High-stability aluminum alloy melting furnace for cold-chamber die-casting machine

A high-stability, cold-chamber die-casting technology, used in furnaces, furnace bottoms, furnaces, etc., can solve the problems of poor thermal insulation performance, inconvenience, low thermal efficiency, etc., achieve good thermal insulation effect, prevent bursting, improve high temperature resistance and resistance The effect of fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

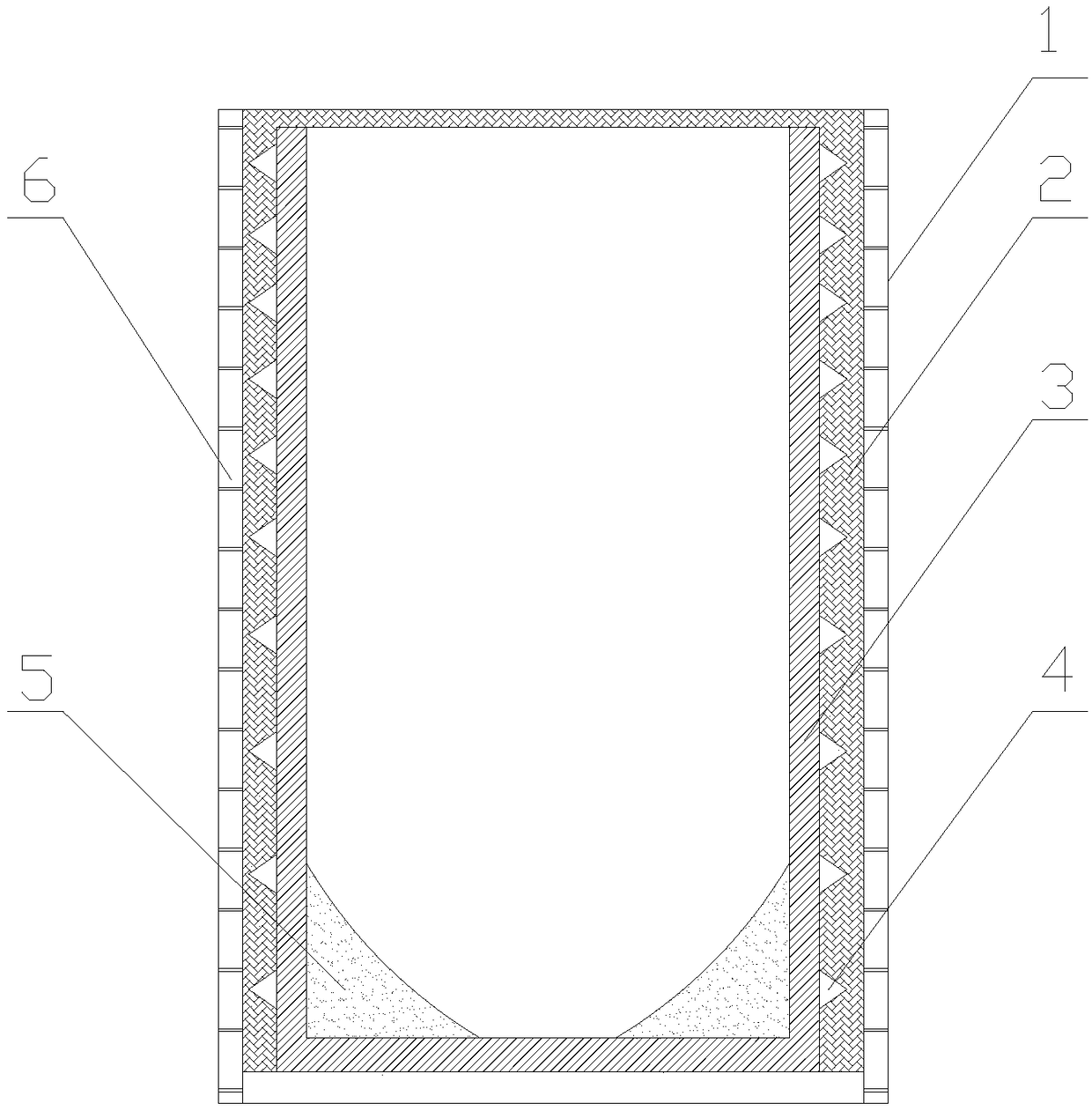

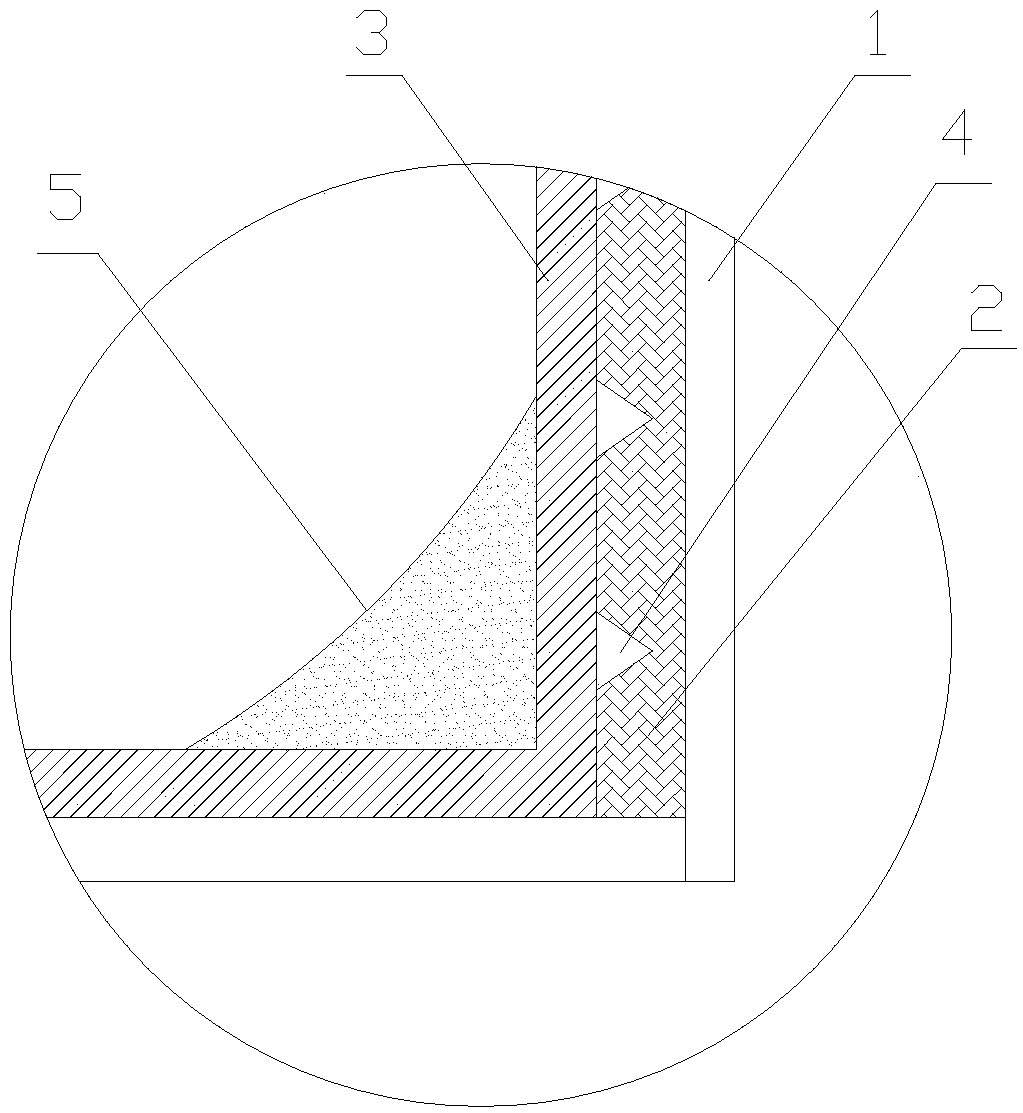

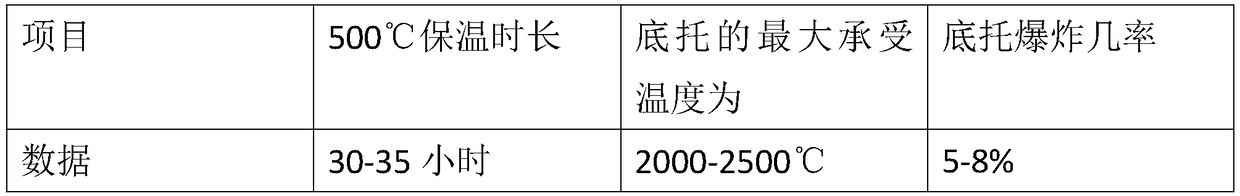

[0039] like figure 1 Shown: High-stability aluminum alloy melting furnace for cold chamber die-casting machine, including furnace body unit, heating unit and control unit: the heating unit and control unit have the same structural scheme as the ordinary melting furnace, and the furnace body unit includes the furnace wall 1. Reinforcement layer 2, insulation layer 3 and bottom support 5. The furnace wall 1 and reinforcement layer 2 are stacked with refractory bricks 6. Between each refractory brick 6, high-temperature-resistant cement is used for caulking and fixing. The reinforcement layer 2 is provided with a reinforcement ring 4 with a triangular cross-section, and high-temperature-resistant cement is filled between the reinforcement rings 4. The insulation layer 3 is arranged inside the reinforcement layer 2, and a bottom support 5 is also provided inside the insulation layer 2. The bottom support 5 annularly arranged on the side wall of the inner bottom of the insulation l...

Embodiment 2

[0041] like Figure 1-2 As shown: the bottom support 5 has an arc structure, and the arc structure of the bottom support 5 matches the bottom arc structure of the inner tank of the melting furnace.

Embodiment 3

[0043] like figure 2 The raw materials for the preparation of the bottom support shown in , in parts by weight, include the following components, 120 parts of coarse aggregate; 50 parts of cement; 13 parts of water; 5 parts of additives; 8 parts of nanoporous materials; 15 parts of nanofibers.

[0044] The aggregate includes coarse aggregate and fine aggregate, wherein the coarse aggregate includes gravel with a particle size of 5-10mm, and the fine aggregate is river sand with a fineness of 3.0-4.0.

[0045] The additives are prepared from the following components: 5 parts of styrene-butadiene rubber, 7 parts of polyethylene wax, 3 parts of microcrystalline wax, 12 parts of petroleum resin, 11 parts of rosin resin, 12 parts of polyvinyl chloride resin, and 10 parts of naphthenic oil .

[0046] After the above additives are mixed and formed, they are mixed, stirred, stacked, extruded, plasticized and dried together with the bottom bracket raw materials to prepare the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com