic pollutants from the wastewater.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

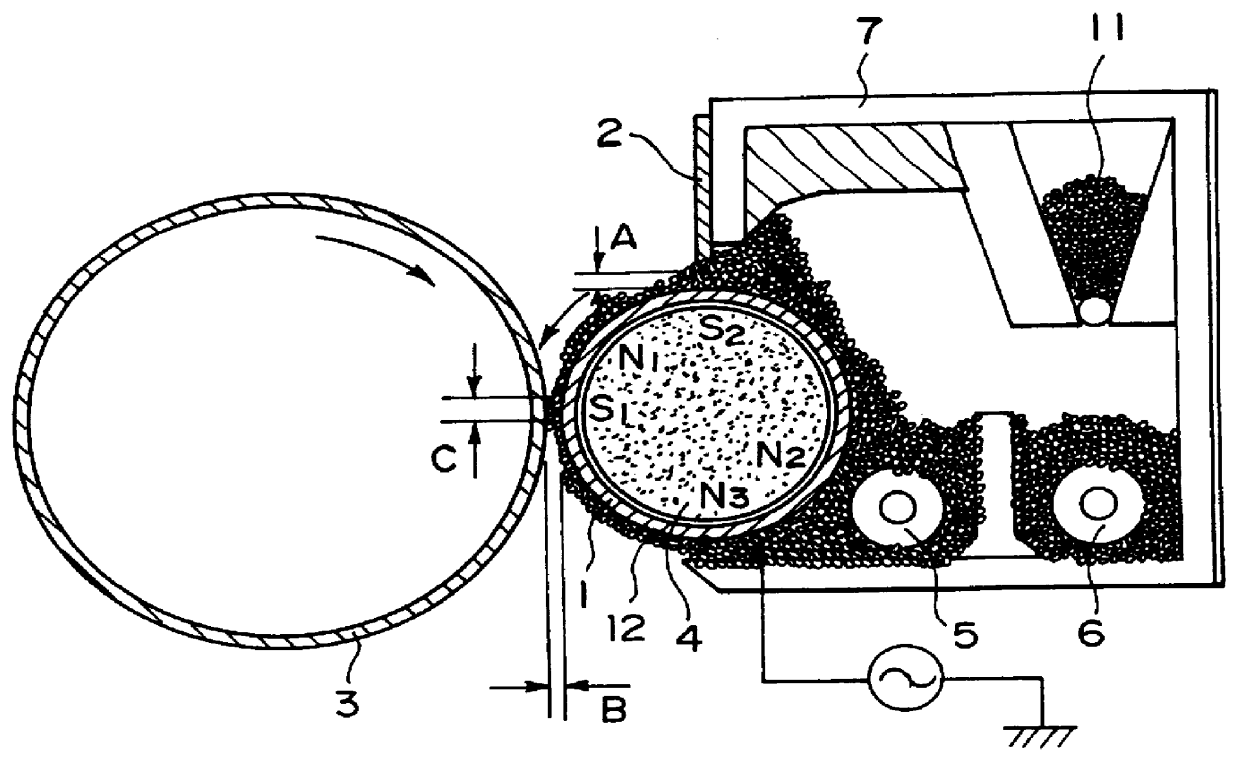

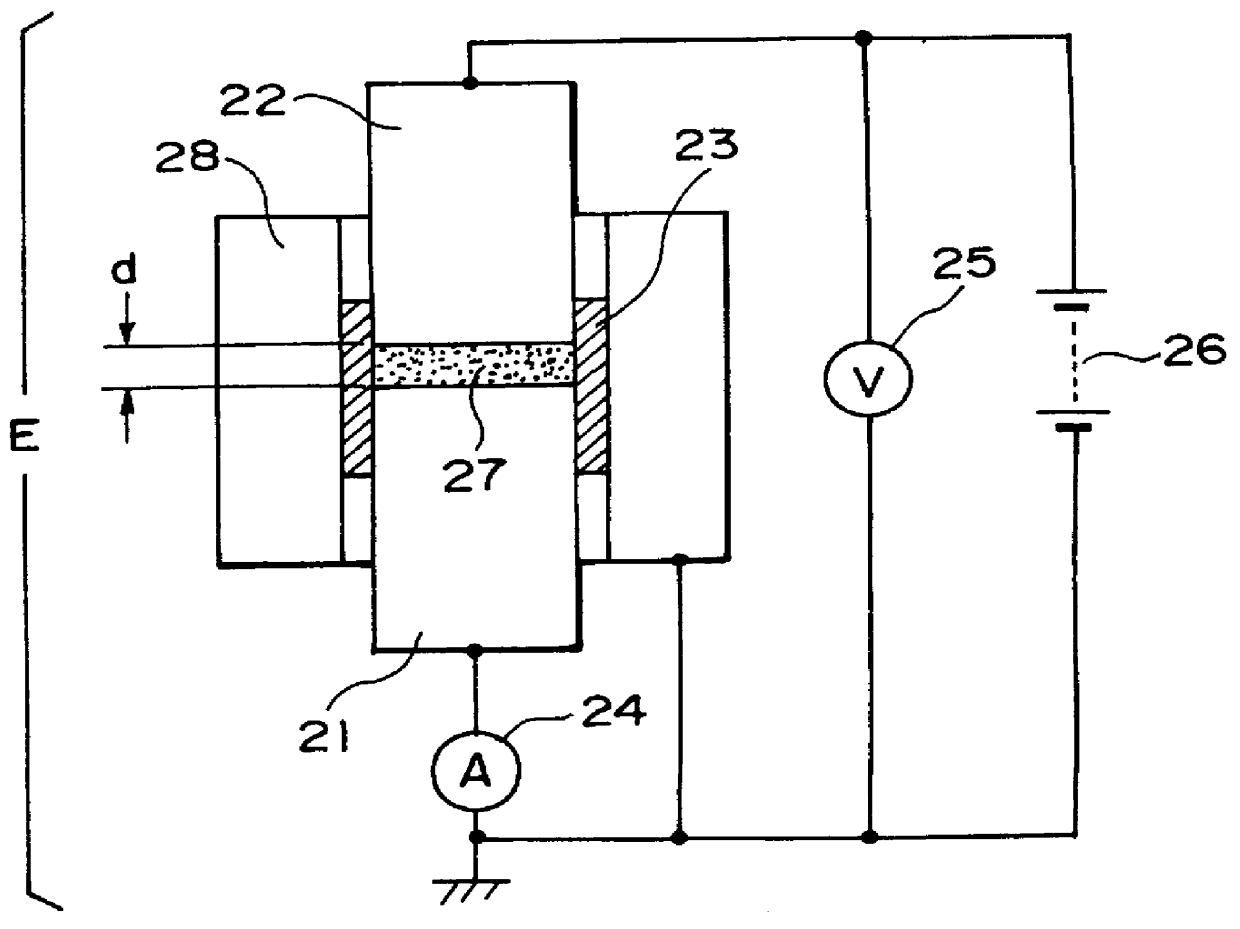

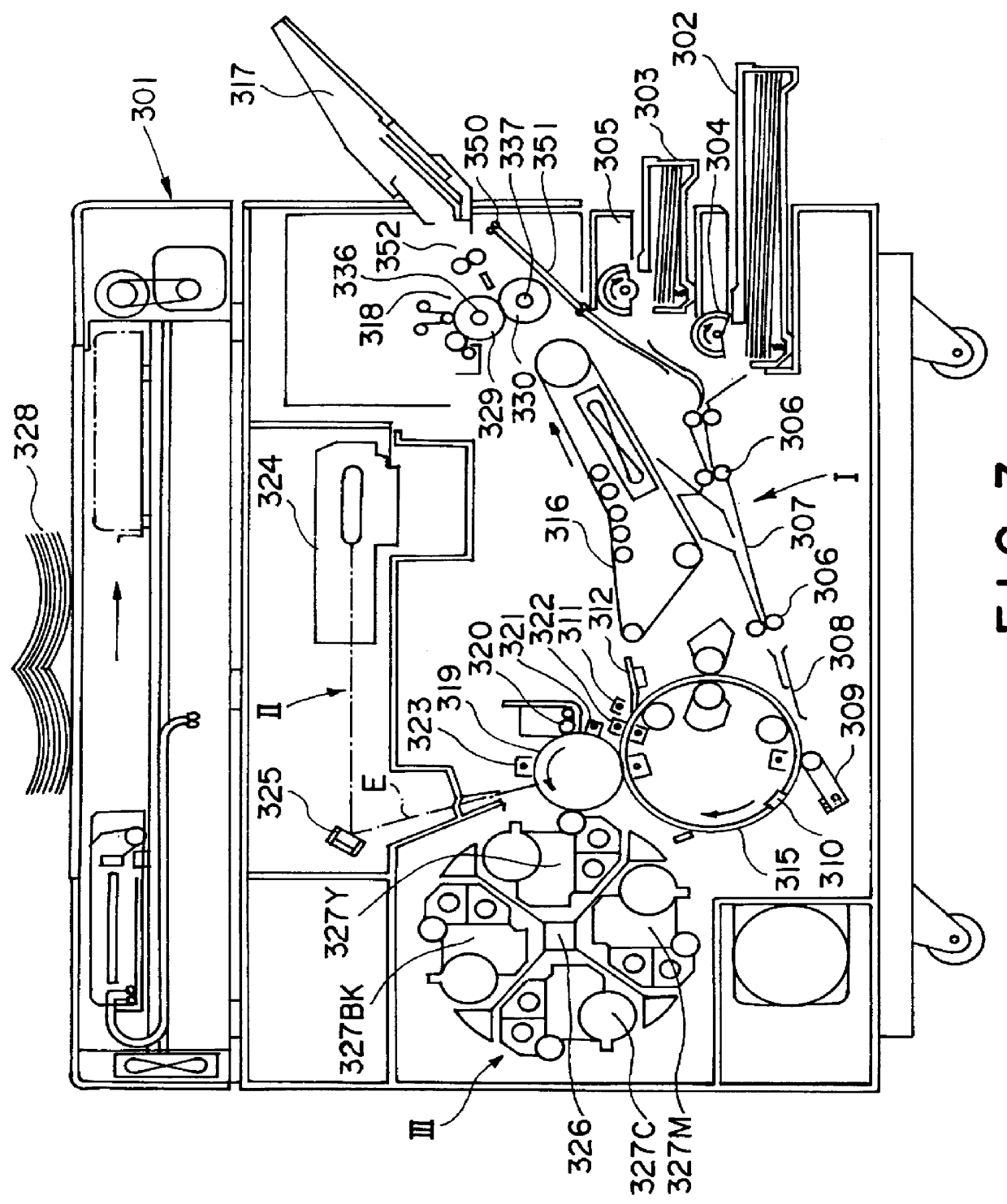

Two-component type developer, developing method and image forming method

InactiveUS6159648APrevent and suppress occurrenceHigh quality imagingDevelopersElectrographic processes using charge patternImage formationNon magnetic

A two-component type developer for developing an electrostatic image is constituted by at least a toner and a magnetic carrier. The toner has a weight-average particle size D4 of at most 10 mu m and a number-average particle size D1 satisfying D4 / D1< / =1.5. The magnetic carrier comprises composite particles comprising magnetic iron compound particles, non-magnetic metal oxide particles, and a binder comprising a phenolic resin. The composite particles contain the magnetic iron compound and the non-magnetic metal oxide in a total proportion of 80-99 wt. %. The magnetic iron compound particles have a number-average particle size ra, and the non-magnetic metal oxide particles have a number-average particle size rb satisfying rb / ra>1.0.

