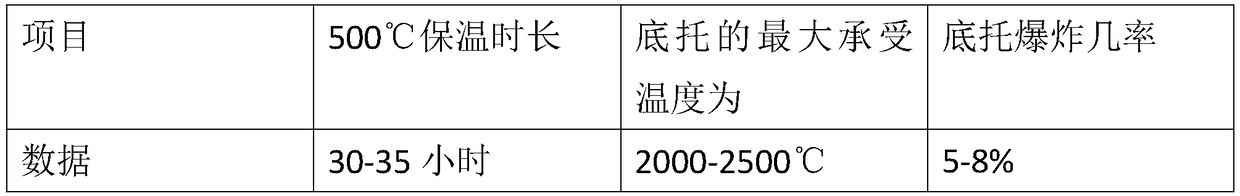

Patents

Literature

38results about How to "Reduce the chance of bursting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

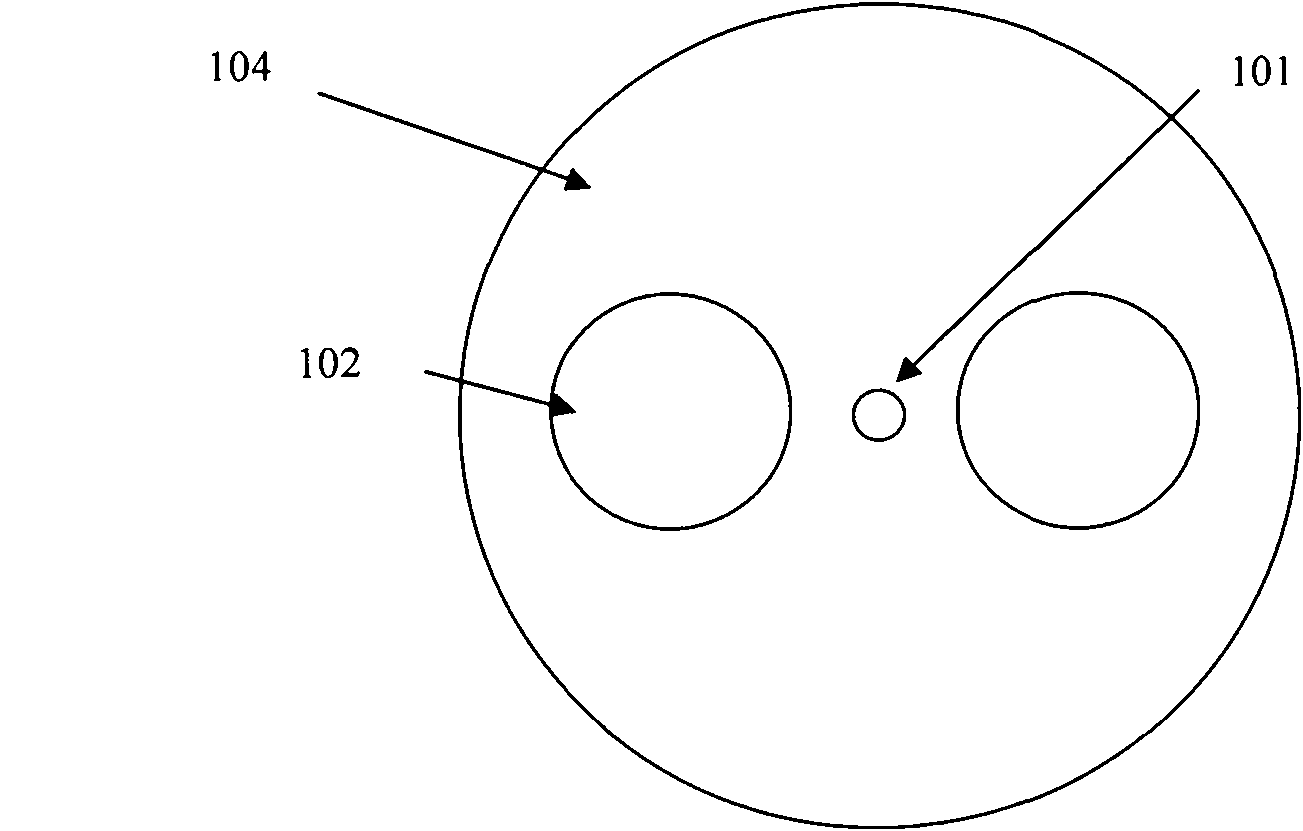

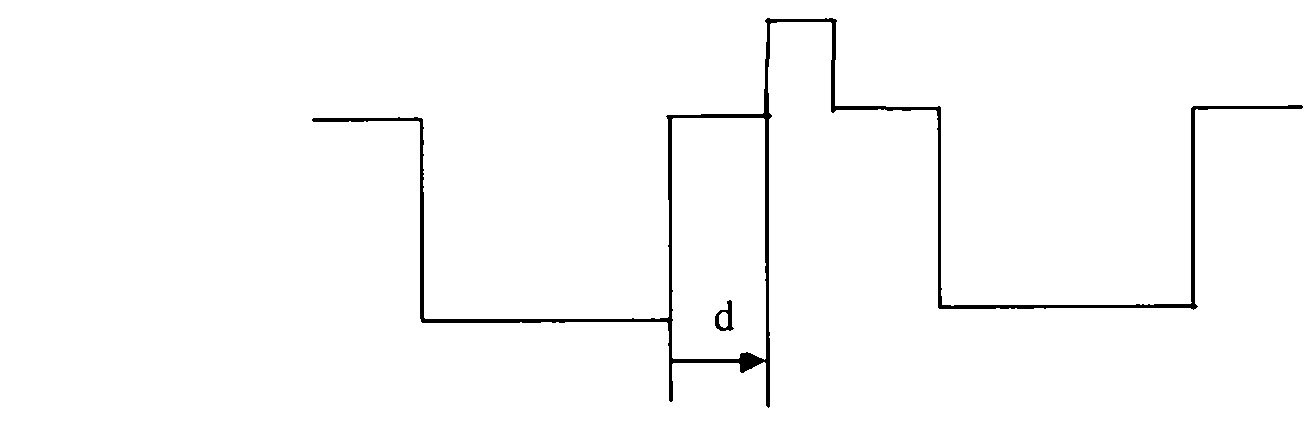

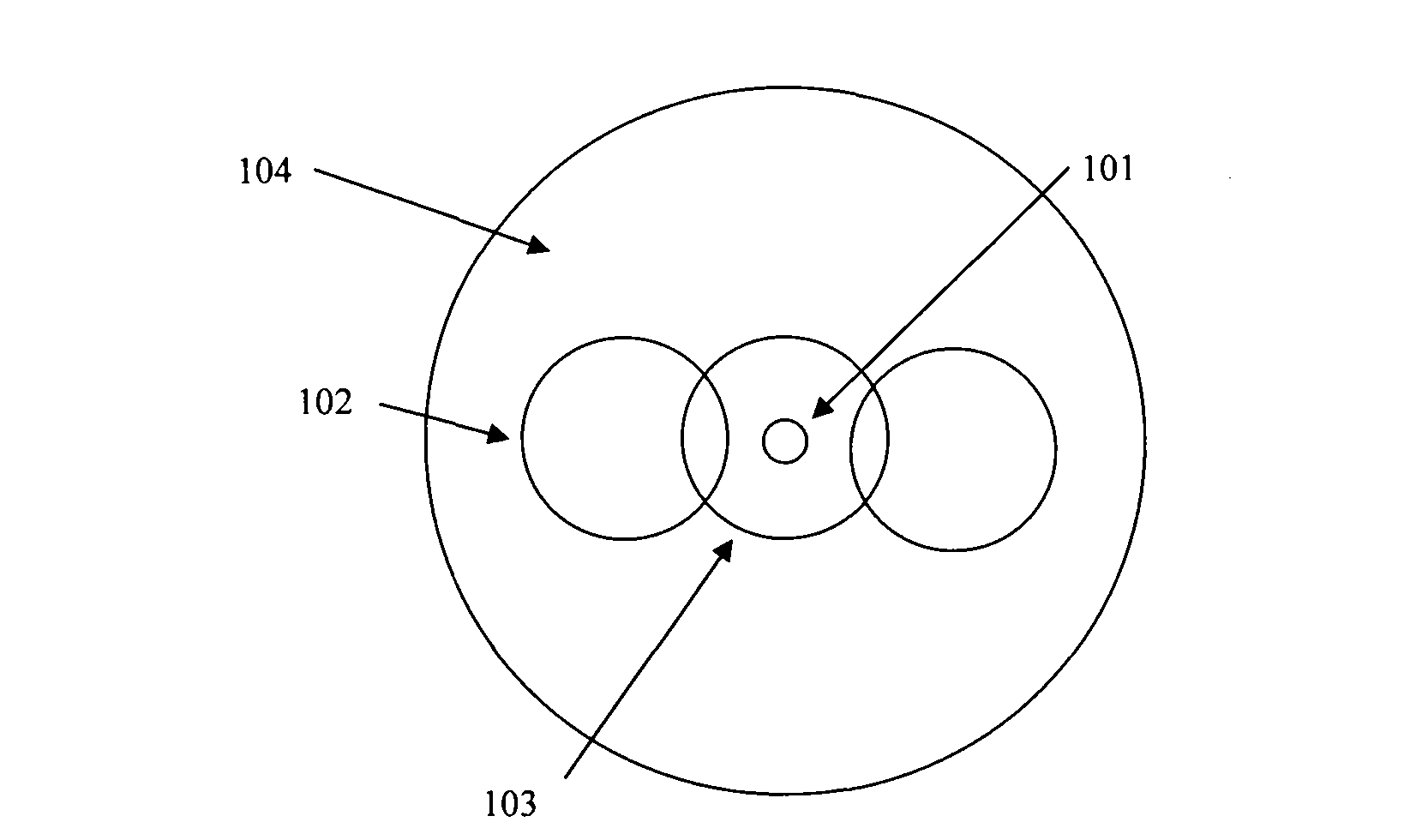

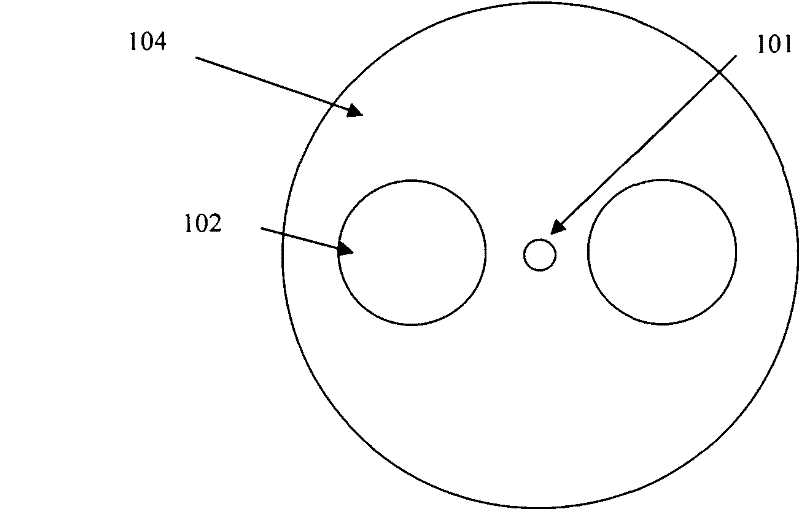

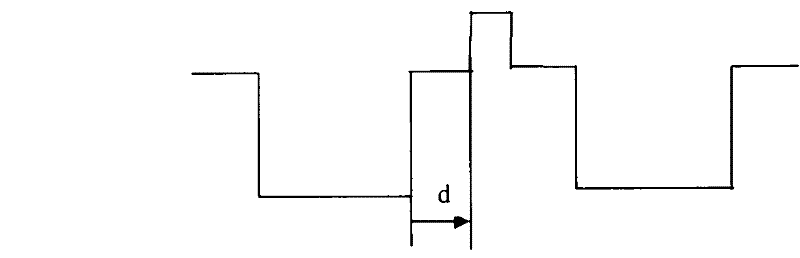

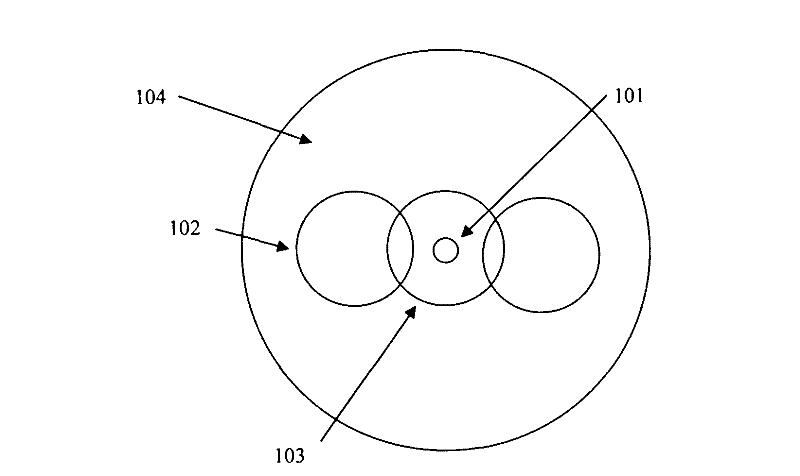

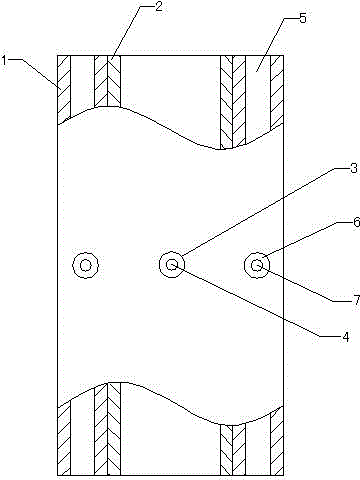

Panda type polarization maintaining optical fiber

ActiveCN101825738AIncrease stressLess adulteratedOptical fibre with polarisationOptical fibre with multilayer core/claddingStress concentrationPunching

The invention relates to a panda type polarization maintaining optical fiber for use in the field of optical fiber guidance and sensing, which comprises a core layer and a pure quartz cladding, wherein stress zones are symmetrically arranged at the two sides of the core layer in the pure quartz cladding. The panda type polarization maintaining optical fiber is characterized in that a depressed inner cladding is arranged outside the core layer, and the space between the boundaries of the stress zones and the boundary of the core layer is reduced, so that the space d between the boundaries of the stress zones and the boundary of the core layer keeps 3-7mu m. The birefringent property of the panda type polarization maintaining optical fiber can be improved by the invention to meet the performance requirements of a high-precision gyro, and the introduction of the depressed inner cladding can effectively reduce the burst probability of the prefabricated core layer in the process of punching in the stress zones under the condition of not increasing the difficulty of process preparation; the depressed inner cladding adopts viscosity doping and matching design, and further reduces the burst probability of the prefabricated core layer caused by the external mechanical stress in the process of punching in the stress zones; and one side of the stress zones and the depressed inner cladding have an overlapped region so as to prevent the mechanical stress from acting on an intrinsic boundary stress concentration point.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

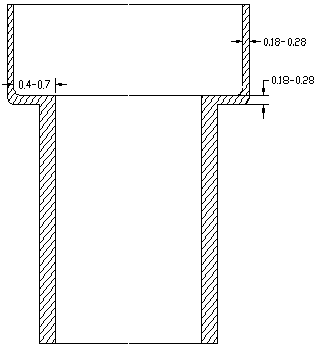

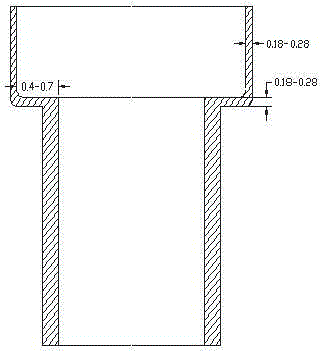

Method for actively sealing sapphire sheet and metal

ActiveCN103949742AGuaranteed wall thicknessReduce the chance of burstingSoldering apparatusThermal dilatationTitanium zirconium

The invention provides a method for actively sealing a sapphire sheet and metal. The method is low in welding temperature, high in efficiency, good in reliability and low in cost. According to the method, high-temperature metallization is not required, expensive vacuum coating equipment and precious metal targets are also not required, the defects of long intermediate treatment process and time consumption are overcome, the total welding time is shortened, and the production efficiency is improved; the defect that flatness with high precise size and demanding requirement is required to be machined when welding sheets are adopted is avoided, and active titanium, zirconium, copper and nickel welding flux is directly adopted; the thickness of the wall of the sealing part of a metal piece is small, so that the thermal stress effect caused by the reaction of extrusion to the metal piece by the thermal expansion of the sapphire sheet during welding is reduced, and the probability of explosion of the sapphire sheet is reduced; meanwhile, welding can be accomplished at one step when the vacuum atmosphere temperature is lower than 1000 DEG C, the requirement on welding equipment is low, the product welding reliability and the yield are high, the air impermeability is good when baking is performed at the high temperature of 560 DEG C for 36 hours, and the requirement on the air impermeability of ultrahigh frequency electron tubes can be guaranteed.

