All-steel engineering tyre twice method double-station integrated forming machine

A technology of French double station and OTR tire, which is applied in the field of all-steel OTR tire two-time French double station integrated molding machine, which can solve the problems of high time cost, manual installation, and embryo weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

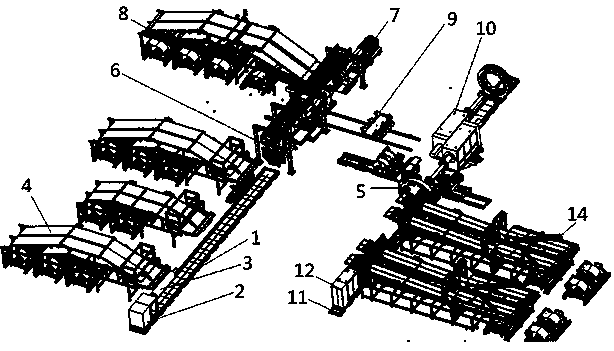

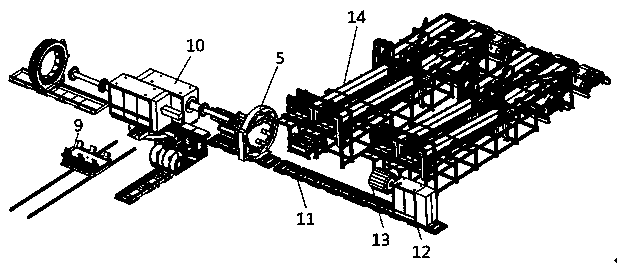

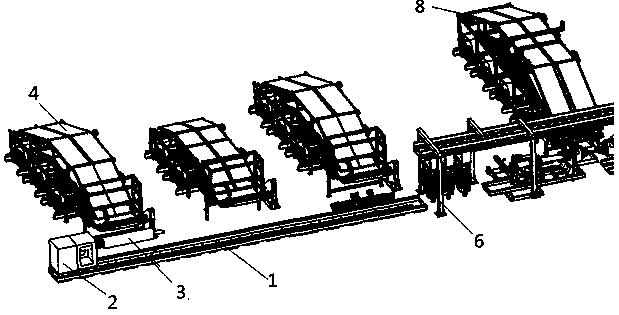

[0077] An all-steel engineering tire double-station integrated molding machine of the present invention, refer to the attached Figure 1-29 , including one section of embryo transfer device and two sections of embryo transfer device, between the two embryo transfer devices there is a transfer trolley 9 for conveying a section of embryo and a rotating mechanism 10 for removing a section of embryo from the transfer trolley 9, A tire embryo transfer device includes a first rail 1 and a carcass drum case 2 that can move back and forth along the length direction of the first rail 1. A carcass drum 3 is installed on the carcass drum case 2, and multiple A first feeding rack 4 for feeding the carcass drum 3, the carcass drum 3 forms a carcass tube on the surface of the carcass drum 3 after passing through a plurality of first feeding racks 4, and the end of the first track 1 is provided for The carcass tube transfer mechanism 6 that removes the carcass tube from the carcass drum 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com