Composite coated modified high vibrancy solid lithium ionic battery positive electrode, preparation and application thereof

A lithium-ion battery, tap density technology, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of complex process, reduction of material volume specific energy and volume specific power, limited improvement of electrochemical performance, etc. , to achieve high volume specific energy and volume specific power, simplify the composite coating modification process, and facilitate industrialized large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The first step is to prepare 0.05mol LiFePO 4 , first weigh 0.025mol of Li 2 CO 3 and 0.05mol of (NH 4 ) 2 HPO 4 After that, add 20% 0.05mol LiFePO 4 Heavy organic iron source - ferric citrate (1.9097g). At this time, the content of iron has not reached the amount required by stoichiometry, and the insufficient amount of iron is obtained from the source of inorganic iron——Fe 2 o 3 Come to make up (3.5371g), take 28.5g ethanol as dispersant, mix through high-speed ball milling;

[0038] In the second step, put the mixed raw materials in a 30ml alumina crucible, put them into a well-type furnace, pass in nitrogen gas for protection, heat at 300°C for 10 hours, cool and grind to obtain PO 4 3- , Li + , Fe 2+ / Fe 3+ and the reactive precursor of conductive carbon;

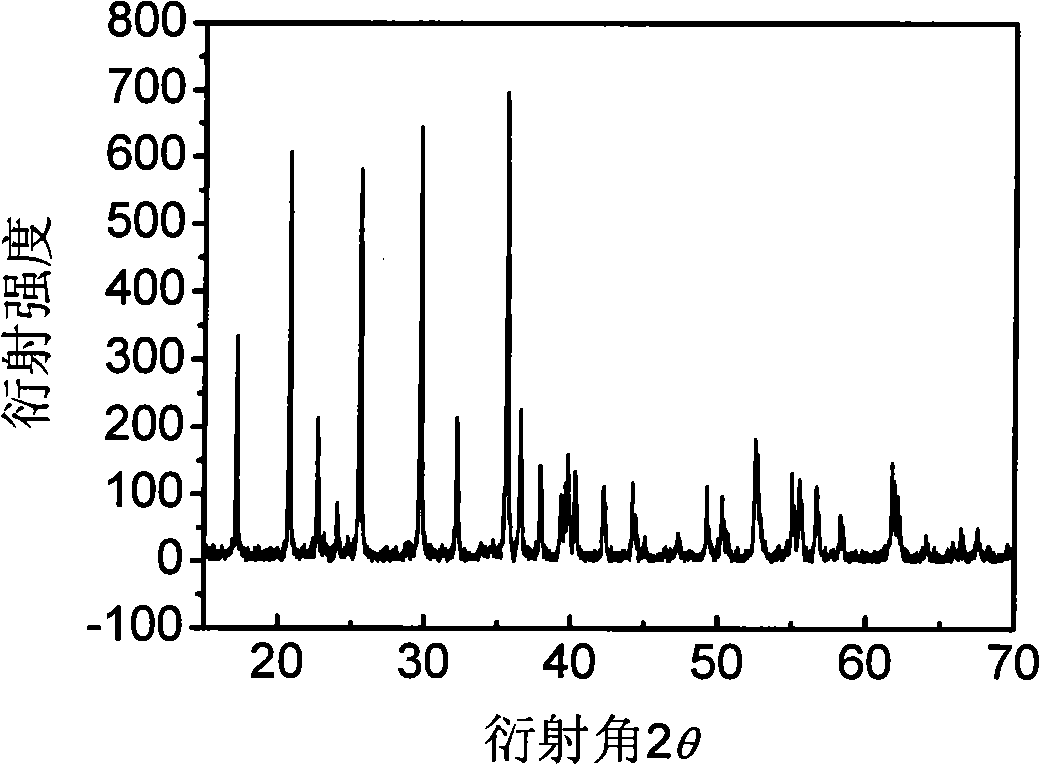

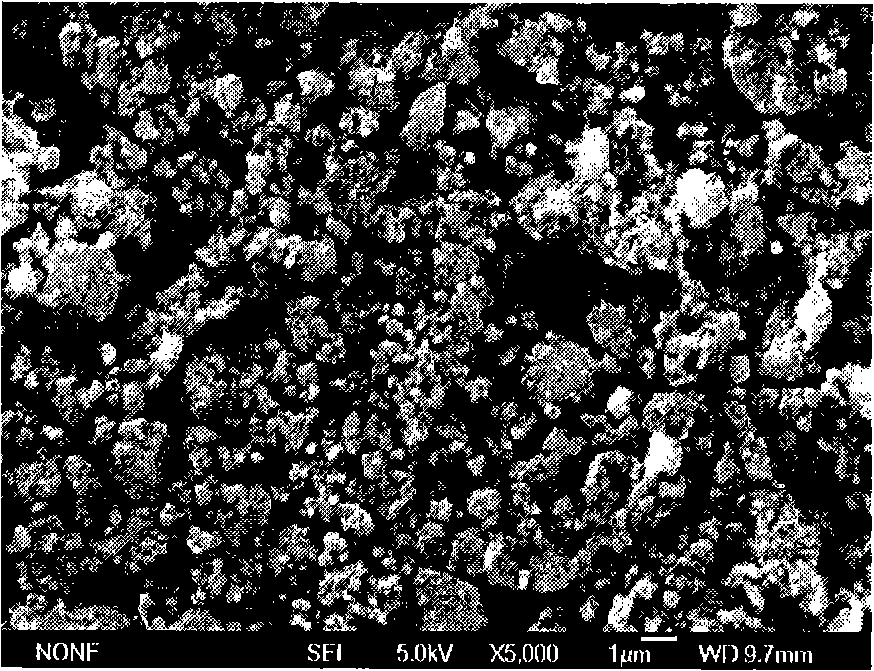

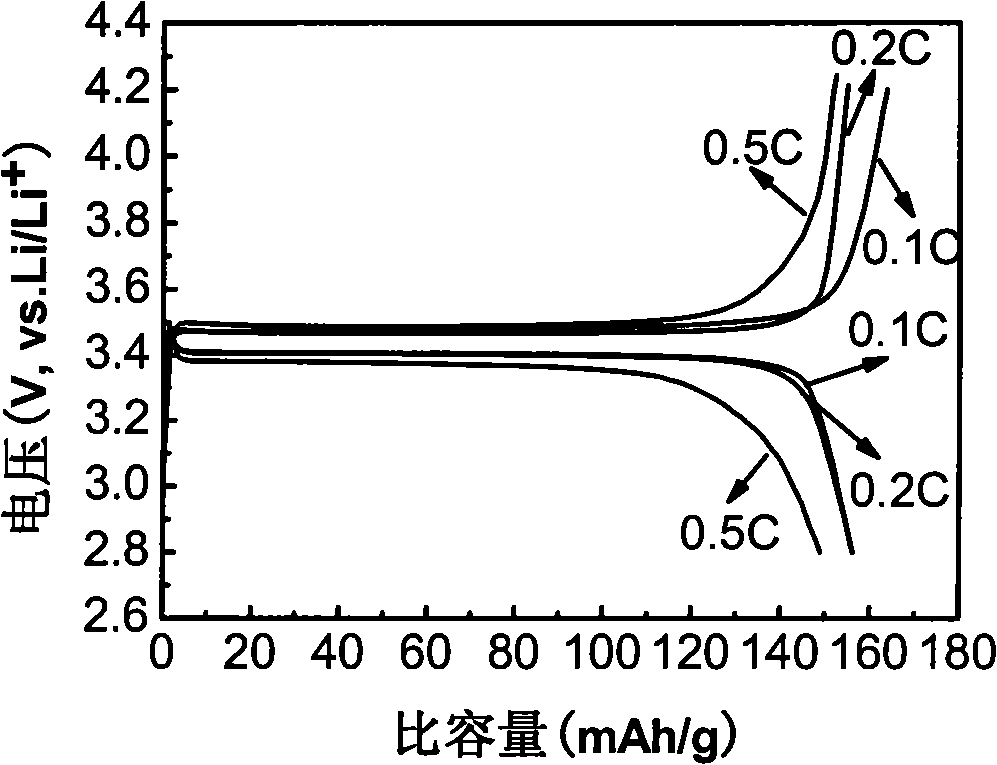

[0039] The third step is to put the reaction precursor into a 30ml alumina crucible, place it in a well-type furnace, pass through nitrogen as a protection, calcinate at 700°C for 24h, and obtain Li...

Embodiment 2

