Panda type polarization maintaining optical fiber

A polarization-maintaining optical fiber and panda-type technology, which is applied in the field of high-precision sensing, can solve the problems of reducing the temperature stability of polarization-maintaining optical fiber and the consistency of end-face polishing, reducing the yield of stress rod manufacturing, and reducing the mechanical performance of polarization-maintaining optical fiber. To achieve the effect of increasing the stress effect, meeting the performance requirements, and preventing the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

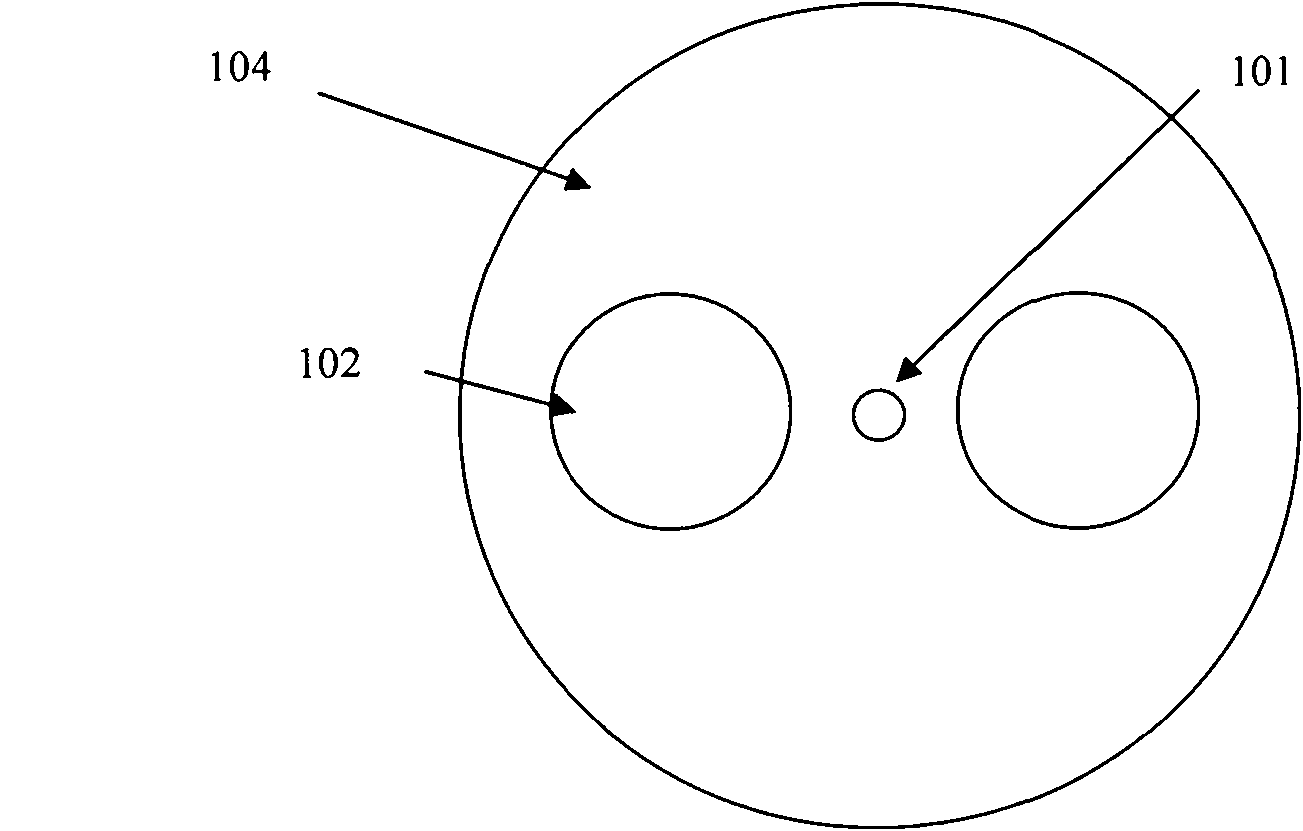

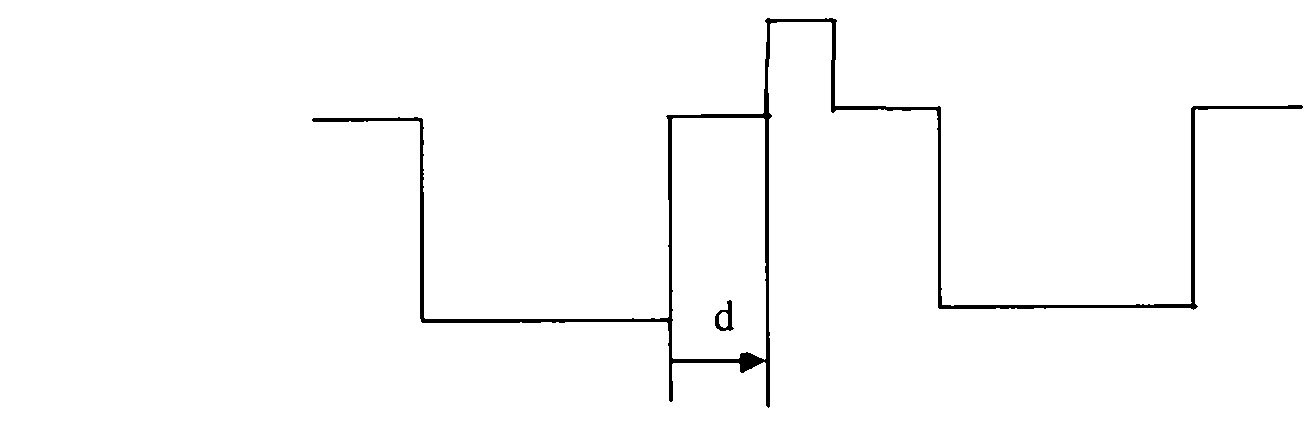

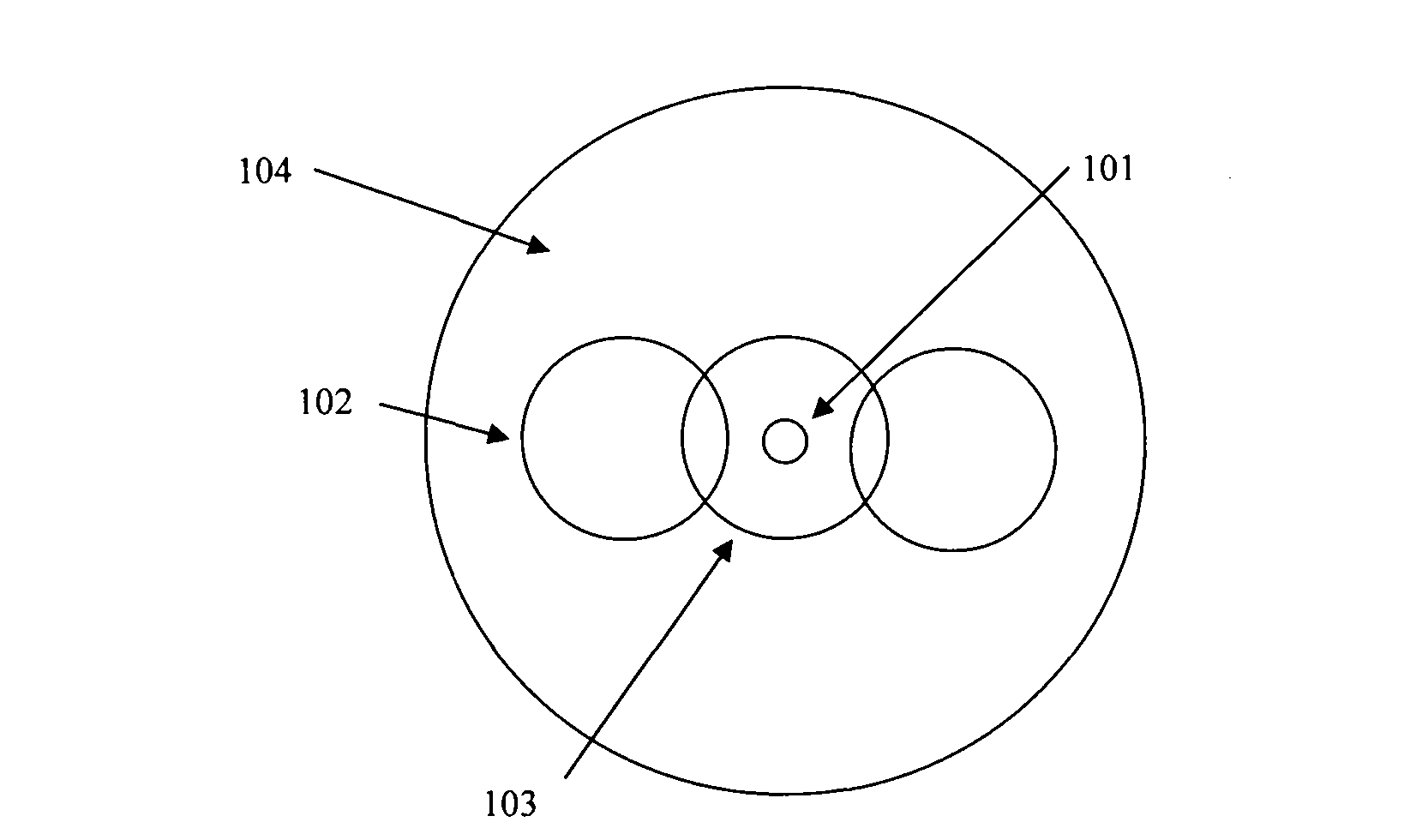

[0023] using as image 3 and Figure 4 The optical fiber refractive index distribution design and optical fiber geometric design shown are prepared to prepare a panda-type polarization-maintaining fiber, including a core layer 101 and a pure silica cladding layer 104, a sunken inner cladding layer 103 outside the core layer, and a core layer in the pure silica cladding layer. The stress regions 102 are set symmetrically on both sides of the fiber core; the two parameters of the fiber core diameter a and the relative refractive index difference of the fiber core are kept consistent with those of the ordinary structure panda-type polarization-maintaining fiber. The fiber is carried out by setting the depressed inner cladding and adjusting the following parameters. The optimization of the stress structure of the preform and the optimization of the birefringence performance of the fiber:

[0024] (1) The thickness b of the subsidence inner cladding;

[0025] (2) The relative ref...

Embodiment 2-8

[0032] Adopt the preparation process described in Example 1, by changing the optical fiber structural parameters, the following 7 kinds of polarization-maintaining optical fiber products of the embodiment are obtained, and the optical fiber structural parameters and the optical fiber birefringence performance table are as follows:

[0033]

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com