Method for packing alkali metal simple substance

An encapsulation method and alkali metal technology, which are applied in metal material coating process, decorative arts, microstructure devices, etc., can solve problems such as device errors and implementation difficulties, and achieve a low-cost, easy-to-integrate solution that reduces the content of atomic impurities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The concrete realization method of the method for alkali metal simple substance microencapsulation described in this patent is as follows:

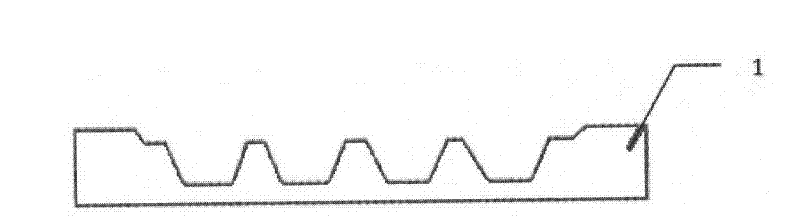

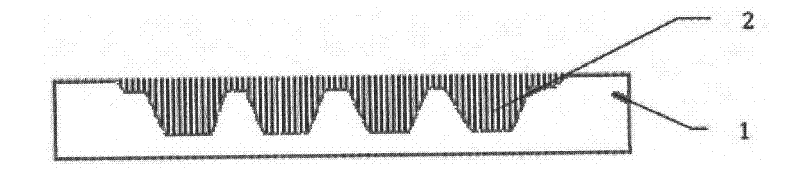

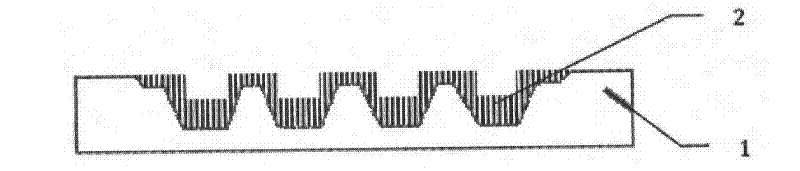

[0074] (1) Select an n-type silicon wafer, clean the silicon wafer, and process a silicon-based wax seal forming mold (including a bottom mold, a top mold, and a positive mold), wherein the bottom mold is a silicon-based double-layer stepped structure , the top mold is a double-layer stepped structure based on a silicon base, or a single-layer stepped structure based on a silicon base, and the male mold is a high-low stepped structure with a microneedle array;

[0075] (2) Paraffin wax is selected as the alkali metal packaging material, and its main physical properties are: white particles; melting point: 58°C-62°C; boiling point: 322°C; density: 0.880g / cm3-0.915g / cm3. Melting the paraffin, coating the paraffin on the bottom mold, so that the paraffin fills the step groove;

[0076] (3) On the paraffin layer, the place correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com