Lithium metal battery negative electrode and preparation method and application thereof

A lithium metal battery and negative electrode technology, which is applied in the field of lithium metal battery negative electrode and its preparation, can solve problems such as difficult to improve and low ion conductivity, and achieve the effects of improved cycle life, low charge density, and uniform charge distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

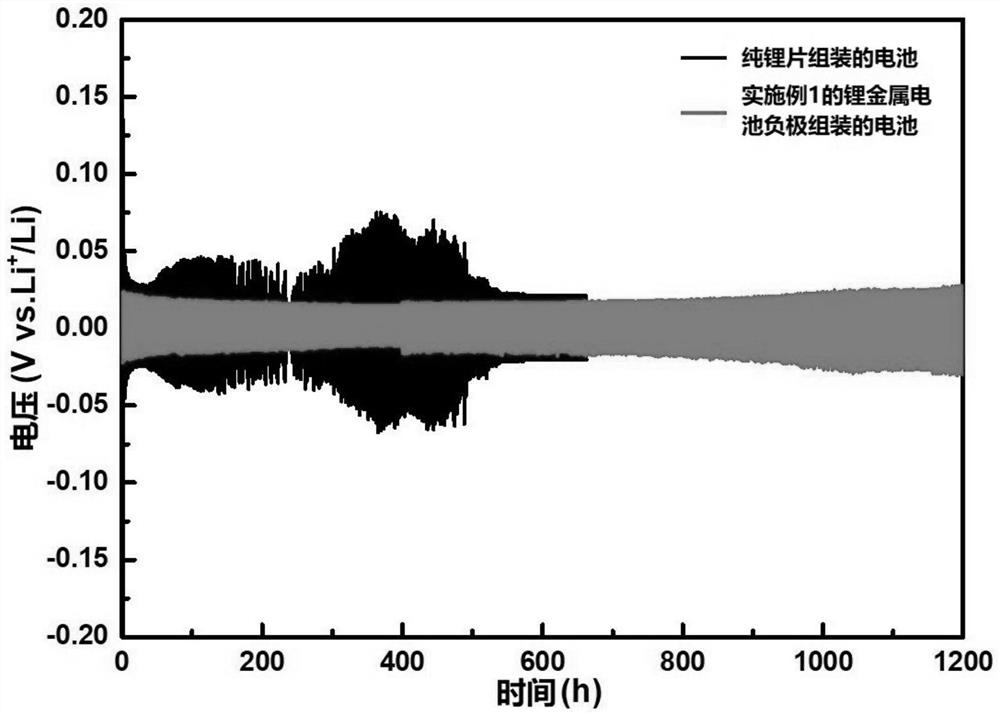

[0036] A lithium metal battery negative pole, its preparation method comprises the following steps:

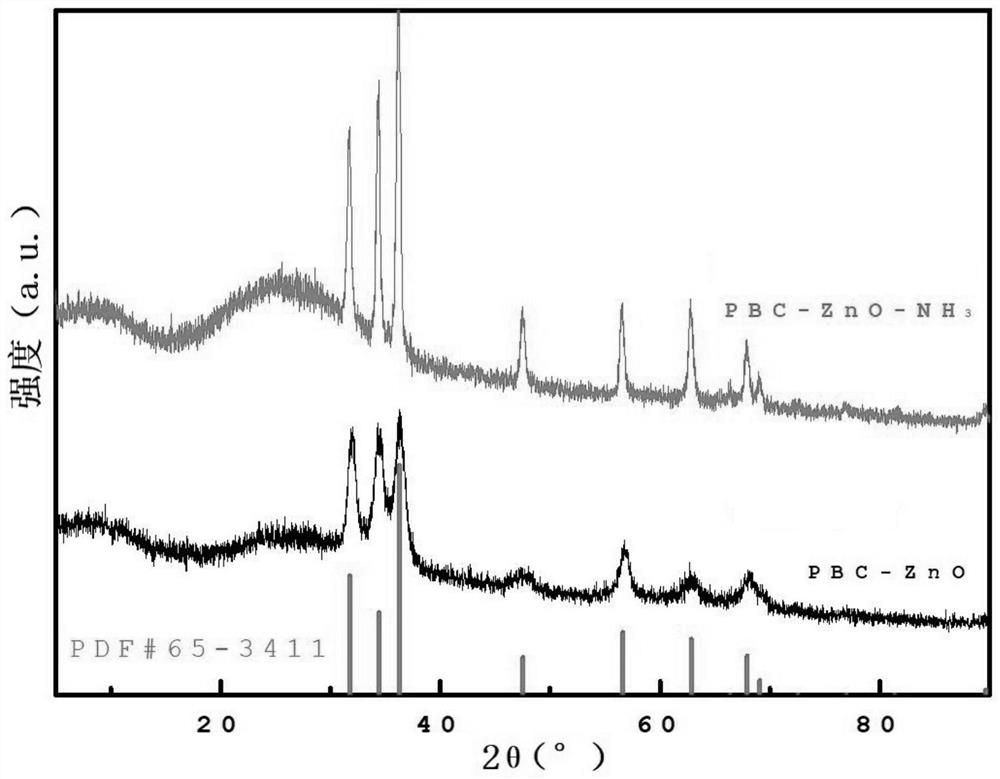

[0037] 1) Add 0.4g of bacterial cellulose (PBC) to 300mL of zinc acetate solution with a concentration of 0.1mol / L, sonicate for 30min, dry to remove the solvent, and then place it in a nitrogen atmosphere for calcination at 500°C for 3h to obtain nanoparticles loaded with zinc oxide The porous carbon matrix (denoted as PBC-ZnO);

[0038] 2) The porous carbon matrix loaded with zinc oxide nanoparticles was calcined in an ammonia atmosphere at 400 °C for 3 h to obtain a three-dimensional current collector (denoted as PBC-ZnO-NH 3 );

[0039] 3) Composite 0.001g of the three-dimensional current collector and 0.03g of metal lithium through a melting method to obtain the negative electrode of the lithium metal battery.

