Combined pump barrel small-diameter oil well pump

An oil well pump, small-diameter technology, applied in variable displacement pump parts, pumps, pump components, etc., can solve the problems of plunger pump barrel gap leakage, plunger strength, oil outlet valve cover fatigue breakage, valve ball hysteresis closing, etc. problems, to achieve the effect of prolonging the pump inspection cycle, reducing maintenance costs, and increasing the flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

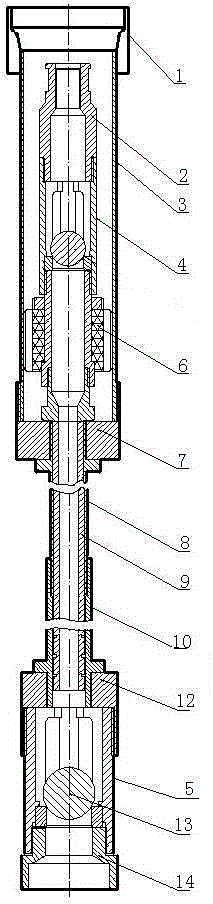

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

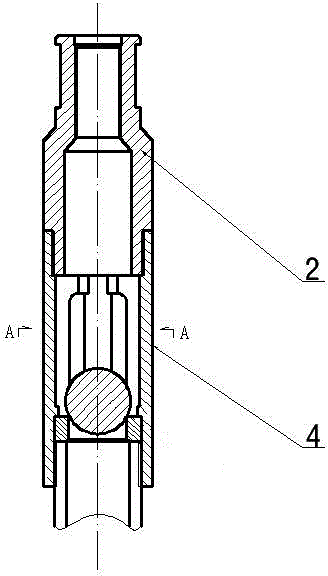

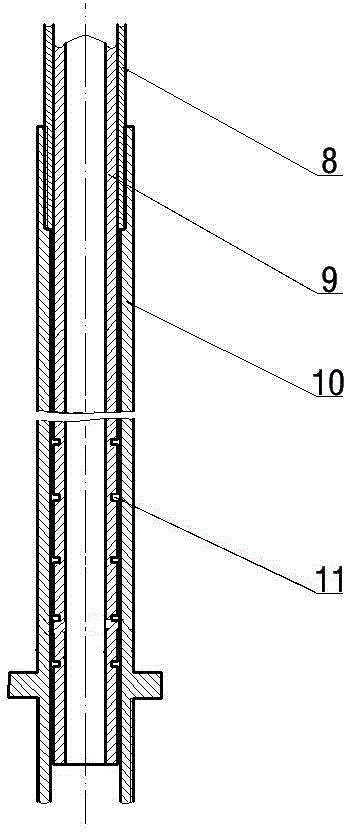

[0018] Such as figure 1 As shown, this combined pump barrel small diameter oil well pump includes a pump barrel assembly, a plunger assembly, and an oil inlet valve assembly 13, and the plunger assembly includes an upper cover 2, a closed oil outlet valve cover 4, a swimming Composed of valve ball, floating valve seat, plunger centralizer 6, long hollow plunger 9, upper cover 2, closed oil outlet valve cover 4, floating valve ball, floating valve seat, plunger centralizer 6 settings In the oil pipe short connection 3, the upper cover 2 has external threads, the closed oil outlet valve cover 4 has internal threads, the upper cover 2 is threadedly connected with the closed oil outlet valve cover 4, and the floating valve ball and the floating valve seat are arranged on Inside the closed oil outlet valve cover 4, the closed oil outlet valve cover 4 is a plum blossom-shaped o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com