Owner:XI AN JIAOTONG UNIV +1

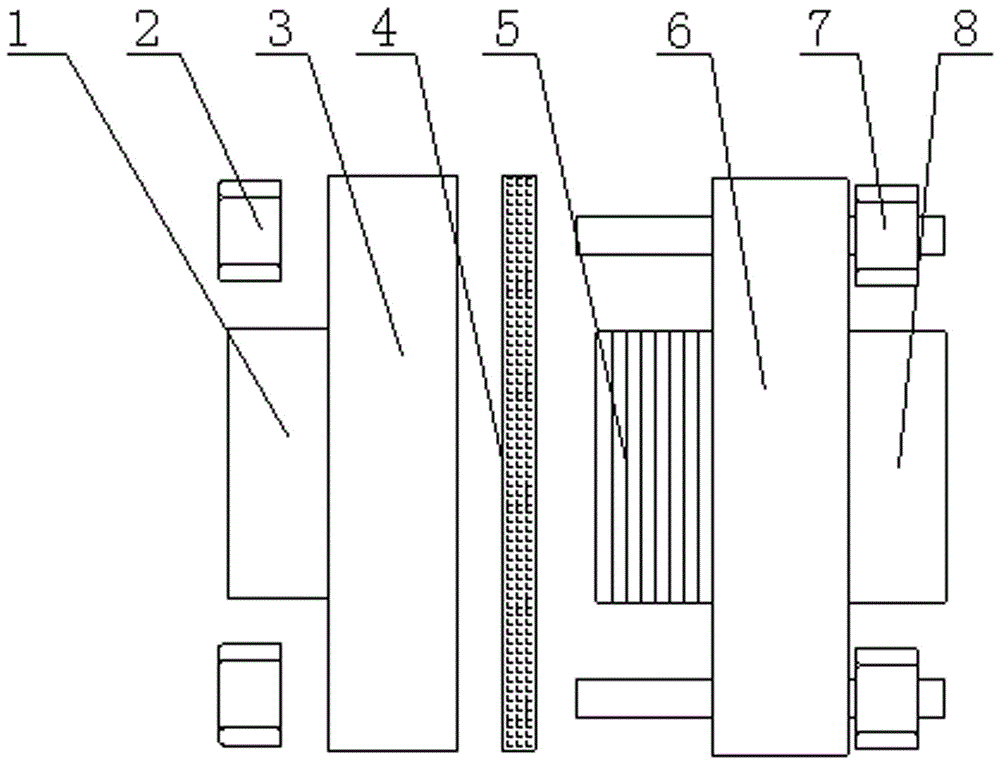

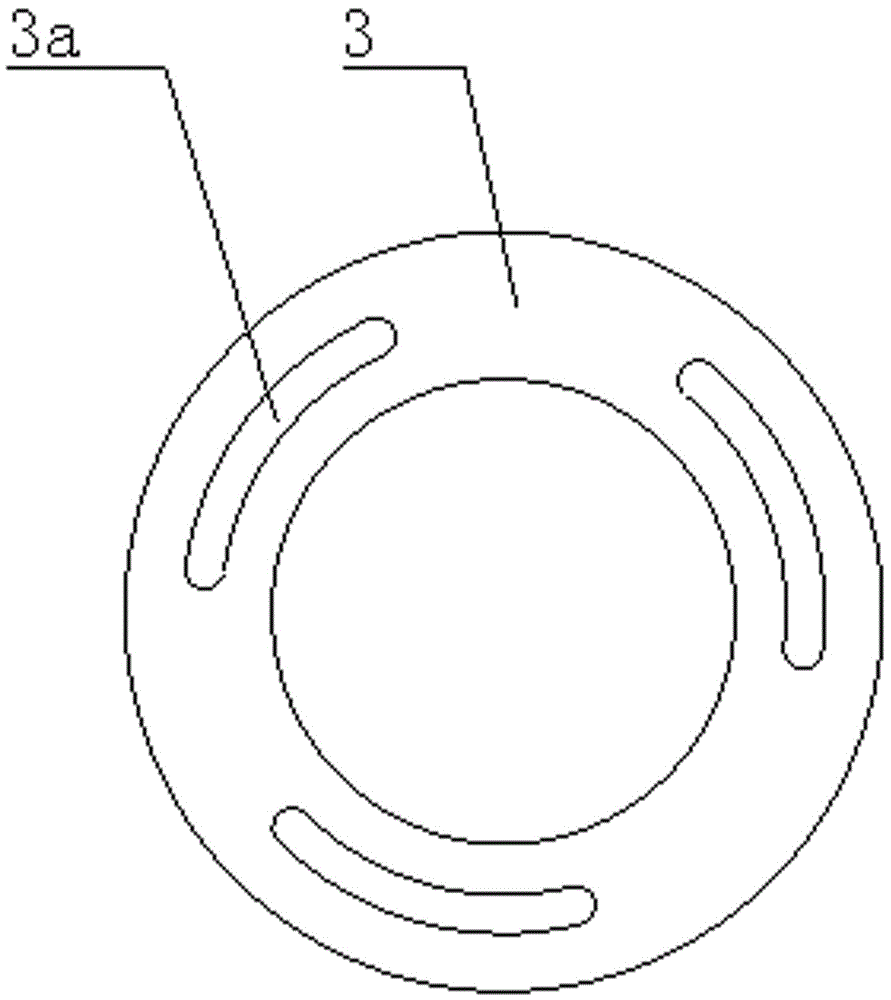

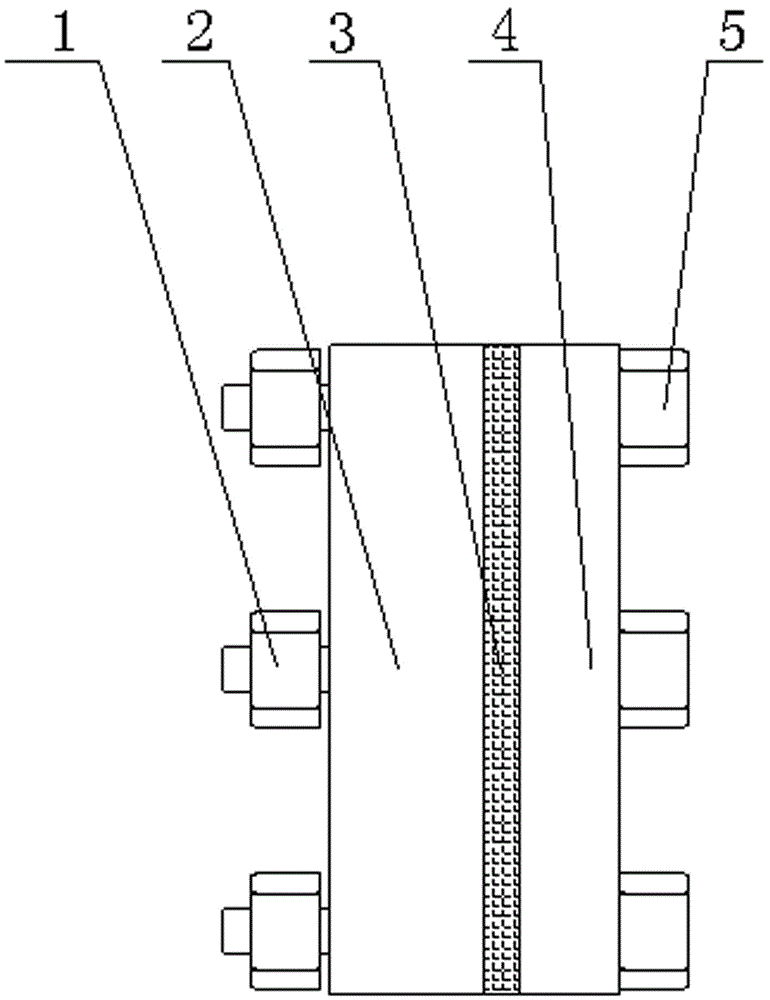

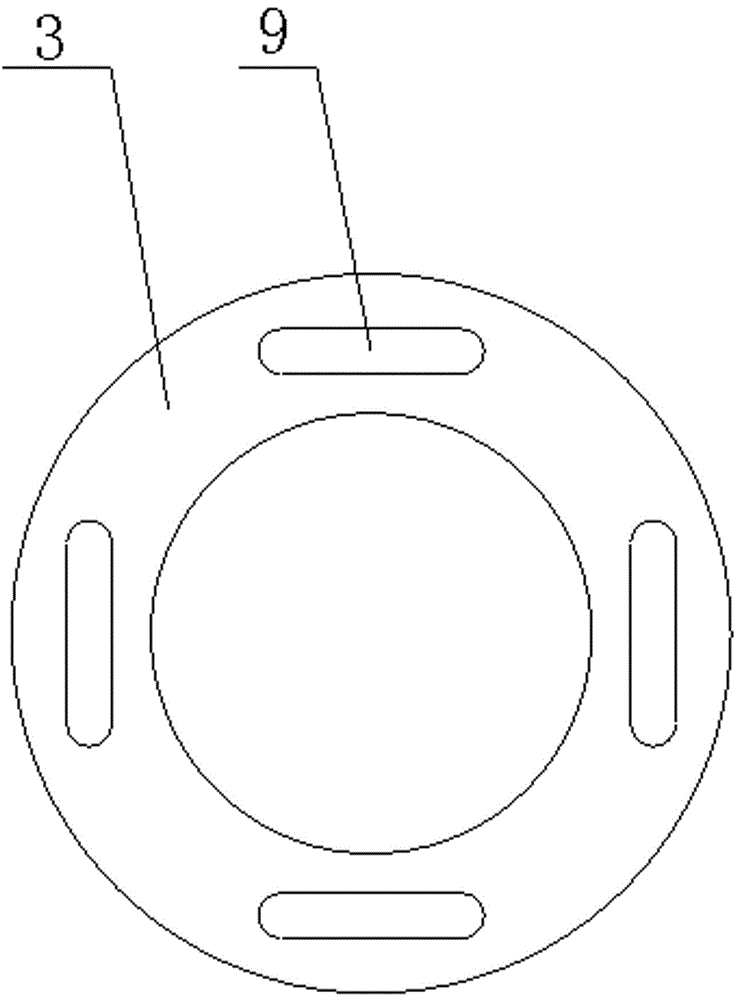

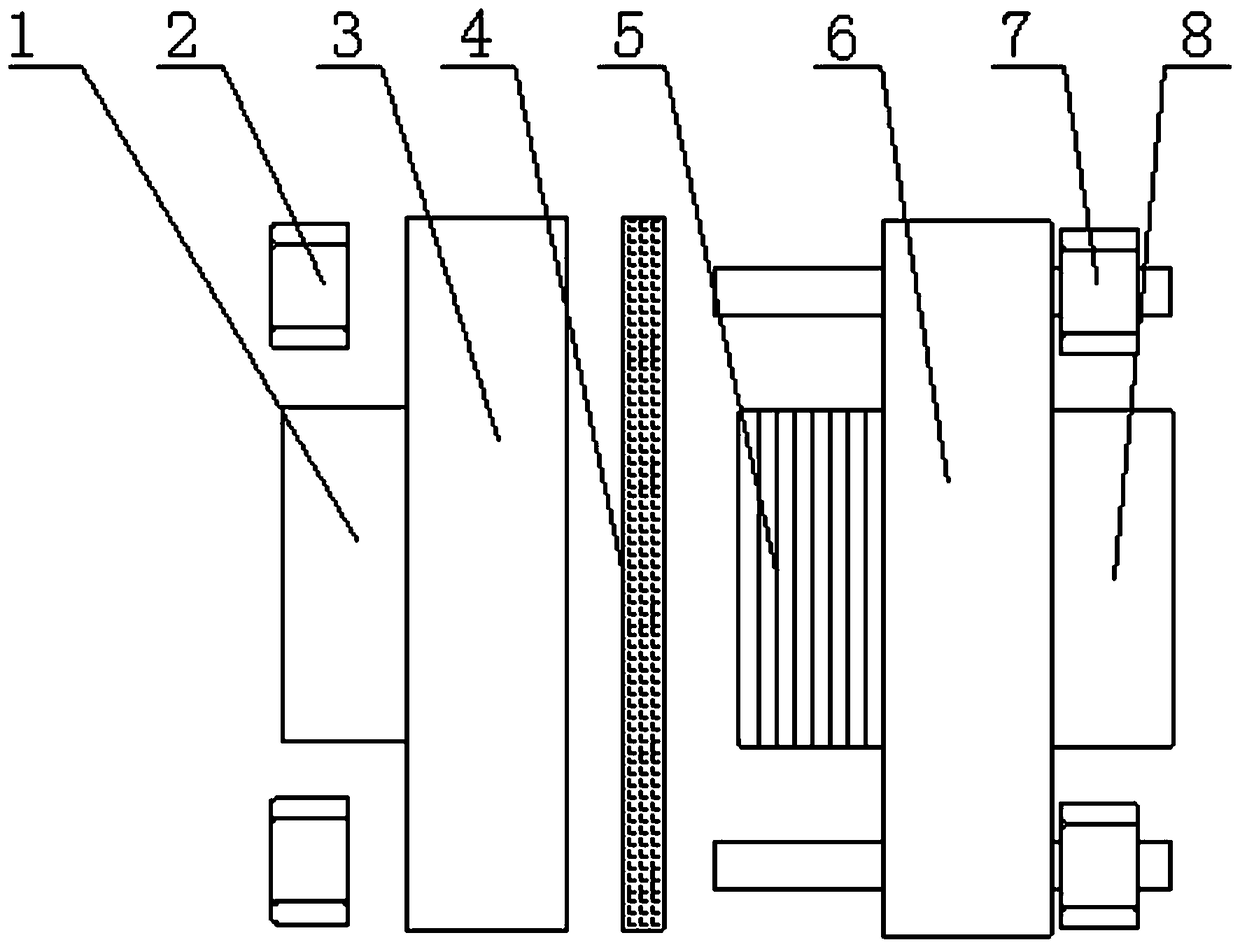

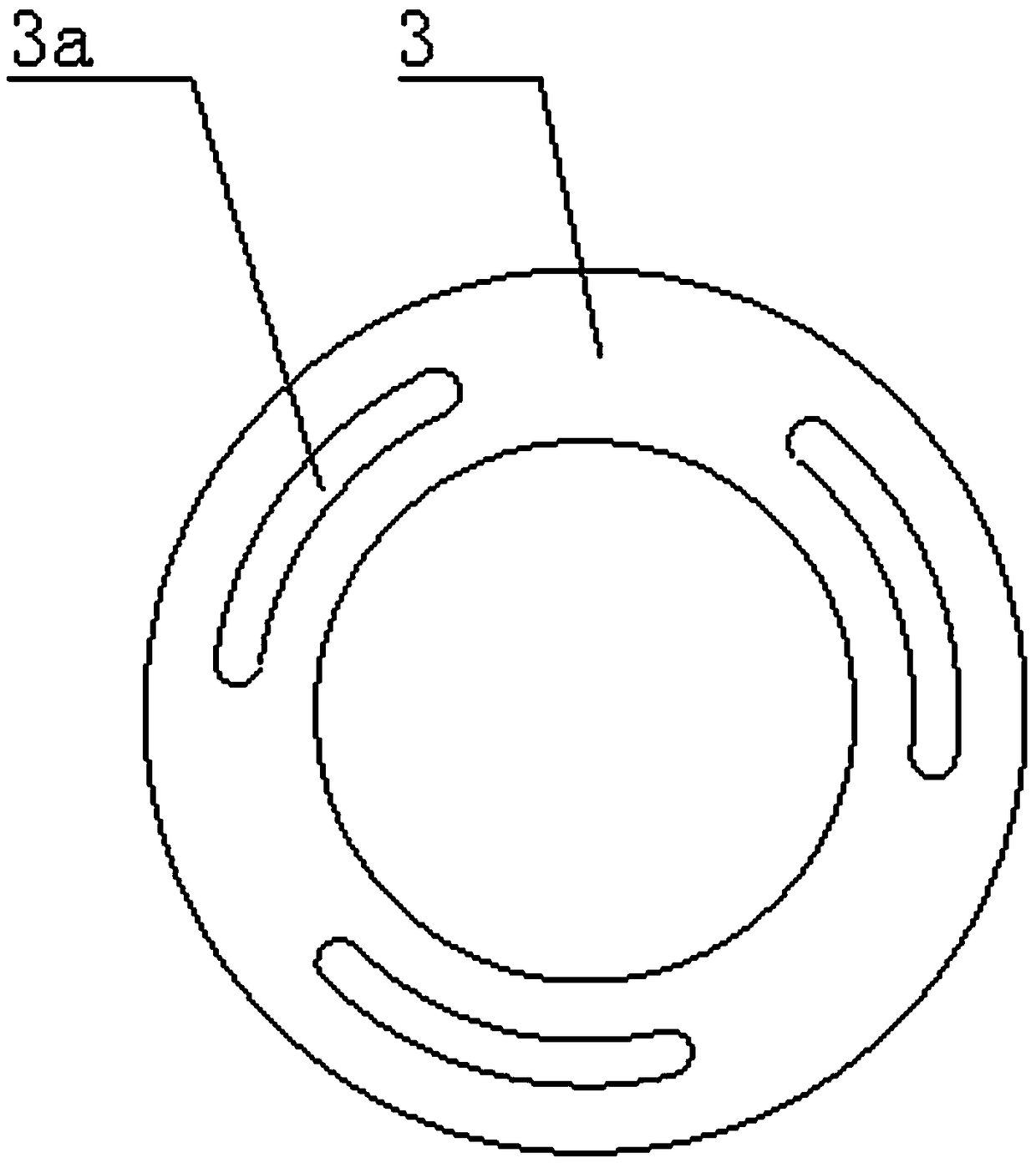

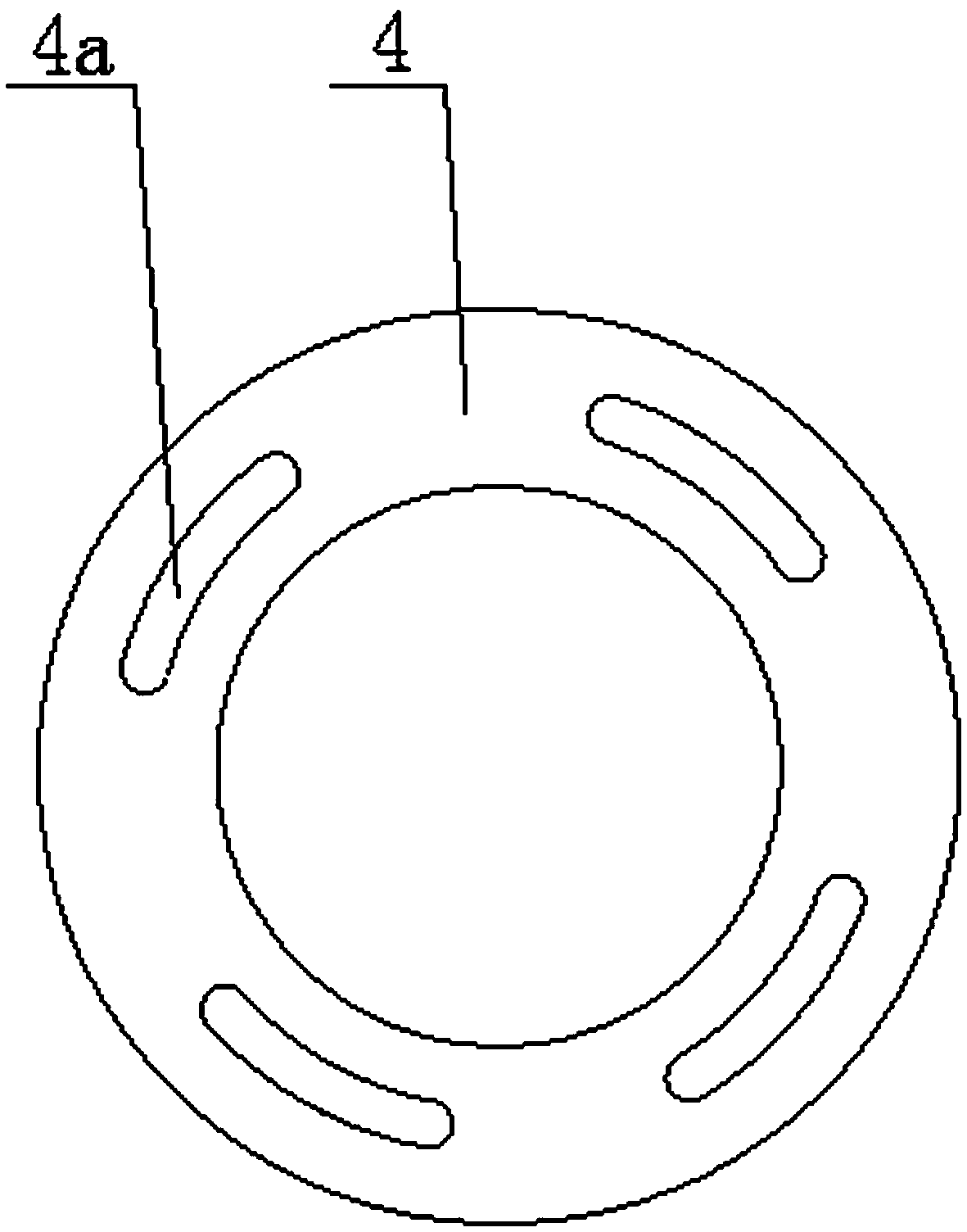

Flange fast and firm in connection

ActiveCN106224667AQuick and efficient installationEasy to installFlanged jointsFoundry mouldsEngineeringFlange

The invention relates to a flange fast and firm in connection. The flange fast and firm in connection comprises a first flange body, a second flange body, a sealing gasket, a fastening bolt and a nut. The corresponding positions of the first flange body and the second flange body are each provided with at least two arc-shaped holes. The fastening bolt sequentially penetrates the arc-shaped holes in the first flange body and the arc-shaped holes of the second flange body and is connected with the nut in a threaded manner. The sealing gasket is arranged between the first flange body and the second flange body. The side, close to the first flange body, of the second flange body is provided with an annular connecting block. An external thread is machined on the outer side of the annular connecting block. A connecting groove matched with the annular connecting block is formed in the first flange body. An internal thread matched with the external thread of the annular connecting block is machined on the inner wall of the connecting groove. According to the flange fast and firm in connection, the first flange body and the second flange body are connected through the thread of the connecting block firstly and thereafter connected through the bolt when connected, and the two connecting manners are matched mutually, so that connection of the first flange body and the second flange body is firmer and more stable, and the problems of leakage and the like caused by infirm connection are reduced greatly.

Owner:YANCHENG FENGGONG MACHINERY

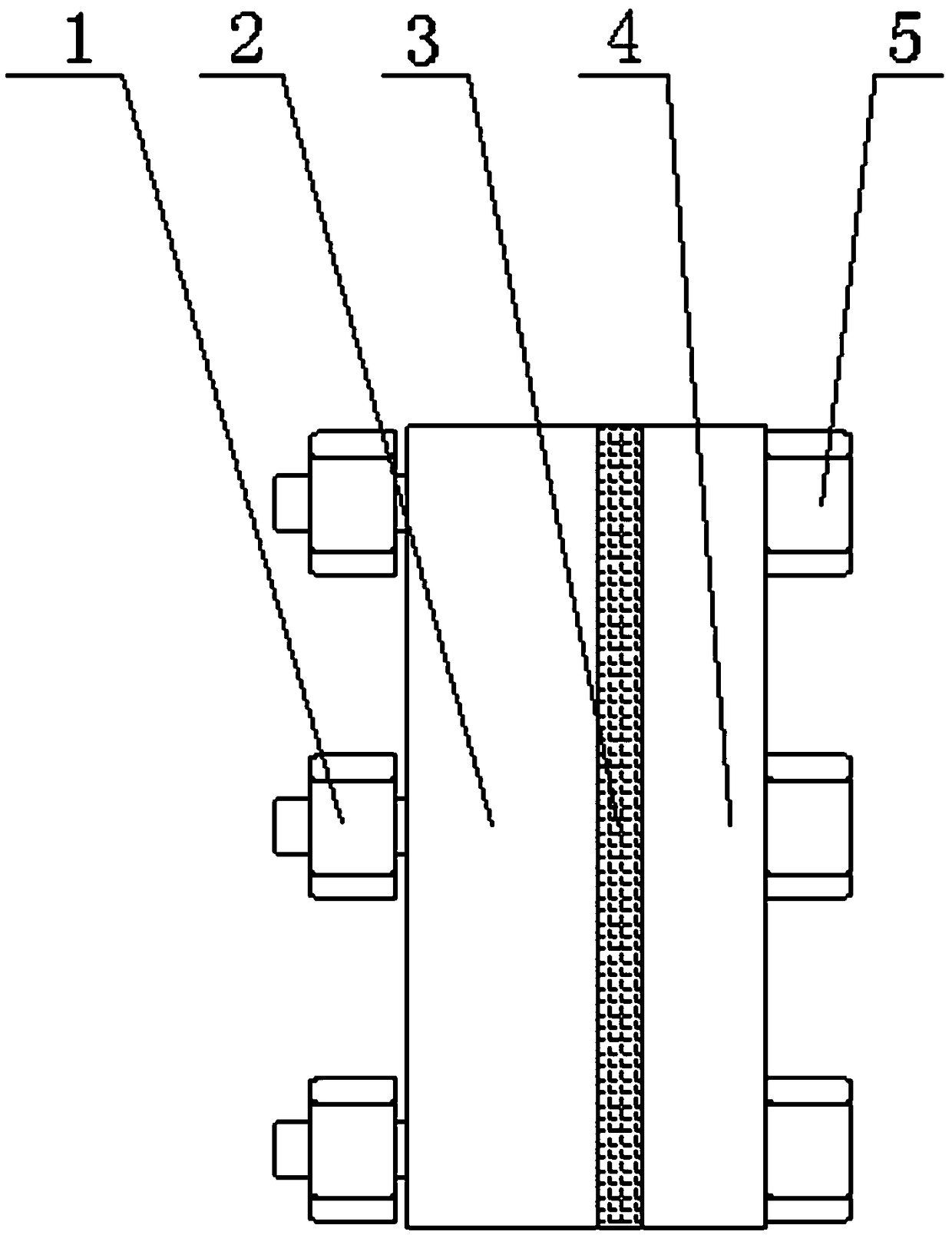

Efficient sealing flange

ActiveCN106247048AQuick and efficient installationEasy to installEngine sealsFlanged jointsScrew threadScreen filter

The invention relates to an efficient sealing flange which comprises a first flange body, a second flange body, a round filter screen, fastening bolts and nuts. The corresponding positions of the first flange body, the second flange body and the round filter screen are each provided with arc-shaped holes. Each fastening bolt sequentially penetrates the corresponding arc-shaped hole of the first flange body, the corresponding arc-shaped hole of the round filter screen and the corresponding arc-shaped hole of the second flange body to be in threaded connection with the corresponding nut. An annular connecting block is arranged on the side, close to the first flange body, of the second flange body. An external thread is manufactured on the outer side of the annular connecting block. A connecting groove is formed in the first flange body, and an internal thread is manufactured on the inner wall of the connecting groove. The surfaces of the opposite sides of the first flange body and the second flange body are covered with a first rubber sealing layer and a second rubber sealing layer correspondingly. The side, in contact with the first flange body, of each fastening bolt and the side, in contact with the second flange body, of each nut are covered with a third rubber sealing layer and a fourth rubber sealing layer correspondingly. The edge of the outer side of the round filter screen is covered with a rubber sealing ring. According to the efficient sealing flange, by means of the cooperation of the four rubber sealing layers, it is guaranteed that the sealing performance of the flange is efficient and stable, and the flange is prevented from leaking at the connecting position.

