Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

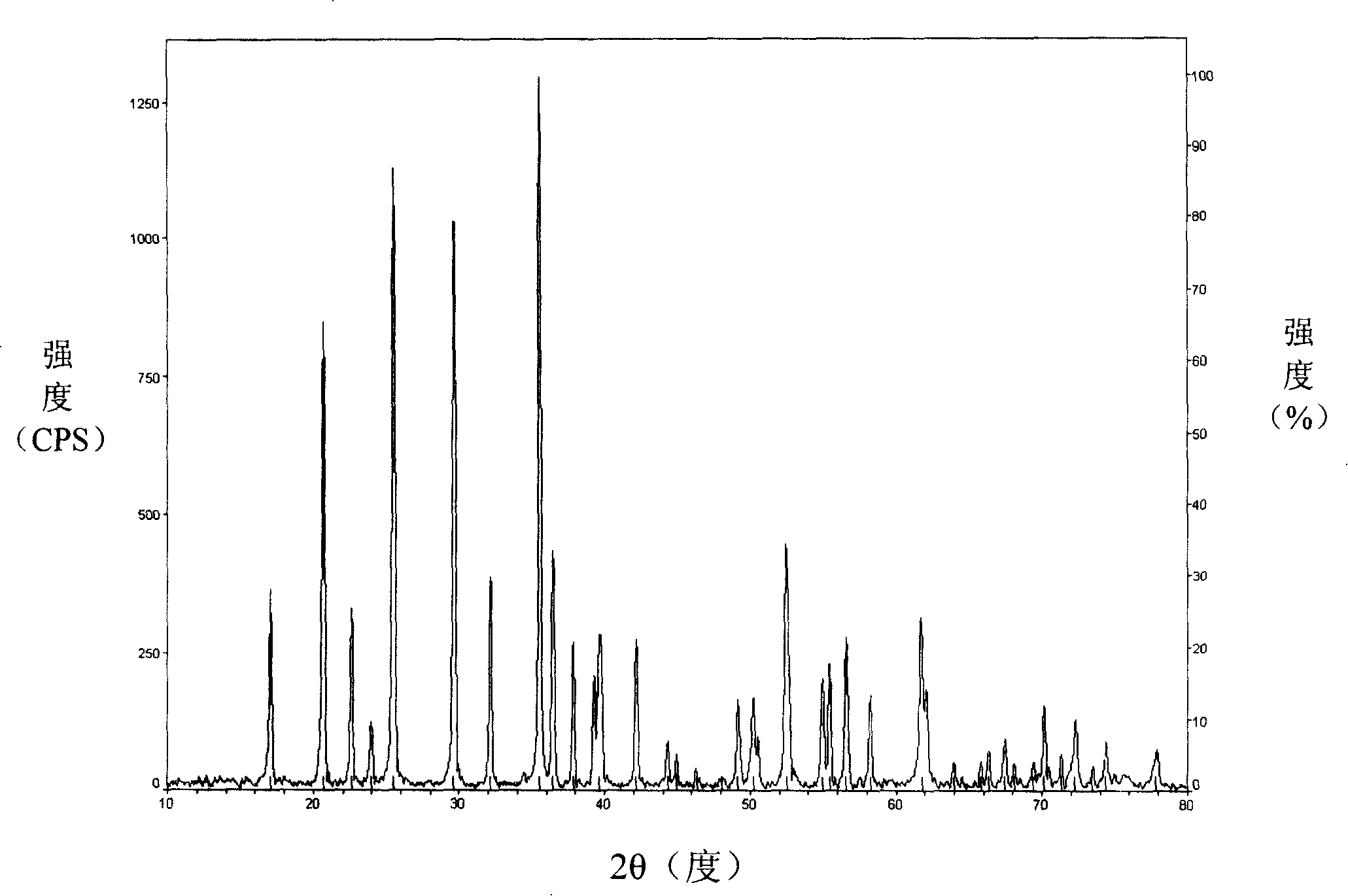

A positive electrode active material, lithium iron phosphate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as uneven particle size distribution of lithium iron phosphate crystals, poor cycle performance, and low specific capacity for the first discharge , to achieve significant first discharge specific capacity and cycle performance, uniform crystal particle size distribution, and improved first discharge specific capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This example illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the present invention.

[0023] 323.40 g CH 3 COOLi·2H 2 O and 190 grams of glucose were dissolved in 2000 grams of deionized water and 478.10 grams of median particle size D was added 50 1.8 µm, D 95 4.0 µm FePO 4 And 5 grams of dispersant polyacrylic acid, the gained mixture is put into the water bath of 80 ℃ and heated and stirred for 1 hour, then the mixed slurry obtained is spray-dried with the QPG50 type air flow spray drier (Jingjiang Dadi Machinery Manufacturing Co., Ltd.) , spray-dried at an inlet temperature of 250°C and an atomization pressure of 0.2 MPa. The product obtained by spray drying was heated up to 500° C. at a rate of 2° C. / min under an argon atmosphere in a low-temperature tube furnace, and kept at a constant temperature for 4 hours. Then continue to heat up to 700°C at a rate of 2°C / min, and keep the temperature constant for ...

Embodiment 2

[0026] This example illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the present invention.

[0027] 266.3 g CH 3 COOLi, 150 g of sucrose and 418.63 g of ammonium hydrogen phosphate were dissolved in 2000 g of deionized water, and 228.24 g of median particle size D 50 2.7 µm, D 95 3.9 microns of FeO and 6 grams of molecular weight are dispersant polyvinyl alcohol of 100,000. After stirring the resulting mixture at 100 rpm for 3 hours in an infrared heating electromagnetic stirrer (Germany SCHOTT), the temperature is raised at a speed of 5°C / min. to 90°C, and continue stirring at a speed of 100 revolutions per minute while raising the temperature until dry. The product obtained by stirring and drying was heated up to 400° C. at a rate of 5° C. / min under an argon atmosphere in a low-temperature tube furnace, and kept at a constant temperature for 4 hours. Then continue to heat up to 800°C at a rate of 5°C / min, and keep t...

Embodiment 3-7

[0029] According to the method of embodiment 1 positive electrode active material lithium ferrous phosphate, difference is, lithium compound and weight thereof, phosphorus compound and weight thereof, carbon source additive and weight thereof, lithium compound and weight thereof, weight of water, iron compound and its weight and particle size, the molar ratio of Li:Fe:P, the dispersant and its weight and molecular weight, the air inlet temperature and atomization pressure of spray drying, the heating rate, temperature and constant temperature time of the first sintering, the second The heating rate, temperature and constant temperature time of the second-stage sintering are shown in Table 1 for specific differences.

[0030] Table 1

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com