[0044] The first step is to prepare 0.05mol LiFePO 4 , first weigh 0.05mol of lithium acetate and 0.05mol of NH 4 h 2 PO 4 After that, add 10% 0.05mol LiFePO 4 Heavy source of organic iron - ferric citrate (0.9481 g). At this time, the amount of iron has not reached the stoichiometric amount, and the insufficient amount of iron is replaced by inorganic iron source——Fe 3 o 4 (3.6404g) to make up, take 40g ethanol as dispersant, mix through high-speed ball milling;

[0045] In the second step, put the mixed raw materials in a 30ml alumina crucible and put them into a well-type furnace, pass in nitrogen gas for protection, heat at 250°C for 5 hours, cool and grind to obtain PO 4 3- , Li + , Fe 2+ / Fe 3+ and the reactive precursor of conductive carbon;

[0046] The third step is to put the reaction precursor into a 30ml alumina crucible, place it in a well-type furnace, pass through nitrogen as a protection, calcinate at 800°C for 5h, and obtain LiFePO after cooling wi...

Embodiment 3

[0049] The first step is to prepare 0.05mol LiFePO 4 , first weigh 0.05mol of LiNO 3 After that, add 45% 0.05molLiFePO 4 Heavy organic iron source - ferric citrate (4.2685g), at this time the amount of iron has not reached the stoichiometric, insufficient iron source - FePO 4 (5.6195g) to make up. However, at this time the PO in the precursor 4 3- The amount has not reached the stoichiometric amount, and the insufficient amount of phosphate radical is (NH 4 ) 3 PO 4 (1.9000g) is insufficient, with 14g ethanol as dispersant, mix through high-speed ball mill;

[0050] In the second step, put the mixed raw materials in a 30ml alumina crucible, put them into a well-type furnace, pass in nitrogen gas for protection, heat at 450°C for 20 hours, cool and grind to obtain PO 4 3- , Li + , Fe 2+ / Fe 3+ and the reactive precursor of conductive carbon;

[0051] The third step is to put the reaction precursor into the reactor, place it in a well-type furnace, pass through nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com