Owner:YANCHENG FENGGONG MACHINERY

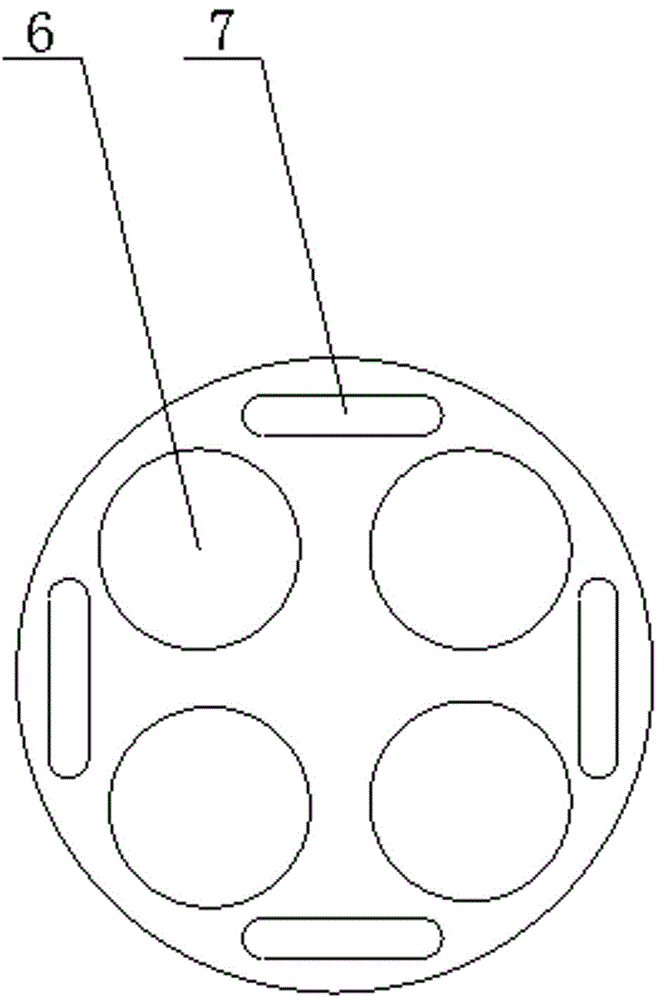

Multi-pipeline connecting flange

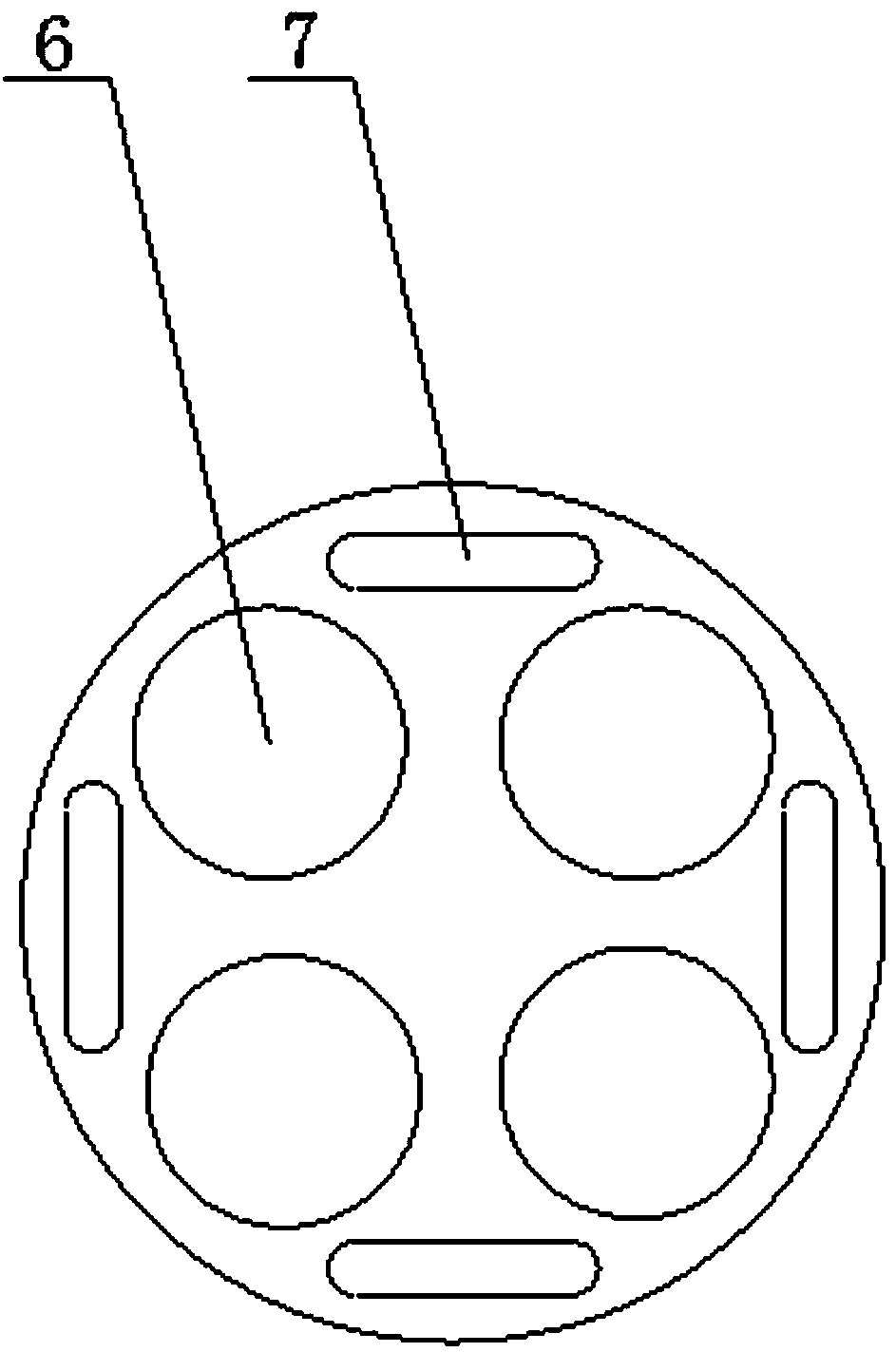

ActiveCN106247058AQuick and efficient installationImprove engineering efficiencyFlanged jointsPipe elementsMaterial resourcesEngineering

The invention relates to a multi-pipeline connecting flange which comprises a first flange body, a second flange body, a sealing gasket, fastening bolts and nuts. The sealing gasket is arranged between the first flange body and the second flange body. The corresponding positions of the first flange body and the second flange body are each provided with at least two pipe containing holes and are further each provided with at least two fastening through holes. The fastening bolts sequentially penetrate the fastening through holes of the first flange body and the fastening through holes of the second flange body to be in threaded connection with the nuts. According to the multi-pipeline connecting flange, due to the fact that the corresponding positions of the first flange body and the second flange body are each provided with the at least two pipe containing holes, multiple pipelines can be connected at the same time, the engineering efficiency is greatly improved, manpower and material resources are saved, and the construction progress is accelerated.

Owner:YANCHENG FENGGONG MACHINERY

Filter flange fast and convenient to connect

InactiveCN106244953AImprove installation efficiencyEfficient and quick installationFlanged jointsFoundry mouldsEngineeringMechanical engineering

The invention relates to a filter flange fast and convenient to connect. The filter flange comprises a first flange, a second flange, a round filter screen, fastening bolts and nuts. One or more kidney-shaped holes are formed in the corresponding positions of the first flange, the second flange and the round filter screen. Each fastening bolt sequentially penetrates the first flange, the round filter screen and the second flange and is in threaded connection with the corresponding nut. One or more sealing washers are arranged between the first flange and the second flange. When the filter flange fast and convenient to connect is mounted, the first flange, the second flange and the round filter screen can be fixed only by making the bolts sequentially penetrate the kidney-shaped holes, it is not needed to slowly align mounting holes in the first flange, the second flange and the round filter screen in sequence, and therefore mounting efficiency is greatly improved; the flange can be mounted efficiently, fast and conveniently; and the progress of a project can be effectively accelerated.

Owner:YANCHENG FENGGONG MACHINERY

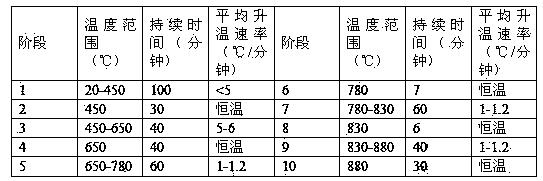

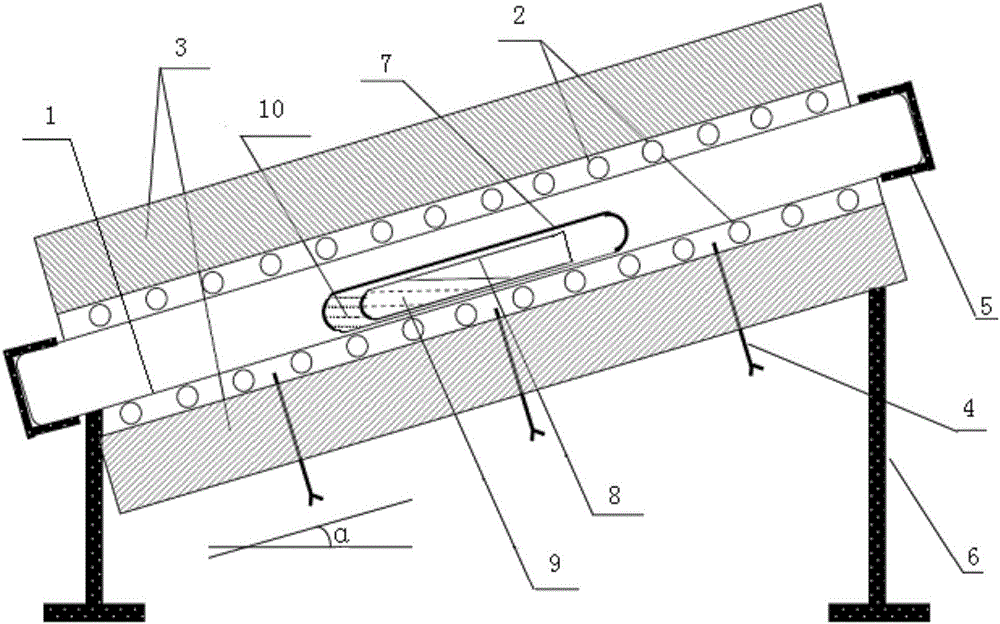

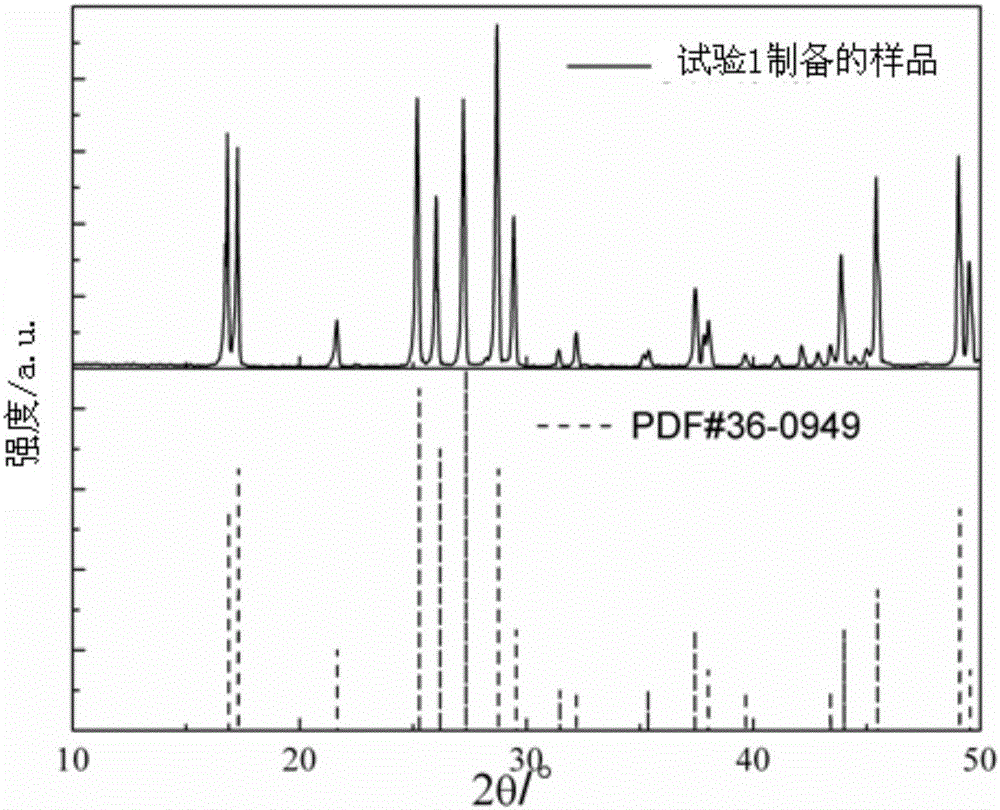

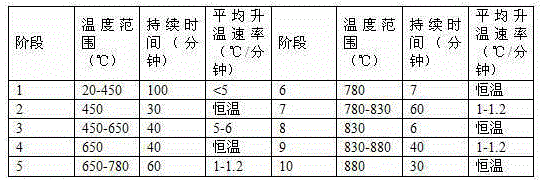

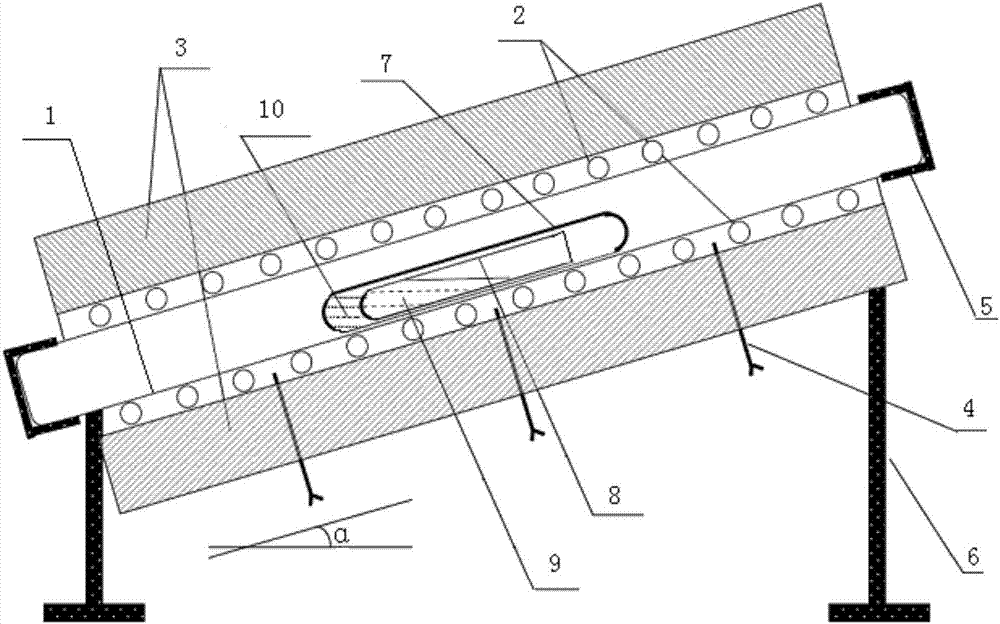

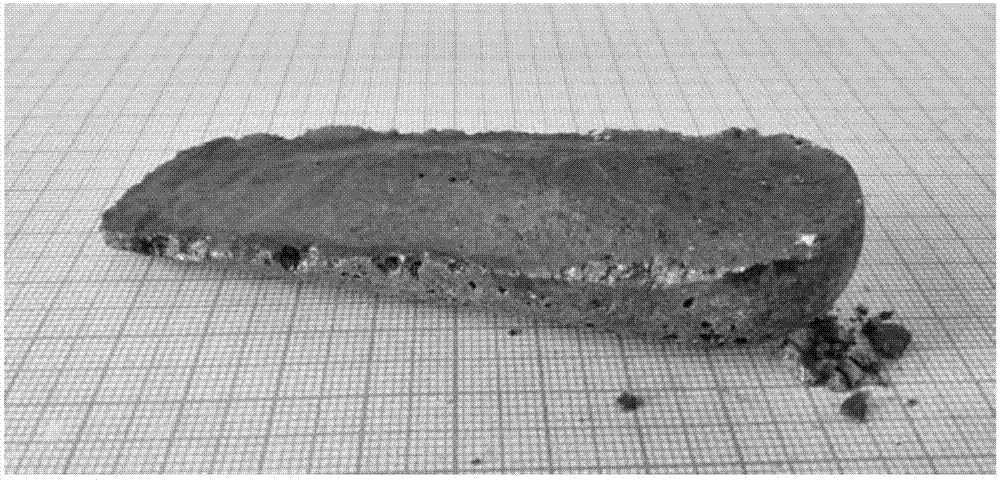

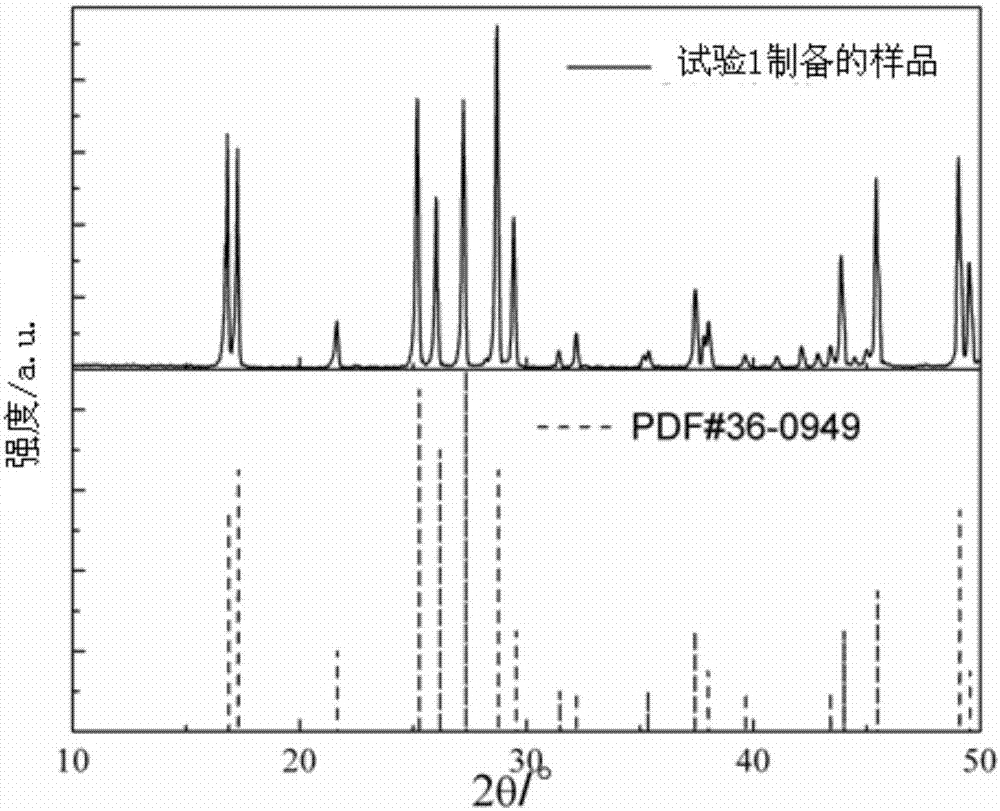

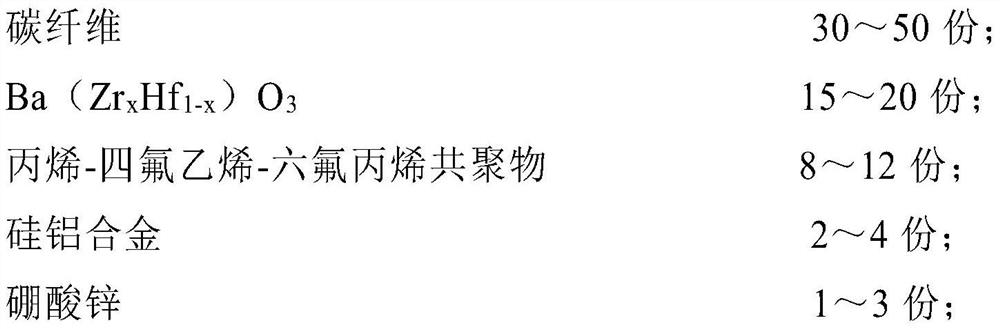

Synthesis method of Li-containing I-III-VI2 type mid and far infrared polycrystalline

ActiveCN105714375AReduce the chance of burstingPolycrystalline material growthSingle crystal growth detailsSynthesis methodsFar infrared

The invention provides a synthesis method of a Li-containing I-III-VI2 type mid and far infrared polycrystalline and relates to a synthesis method of the mid and far infrared polycrystalline. The synthesis method aims at solving the technical problem that existing quartz tubes for synthesizing the Li-containing I-III-VI2 type mid and far infrared polycrystalline are susceptible to corrosion cracking to produce burst. The synthesis method comprises the steps that 1, a tubular crucible and a quartz tube are cleaned; 2, an elementary-substance raw material of Li-containing I-III-VI2 type mid and far infrared crystals is weighed; 3, Li and a third main group element elementary substance are put into the tubular crucible, a sixth main group element elementary substance is put in the bottom of the quartz tube, then the tubular crucible is put in the middle of the quartz tube, vacuum pumping is performed to seal the quartz tube, and the quartz tube is put in an oblique single-temperature-zone tube type resistance furnace; 4, the resistance furnace is heated for synthesis, and the Li-containing I-III-VI2 type mid and far infrared polycrystalline is obtained. The synthesis method is safe and simple, reduces the probability of quartz tube burst in the synthesis process and can be used for synthesis of the lithium-containing mid and far infrared polycrystalline.

