Wax injection mold for investment casting of hollow turbine blades and method for rapidly manufacturing wax injection mold

A technology of turbine blade and investment casting, which is applied in the manufacture of tools, casting molding equipment, casting molds, etc., can solve the problems of high cost, long production cycle, and poor precision, and achieve low manufacturing cost, short cycle, and guaranteed precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be further described below in conjunction with drawings and embodiments.

[0086] An embodiment of a wax injection mold for investment casting of hollow turbine blades, such as Figure 1-11 shown.

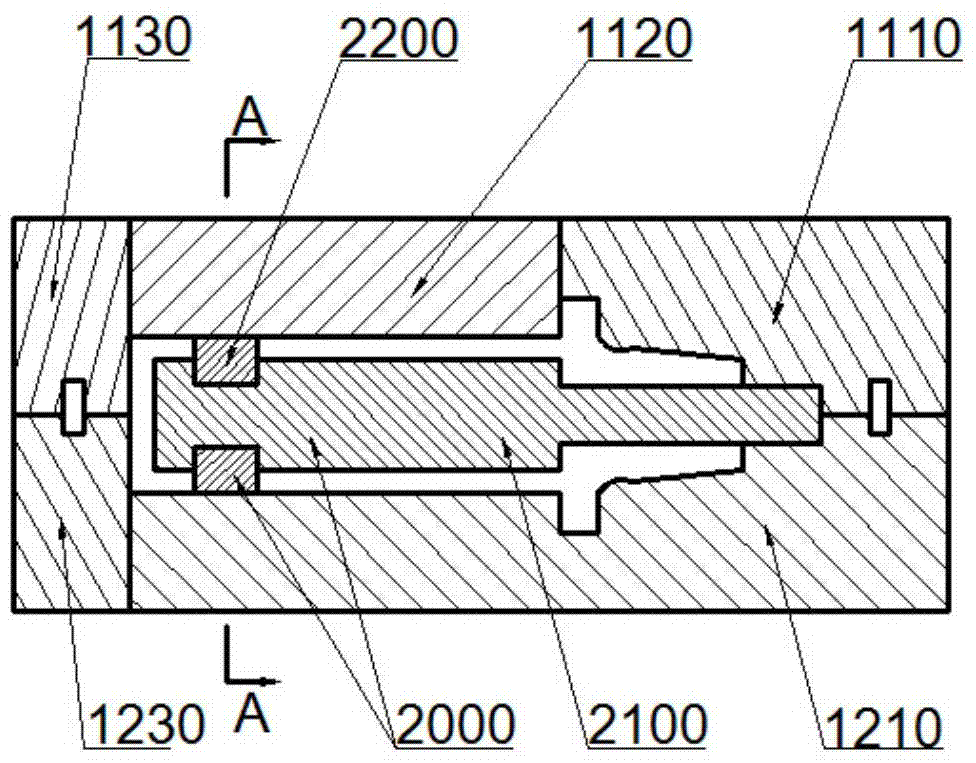

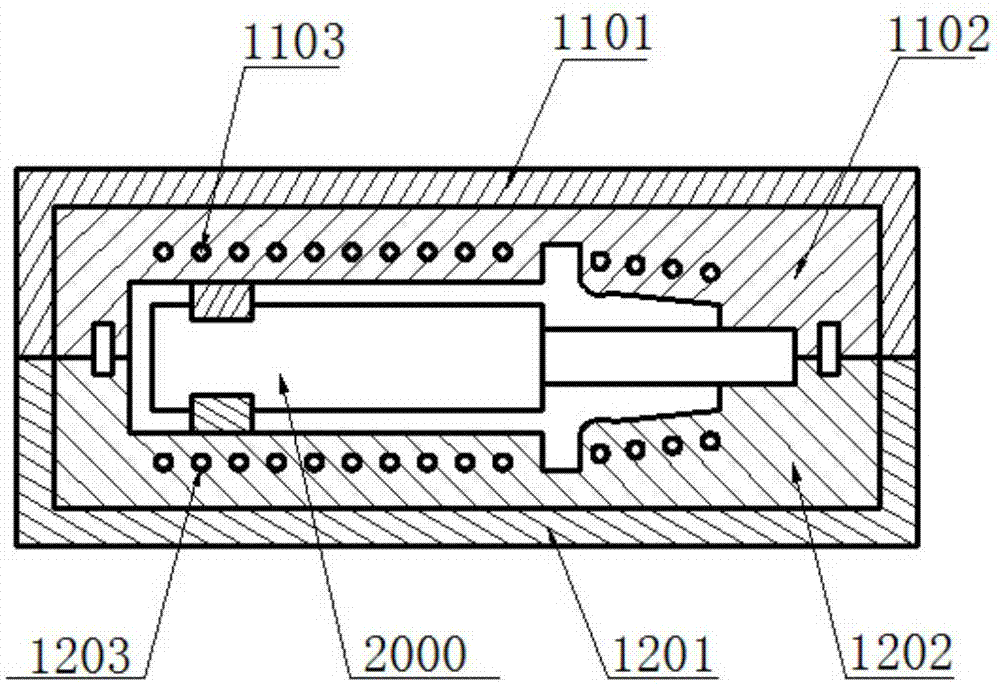

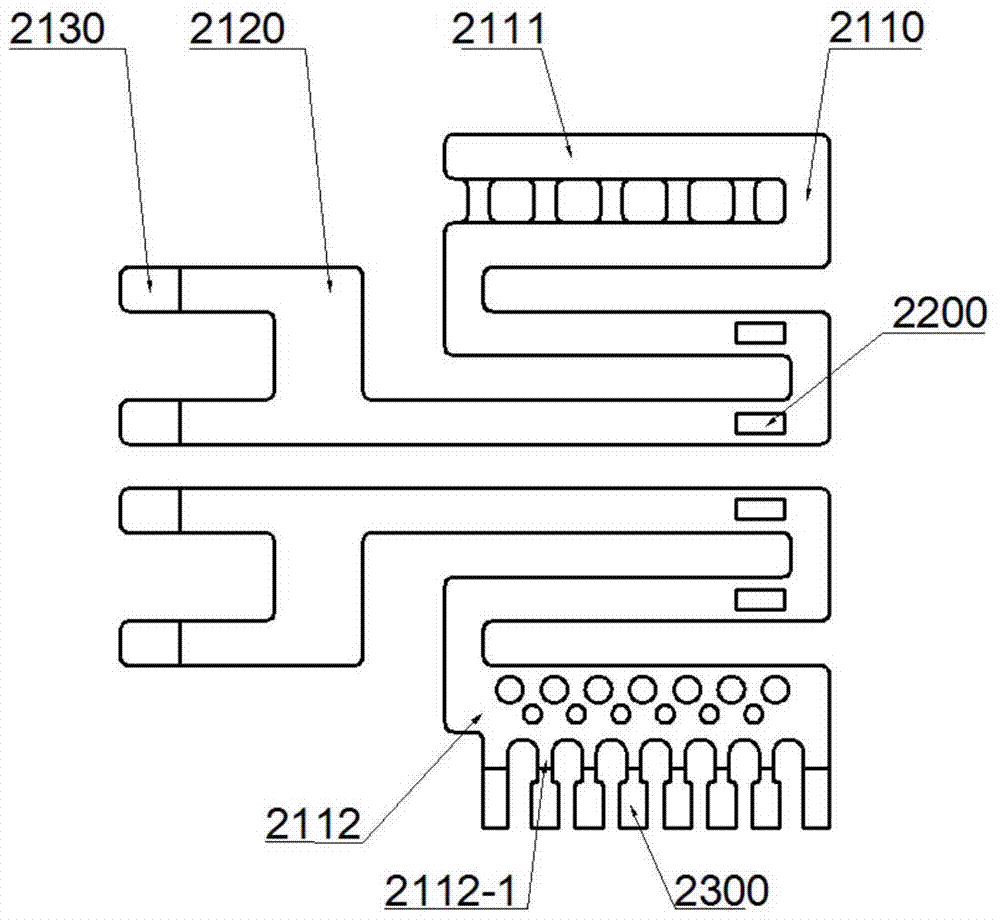

[0087] A wax injection mold for investment casting of hollow turbine blades, which is mainly composed of a cavity mold, a core 2000 and ancillary structures, and the cavity mold includes an upper mold 1100 and a lower mold 1200, such as Figure 4As shown, the upper mold is used for forming the back surface of the turbine blade, and the lower mold is used for forming the basin surface of the turbine blade. Both the upper mold and the lower mold are combined structures, and the upper mold is composed of a blade root block 1110, a blade body block 1120 and an end cover plate 1130 ( figure 1 ), the lower mold is composed of the main cavity block 1210 and the end cover plate 1230 ( figure 1 ). Each block of the upper mold and the lower mold is made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com