Owner:CANON KK

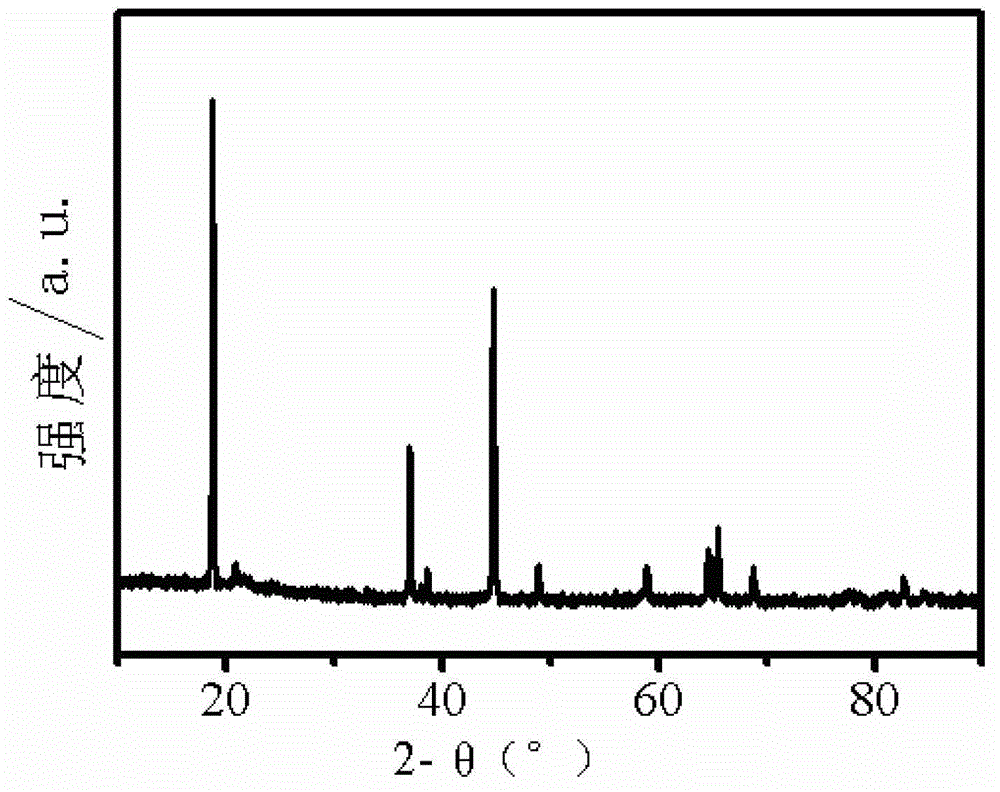

Method for preparing nano ferrate in fused salt manner

ActiveCN102923786ASimple and fast operationShort reaction timeMaterial nanotechnologyIron compoundsCrucibleDivalent metal

The invention discloses a method for preparing nano ferrate in a fused salt manner. The method comprises the following steps of grinding and uniformly mixing a divalent metal compound serving as a raw material, a ferric iron compound serving as a raw material, sodium chloride serving as fused salt and potassium chloride as fused salt, putting the mixture in a crucible, putting the crucible into a tubular furnace, and roasting for 4-6 hours at 800-880 DEG C, and carrying out aftertreatment to obtain nano ferrate, wherein the mole ratio of the raw materials to the fused salt is 3:11y and y is not less than 0.6 and not larger than 50; the mole ratio of the divalent metal compound to the ferric iron compound is x:3-x and x is not less than 0.01 and not larger than 1; and the mole ratio of sodium chloride to potassium chloride in the fused salt is 10:1. The method for preparing nano ferrate in a fused salt manner, disclosed by the invention, has the advantages of simpleness in equipment, short reaction time, low energy consumption, environment friendliness, low cost and product diversity, and is suitable for industrial production.

Owner:JIANGSU UNIV OF TECH

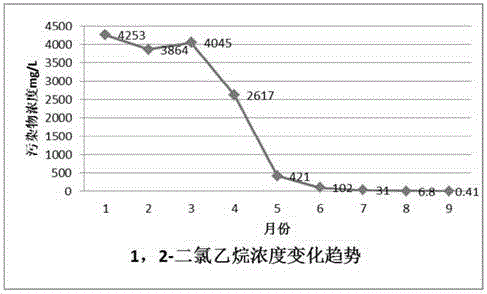

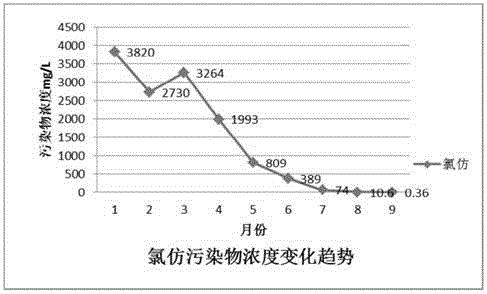

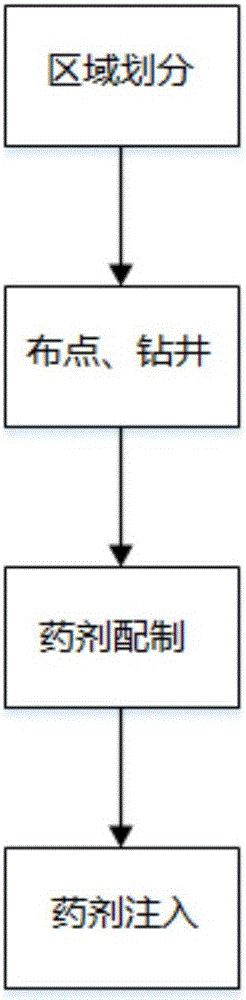

In-situ oxidation medicine and pollution soil in-situ oxidation remediation method