[0040] Performance Testing:

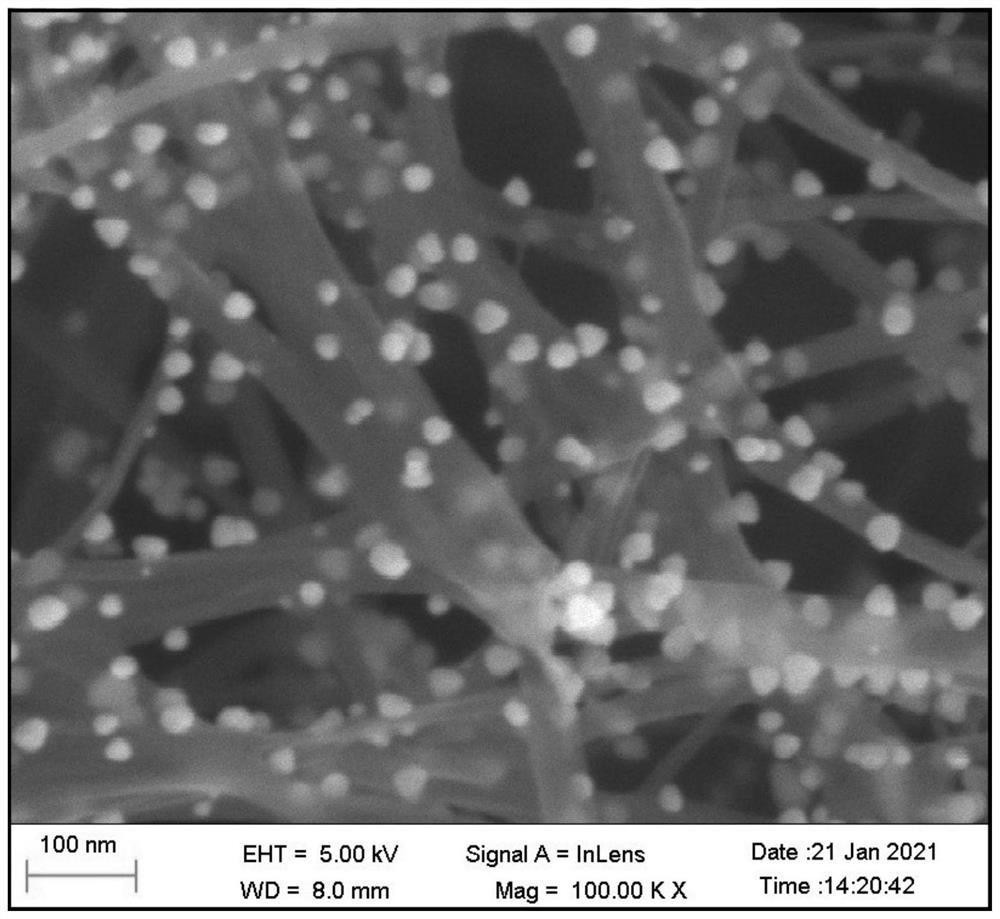

[0041] 1) PBC-ZnO-NH in the present embodiment 3 The scanning electron microscope (SEM) image of figure 1 shown.

[0042] Depe...

Embodiment 2

[0048] A lithium metal battery negative pole, its preparation method comprises the following steps:

[0049] 1) Add 0.4 g of bacterial cellulose to 300 mL of zinc nitrate solution with a concentration of 0.1 mol / L, sonicate for 30 min, dry to remove the solvent, and place in a nitrogen atmosphere for calcination at 500°C for 3 h to obtain porous carbon loaded with zinc oxide nanoparticles matrix;

[0050] 2) Calcining the porous carbon matrix loaded with zinc oxide nanoparticles in an ammonia atmosphere at 500°C for 3 hours to obtain a three-dimensional current collector;

[0051] 3) Composite 0.001g of the three-dimensional current collector and 0.03g of metal lithium through a melting method to obtain the negative electrode of the lithium metal battery.

[0052] Performance Testing:

[0053] 1) Through SEM testing, it is found that the morphology of the three-dimensional current collector in this example is highly similar to the three-dimensional current collector in Example...

Embodiment 3

[0056] A lithium metal battery negative pole, its preparation method comprises the following steps:

[0057] 1) Add 0.4 g of bacterial cellulose to 300 mL of zinc nitrate solution with a concentration of 0.2 mol / L, sonicate for 60 min, dry to remove the solvent, and place in a nitrogen atmosphere for calcination at 500°C for 2 h to obtain porous carbon loaded with zinc oxide nanoparticles matrix;

[0058] 2) Calcining the porous carbon matrix loaded with zinc oxide nanoparticles in an ammonia atmosphere at 400°C for 3 hours to obtain a three-dimensional current collector;

[0059] 3) Composite 0.001g of the three-dimensional current collector and 0.03g of metal lithium through a melting method to obtain the negative electrode of the lithium metal battery.

[0060] Performance Testing:

[0061] 1) Through SEM testing, it is found that the morphology of the three-dimensional current collector in this example is highly similar to the three-dimensional current collector in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com