Method for actively sealing sapphire sheet and metal

A metal active and sapphire technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of insufficient particle size and insufficient affinity between gemstones, and achieve good air tightness, welding reliability and yield rate High, reduced complexity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for active sealing of sapphire sheet and metal, the operation steps are as follows:

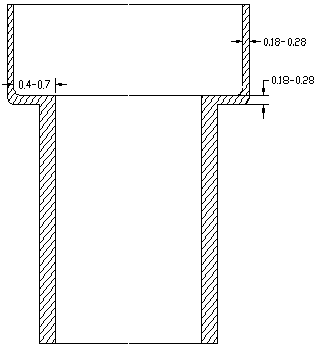

[0025] The first step: machining the Kovar metal piece so that the processed Kovar metal piece has a supporting step radially matched with the sapphire sheet, the width of the supporting step is 0.7mm, and the side wall thickness of the supporting step 0.18mm, the Kovar metal parts after mechanical processing need to be nickel-plated and hydrogen-burned;

[0026] The second step: processing the sapphire sheet with a thickness of 0.08mm so that the radial fit clearance between the sapphire sheet and the Kovar metal piece is 0.12mm, followed by 10s of potassium dichromate sulfuric acid mixed solution cleaning, and 3s of hydrofluoric acid surface cleaning. Chemical step to increase the contact area and adhesion between solder and sapphire;

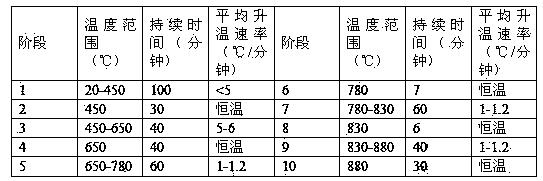

[0027] The third step: select the titanium-zirconium-copper-nickel solder paste with a melting point of 830-850°C and an average particle size of ...

Embodiment 2

[0034] A method for active sealing of sapphire sheet and metal, the operation steps are as follows:

[0035] The first step: machining the Kovar metal piece so that the processed Kovar metal piece has a support step radially matching with the sapphire sheet, the step width of the support step is 0.4mm, and the side wall thickness of the support step 0.28mm, the Kovar metal parts after mechanical processing need to be nickel-plated and hydrogen-burned;

[0036] The second step: processing the sapphire sheet with a thickness of 0.20mm so that the radial fit clearance between the sapphire sheet and the Kovar metal piece is 0.06mm, followed by 5s of potassium dichromate sulfuric acid mixed solution cleaning, and 5s of hydrofluoric acid surface cleaning. Chemical step to increase the contact area and adhesion between solder and sapphire;

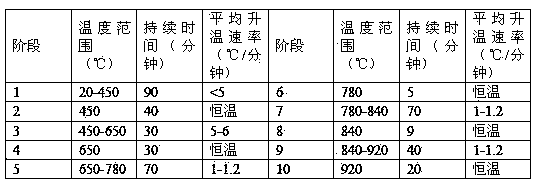

[0037] The third step: select the titanium-zirconium-copper-nickel solder paste with a melting point of 830-850°C and an average particle size of the ...

Embodiment 3

[0044] A method for active sealing of sapphire sheet and metal, the operation steps are as follows:

[0045] The first step: machining the Kovar metal piece so that the processed Kovar metal piece has a support step radially matching the sapphire sheet, the step position width of the support step is 0.6mm, and the side wall thickness of the support step 0.24mm, the Kovar metal parts after mechanical processing need to be nickel-plated and hydrogen-burned;

[0046] Step 2: Processing a sapphire sheet with a thickness of 0.10mm, so that the radial fit gap between the sapphire sheet and the Kovar metal piece is 0.10mm, and then perform 5s potassium dichromate sulfuric acid mixed solution cleaning and 5s hydrofluoric acid surface cleaning. Chemical step to increase the contact area and adhesion between solder and sapphire;

[0047] The third step: select the titanium-zirconium-copper-nickel solder paste with a melting point of 830-850°C and an average particle size of the titanium-zirco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com