Polybenzazole fiber and article comprising the same

A technology of polybenzazole fiber and fiber, applied in the same field as No. 2003-424654 and No. 200, which can solve problems such as not being resistant to bending fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

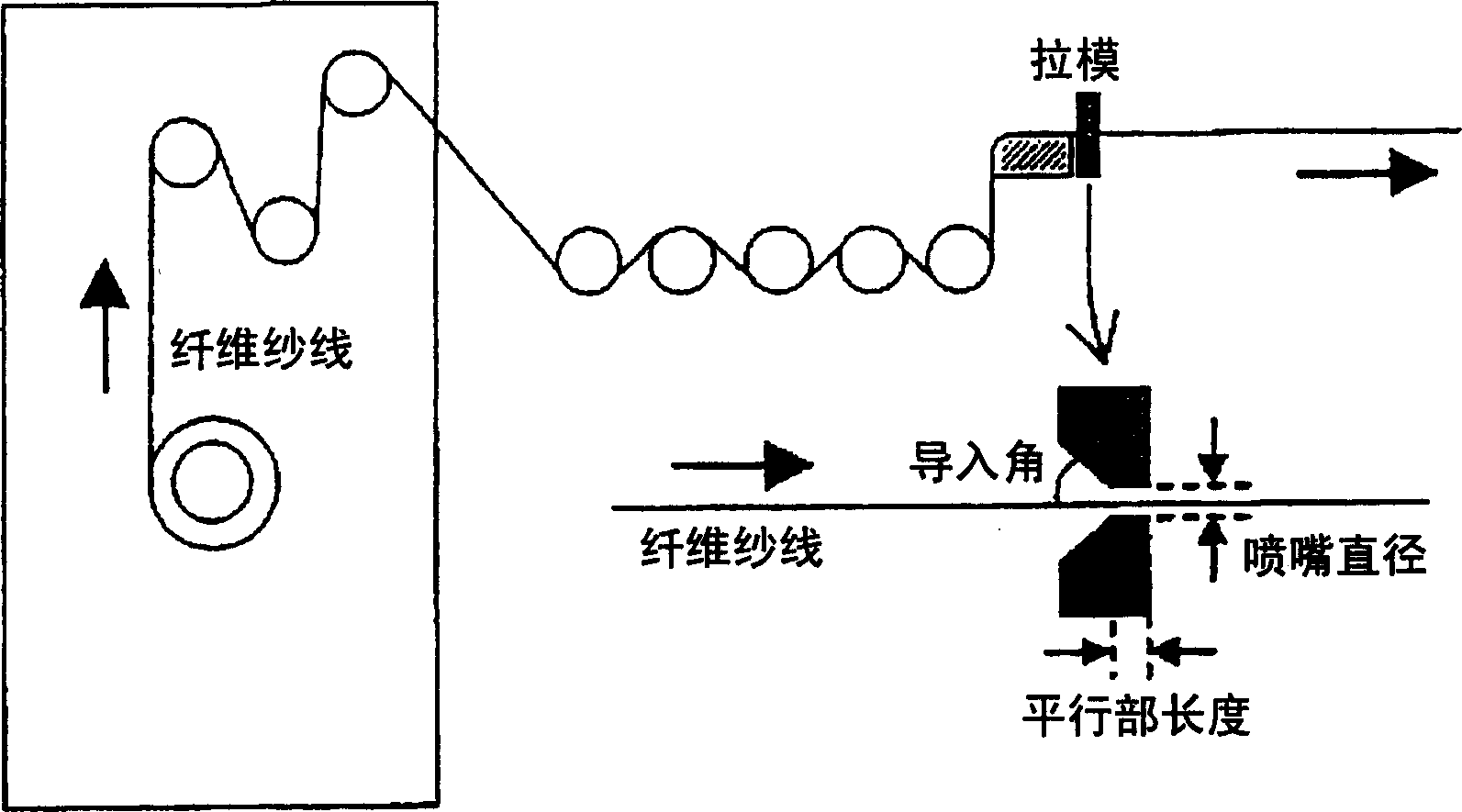

[0125] Under nitrogen flow, at 60°C, 334.5g of 4,6-diaminoresorcinol dihydrochloride, 260.8g of terephthalic acid, and 2078.2g of 122% polyphosphoric acid were stirred for 1 hour, then slowly heated up to separate The reaction was carried out at 135°C, 150°C, and 170°C for 25 hours, 5 hours, and 20 hours. Add 14.8 g ± 14.8 g of poly (p-phenylene benzobisoxazole) (poly (p-phenylenebenzobisoxazole)) spinning stock solution with an intrinsic viscosity of 29 dL / g measured by the methanesulfonic acid solution obtained at 2.0 kg. forest (threne) and stirred to mix.

[0126] Thereafter, spinning was carried out under the conditions that the filament diameter of the single yarn became 11.5 μm and 1.5 denier. At a spinning temperature of 175°C, the spinning dope is extruded from a nozzle with a hole diameter of 0.18 mm and a number of holes of 166 to form filaments, which are converged at an appropriate position and immersed in the first cleaning tank arranged to make multifilaments ...

Embodiment 2

[0140] Under nitrogen flow, at 60°C, 334.5g of 4,6-diaminoresorcinol dihydrochloride, 260.8g of terephthalic acid, and 2078.2g of 122% polyphosphoric acid were stirred for 1 hour, then slowly heated up to separate The reaction was carried out at 135°C, 150°C, and 170°C for 25 hours, 5 hours, and 20 hours. 14.8 g of copper phthalocyanine was added to 2.0 kg of the obtained poly(p-phenylene benzobisoxazole) spinning stock solution having an intrinsic viscosity of 30 dL / g measured from a 30° C. methanesulfonic acid solution, and stirred and mixed.

[0141] Thereafter, spinning was carried out under the conditions that the filament diameter of the single yarn became 11.5 μm and 1.5 denier. At a spinning temperature of 175°C, the spinning dope is extruded from a nozzle with a hole diameter of 0.18 mm and a number of holes of 166 to form filaments, which are converged at an appropriate position and immersed in the first cleaning tank arranged to make multifilaments and solidified. ...

Embodiment 3

[0155] Under nitrogen flow, at 60°C, 334.5g of 4,6-diaminoresorcinol dihydrochloride, 260.8g of terephthalic acid, and 2078.2g of 122% polyphosphoric acid were stirred for 1 hour, then slowly heated up to separate The reaction was carried out at 135°C, 150°C, and 170°C for 25 hours, 5 hours, and 20 hours. 14.8 g of copper phthalocyanine was added to 2.0 kg of the obtained poly(p-phenylene benzobisoxazole) spinning stock solution having an intrinsic viscosity of 30 dL / g measured from a 30° C. methanesulfonic acid solution, and stirred and mixed.

[0156]Thereafter, spinning was carried out under the conditions that the filament diameter of the single yarn became 11.5 μm and 1.5 denier. At a spinning temperature of 175°C, the spinning dope is extruded from a nozzle with a hole diameter of 0.18 mm and a number of holes of 166 to form filaments, which are converged at an appropriate position and immersed in the first cleaning tank arranged to make multifilaments and solidified. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com