Owner:HEILONGJIANG INST OF TECH

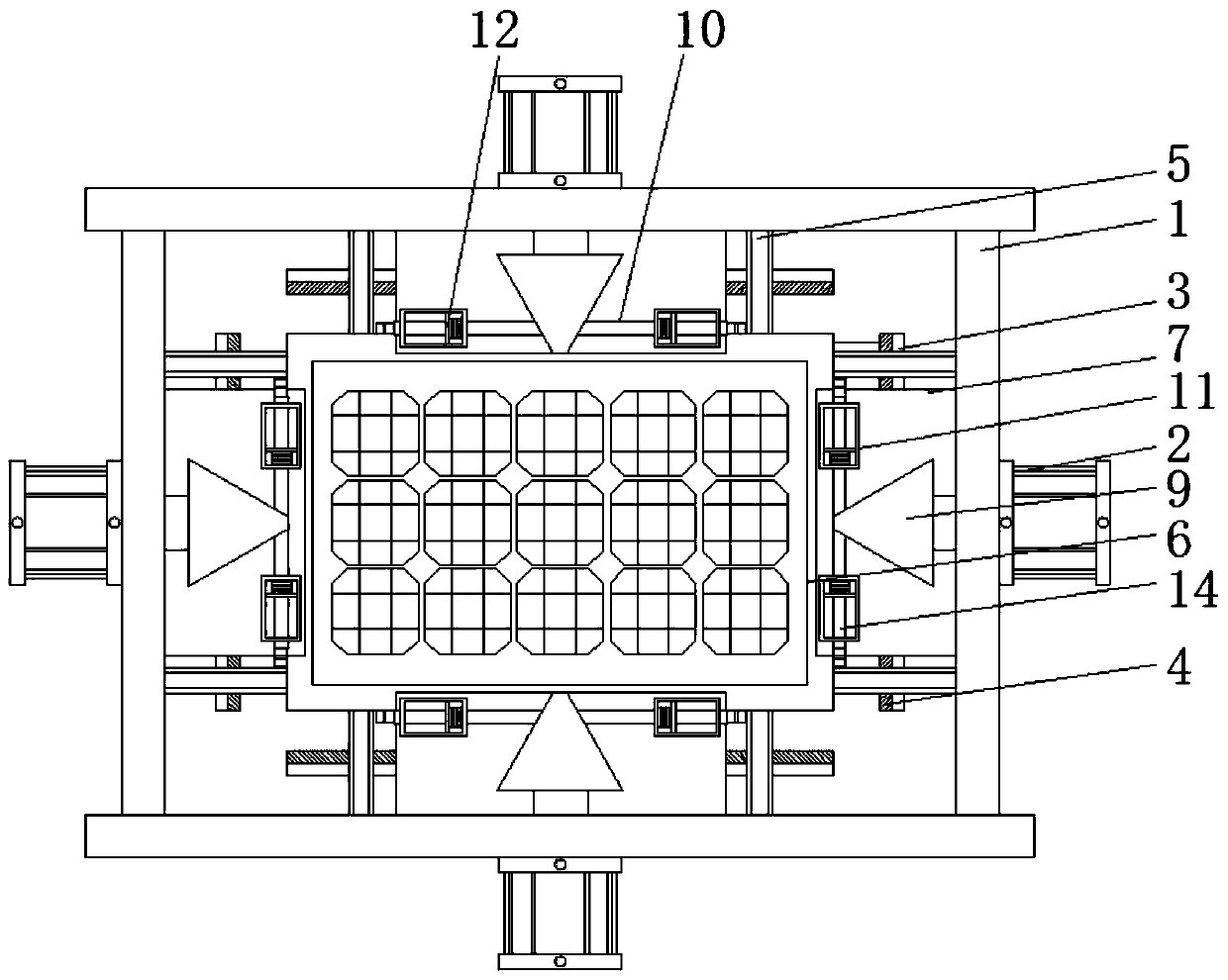

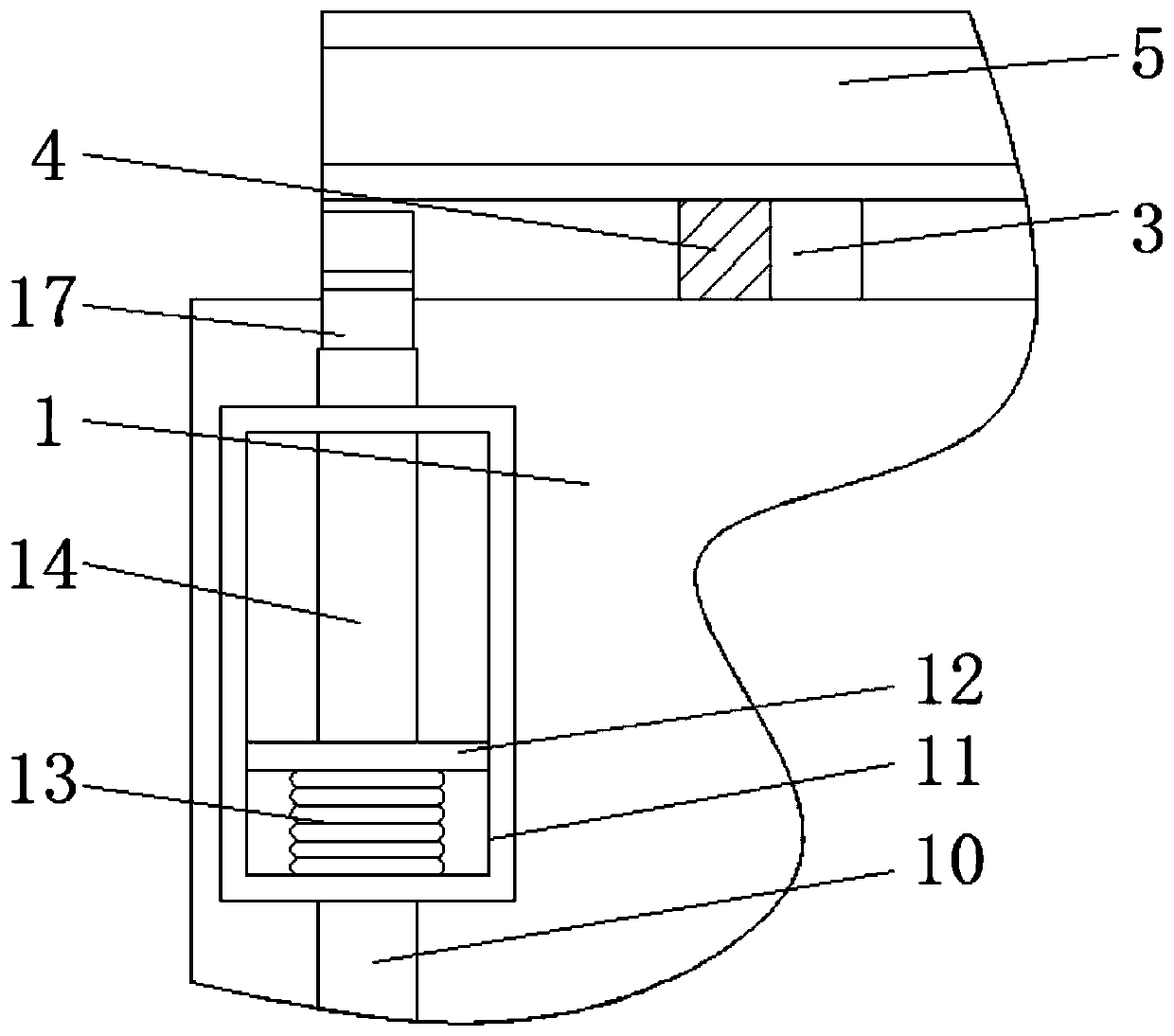

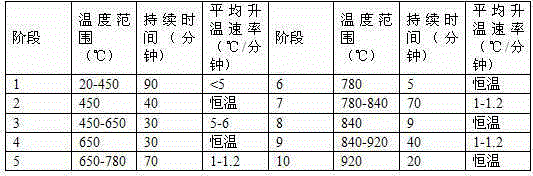

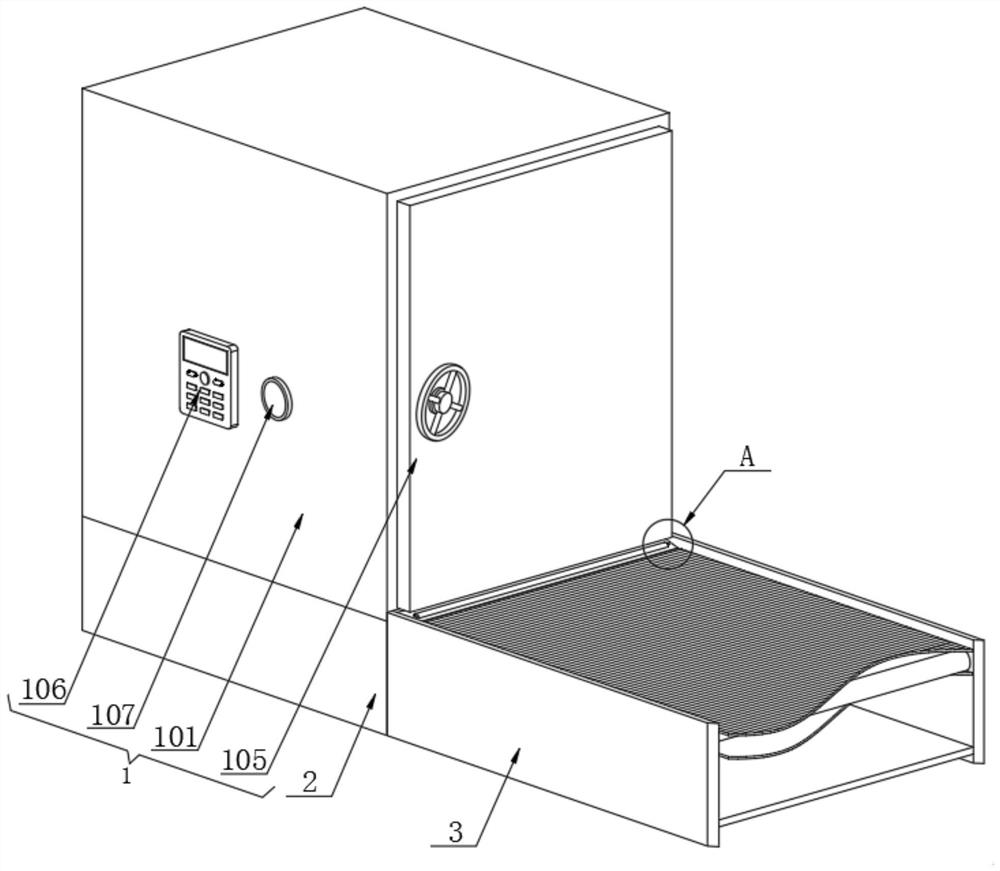

Frame mounting machine for processing solar panel

ActiveCN110808311AIncrease distanceReduce capacityFinal product manufacturePhotovoltaicsCells panelSlide plate

The invention relates to the technical field of cell panel processing, and discloses a frame mounting machine for processing a solar panels. The frame mounting machine comprises a frame. A support plate positioned below the frame is fixedly connected on the side surface of the frame. A slide plate is fixedly connected on the bottom of an oil cylinder. Slide rods are slidably connected on the two sides of the slide plate. Limiting cylinders are slidably connected on the end parts of the slide rods. A positioning rod is slidably connected on the side surface of each limiting cylinder. A positioning block is fixedly connected on the end part of the positioning rod. The scraper is automatically pushed to the two sides to extend the distance so that the scraper is enabled to directly scrape offthe silicone at the bottom of the frame, the scraper just passes through the bottom of the frame when the silica gel is extruded from the inside of the frame, then the silica gel flows out of the scraper and the outflow silica gel can be scraped off, the automatic cleaning of the frame is realized, the silica gel cannot flow into the inside of the linear guide rail and the slide plate and the linear guide rail always maintain a certain fluency, thus reducing the quality problem of the cell during processing and increasing the processing quality of the cell.

Owner:广东晶正科技有限公司

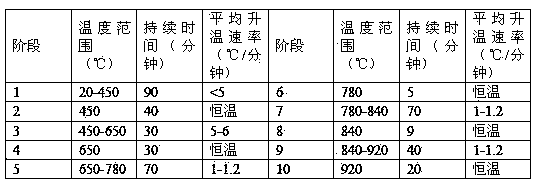

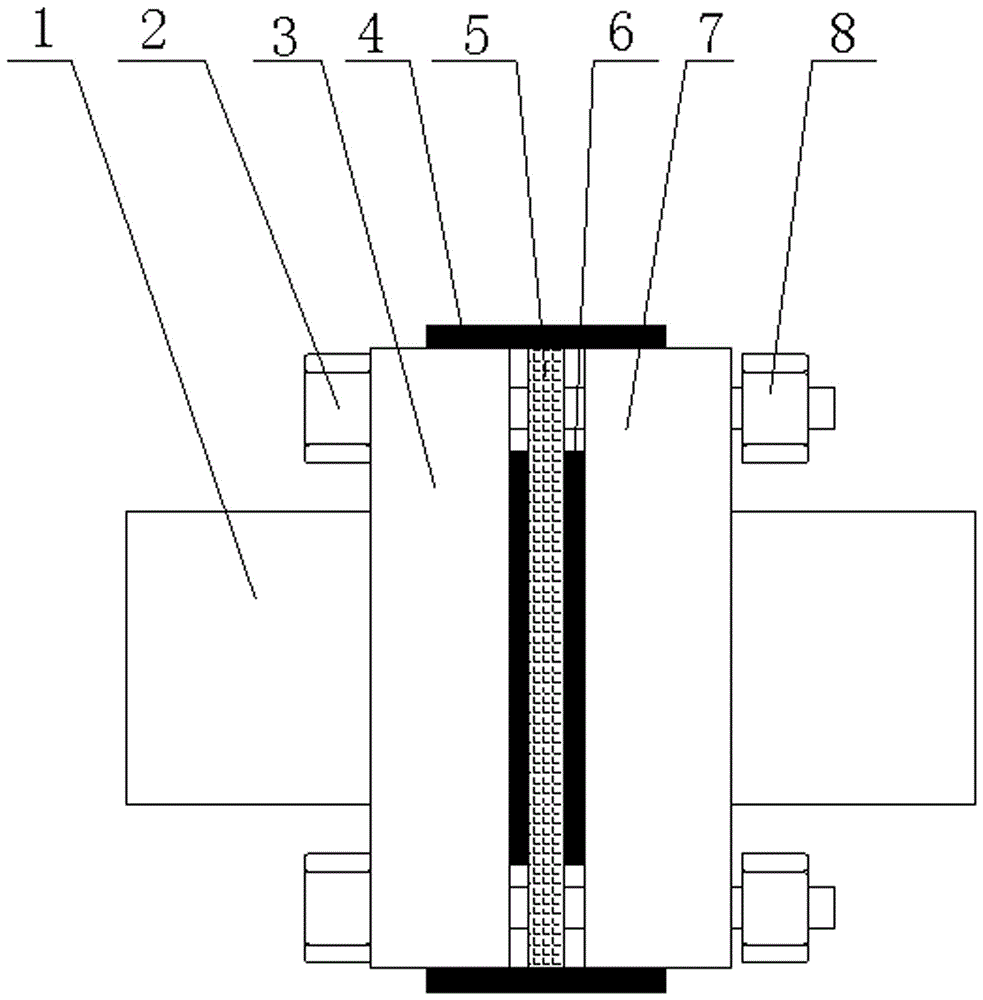

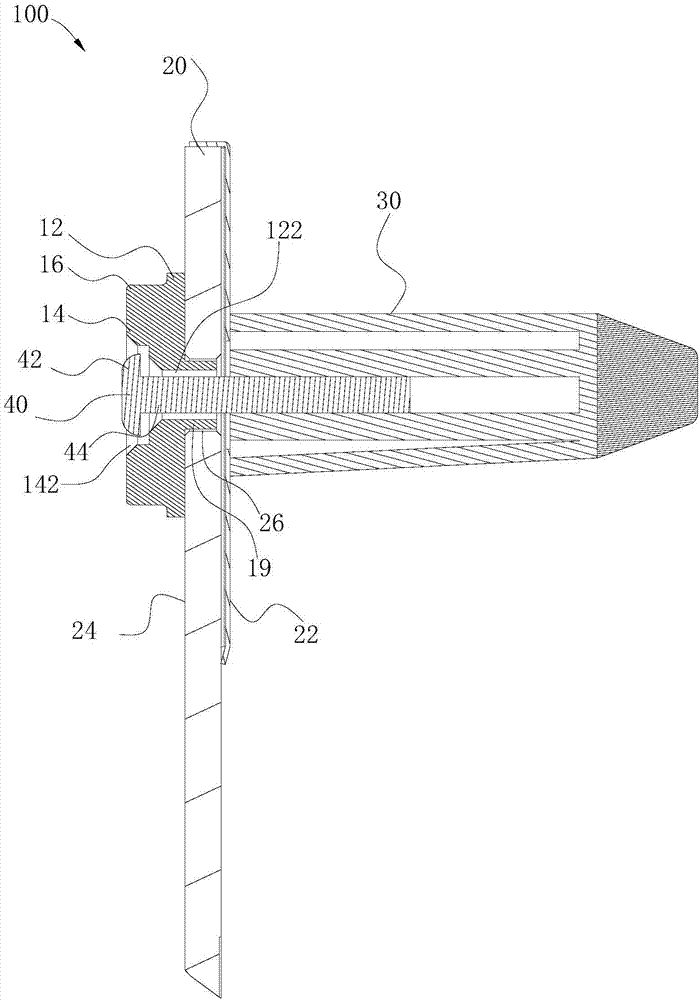

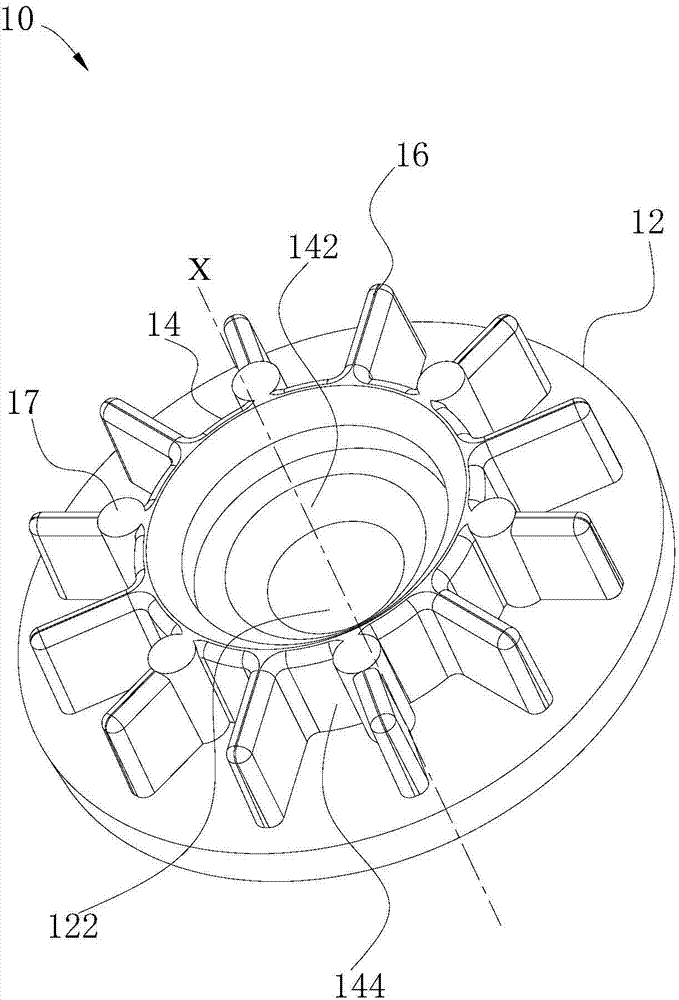

Perforating gun for horizontal well

ActiveCN110671081AReduce the chance of burstingReduce card encountersFluid removalPhysicsEngineering

The invention discloses a perforating gun for a horizontal well, and belongs to the technical field of oil exploration equipment. The gun comprises a gun body, a gun carrier and a booster tube. The gun body is in a cylindrical tubular shape, the surface of the gun body is provided with preset holes corresponding to perforating bullets in position, the head segment and the tail segment of the gun body are correspondingly provided with a gun head and a gun tail, the two ends of the gun carrier are fixed into the gun body through a positioning ring, the center line of the gun carrier and the center line of the gun body coincide, perforating bullets are arranged on the gun carrier, the booster tube is arranged on the gun head of the gun body, and is connected with a detonating cord, the positioning ring comprises a ring body, the ring body is provided with a positioning hole, the positioning hole and the axis line of the ring body are inclined, the inner wall of the gun body is provided with a blind hole corresponding to the positioning hole, a positioning ring is matched with the blind hole through a fastening part to fix the gun carrier in the gun body, and the blind hole is filled with a packing material in advance. The perforating position precision and alignment of the perforating direction and the preset hole can be effectively ensured, the friction resistance of the perforating gun can be reduced, a compensation type detonation transmission is designed, and fail transmission of perforating can be avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

