Method for preparing carbon coated lithium ferrous phosphate composite material including metal conductive agent

A carbon-coated lithium ferrous phosphate, metal conductive technology, applied in electrode manufacturing, circuits, electrical components, etc., can solve the problems of complex preparation process, increased cost, and difficult to control product purity, and achieves narrow particle distribution and phase. The effect of uniform composition and improved electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

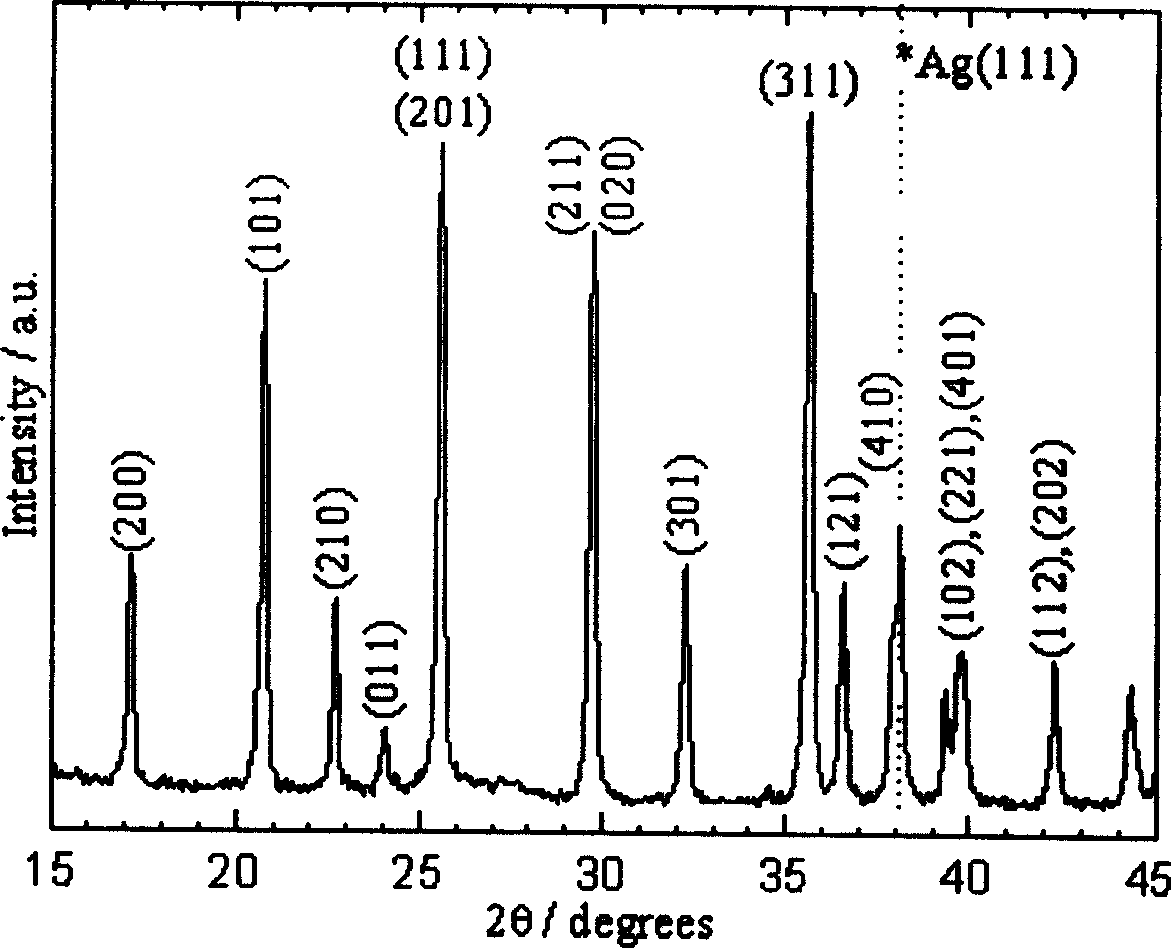

[0026] 0.05 mol Fe(NO 3 ) 3 9H 2 O, 0.001 mole AgNO 3 Place it in a beaker, add deionized water to form a 0.5 mol / L solution, and weigh 0.4 mol citric acid to add to the solution. Stir and place it in a constant temperature water bath at 90°C for 60 minutes to obtain a yellow clear solution, and then add 0.05 moles of NH to the clear solution 4 h 2 PO 4 , stirred and dissolved, and then added 0.05 moles of LiOH·H 2 O, a yellow solution was obtained after stirring and dissolving. A yellow sol was obtained after constant temperature at 90°C for 2 hours. Then transfer to an oven at 120° C. for 5 hours to obtain light yellow gel. Grind and evenly mix with 2.5 grams of polypropylene powder and put them together in a tube furnace, rise to 700°C at a rate of 5°C / min in a nitrogen flow of 5 liters / min, and keep at this temperature for 10 hours. After natural cooling in the furnace, the black powder is ground, which is carbon-coated lithium iron phosphate (LiFePO4) containing ...

Embodiment 2

[0028] 0.04 moles of Fe(NO 3 ) 3 9H 2 O, 0.002 mole AgNO 3 Place it in a beaker, add deionized water to form a 0.5 mol / L solution, and weigh 0.6 mol citric acid to add to the solution. Stir and place it in a constant temperature water bath at 90°C for 80 minutes to obtain a yellow clear solution, and then add 0.04 moles of NH 4 h 2 PO 4 and 0.04 mol LiOH·H 2 O, a yellow solution was obtained after stirring and dissolving. A yellow sol was obtained after constant temperature at 90°C for 3 hours. Then transfer to an oven at 110° C. for 8 hours to obtain light yellow gel. Grind and evenly mix with 3 grams of polypropylene powder and put them together in a tube furnace, raise it to 600°C at a rate of 5°C / min in a nitrogen flow of 5 liters / min, and keep it at this temperature for 15 hours. After natural cooling in the furnace, the black powder is ground, which is carbon-coated lithium iron phosphate (LiFePO4) containing metal Ag conductive agent. 4 / Ag / C) composite cathod...

Embodiment 3

[0030] 0.05 mol Fe(NO 3 ) 3 9H 2 O, 0.001 mole Cu(NO 3 ) 2 ·3H 2 O was placed in a beaker, and deionized water was added to form a 0.5 mol / L solution, and 0.5 mol citric acid was weighed and added to the solution. Stir and place it in a constant temperature water bath at 100°C for 60 minutes to obtain a light yellow clear solution, and then add 0.05 mol NH to the clear solution 4 h 2 PO 4 , stirred and dissolved, and then added 0.05 moles of LiOH·H 2 O, a yellow solution was obtained after stirring and dissolving. A yellow sol was obtained after constant temperature at 90°C for 2 hours. Then transfer to an oven at 120° C. for 5 hours to obtain light yellow gel. Grind and evenly mix with 3 grams of polypropylene powder and put them together in a tube furnace, raise it to 500°C at a rate of 5°C / min in a nitrogen flow of 5 liters / min, and keep it at this temperature for 10 hours. After natural cooling in the furnace, the black powder is ground, which is carbon-coated l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com