InactiveCN105860982AImprove stabilityGood water solubilityContaminated soil reclamationOrganic fertilisersSoil scienceActive agent

The invention discloses an in-situ oxidation medicine and a pollution soil in-situ oxidation remediation method. The in-situ oxidation medicine comprises components sodium persulfate, calcium oxide, an iron-containing compound, a surfactant and a cosolvent according to the weight ratio of (60-70):(20-30):(10-15):(5-10):(1-5). The mediation method comprises the following steps: (1) dividing a pollution area; (2) arranging points and drilling wells; (3) preparing a medicine; (4) injecting the medicine. By adopting the pollution soil in-situ oxidation remediation method, the problems can be solved. The in-situ oxidation medicine and the pollution soil in-situ oxidation remediation method are easy to operate, the time and labor can be saved, and an address structure is not damaged.

Owner:JIANGSU TIANSHENG ENVIRONMENTAL TECH CO LTD

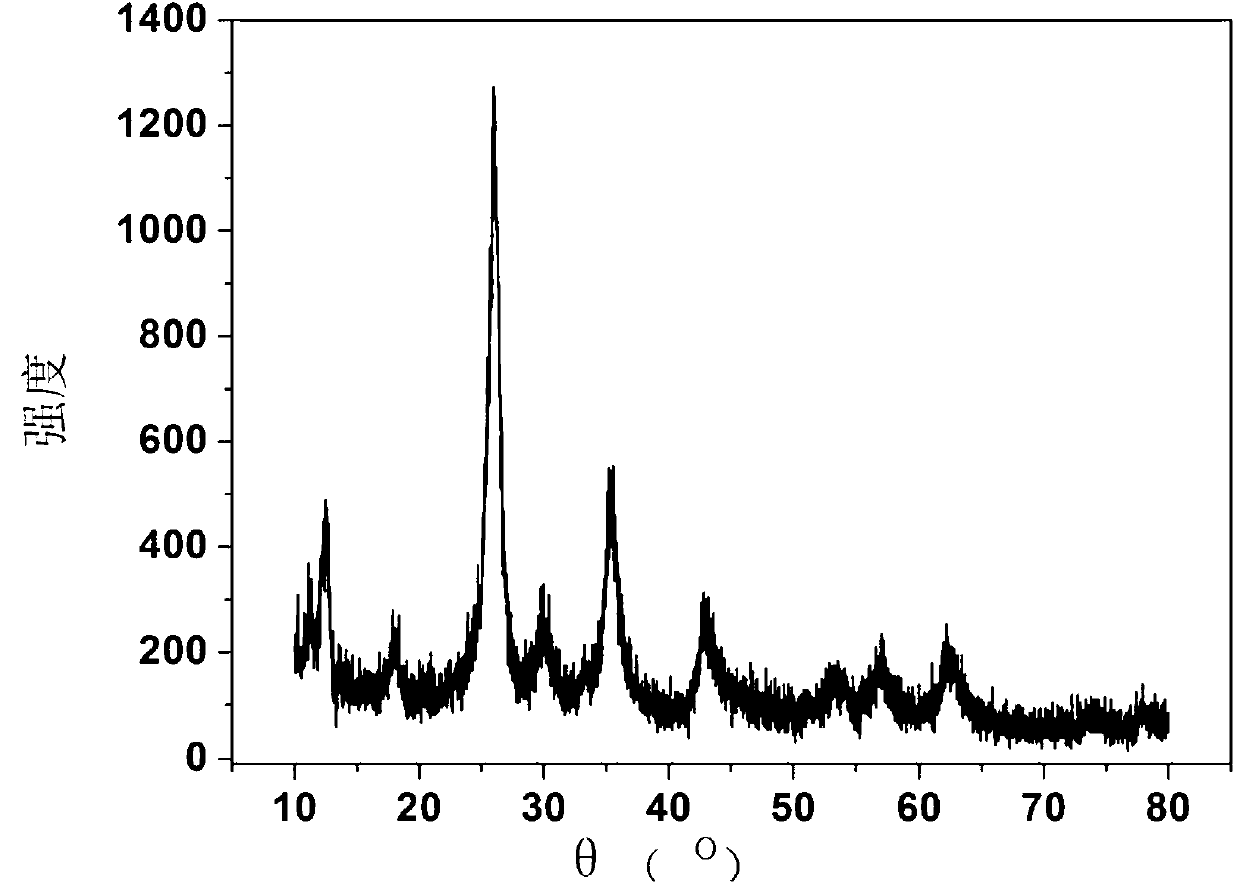

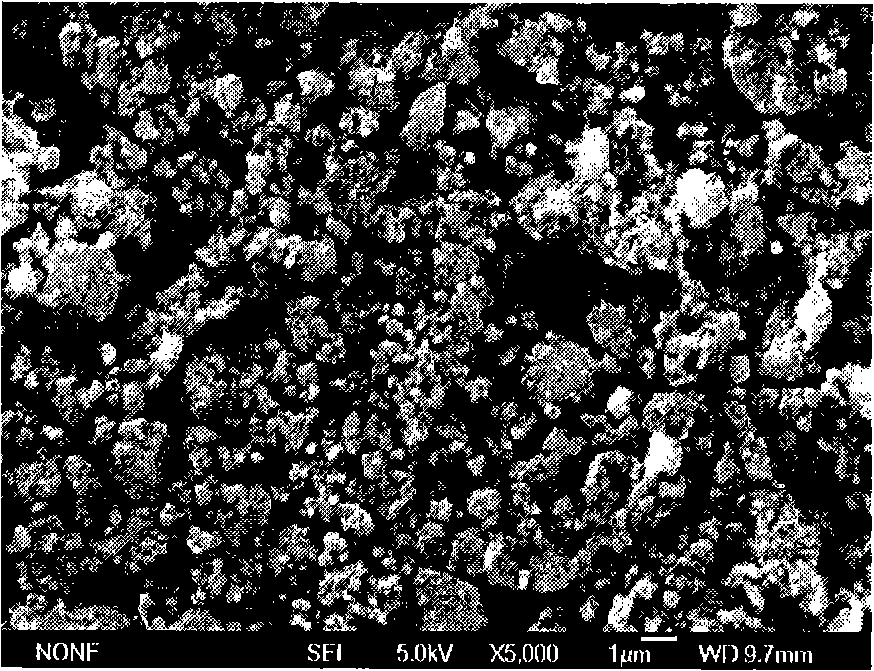

Composite coated modified high vibrancy solid lithium ionic battery positive electrode, preparation and application thereof

InactiveCN101339991AReduce manufacturing costConducive to large-scale industrial productionElectrode manufacturing processesChemical/physical/physico-chemical processesLithium iron phosphateNanometre

The invention provides a lithium-ion battery anode material with compound cladding modification and high tap density and a preparation method thereof and an application thereof to the manufacturing field of lithium-ion batteries. The material of the invention consists of carbon, Fe2P and lithium iron phosphate. The carbon and the Fe2P form a conductive nanometer network to compound and clad the lithium iron phosphate particles so as to form the LiFePO4 / (C+Fe2P) compound material. The lithium-ion battery anode material of the invention takes the mixture of an organic ferric iron compound and an inorganic ferric iron compound as an iron source, and is mixed with the compound of the lithium source and the phosphorous source, and makes use of a solid phase-carbon thermal reduction method to prepare the material. The preparation method of the invention is relatively simple and practicable, the price of the raw material is relatively cheap, the production cost is relatively low, and the prepared material has good electrochemical performance, high tap density and is suitable for industrialized production.