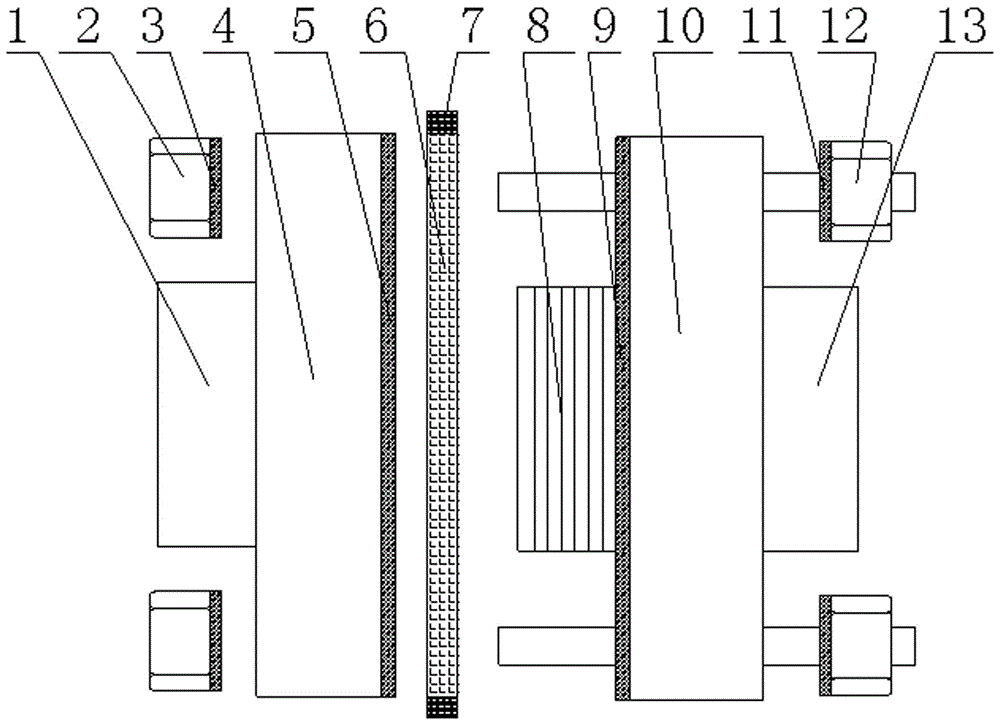

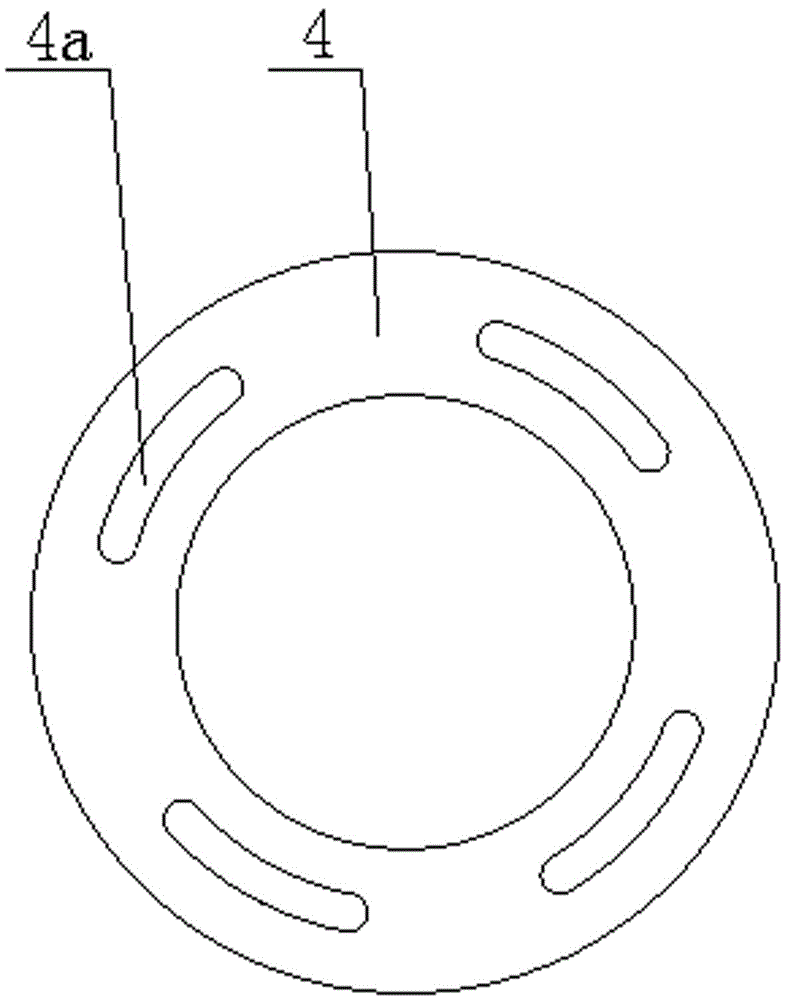

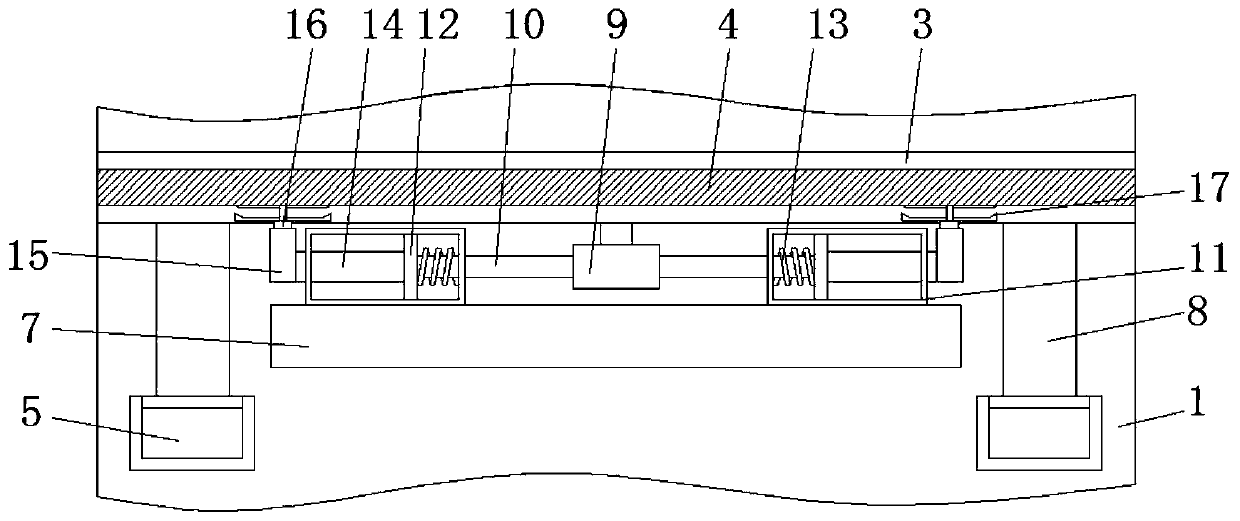

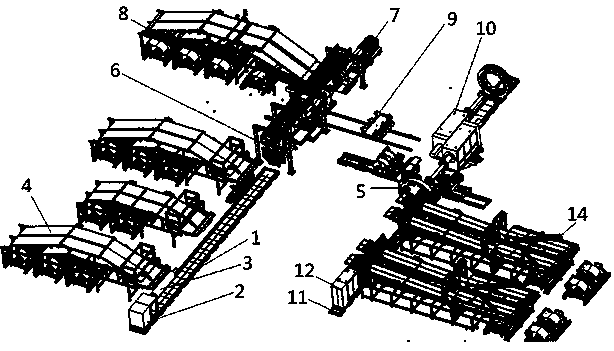

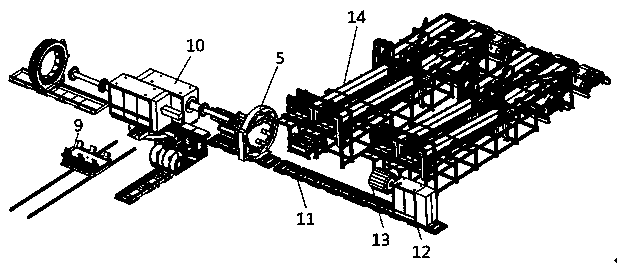

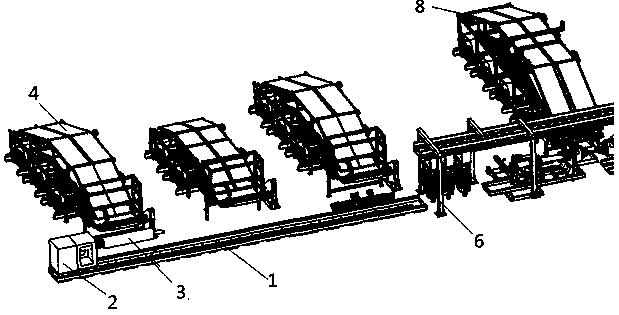

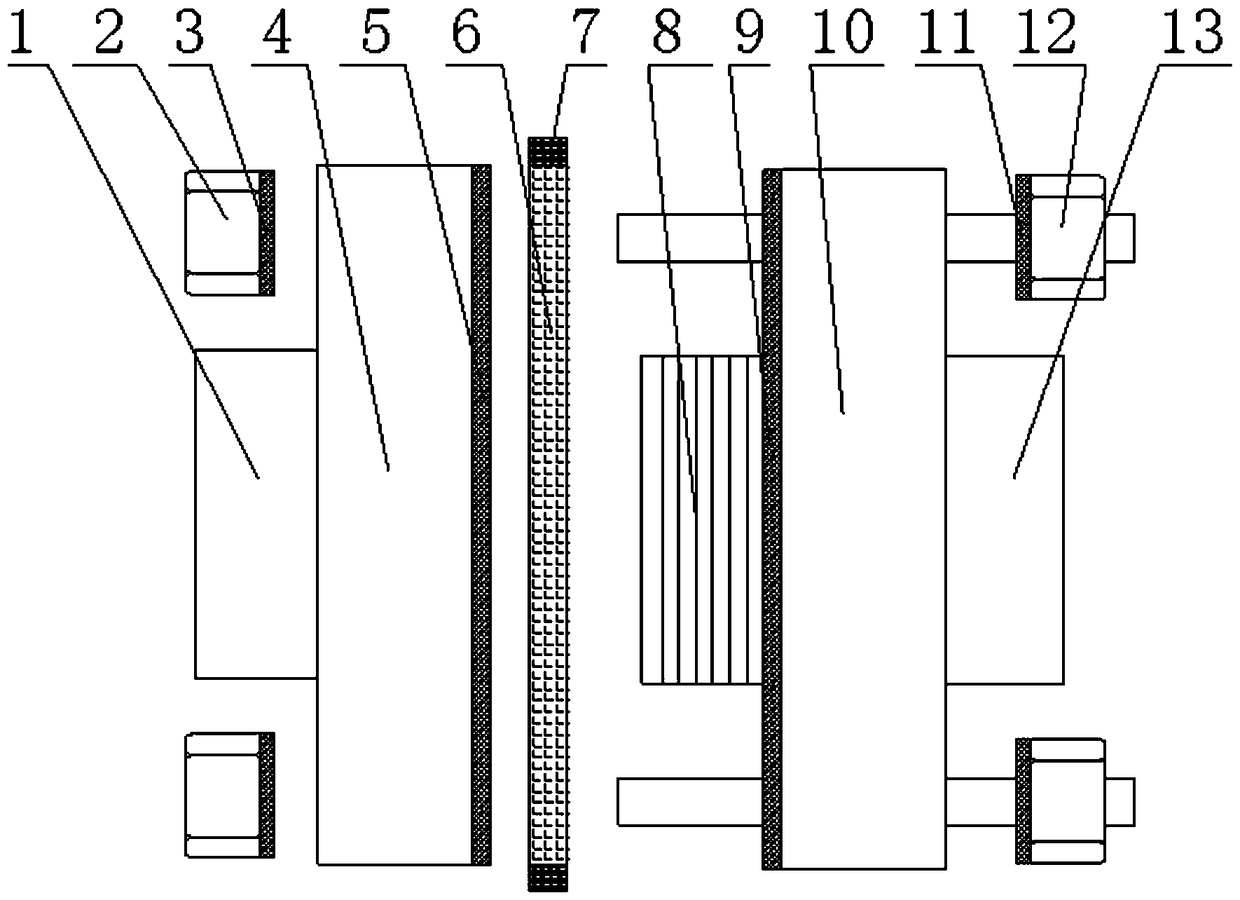

All-steel engineering tyre twice method double-station integrated forming machine

PendingCN111086252AReduce the chance of burstingEven contactTyresTransfer mechanismCylinder (engine)

The invention relates to an all-steel engineering tyre twice method double-station integrated forming machine and belongs to the technical field of tyre processing equipment. The all-steel engineeringtyre twice method double-station integrated forming machine comprises a first-section tyre transfer device and a second-section tyre transfer device; a transfer trolley and a rotating mechanism are arranged between the two tyre transfer device; the first-section tyre transfer device comprises a first rail and a tyre body drum machine case; a tyre body drum is arranged on the tyre body drum machine case; a plurality of supply racks for feeding for the tyre body drum are arranged on one side of the first rail; a tyre body cylinder transfer mechanism is arranged at the tail end of the first rail; a second supply rack is arranged on the side surface of the tyre body cylinder transfer mechanism; the second-section tyre transfer device comprises a second rail and a belt drum machine case; a belt drum is arranged on the belt drum machine case; a plurality of belt supply racks are arranged on one side of the second rail; and a belt transfer ring is arranged close to one belt supply rack positioned at the tail end. The all-steel engineering tyre twice method double-station integrated forming machine can reduce human cost, improve efficiency and improve the quality of the tyre.

Owner:烟台富瑞达机械有限公司

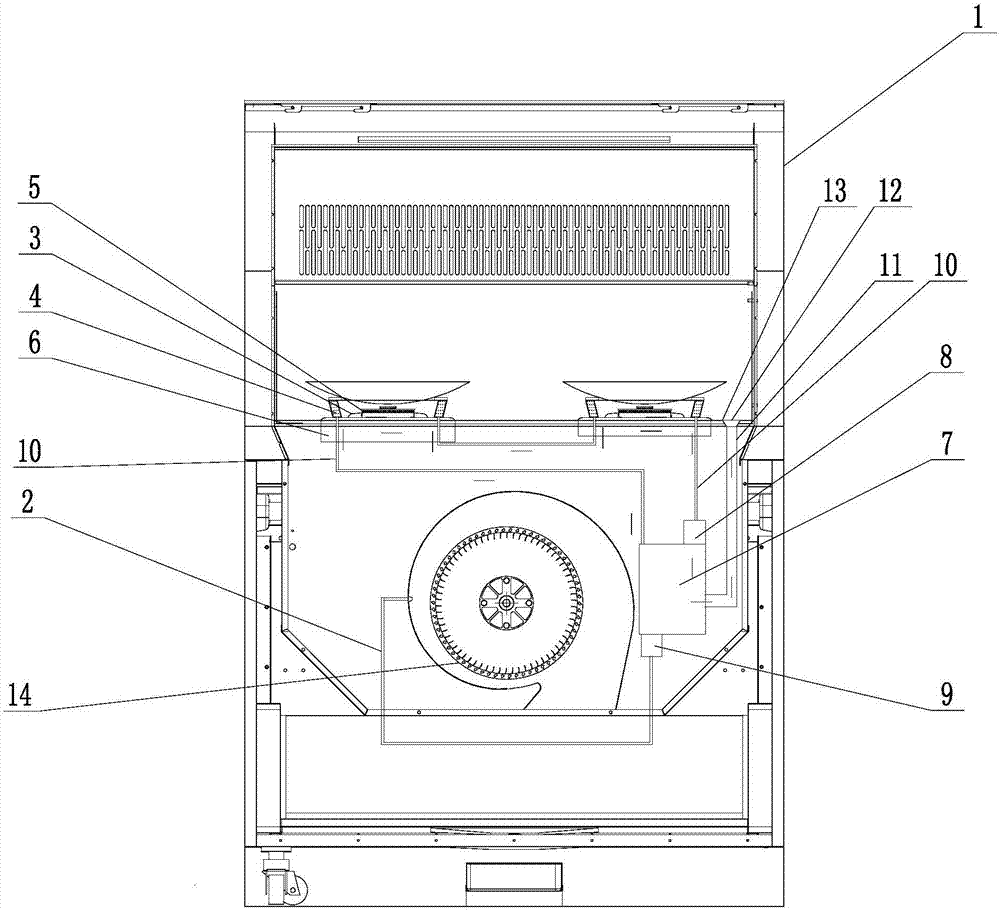

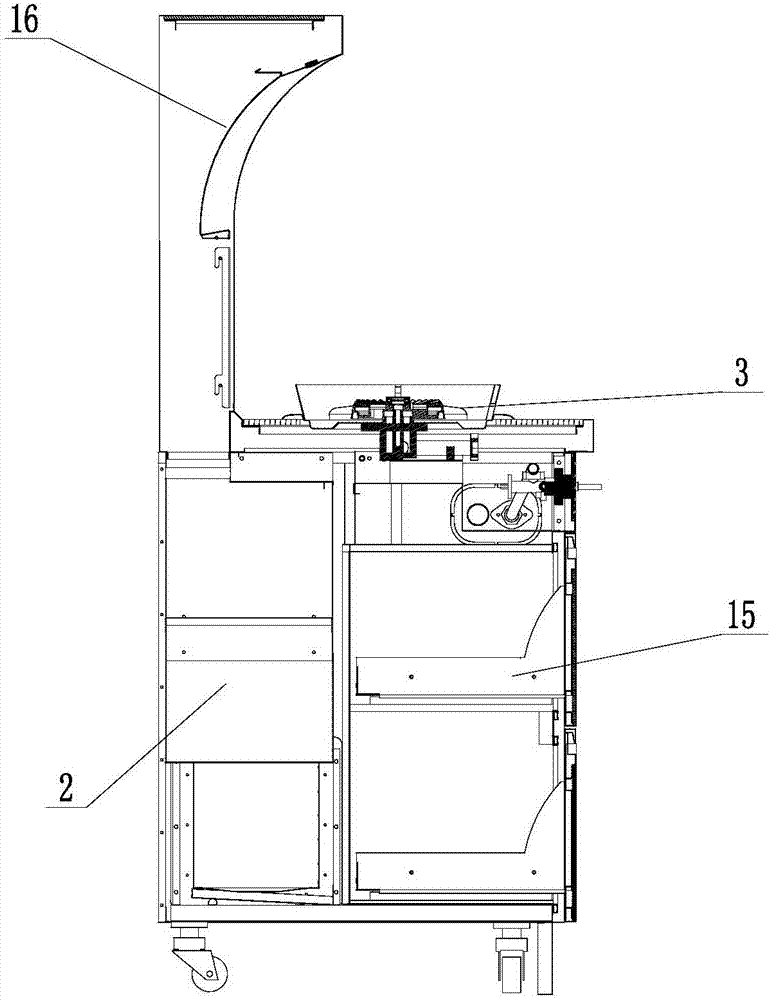

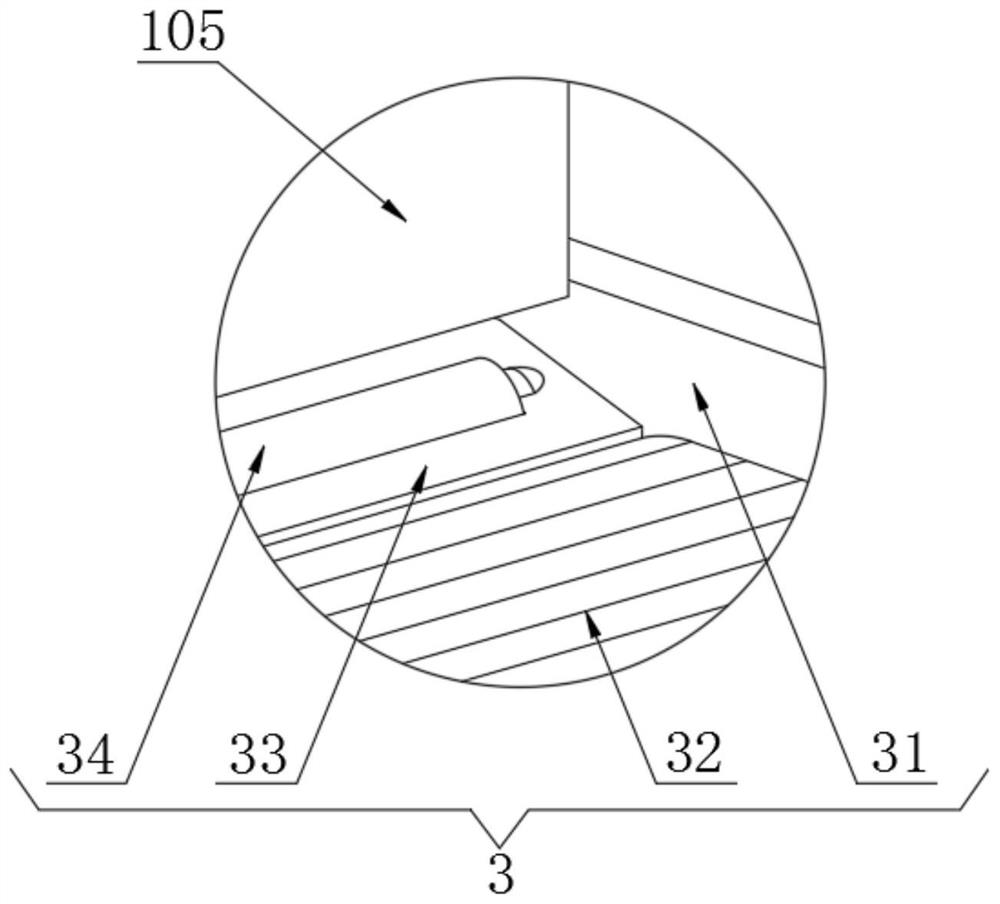

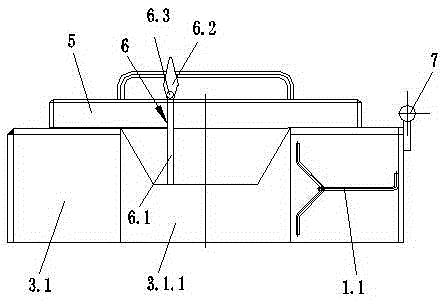

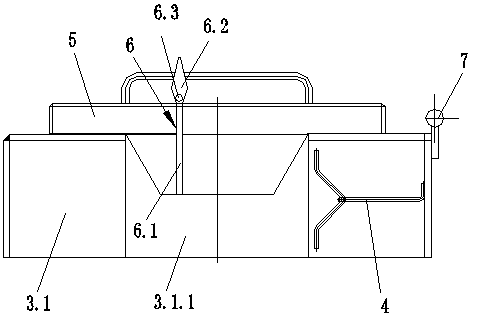

Hot water cleaning structure of integrated stove range hood

PendingCN107044670AGood cleaning effectReduce wasteLighting and heating apparatusWater heating stoves/rangesProcess engineeringCooker

A hot water cleaning structure of an integrated stove range hood comprises an integrated stove body; the lower portion of the integrated stove body is a range hood assembly, and the upper portion of the integrated stove body is a cooker assembly; the cooker assembly is mainly composed of a pot holder, a burner and a soup pan, and the cooker assembly is characterized in that annular grooves are formed in the pot holder, the soup pan and / or the inside of the burner; the pot holder, the soup pan and / or the burner are connected with a water tank; and a water pump A and a water pump B are respectively arranged on the upper and lower sides of the water tank. According to the hot water cleaning structure of the integrated stove range hood, the annular grooves are formed in the cooker assembly and connected with the water tank, the water tank conducts self-absorption circulation through the water pump A, an excessive part of the flame in the cooker is utilized to heat flowing water in the annular grooves, the heated water is sprayed onto a wind wheel by the water pump B for cleaning, high temperature and high pressure cleaning is achieved, and compared with the prior art, the cleaning effect is better.

