Mold for inflating, filling and forming of full-dry optical-cable loose tube

A technology for forming molds and loosening optical cables, which is applied in the field of inflatable filling forming molds for loose tubes of fully dry optical cables, can solve problems such as inability to manufacture, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

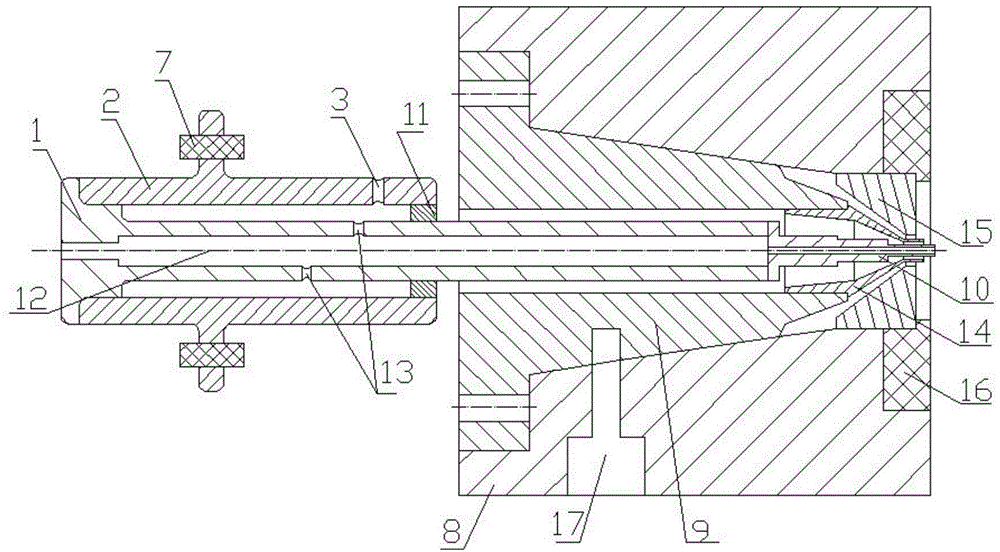

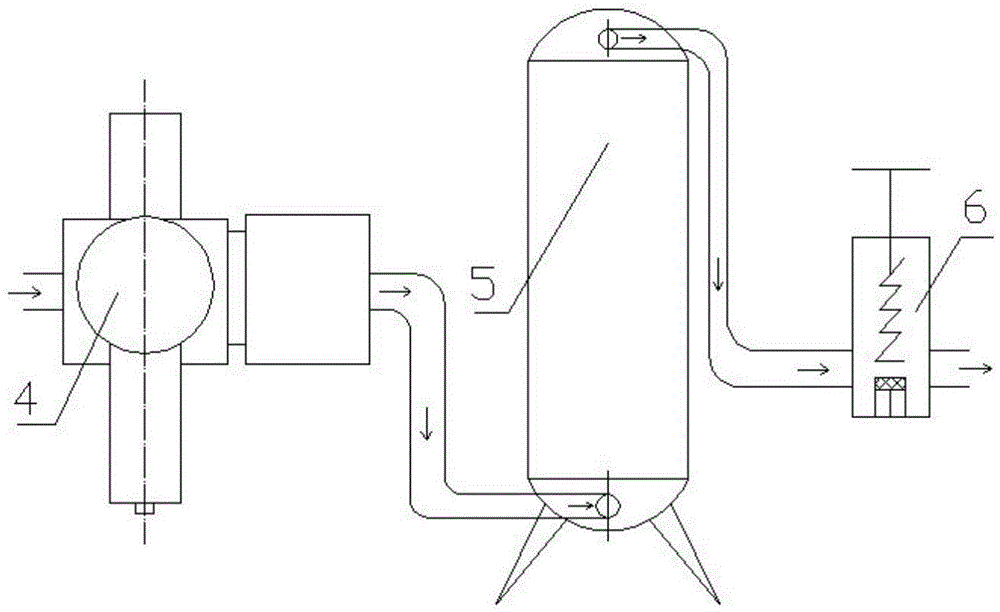

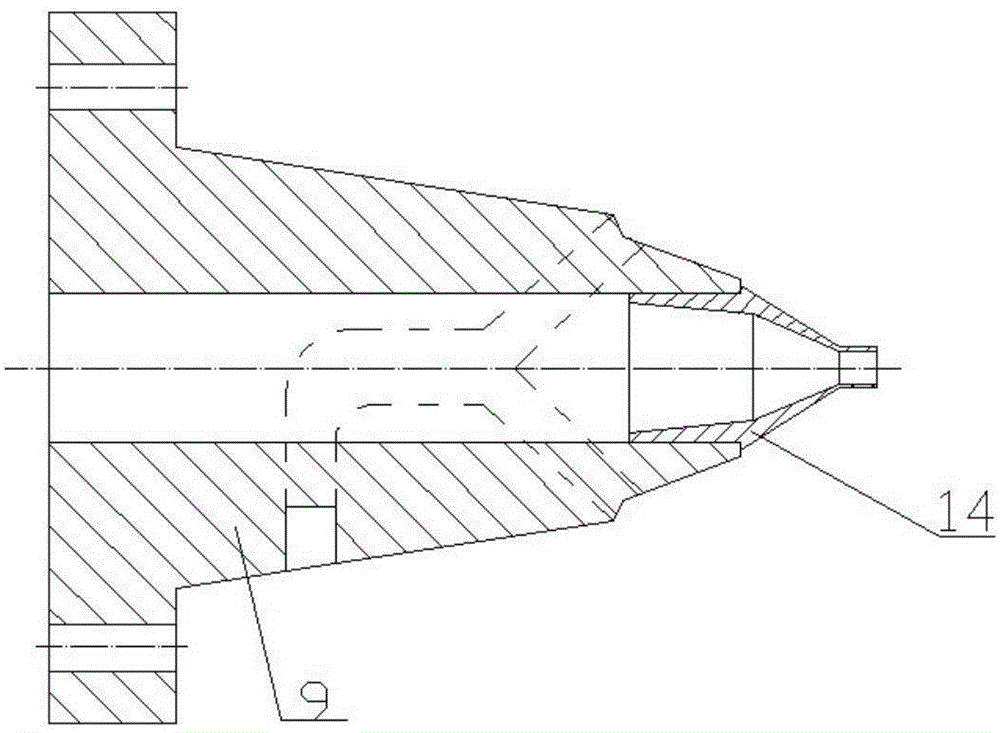

[0017] Such as figure 1 As shown, a fully dry type optical cable loose tube inflation filling molding mold includes an extrusion mold, a fiber guide tube, an inflatable support and an air source mechanism. The extrusion mold includes a machine head 8, a splitter cone 9, a mold core 14, The mold cover 15, the needle tube 10, and the diverter cone 9 are installed in the central cone hole of the machine head 8. The tail of the diverter cone 9 is a flange structure and is fixedly connected with the machine head 8 through bolts. The mold core 14 is clamped with the tip of the diverter cone. The mold cover 15 and the central taper hole of the machine head are installed with interference fit and positioned by the gland 16. The mold cover and the mold core form an annular flow channel, and the material enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com