Lithium iron carbonate material prepared by vacuum carbon reduction and method

A lithium iron phosphate, vacuum technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry and other directions, can solve the problems of low bulk density, poor electrical conductivity, increased production cost, etc., to simplify the synthesis process, shorten the reaction time, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

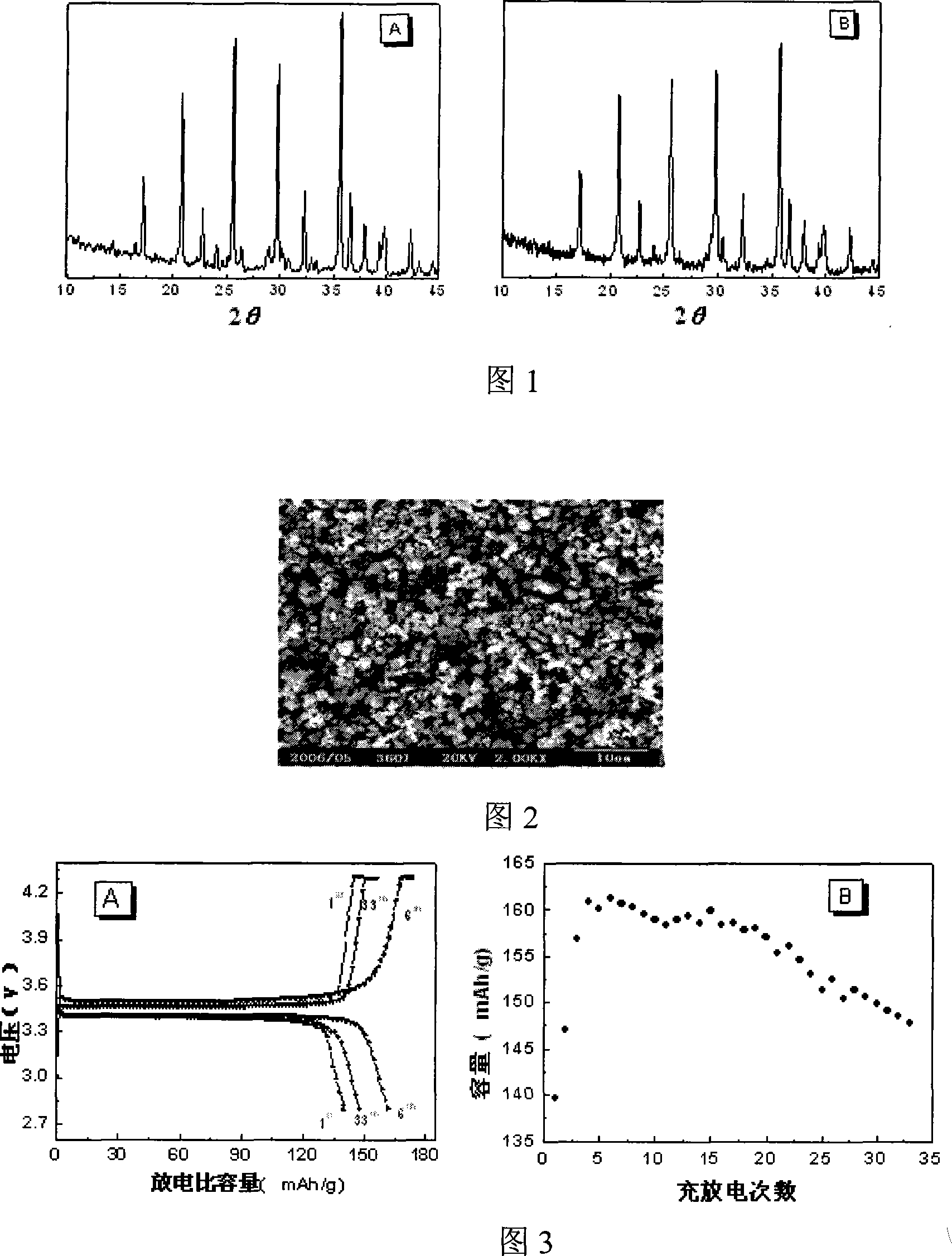

Image

Examples

Embodiment 1

[0029] In the first step, ferric phosphate, lithium hydroxide, and aluminum dihydrogen phosphate are mixed in a ratio of 1:1:1:0.05 in a molar ratio of P:Fe:Li:Al;

[0030] In the second step, the above mixture is placed in a vacuum high-energy ball mill jar and vacuumized to 10 -2 Pa, ball milled for 12 hours;

[0031] In the third step, the carbon reducing agent activated carbon is added to the above-mentioned ball-milled mixture in the ratio of Fe: C molar ratio of 1: 0.8, and vacuumized to 10 -2 Pa, continue ball milling for 6 hours to obtain a reaction precursor;

[0032] The fourth step is to transfer the above-mentioned reactant precursor to the vacuum reaction furnace, pass high-purity nitrogen gas for 5 minutes, and then vacuumize to 10 -2 Pa, heating, controlling the temperature to 450°C, keeping the furnace temperature constant for 24 hours, passing high-purity nitrogen gas for 45 minutes, sealing and cooling to room temperature, and obtaining carbon-coated alumin...

Embodiment 2

[0035] In the first step, ferrous phosphate and lithium phosphate, doped metal compound aluminum dihydrogen phosphate, zinc oxide, magnesium oxide, and cobalt oxide are mixed according to P: Fe: Li: M (M represents doped metal, Al: Zn: Mg: Co Molar ratio is 1: 1: 1: 0.5) and the molar ratio is 1: 1: 1: 0.03 ratio mixing;

[0036] In the second step, the above mixture is placed in a vacuum high-energy ball mill jar and vacuumized to 10 -3 Pa, ball milled for 10 hours;

[0037] In the third step, the carbon reducing agent acetylene black and graphite (ratio of 1:1) are added to the above-mentioned treated mixture in the ratio of Fe:C molar ratio of 1:1, and vacuumized to 10 -3 Pa, continue ball milling for 8 hours to obtain a reaction precursor;

[0038] The fourth step is to transfer the above-mentioned reactant precursor to the vacuum reaction furnace, pass high-purity nitrogen gas for 30 minutes, and then vacuumize to 10 -3 Pa, heat, control the temperature at 650°C, keep ...

Embodiment 3

[0041] The first step mixes ferrous phosphate with lithium phosphate and zinc oxide in a ratio of 1:1:1:0.02 in the molar ratio of P:Fe:Li:Zn;

[0042] In the second step, the above mixture is placed in a vacuum high-energy ball mill jar and vacuumized to 10 -2 Pa, ball milled for 11 hours;

[0043] In the third step, the carbon reducing agent graphite is added to the above-mentioned ball-milled mixture in the ratio of Fe: C molar ratio of 1: 1.4, and vacuumized to 10 -2 Pa, continue ball milling for 9 hours to obtain a reaction precursor;

[0044] The fourth step is to transfer the above-mentioned reactant precursor to the vacuum reaction furnace, pass high-purity nitrogen gas for 5 minutes, and then vacuumize to 10 -2 Pa, heat, control the temperature at 550°C, keep the furnace temperature constant for 20 hours, pass high-purity nitrogen gas for 45 minutes, seal and cool to room temperature, and obtain metal aluminum-doped lithium iron phosphate powder coated with carbon. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com