Owner:ZHONGSHAN HEME ELECTRICAL APPLIANCES & GAS COOKERS

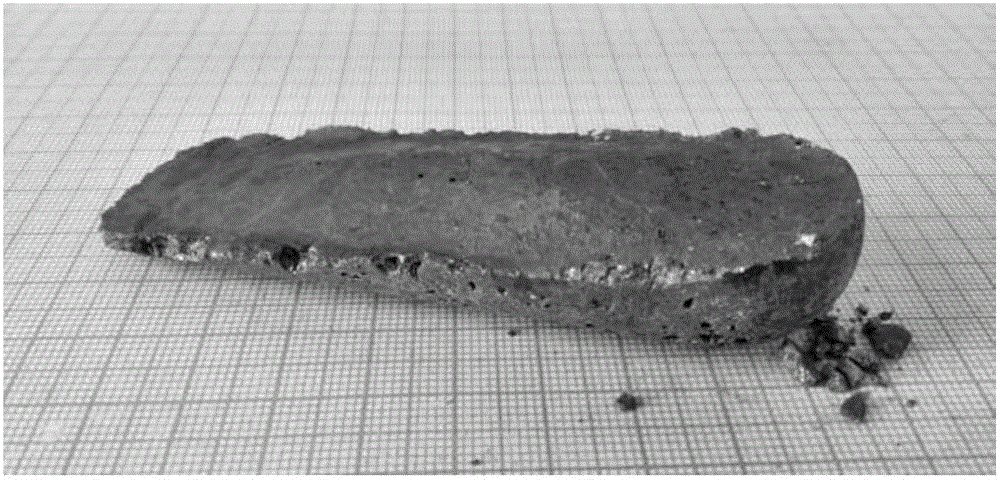

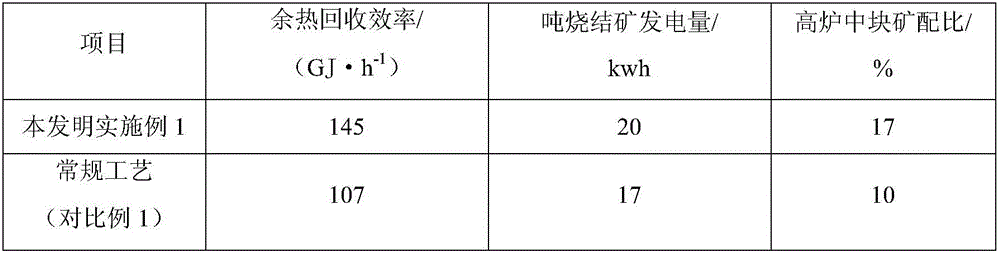

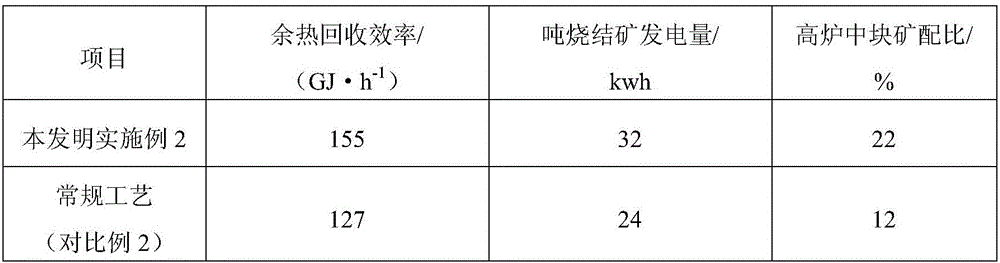

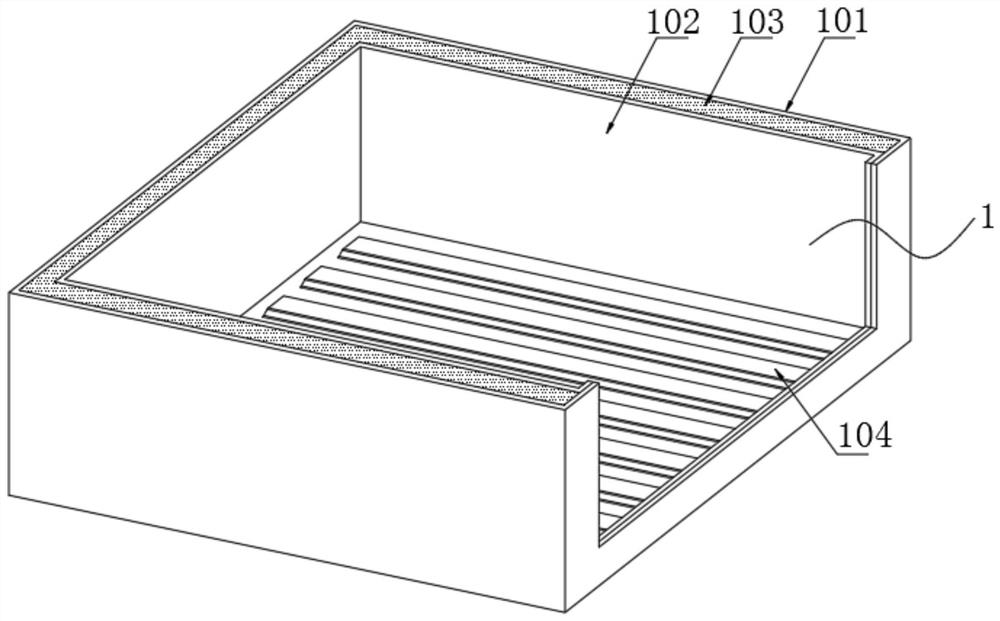

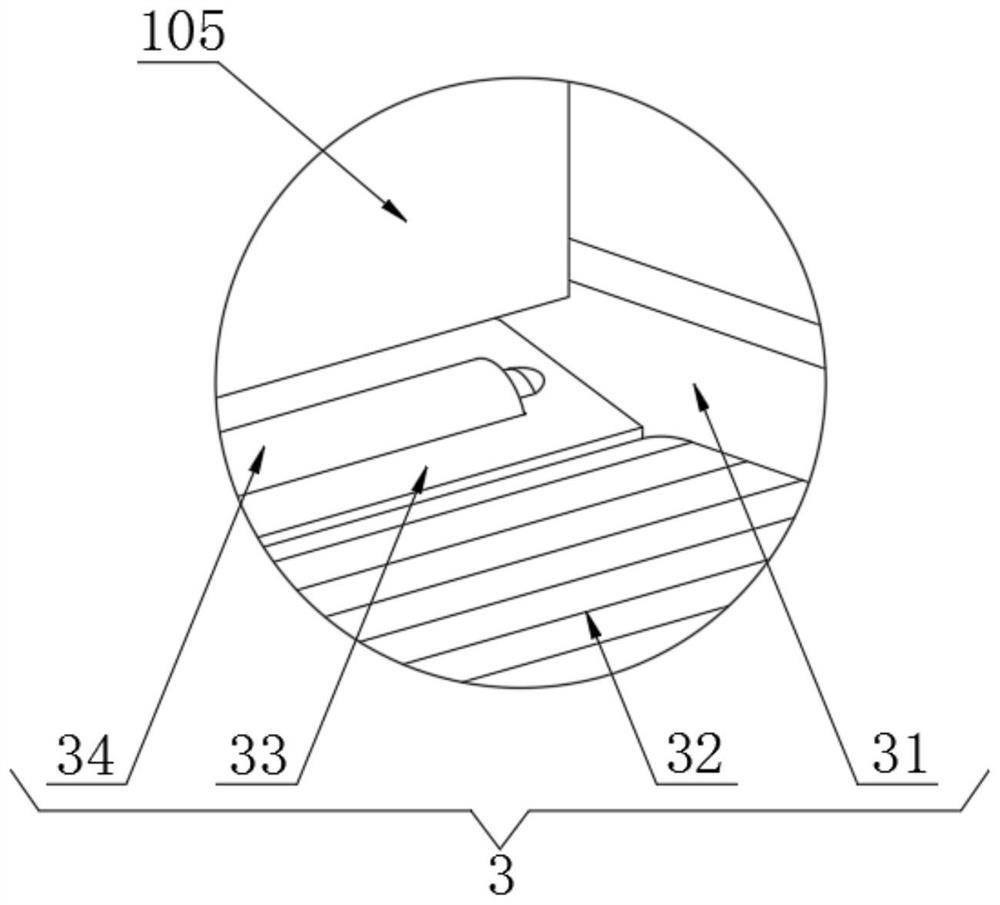

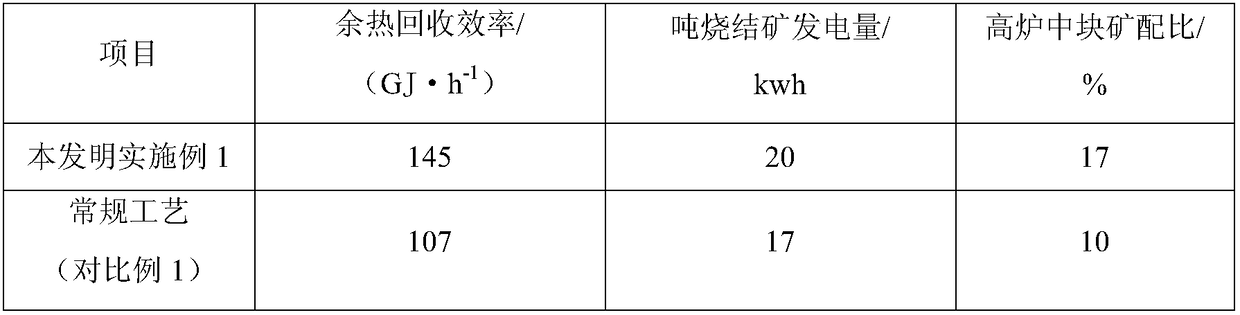

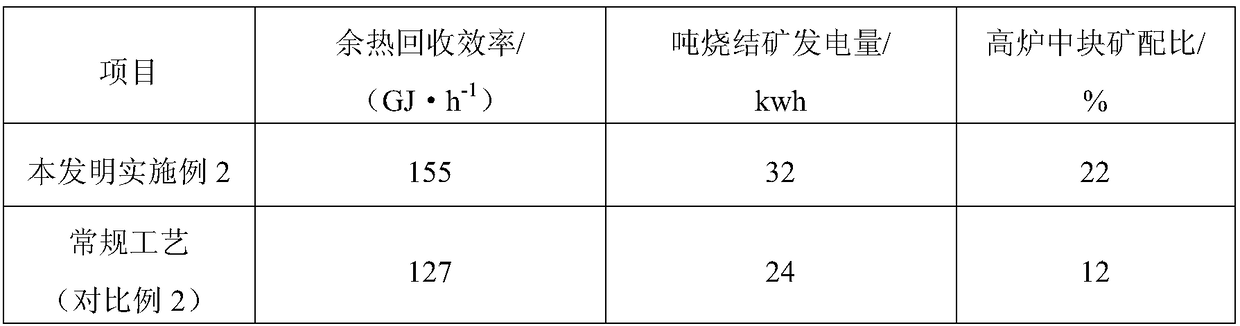

Cooling method for super-thick material layer sintered ore adopting pre-sintering

The invention discloses a cooling method for super-thick material layer sintered ore adopting pre-sintering. In the pre-sintering process, the material layer thickness in the first time of distribution is 500-900 mm, the second time of distribution is carried out after pre-sintering is conducted for 8-40 min, the distribution thickness in the second time of distribution is 100-650 mm, and the total material layer thickness after the two times of distribution is higher than or equal to 900 mm. A sintered ore separating device is arranged at the tail discharging position of a belt type roasting machine, sintered ore which is higher than or equal to 500 DEG C in temperature and provided with a red fire layer and surplus sintered ore are separated into two parts, the sintered ore with the temperature lower than 500 DEG C is cooled on a ring cooling machine, and the sintered ore with the temperature higher than or equal to 500 DEG C and natural lump ore with the granularity being 10-50 mm are placed in a vertical cooling furnace to be cooled. Screening is conducted after cooling, the sintered ore with the granularity being higher than or equal to 5 mm directly enters a blast furnace to be smelted, and the sintered ore with the granularity being smaller than 5 mm returns to be sintered. By means of the cooling method, the waste heat recovery efficiency of the sintered ore is greatly improved, and the problem that the natural lump ore explodes in the blast furnace is solved.

Owner:ANGANG STEEL CO LTD

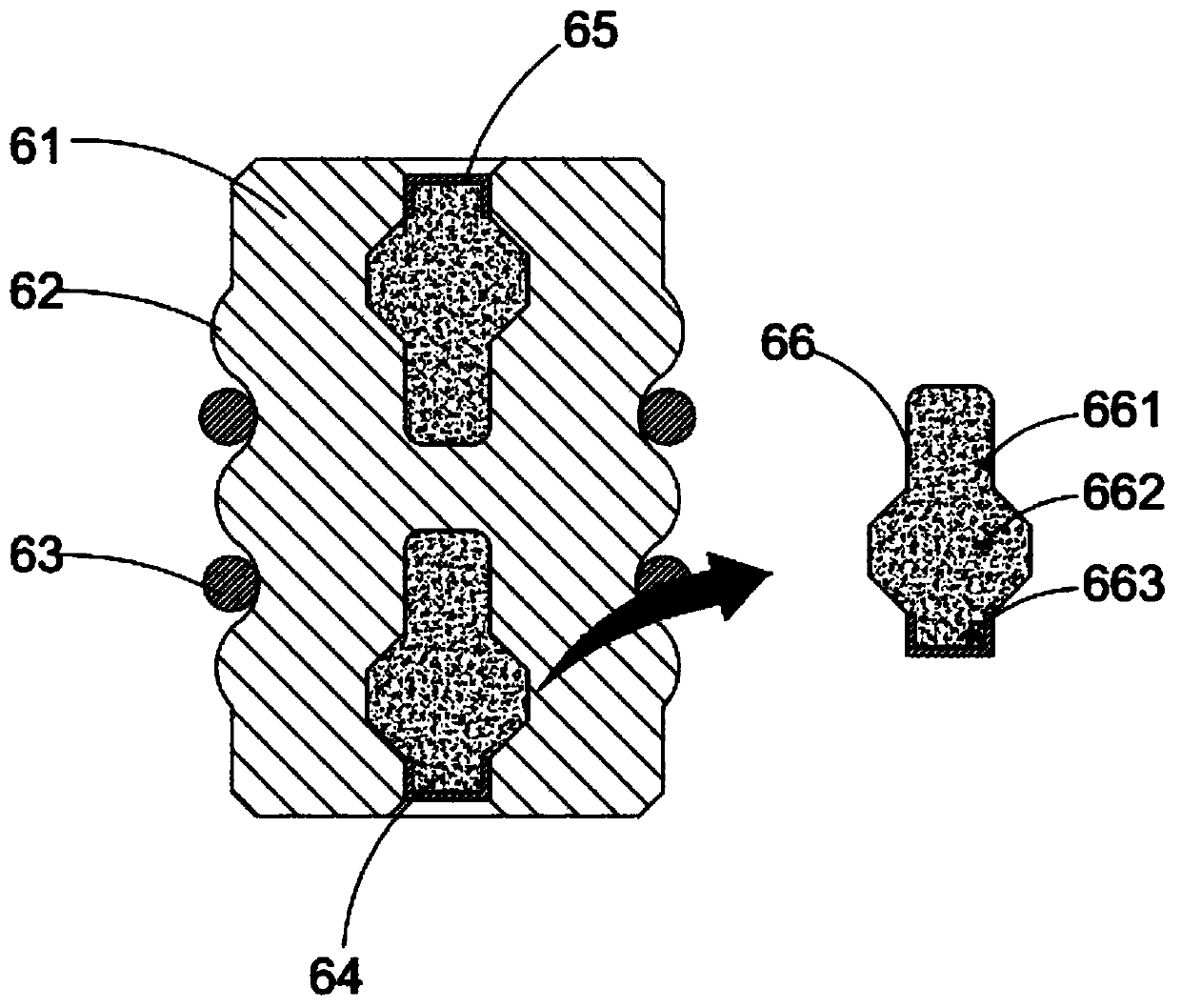

High reliability PTC thermistor

ActiveCN109686515AImprove stabilityReduce the chance of burstingOther resistor networksResistor cooling/heating/ventillationElectrical resistance and conductanceEngineering

The invention relates to a high reliabiliy PTC thermistor comprising a PTC chip, a first electrode attached to the upper surface of the PTC chip, a second electrode attached to the lower surface of the PTC chip and an electrode lead soldered to the surfaces to the first electrode and the second electrode. The outside of a solder joint of the PTC chip, the first electrode, the second electrode andthe lead is wrapped with an encapsulation layer from the inside to the outside. A gap is left between the PTC chip and the encapsulation layer. The thermistor improves the capability to withstand external impact by means of the encapsulation layer. By means of an explosion-proof layer, a cooling layer and a moisture-proof layer, the thermistor can be better protected, the capability to withstand the external impact is improved, and better stability can be achieved.

Owner:苏州团芯终端有限公司

A fast and firm flange

ActiveCN106224667BQuick and efficient installationEasy to installFlanged jointsFoundry mouldsEngineeringFlange

Owner:YANCHENG FENGGONG MACHINERY

A multi-pipe connection flange

ActiveCN106247058BQuick and efficient installationGuaranteed tightnessFlanged jointsPipe elementsMaterial resourcesFlange