Owner:SOUTH CHINA UNIV OF TECH

Molding material, prepreg, fiber-reinforced composite material, fiber-reinforced composite material laminate, and process for production of fiber-reinforced molding base material

InactiveUS10005905B2Good moldabilityIncrease productivityWoven fabricsCoatingsProduction rateFiber-reinforced composite

Owner:TORAY IND INC

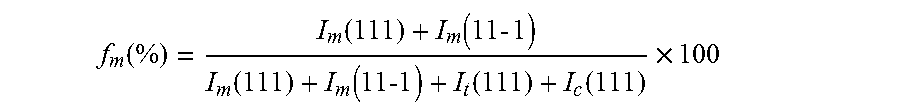

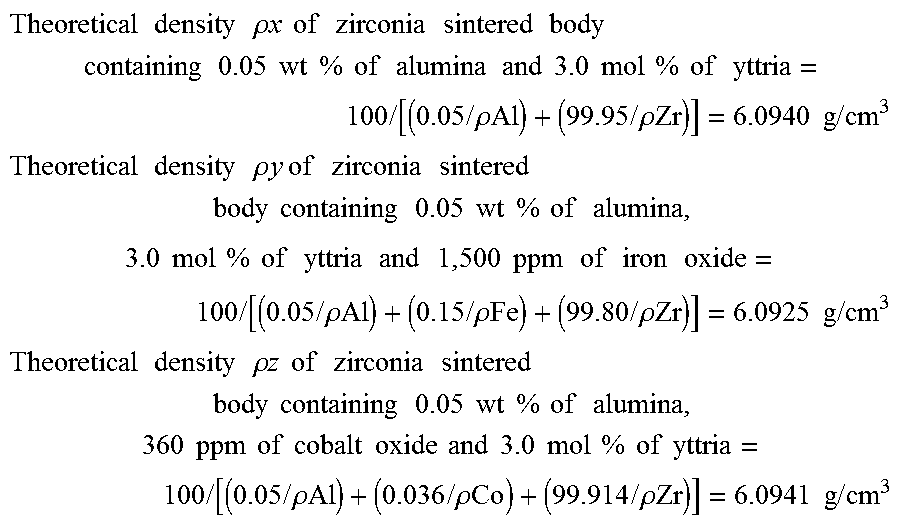

Colored translucent zirconia sintered body and its use

ActiveUS9428422B2Satisfies colorSatisfies strengthBracketsImpression capsTransmittanceFerric iron compound

A pink-colored zirconia sintered body has a high sintered body density and strength, and a colored translucency, which has a color tone similar to teeth and excellent translucency and has high aesthetic properties. A colored translucent zirconia sintered body includes from 2 to 4 mol % of yttria, from 0.02 to 0.8 mol % of Er2O3, at least 20 and less than 2,000 ppm, as calculated as Fe2O3, of an iron compound, at least 0.005 and less than 0.2 wt % of Al2O3 and the rest being zirconia, and having a lightness L* of from 55 to 75, a* of from 0 to 10 and b* of from 0 to 30 as chromatic parameters stipulated in JIS-Z8729, has a relative density of at least 99.80% and has a total light transmittance of at least 18% and at most 40% as measured at a sample thickness of 1 mm using a D65 light source.

Owner:TOSOH CORP

Production method of ammonium ferric citrate

ActiveCN101704738AAvoid generatingIncrease productivityCarboxylic acid salt preparationImpurityAmmonium ferric citrate

The invention discloses a production method of ammonium ferric citrate. The ammonium ferric citrate is prepared by water, citric acid and iron powder according to the following steps: 1. placing water and citric acid into a stirring device to be heated to 60 DEG C; 2. opening the stirring device, adding the iron powder, slowly heating to 80 DEG C, keeping the temperature, stirring and reacting to generate ferrous citrate; 3. cooling the ferrous citrate obtain in step 2 to 40 DEG C, adding hydrogen peroxide for oxidizing until no ferrousion exists; 4. introducing ammonia to neutralize the ferrate compound obtained in step 3 to the pH value more than or equal to 7, filtering, removing impurities and concentrating to be in a pasty shape; and 5. placing the concentrated matter obtained in step 2 into an oven for drying at the temperature of 80 DEG C. The invention has the advantages of adopting the iron powder to replace ferrous sulphate, using the hydrogen peroxide as oxidant and adopting scientific proportioning and production process, thus avoiding chloridion and sulfate ion and other impurities from being carried in, preventing from generating ferric hydroxide intermediate products which are difficult to dehydrate and wash, greatly simplifying production processes, reducing production cost and improving production efficiency of the ammonium ferric citrate.

