A secondary combustion furnace

A secondary combustion and furnace technology, which is applied in the direction of furnaces, vertical furnaces, furnace components, etc., can solve problems such as furnace body burst, personnel and property loss, and insufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

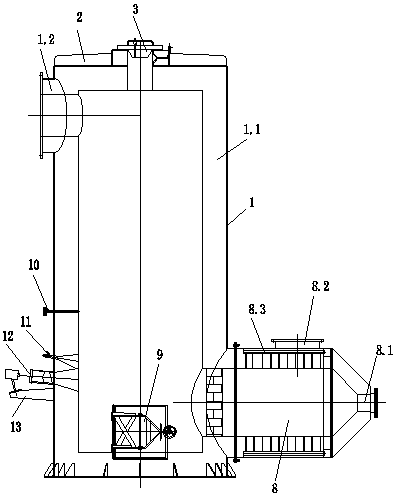

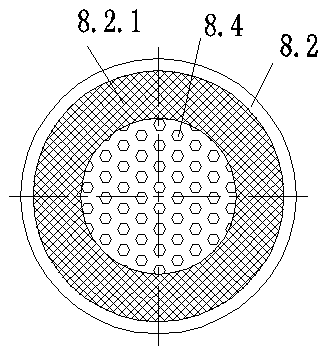

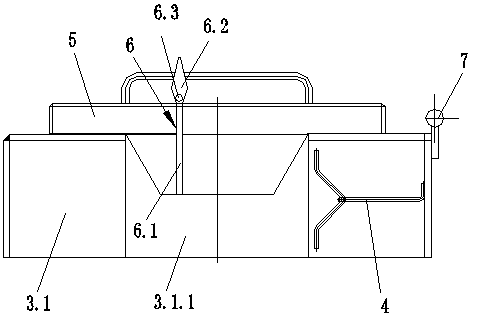

[0015] Example 1: A secondary combustion furnace, including a cylindrical furnace body 1 vertically arranged, an explosion-proof end cover 2 is provided on the top of the furnace body 1, and the explosion-proof end cover 2 is composed of a steel plate with a thickness of 10 cm. 2 There is an explosion-proof opening in the center, and an explosion-proof device 3 is arranged in the explosion-proof opening. The explosion-proof device 3 includes a base 3.1 embedded in the explosion-proof opening. The side wall of the base 3.1 is provided with a steel hook 4 and the explosion-proof end cover 2 is fixedly connected to the base 3.1 The center is provided with a central hole 3.1.1, the central hole 3.1.1 is provided with an explosion-proof cover 5, the end of the explosion-proof cover 5 is inserted into the central hole 3.1.1, and the explosion-proof cover 5 is provided with a pressure relief tube 6, the pressure relief tube 6 includes a vertical section 6.1 and a conical enlargement se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com