Owner:YANCHENG FENGGONG MACHINERY

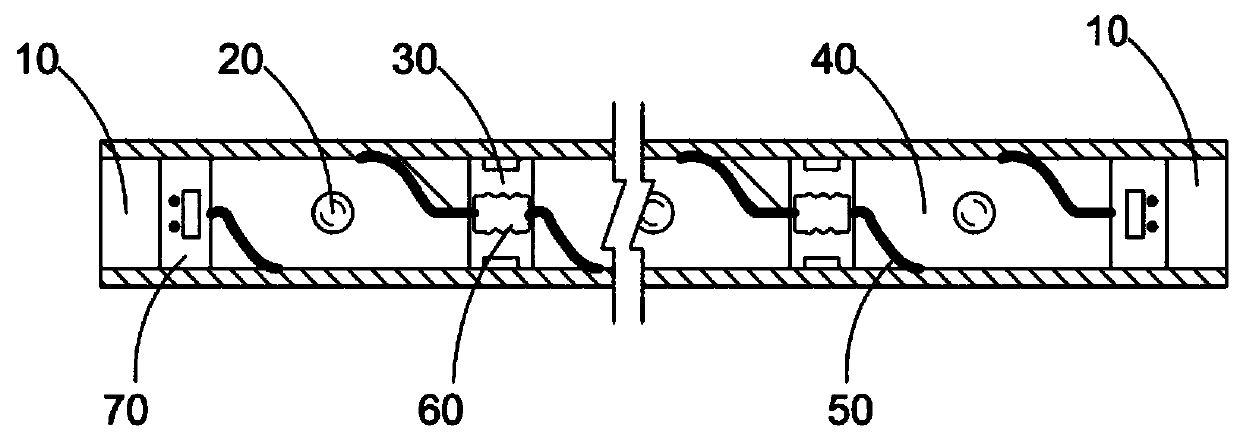

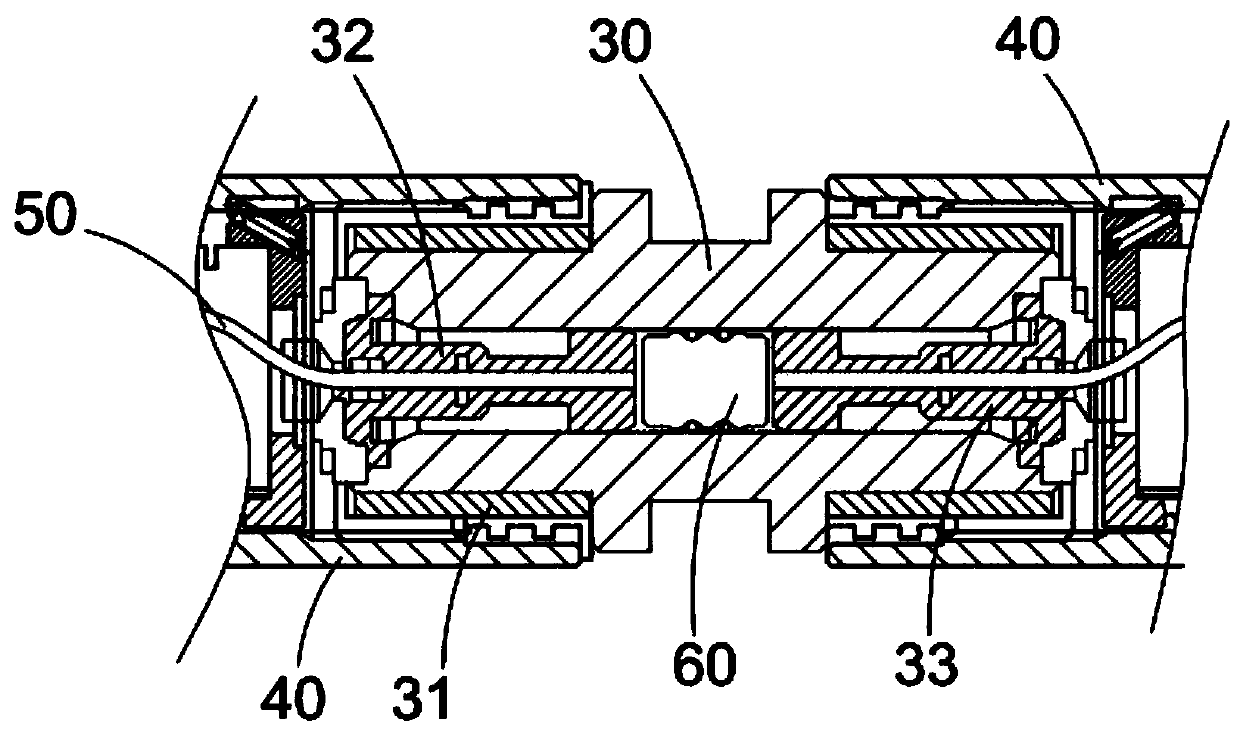

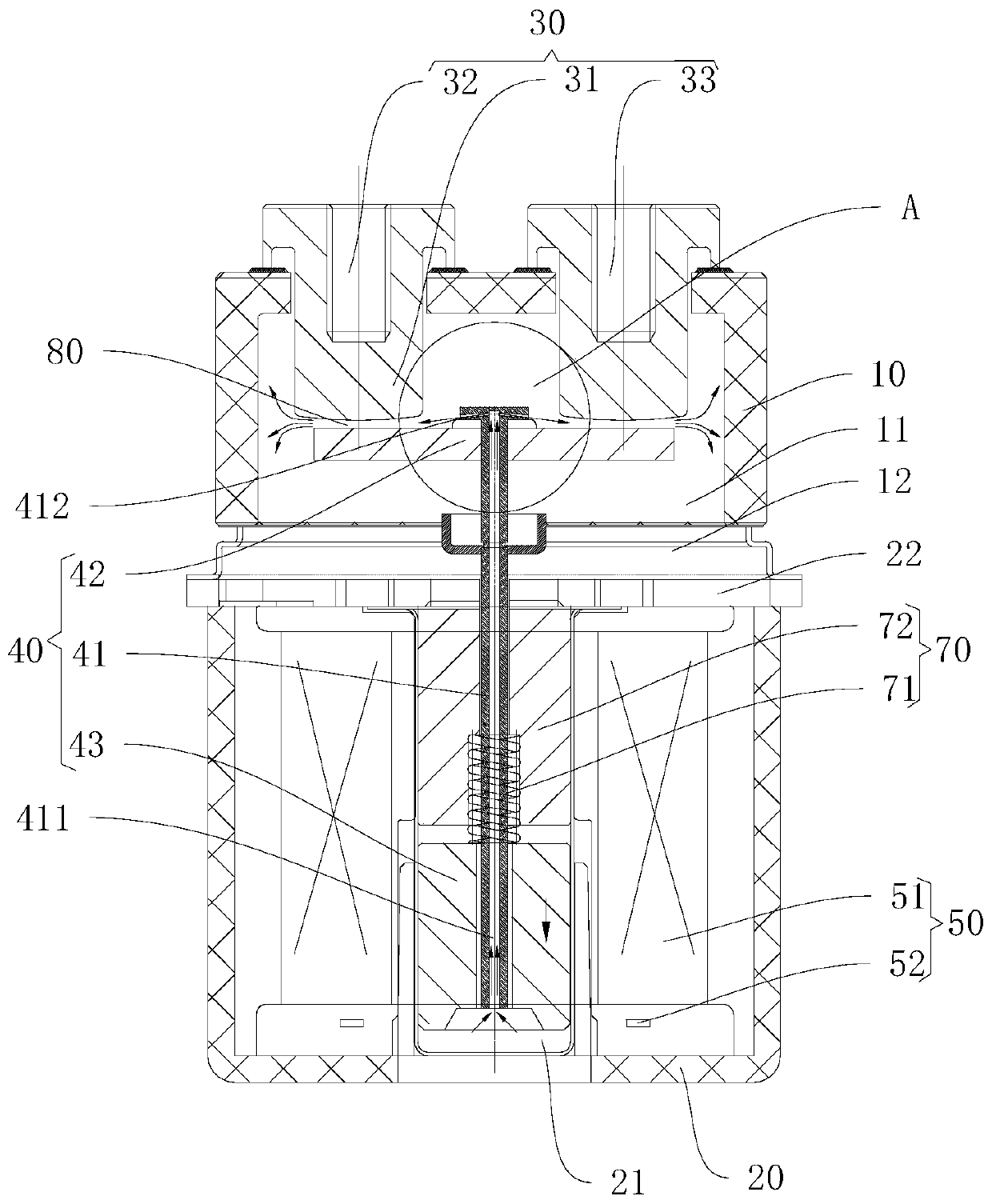

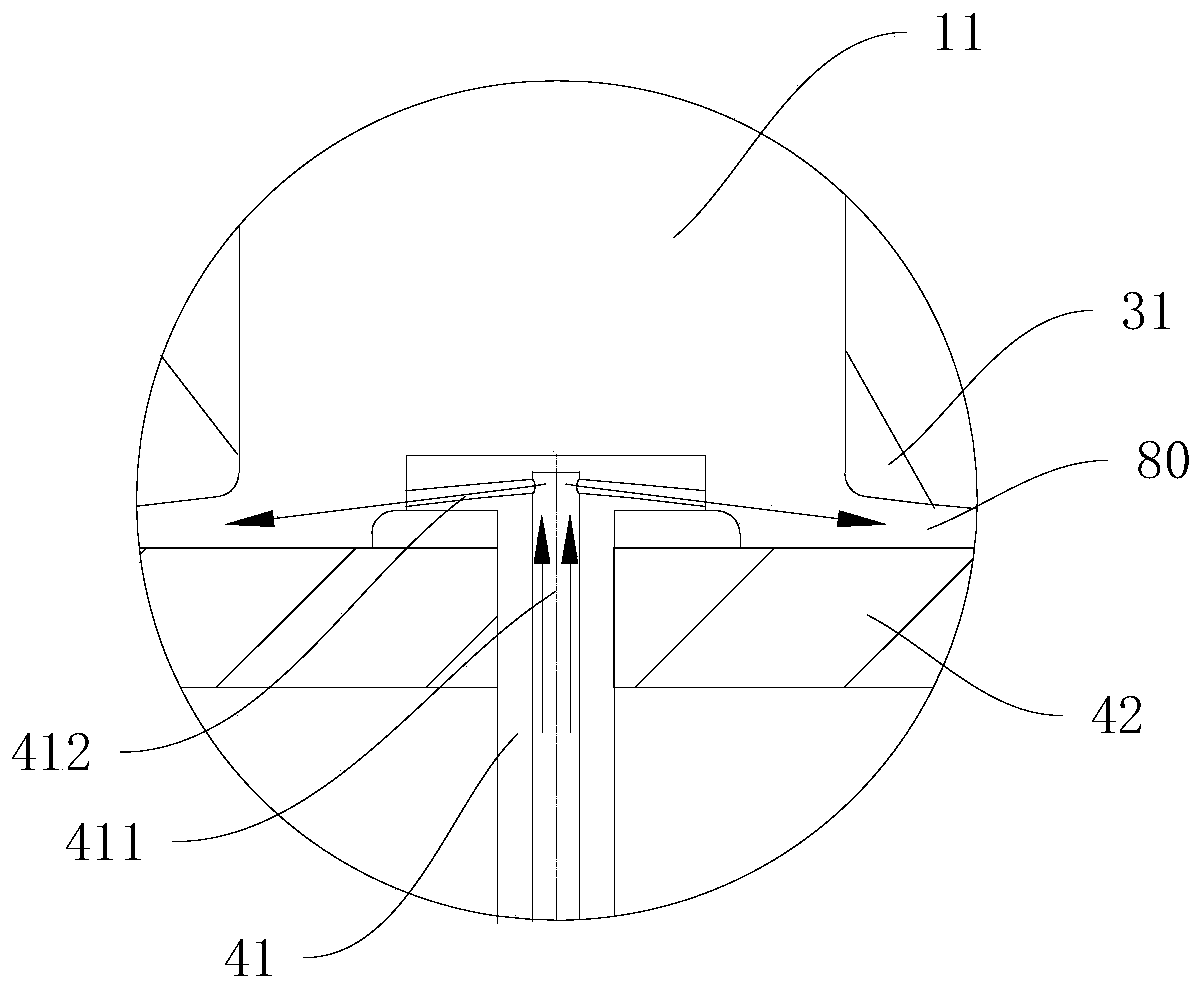

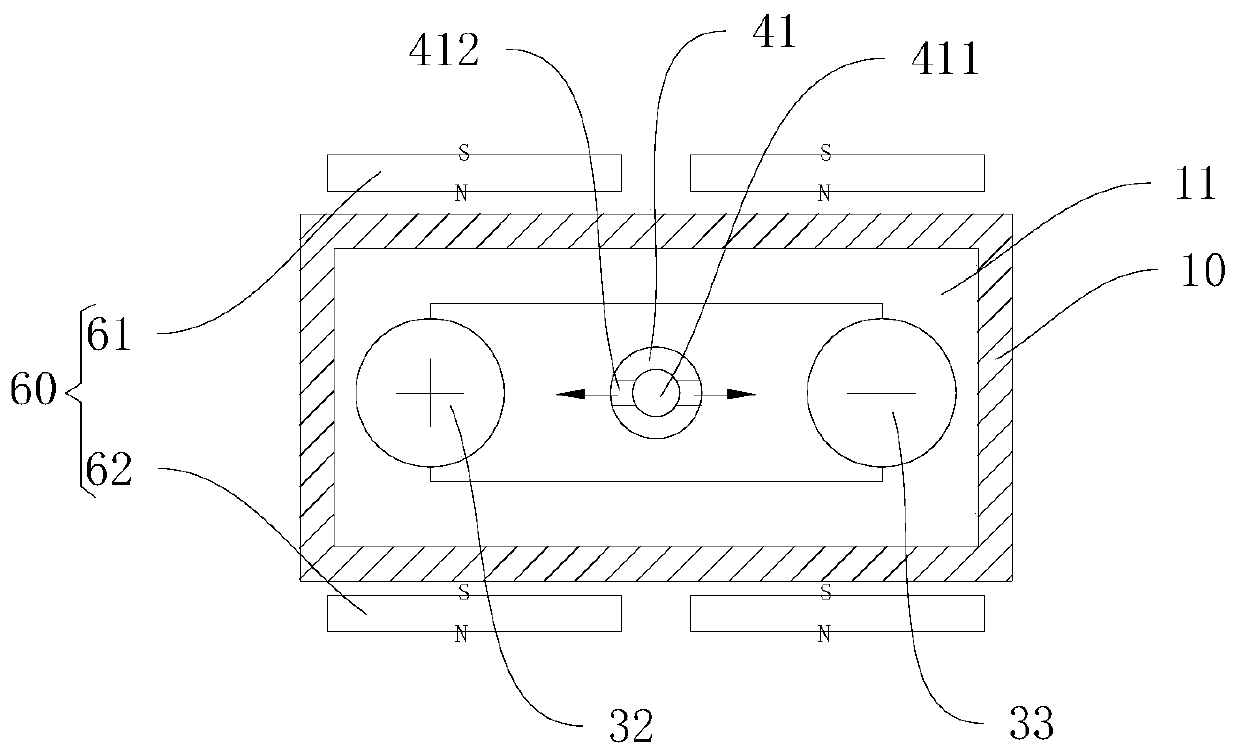

relay

ActiveCN108807043BTurn fasterImprove liquidityElectric switchesElectromagnetic relay detailsClosed chamberEngineering

Disclosed is a relay. The relay comprises a first frame body, a second frame body, a lead out terminal assembly, a pushing assembly, and a resetting assembly. A first closed chamber is disposed within the first frame body. A second closed chamber is disposed within the second frame body. The lead out terminal assembly comprises two stationary contacts disposed in the first closed chamber. The pushing assembly comprises a hollow pushing rod, a movable contact plate, and a movable iron core. The movable contact plate is fixed on one end of the hollow pushing rod, and is located within the first closed chamber, and a gap is formed between the movable contact plate and the stationary contacts. The movable iron core is disposed on the other end of the hollow pushing rod, and is located within the second closed chamber. The hollow pushing rod is provided with a gas vent conduit for connecting the first closed chamber and the second closed chamber and a nozzle in communication with the gas vent conduit, the nozzle being located above the movable contact plate. The relay has a better arc-extinguishing effect and control of a controlled circuit is more sensitive.

Owner:BYD CO LTD

A kind of sapphire chip and metal active sealing method

ActiveCN103949742BGuaranteed wall thicknessReduce the chance of burstingSoldering apparatusThermal dilatationTitanium zirconium

The invention provides an active sealing method between sapphire sheet and metal with low welding temperature, high efficiency, good reliability and low cost. It eliminates the defects of long, complex and time-consuming intermediate processing, shortens the total welding time, and improves production efficiency; avoids the defects that the solder sheet must be processed into precise dimensions and requires extremely high flatness, and directly uses active titanium zirconium copper Nickel solder; the wall thickness of the sealing part of the metal part is made relatively thin to reduce the thermal stress caused by the reaction of the thermal expansion of the sapphire sheet to the extrusion of the metal part during welding, and reduce the probability of the sapphire sheet bursting; at the same time, the temperature of the welding in the vacuum atmosphere is less than 1000 It can be completed at one time at ℃, and the requirements for welding equipment are extremely low. The welding reliability and yield rate of the product are high. The airtightness is good when baked at 560℃ for 36 hours, which can ensure the airtightness requirements of ultra-high frequency electric vacuum devices.

Owner:XI AN JIAOTONG UNIV +1

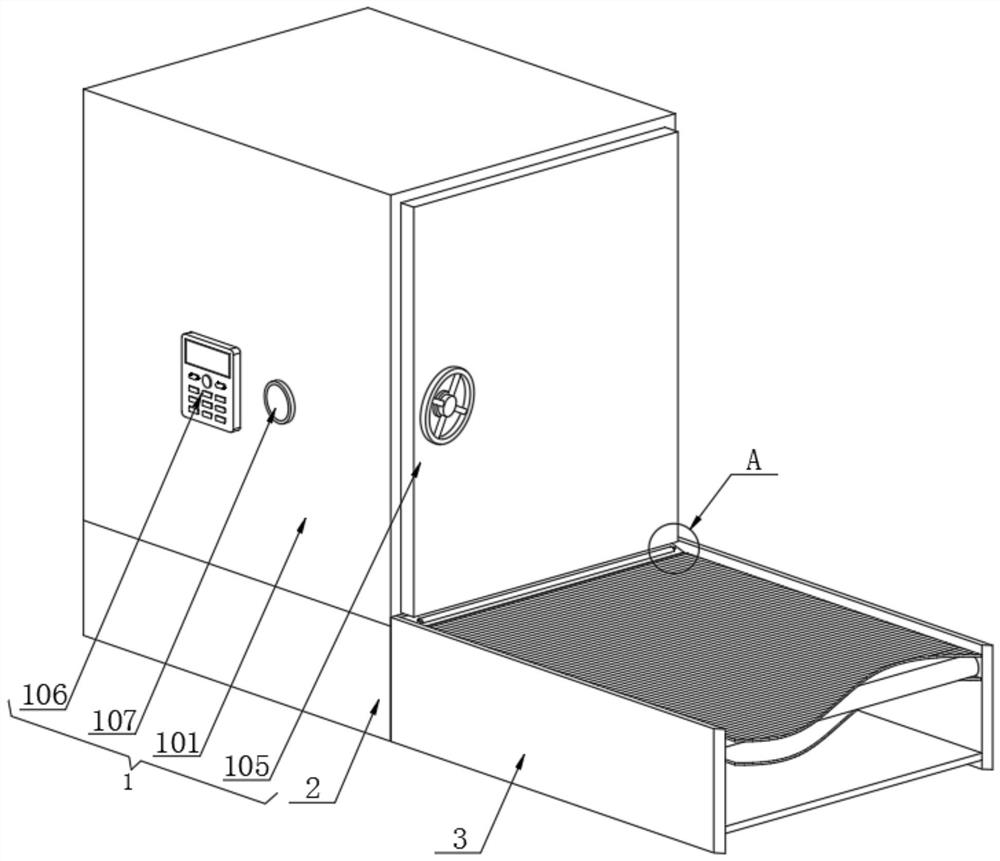

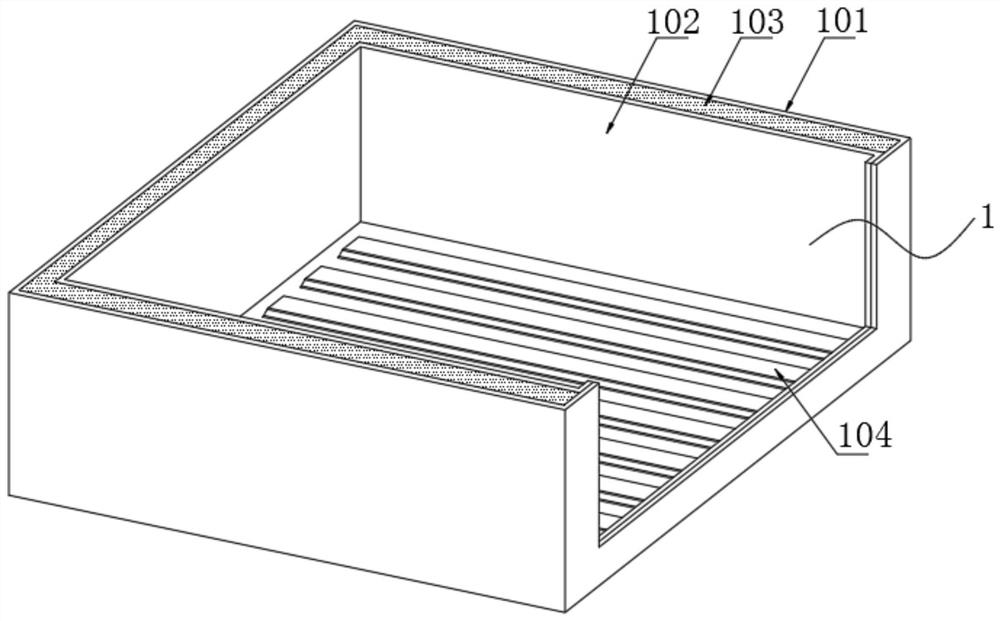

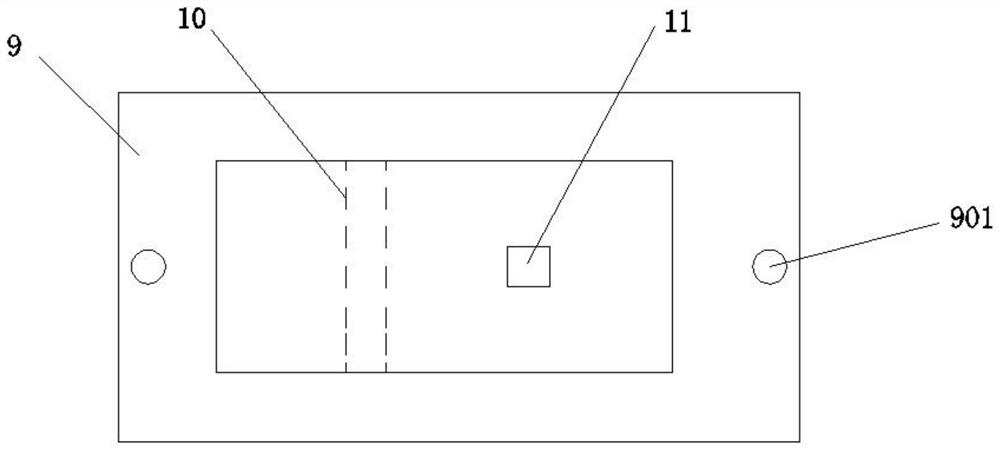

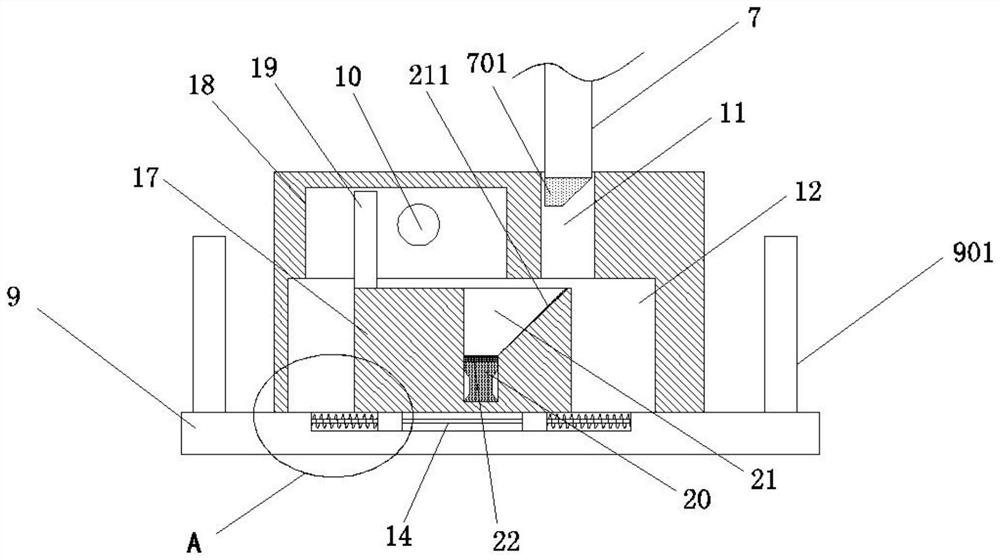

Support base, door body assembly and electrical cook appliance

The invention discloses a support base, a door body assembly and an electrical cook appliance. The door body assembly comprises a door body panel and a handle, the door body panel comprises a first surface and a second surface which are opposite, the handle is arranged at the first surface, and the support base comprises a base and a support part. The base is arranged at the second surface, and is provided with through holes. The support part extends axially from the base, the support part and the door body panel are arranged at the two opposite sides of the base, the support part surrounds the through holes, and the distances between the inner surfaces of the through holes and the outer surface of the support part are larger than or equal to 4.5 mm and smaller than or equal to 5.5 mm. In the support base, the door body assembly and the electrical cook appliance, by reducing the distances between the inner surface of the through hole and the outer surface of the support part, the wall thickness of the support part can be further reduced, so that when the support body is injection-molded, the flatness of the base is better, when the base is combined with the door body assembly, the stress of the door body panel is more uniform, and the probability that the door body panel bursts since the door body panel is under non-uniform stress is lowered.

Owner:WUHU MIDEA KITCHEN APPLIANCES MFG +1

Flame-retardant plate flame-retardant processing technology based on macromolecular flame retardant

InactiveCN113844065AMultiple efficiencyImprove flame retardant effectFlat articlesProcess engineeringFire retardant

The invention discloses a flame-retardant plate flame-retardant processing technology based on a macromolecular flame retardant, and relates to the technical field of plate processing. A high-pressure explosion-proof box is included, a machine box is fixedly connected with the bottom of the high-pressure explosion-proof box, and a feeding mechanism is fixedly connected with the right side of the machine box. According to the flame-retardant plate flame-retardant processing technology based on the macromolecular flame retardant, a pressure pump is arranged to be matched with related pipelines, the high-pressure explosion-proof box can be pressurized, internal air is promoted to circularly flow, heating is carried out in the process, the flame-retardant plate can be uniformly heated and dried, the probability of explosion of the flame-retardant plate can be reduced through pressurization, then the atomized flame retardant is sprayed into the high-pressure explosion-proof box, and the fully dried flame-retardant plate can quickly absorb the flame retardant; and meanwhile, part of steam is mixed in the atomized flame retardant, the fumigation effect can be achieved, the flame retardant can penetrate into the flame-retardant plate more deeply in cooperation with the pressurization effect, and compared with simple soaking, more flame retardants can be absorbed, and the efficiency is higher.

Owner:于焕

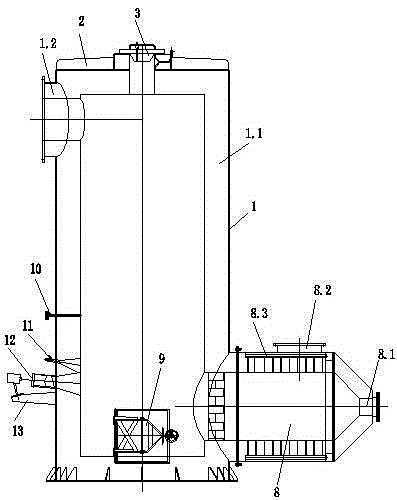

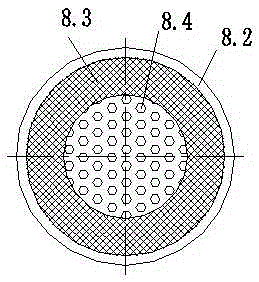

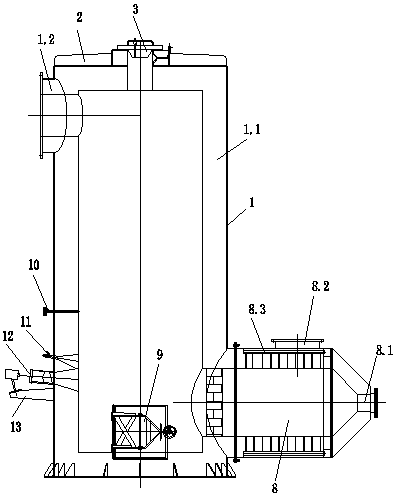

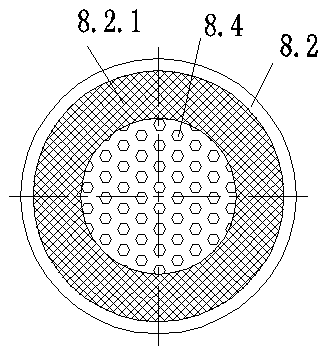

Secondary combustion furnace

ActiveCN105387714AReduce the chance of burstingImprove combustion efficiencyFurnace safety devicesVertical furnacesCombustionBarrel Shaped

A secondary combustion furnace comprises a vertically-arranged barrel-shaped furnace body. An anti-explosion end cover is arranged at the top end of the furnace body and made of a steel plate with the thickness being 10 cm. An anti-explosion opening is formed in the center of the anti-explosion end cover. An anti-explosion device is arranged in the anti-explosion opening and comprises a base embedded in the anti-explosion opening. A steel hook is arranged in the side wall of the base and fixedly connected with the anti-explosion end cover. A central hole is formed in the center of the base. An anti-explosion cover is arranged on the central hole. The tail end of the anti-explosion cover is inserted in the central hole. The anti-explosion cover is provided with a pressure relief pipe which comprises a vertical section and a conical amplification section. A sealing ball is arranged in the conical amplification section. The secondary combustion furnace is simple in structure, automatic pressure relief is conducted, the furnace body is effectively protected against explosion, and combustion is sufficient.

Owner:JIANGSU LIYU ENVIRONMENTAL TECH

A high-efficiency sealing flange

ActiveCN106247048BQuick and efficient installationEasy to installEngine sealsFlanged jointsScrew threadFlange

The invention relates to an efficient sealing flange which comprises a first flange body, a second flange body, a round filter screen, fastening bolts and nuts. The corresponding positions of the first flange body, the second flange body and the round filter screen are each provided with arc-shaped holes. Each fastening bolt sequentially penetrates the corresponding arc-shaped hole of the first flange body, the corresponding arc-shaped hole of the round filter screen and the corresponding arc-shaped hole of the second flange body to be in threaded connection with the corresponding nut. An annular connecting block is arranged on the side, close to the first flange body, of the second flange body. An external thread is manufactured on the outer side of the annular connecting block. A connecting groove is formed in the first flange body, and an internal thread is manufactured on the inner wall of the connecting groove. The surfaces of the opposite sides of the first flange body and the second flange body are covered with a first rubber sealing layer and a second rubber sealing layer correspondingly. The side, in contact with the first flange body, of each fastening bolt and the side, in contact with the second flange body, of each nut are covered with a third rubber sealing layer and a fourth rubber sealing layer correspondingly. The edge of the outer side of the round filter screen is covered with a rubber sealing ring. According to the efficient sealing flange, by means of the cooperation of the four rubber sealing layers, it is guaranteed that the sealing performance of the flange is efficient and stable, and the flange is prevented from leaking at the connecting position.

