Carbon-nanotube-loaded multi-stage nanometer ferroferric oxide adsorbent and preparation method and application thereof

A technology of ferroferric oxide and carbon nanotubes, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problems of cumbersome preparation of composite nanomaterials, and achieve important applications Value, good magnetism, effect of reducing usage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

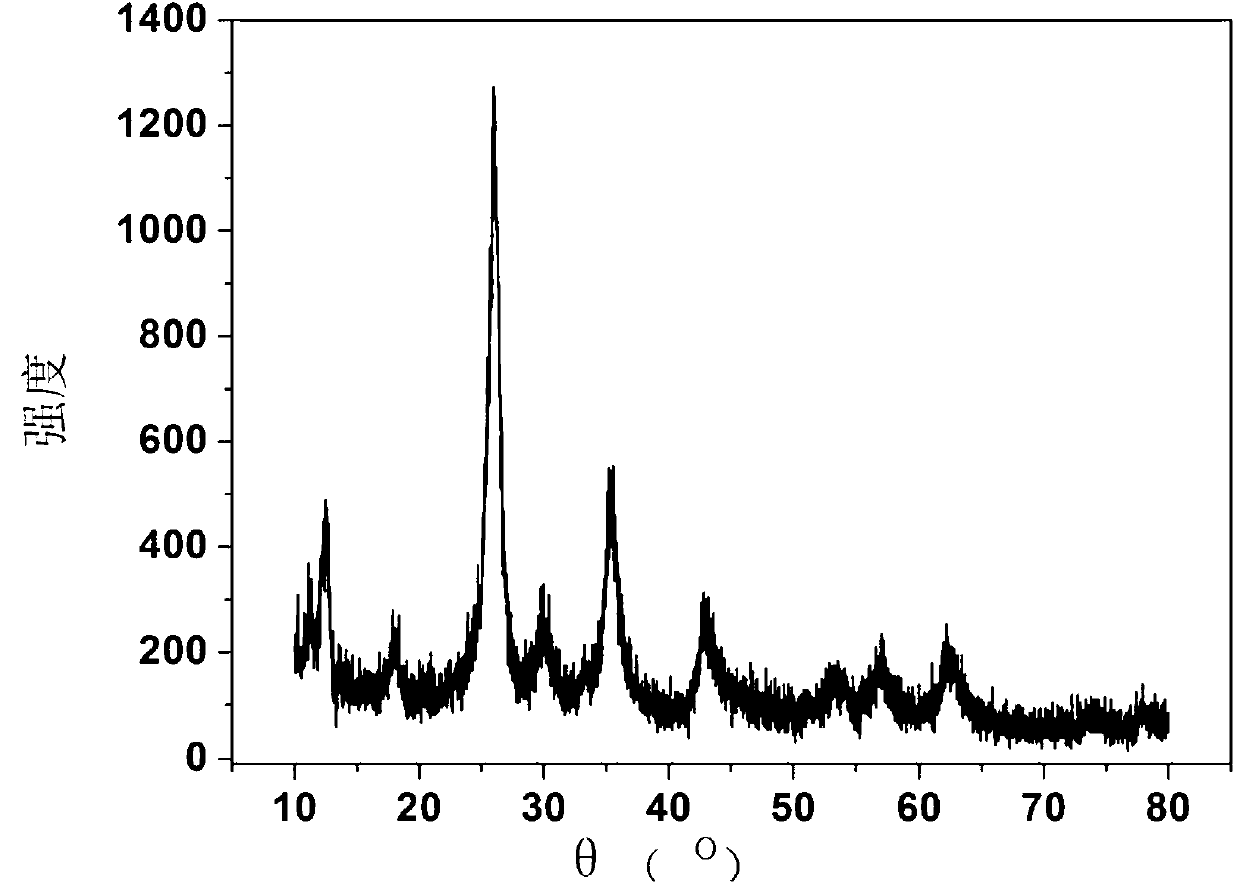

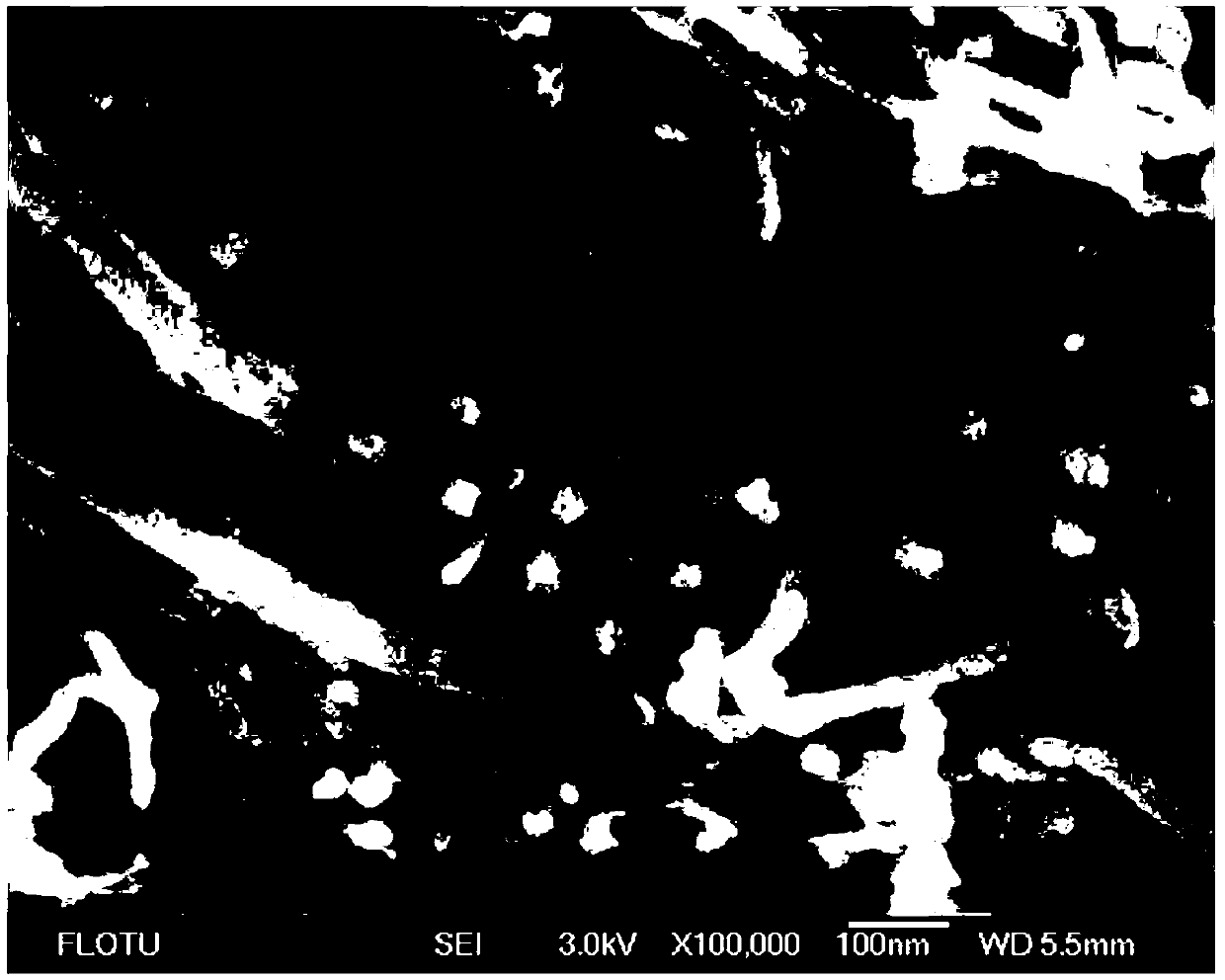

[0027] A carbon nanotube-loaded multi-level nanometer ferric oxide adsorbent includes carbon nanotubes and ferric oxide, and the carbon nanotubes are loaded with ferric oxide, and the ferric oxide is a multi-level nanostructure with a particle size of 50nm to 80nm; the mass fraction of multi-level nanometer ferric oxide in the adsorbent is 28%.

[0028] A preparation method of the above-mentioned carbon nanotube-loaded multi-stage nano-ferric oxide adsorbent, comprising the following steps:

[0029] 1. Preparation of oxidized carbon nanotubes: Add 2g of carbon nanotubes into a 250mL three-neck flask, the diameter of the carbon nanotubes is 30nm to 50nm, and then add 200mL of concentrated nitric acid with a concentration of 15mol / L to the three-neck flask During ultrasonic dispersion for 60 minutes, the resulting mixture was refluxed at 140°C for 14 hours. After the reflux was completed, the product was cooled to room temperature, the supernatant was decanted, and the resultant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com