Liquid sealing type anti-vibration apparatus

一种液体封装、防振装置的技术,应用在动力装置、喷气推进装置、内燃推进装置等方向,能够解决异常声音等问题,达到提高衰减特性、高效吸收、刚性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

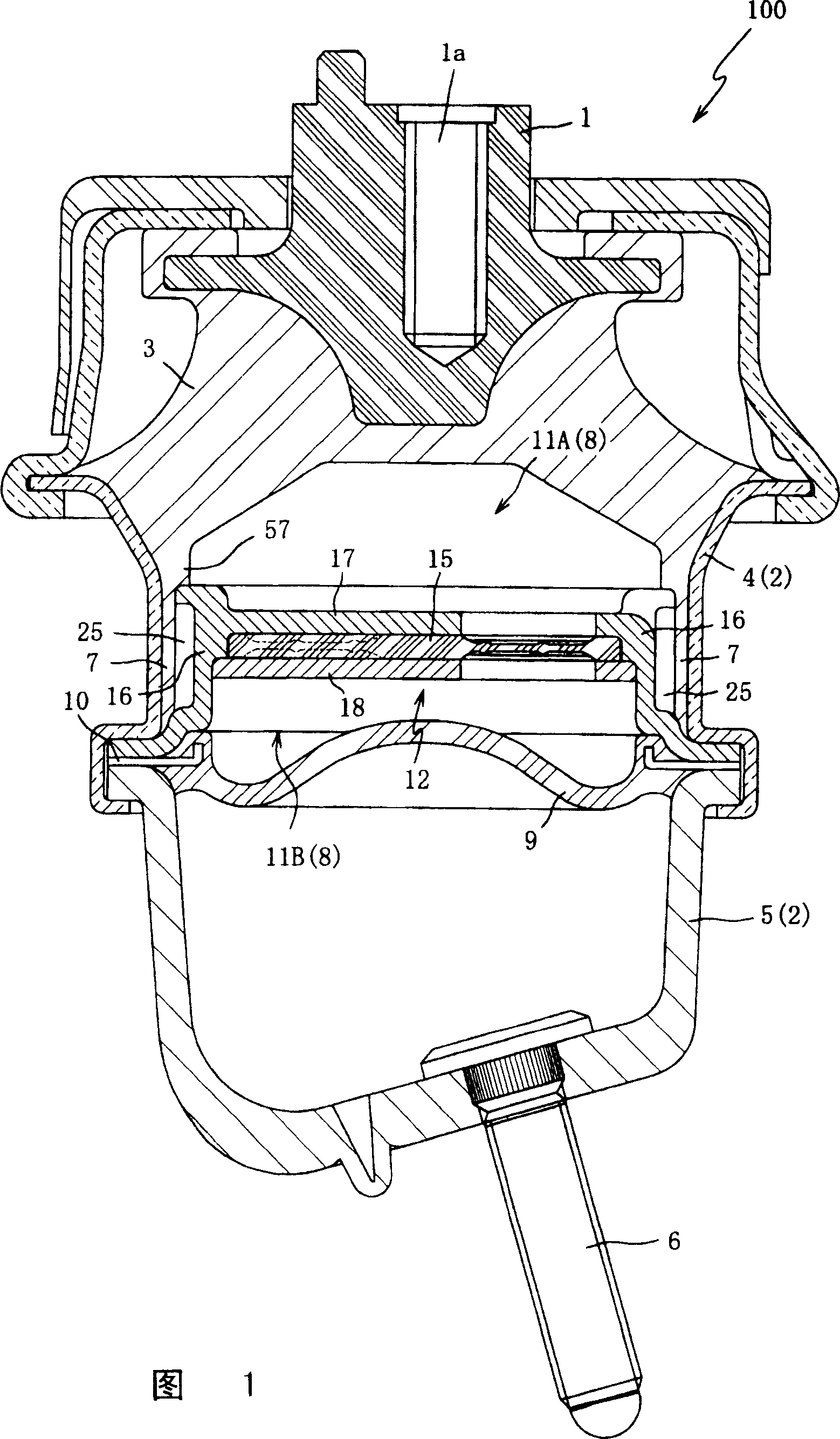

[0074] Below, preferred embodiments of the present invention will be described with reference to the accompanying drawings. FIG. 1 is a cross-sectional view of a liquid-encapsulated anti-vibration device 100 according to an embodiment of the present invention.

[0075] This liquid-encapsulated anti-vibration device 100 is an anti-vibration device that supports and fixes the engine of the automobile and prevents the vibration of the engine from being transmitted to the vehicle frame. As shown in Figure 1, it has: A metal mounting part 1; a cylindrical second metal mounting part 2 mounted on the frame side under the engine; and a main vibration-isolating body 3 made of a rubber-like elastic body connecting them.

[0076] The first metal mounting member 1 is formed in a substantially cylindrical shape from a metal material such as aluminum, and, as shown in FIG. 1 , is provided with a recessed female screw portion 1a on its upper end surface. In addition, on the outer peripheral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com