Owner:YANCHENG FENGGONG MACHINERY

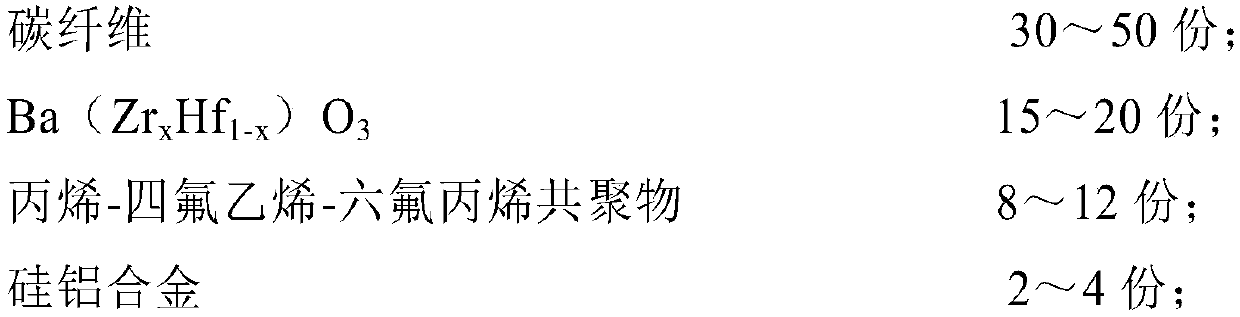

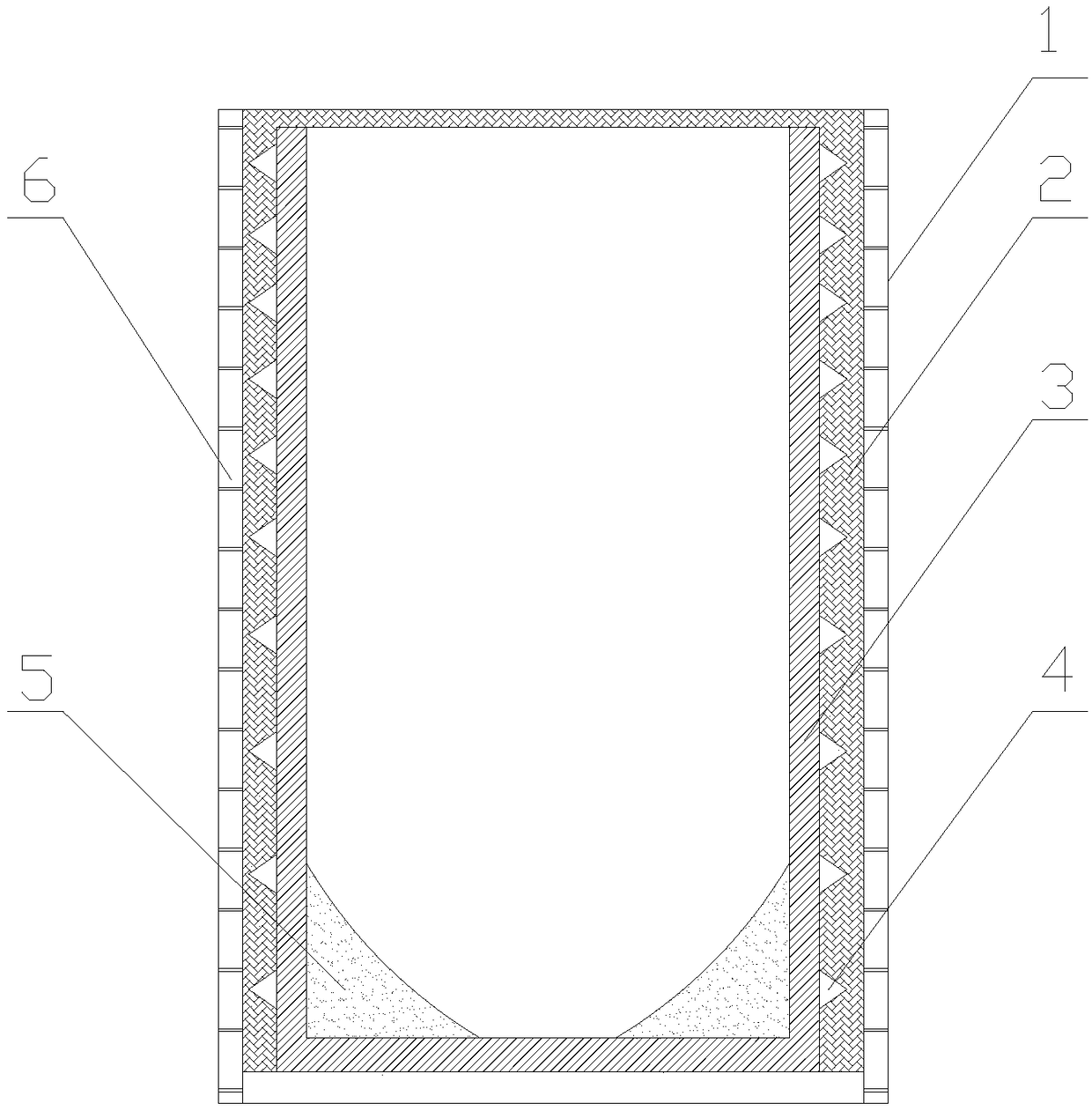

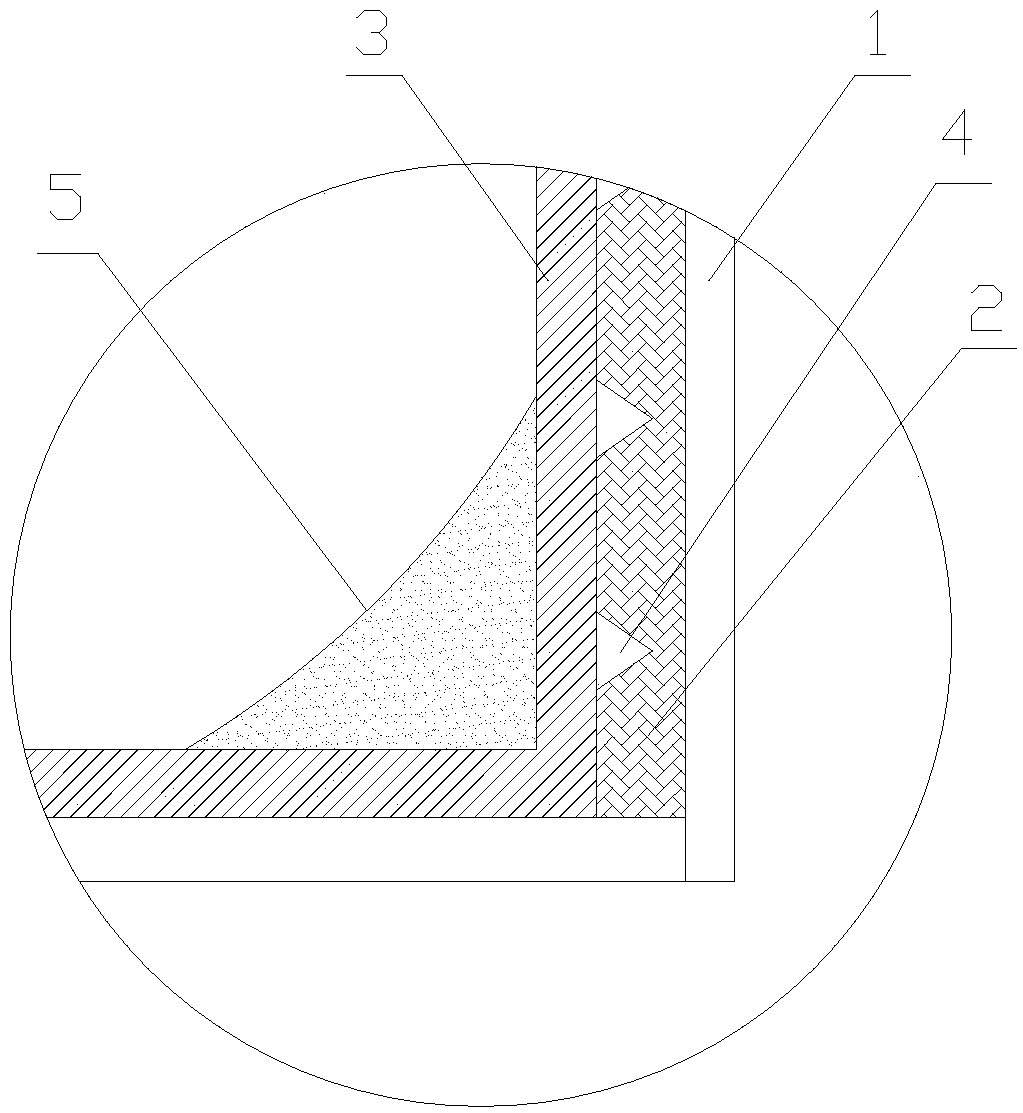

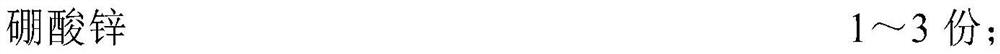

High-stability aluminum alloy melting furnace for cold-chamber die-casting machine

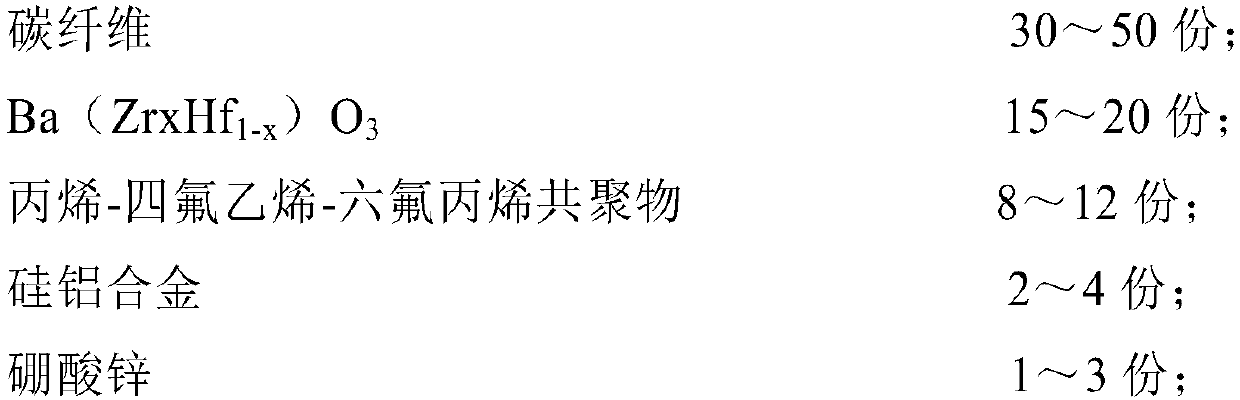

PendingCN108800940AImprove mechanical propertiesImprove high temperature resistanceCeramic shaping apparatusCement mixing apparatusBurstingInsulation layer

The invention discloses a high-stability aluminum alloy melting furnace for a cold-chamber die-casting machine, and belongs to the technical field of die-casting machine devices. The high-stability aluminum alloy melting furnace comprises a furnace body unit, a heating unit and a control unit. The high-stability aluminum alloy melting furnace is characterized in that the furnace body unit comprises a furnace wall, a reinforcing layer, an insulation layer and a bottom bracket, refractory bricks are stacked between the furnace wall and the reinforcing layer, high-temperature-resistant cement isused for caulking and fixing between every two adjacent refractory bricks, reinforcing rings are arranged in the reinforcing layer, the insulation layer is arranged inside the reinforcing layer, the bottom bracket is arranged in the insulation layer, and the insulation layer is annularly arranged on the side wall of the inner bottom of the insulation layer. According to the high-stability aluminumalloy melting furnace, the bottom bracket is additionally arranged inside the furnace body to make an inner tank more stable, and the bottom bracket cannot be damaged under the action of high temperature, so that bottom bracket bursting caused by high temperature is prevented. In addition, the insulation layer is more closely attached to the inner tank after the bottom bracket is utilized, and therefore the insulating effect is better.

Owner:BENGBU LONGHUA DIE CASTING MACHINE CO LTD

Panda type polarization maintaining optical fiber

ActiveCN101825738BIncrease stressLess adulteratedOptical fibre with polarisationOptical fibre with multilayer core/claddingStress concentrationPunching

The invention relates to a panda type polarization maintaining optical fiber for use in the field of optical fiber guidance and sensing, which comprises a core layer and a pure quartz cladding, wherein stress zones are symmetrically arranged at the two sides of the core layer in the pure quartz cladding. The panda type polarization maintaining optical fiber is characterized in that a depressed inner cladding is arranged outside the core layer, and the space between the boundaries of the stress zones and the boundary of the core layer is reduced, so that the space d between the boundaries of the stress zones and the boundary of the core layer keeps 3-7mu m. The birefringent property of the panda type polarization maintaining optical fiber can be improved by the invention to meet the performance requirements of a high-precision gyro, and the introduction of the depressed inner cladding can effectively reduce the burst probability of the prefabricated core layer in the process of punching in the stress zones under the condition of not increasing the difficulty of process preparation; the depressed inner cladding adopts viscosity doping and matching design, and further reduces the burst probability of the prefabricated core layer caused by the external mechanical stress in the process of punching in the stress zones; and one side of the stress zones and the depressed inner cladding have an overlapped region so as to prevent the mechanical stress from acting on an intrinsic boundary stress concentration point.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

A secondary combustion furnace

ActiveCN105387714BReduce the chance of burstingImprove combustion efficiencyFurnace safety devicesVertical furnacesCombustionBarrel Shaped

A secondary combustion furnace comprises a vertically-arranged barrel-shaped furnace body. An anti-explosion end cover is arranged at the top end of the furnace body and made of a steel plate with the thickness being 10 cm. An anti-explosion opening is formed in the center of the anti-explosion end cover. An anti-explosion device is arranged in the anti-explosion opening and comprises a base embedded in the anti-explosion opening. A steel hook is arranged in the side wall of the base and fixedly connected with the anti-explosion end cover. A central hole is formed in the center of the base. An anti-explosion cover is arranged on the central hole. The tail end of the anti-explosion cover is inserted in the central hole. The anti-explosion cover is provided with a pressure relief pipe which comprises a vertical section and a conical amplification section. A sealing ball is arranged in the conical amplification section. The secondary combustion furnace is simple in structure, automatic pressure relief is conducted, the furnace body is effectively protected against explosion, and combustion is sufficient.

Owner:JIANGSU LIYU ENVIRONMENTAL TECH

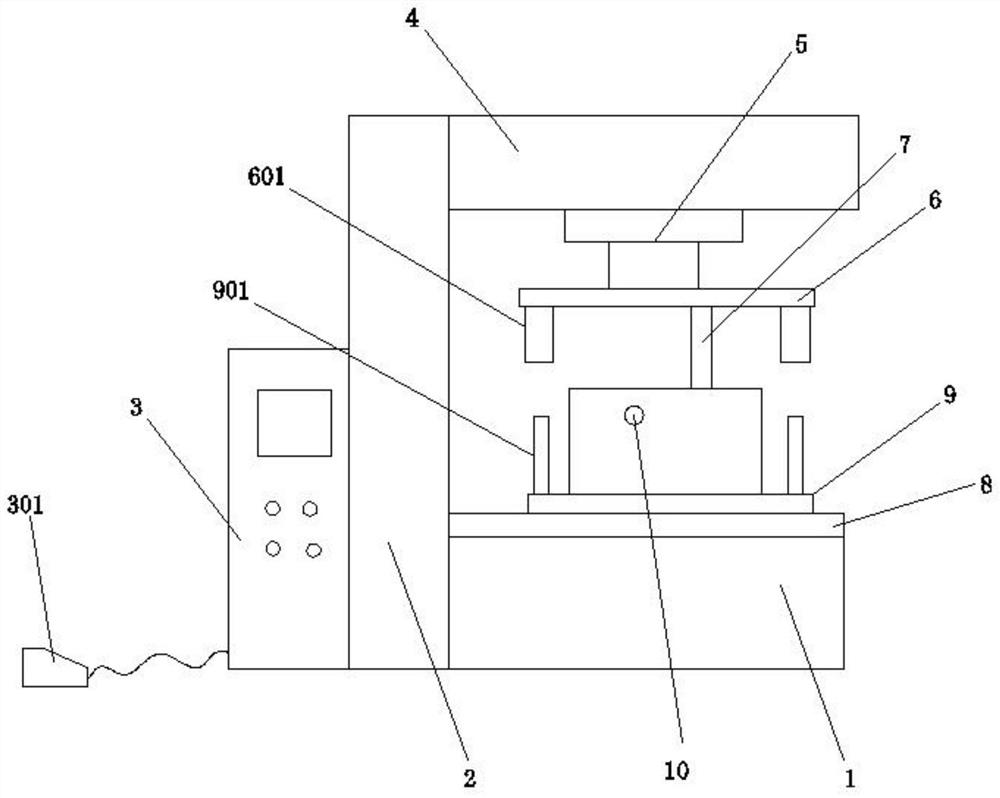

A punching device with a buffer structure

ActiveCN112605237BContinuous punchingReasonable structural designShaping toolsNon-rotating vibration suppressionPunchingElectric control

The invention discloses a punching device with a buffer structure, comprising a machine tool, a support frame is connected to the left side of the machine tool, an electric control box is connected to the left side of the support frame, a fixing seat is connected to the top of the right side wall of the support frame, and the fixing seat The bottom of the machine tool is connected with an air cylinder, the bottom of the cylinder is connected with an upper die base, the bottom of the upper die base is connected with a pressure column, the top of the machine tool is connected with a workbench, the top of the workbench is connected with a lower die base, and the lower die base is located in the upper die base. The present invention has reasonable structure design and simple operation, and can continuously punch the workpiece, the pressing block descends along the buffer cavity to squeeze the buffer liquid, the concave part on the inner tube is slightly deformed by pressing outward, and at the same time, the hoop is reinforced. The bulge of the inner tube is deformed by the outward pressing of the inner tube, and an inward tightening force is generated. The tightening force can offset part of the liquid pressure, achieve a good buffering effect, and avoid damage to stamping equipment and molds. , which is beneficial to improve the service life of the device.

Owner:武汉威普泰科技有限公司

Anti-explosion automobile tire

The invention relates to the technical field of auto parts, in particular to a burst-proof automobile tire. The new automobile tire of the present invention reduces the probability of the burst of the pneumatic tire, thereby protecting the driver, passengers and vehicles, and reducing the occurrence of accidents; including a protective tire And the pneumatic tire, the pneumatic tire is located inside the protective tire, and the outside of the pneumatic tire is communicated with an inflation tube, and the inflation tube is provided with a baffle; A water inlet pipe is arranged on the outside, and a water inlet stopper is arranged at the mouth of the water inlet pipe, and the water inlet pipe is communicated with the water collecting cavity and arranged together.

Owner:QINGDAO HUASHENG RUBBER

Flame-retardant processing technology of flame-retardant plate based on macromolecular flame retardant

InactiveCN114347519APenetrate fastDeep penetrationFlat articlesPhysical chemistryProcess engineering

The invention discloses a flame-retardant processing technology for a flame-retardant plate based on a macromolecular flame retardant, and relates to the technical field of plate processing. The flame-retardant processing technology comprises a high-pressure explosion-proof box, the bottom of the high-pressure explosion-proof box is fixedly connected with a machine box, and the right side of the machine box is fixedly connected with a feeding mechanism. According to the flame-retardant processing technology for the flame-retardant plate based on the macromolecular flame retardant, the pressure pump is arranged to be matched with related pipelines, the high-pressure explosion-proof box can be pressurized, internal air is promoted to circularly flow, heating is conducted in the process, the flame-retardant plate can be uniformly heated and dried, the probability of explosion of the flame-retardant plate can be reduced through pressurization, and the flame-retardant effect of the flame-retardant plate is improved. The flame-retardant plate is fully dried, then the atomized flame retardant is sprayed into the high-pressure explosion-proof box, the fully dried flame-retardant plate can quickly absorb the flame retardant, meanwhile, part of steam is mixed in the atomized flame retardant, the fumigation effect can be achieved, the flame retardant can penetrate into the flame-retardant plate more deeply in cooperation with the pressurization effect, and compared with simple soaking, the flame-retardant effect is better, and the service life of the flame-retardant plate is prolonged. And more flame retardants can be absorbed, and the efficiency is higher.

Owner:于焕

A cooling method for super-thick material layer sintered ore using pre-sintering

The invention discloses a cooling method for super-thick material layer sintered ore adopting pre-sintering. In the pre-sintering process, the material layer thickness in the first time of distribution is 500-900 mm, the second time of distribution is carried out after pre-sintering is conducted for 8-40 min, the distribution thickness in the second time of distribution is 100-650 mm, and the total material layer thickness after the two times of distribution is higher than or equal to 900 mm. A sintered ore separating device is arranged at the tail discharging position of a belt type roasting machine, sintered ore which is higher than or equal to 500 DEG C in temperature and provided with a red fire layer and surplus sintered ore are separated into two parts, the sintered ore with the temperature lower than 500 DEG C is cooled on a ring cooling machine, and the sintered ore with the temperature higher than or equal to 500 DEG C and natural lump ore with the granularity being 10-50 mm are placed in a vertical cooling furnace to be cooled. Screening is conducted after cooling, the sintered ore with the granularity being higher than or equal to 5 mm directly enters a blast furnace to be smelted, and the sintered ore with the granularity being smaller than 5 mm returns to be sintered. By means of the cooling method, the waste heat recovery efficiency of the sintered ore is greatly improved, and the problem that the natural lump ore explodes in the blast furnace is solved.

Owner:ANGANG STEEL CO LTD

A kind of synthetic method of li‑iii‑vi2 type mid-far infrared polycrystal

ActiveCN105714375BAvoid generatingIncrease contact areaPolycrystalline material growthSingle crystal growth detailsSynthesis methodsFar infrared

The invention provides a synthesis method of a Li-containing I-III-VI2 type mid and far infrared polycrystalline and relates to a synthesis method of the mid and far infrared polycrystalline. The synthesis method aims at solving the technical problem that existing quartz tubes for synthesizing the Li-containing I-III-VI2 type mid and far infrared polycrystalline are susceptible to corrosion cracking to produce burst. The synthesis method comprises the steps that 1, a tubular crucible and a quartz tube are cleaned; 2, an elementary-substance raw material of Li-containing I-III-VI2 type mid and far infrared crystals is weighed; 3, Li and a third main group element elementary substance are put into the tubular crucible, a sixth main group element elementary substance is put in the bottom of the quartz tube, then the tubular crucible is put in the middle of the quartz tube, vacuum pumping is performed to seal the quartz tube, and the quartz tube is put in an oblique single-temperature-zone tube type resistance furnace; 4, the resistance furnace is heated for synthesis, and the Li-containing I-III-VI2 type mid and far infrared polycrystalline is obtained. The synthesis method is safe and simple, reduces the probability of quartz tube burst in the synthesis process and can be used for synthesis of the lithium-containing mid and far infrared polycrystalline.

Owner:HEILONGJIANG INST OF TECH

High reliability ptc thermistor

ActiveCN109686515BImprove stabilityReduce the chance of burstingOther resistor networksResistor cooling/heating/ventillationEngineeringThermistor

This case involves a high-reliability PTC thermistor, including a PTC chip, a first electrode attached to the upper surface of the PTC chip, a second electrode attached to the lower surface of the PTC chip, and soldered to the first electrode and the second electrode. The electrode leads on the surface, the outside of the welded part of the PTC chip, the first electrode, the second electrode and the leads are wrapped with an encapsulation layer from inside to outside; there is a gap between the PTC chip and the encapsulation layer. The invention improves its ability to withstand external impact by setting an encapsulation layer; by setting an explosion-proof layer, a cooling layer and a moisture-proof layer, the thermistor is better protected, and its ability to withstand external impact is improved, making it more good stability.

Owner:苏州团芯终端有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com