Owner:郑州瑞普生物工程有限公司

Process for recycling waste acid

ActiveUS20080056982A1Quality improvementWater/sewage treatment by irradiationOrganic compound preparationSULFATE IONSpent acid

A recycling process is presented to treat spent waste acid solutions whereby useful products are produced. Spent waste acid containing inorganic and organic contaminants is mixed with a magnesium compound containing aluminum and iron compounds that form oxyhydroxide flocs that complex, react, sequester and / or co-precipate the contaminates from the admixture. The magnesium reacts with sulfate ions to form a high quality magnesium sulfate solution.

Owner:VEOLIA & TECHN SOLUTIONS

Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

InactiveCN101209821AReasonable proportionAvoid stickingCell electrodesPhosphorus compoundsLithium iron phosphateBoiling point

The invention relates to a preparation method of lithium iron phosphate, an active substance applied in the anode of lithium-ion secondary batteries. The method comprises the step that a mixture that contains lithium compound, iron compound, phosphorus compound, carbon source additive, water and dispersant is dried and sintered; wherein, the lithium compound, the phosphorus compound and the carbon source additive are compounds that are water soluble, while the iron compound is undissolved or insoluble in water; the dispersant is water soluble and has higher boiling point than water. The lithium iron phosphate acquired by the method has even distribution of crystal particle size, high specific capacity of initial discharge and good cycling performance.

Owner:BYD CO LTD

Surface treatment method of powder metallurgy part

InactiveCN102115865AHigh surface hardnessImprove wear resistanceSolid state diffusion coatingHigh resistanceChromium Compounds

The invention discloses a surface treatment method of a powder metallurgy part. The method comprises the following steps of: firstly, performing complex cementation on the powder metallurgy part with nitrogen gas, sulfur gas and chromium gas to form a dense coating tissue of a nitrogen-sulfur-chromium compound with the size of between 15 microns and 45 microns on the surface of the powder metallurgy part; secondly, polishing the surface of the powder metallurgy part; and lastly, oxidizing the powder metallurgy part at low temperature to form a dense oxide layer. The compound coating tissue is a dense oxide layer covered by a polynary ultra-hard nitrogen-sulfur-chromium compound, so that the powder metallurgy part has high wear resistance, corrosion resistance and high temperature resistance, the friction coefficient is greatly lowered, the seizing resistance magnitude order is raised, the working quality of the powder metallurgy part is remarkably enhanced, and the service life is prolonged.

Owner:杭州力合金邦表面技术有限公司

Preparation method and application of nanoscale zero-valent iron-beta zeolite new composite nano material

InactiveCN104118920AFully dispersedEvenly combinedWater/sewage treatment by ion-exchangeWater/sewage treatment by sorptionIon exchangeChemistry

The invention relates to a preparation method and application of a nanoscale zero-valent iron-beta zeolite new composite nano material, an iron source is Fe<2+> or Fe<3+> iron containing compounds (such as anhydrous ferric chloride, ferrous sulfate, and the like), and a loading base is beta zeolite with total ion exchange capacity. The preparation is characterized in that a loading base material is fully dispersed and iron ions and the loading base are uniformly combined through the long time reaction under ultrasonic synergistic effect, free iron ions in the solution are removed by centrifugation, the iron-containing solution is recycled, the homogeneity of the properties of the synthetic material system is enhanced, iron ions absorbed on the loading base surface are reduced under the function of sodium borohydride, and anhydrous ethanol is used for cleaning and storage. The preparation method has the advantages of being low in cost, convenient, fast, low in technical threshold, and in favor of the popularization and promotion, and nano zero valent iron particles in the synthetic material are smaller, is not easy to agglomerate and have very good removal effect on heavy metal pollutant stibonium and the like difficult to remove in the environment.

Owner:TONGJI UNIV

Chemical mechanical polishing aqueous dispersion and chemical mechanical polishing method

A chemical mechanical polishing aqueous dispersion is used to polish a polishing target that includes an interconnect layer that contains tungsten. The chemical mechanical polishing aqueous dispersion includes: (A) a cationic water-soluble polymer; (B) an iron (III) compound; and (C) colloidal silica particles. The content (MA) (mass %) of the cationic water-soluble polymer (A) and the content (MB) (mass %) of the iron (III) compound (B) satisfy the relationship “MA / MB=0.004 to 0.1”. The chemical mechanical polishing aqueous dispersion has a pH of 1 to 3.

Owner:JSR CORPORATIOON +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com