Suspension arm

A suspension arm and suspension system technology, applied in the field of suspension arms, can solve the problems of inability to obtain dimensional accuracy, increase in operation steps and manufacturing costs, and achieve the effects of weight reduction, elimination of wall thickness parts, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

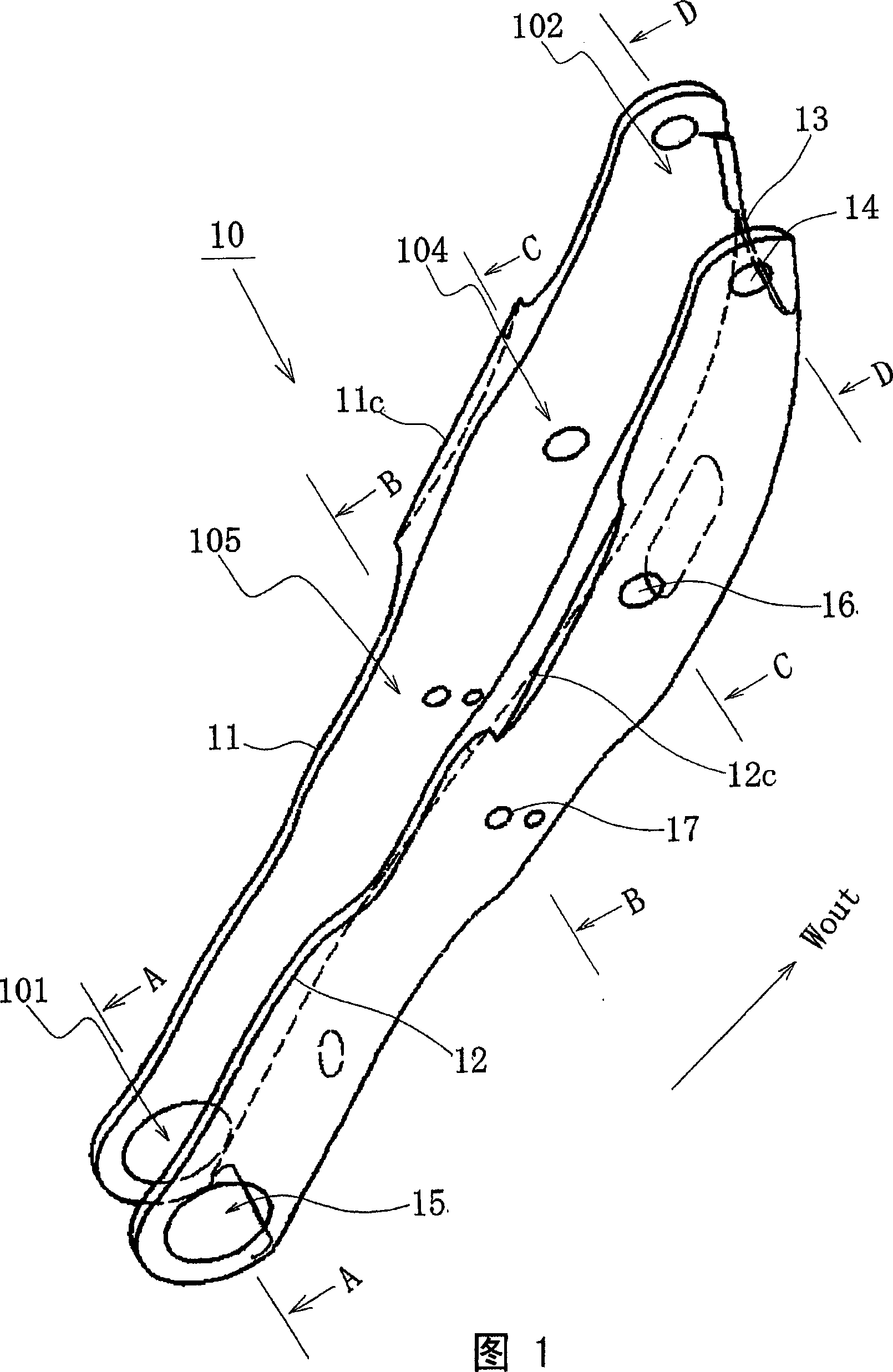

[0073] 1 is a perspective view of a suspension arm 10 of the present invention;

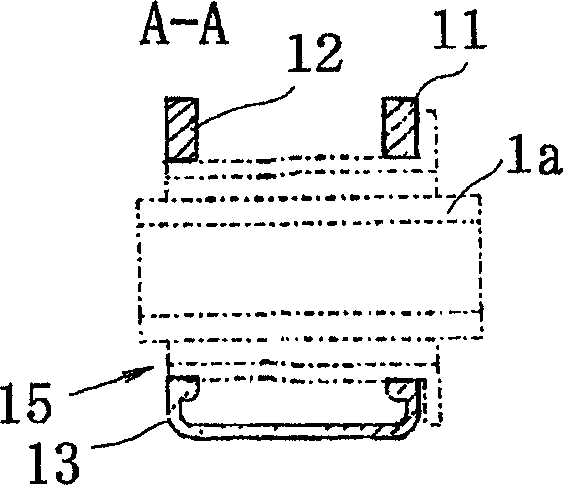

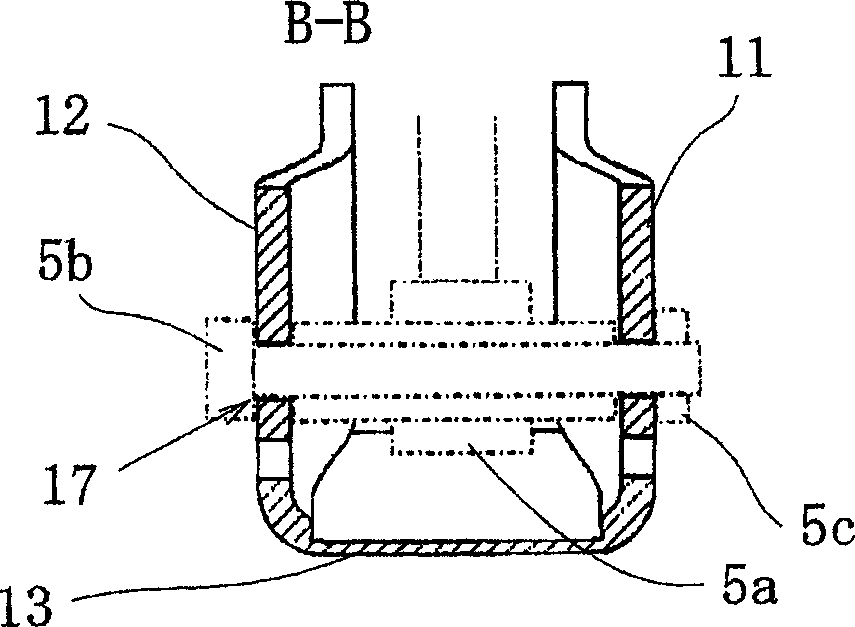

[0074] Fig. 2 is a cross-sectional view of various parts of the suspension arm, which is explained together with the assembly diagram of Fig. 4;

[0075] Fig. 2 (a) is the cross-sectional view (the cross-sectional view of the A-A line in Fig. 1) of the mounting part 101 of the suspension system component 1, and Fig. 2 (b) is the cross-sectional view of the mounting part 105 of the stabilizing link 5 (along the cross-sectional view of the 2 (c) is a sectional view of the mounting portion 104 of the shock absorber 4 (a sectional view along the line C-C in FIG. 1 ), and FIG. 2 (d) is a sectional view of the mounting portion 102 of the axle bracket 2. Section view (section view along the D-D line in Fig. 1), Fig. 2 (a)~(d) shows the peripheral parts (shock absorber 4 etc.) of suspension arm 10 by double-dot chain line, and it shows the state of its assembly, image 3 It is a cross-sectional view of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com