A high-efficiency sealing flange

A technology for sealing flanges and flanges, which is applied in the direction of flange connection, engine sealing, separation methods, etc., and can solve problems such as flange connection failure, waste of manpower and material resources, and slow down construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

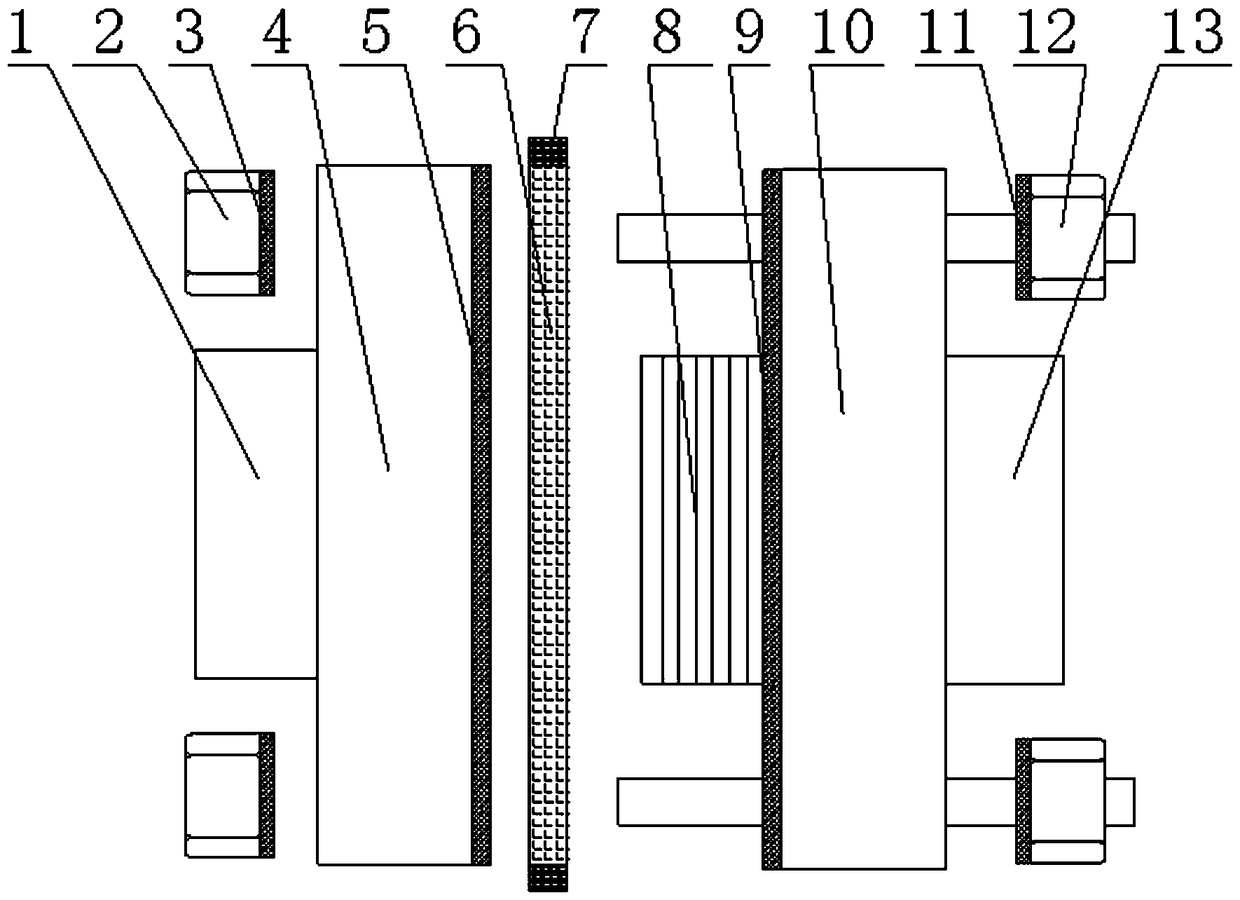

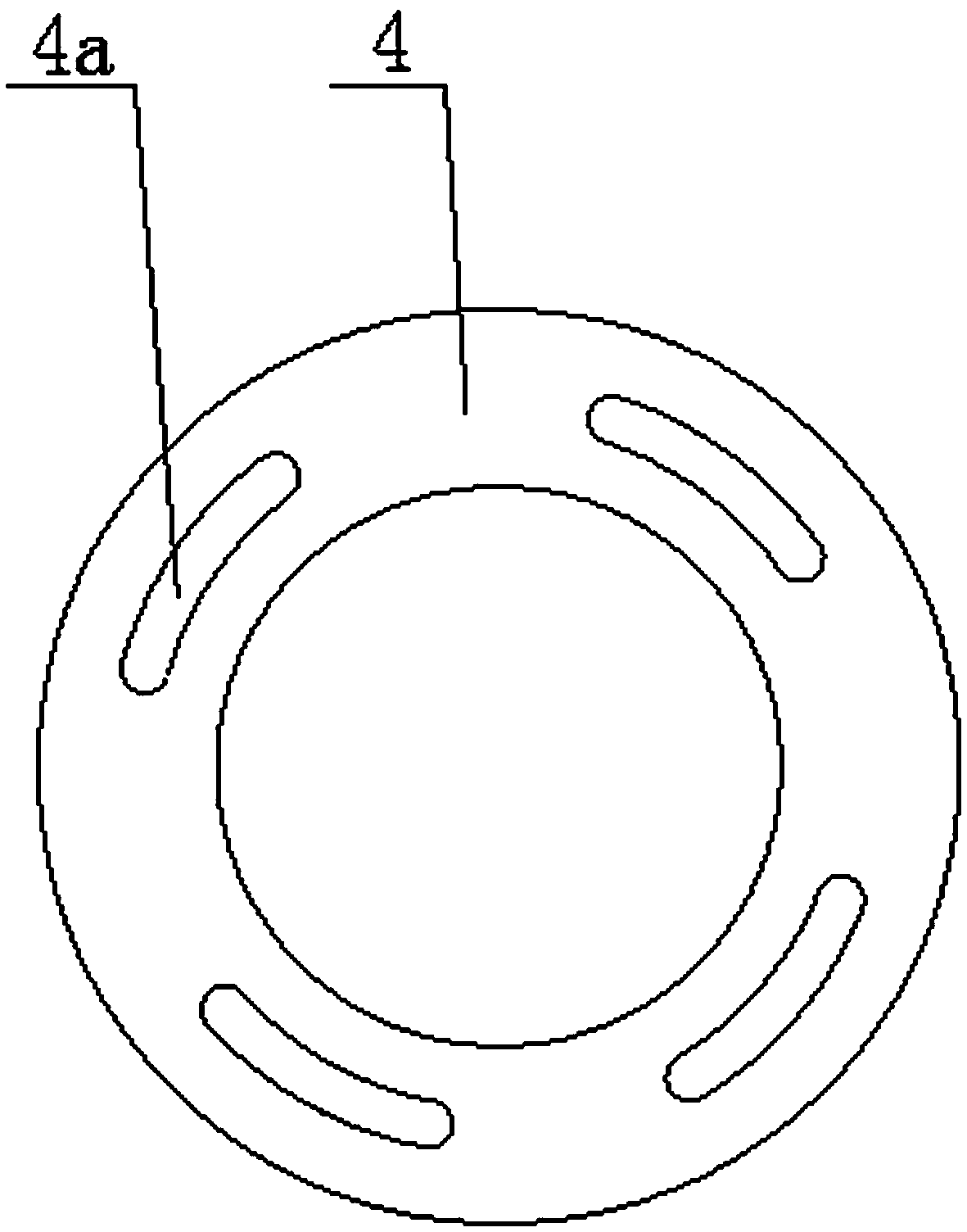

[0057] The high-efficiency sealing flange of this embodiment is as figure 1 and 2 As shown, including the first flange 4, the second flange 10, the circular filter screen 6, the fastening bolt 12 and the nut 2, the corresponding positions of the first flange 4, the second flange 10 and the circular filter screen 6 Arc-shaped holes 4a are respectively opened, and the fastening bolts 12 pass through the arc-shaped holes 4a of the first flange 4, the circular filter screen 6 and the second flange 10 in turn to be threaded with the nut 2; the second flange 10 is close to the first One side of the flange 4 is provided with an annular connection block 8, and the outer side of the annular connection block 8 is shaped on an external thread. The first flange 4 is provided with a connection groove matching the The external threads match the internal threads; the opposite side surfaces of the first flange 4 and the second flange 10 are respectively covered with the first rubber sealing ...

Embodiment 2

[0098] The high-efficiency sealing flange of this embodiment is basically the same as that of Embodiment 1, except that the mass percentages of the components in the first flange and the second flange are: C: 0.02%, Al: 1.12%, Zn: 0.33% , Si: 0.21%, Mn: 0.77%, S: ≤0.030%, P: ≤0.030%, Cr: 0.04%, Ni: 0.38%, Cu: 0.11%, V: 0.14%, Mo: 0.13%, Ti: 0.59%, B: 0.02%, Pd: 0.04%, Pt: 0.18%, W: 0.25%, Ta: 0.02%, Nd: 0.09%, Ce: 0.02%, Eu: 0.13%, Lu: 0.13%, Au: 0.14%, Ag: 0.44%, Ga: 0.02%, Y: 0.23%, Sn: 0.46%, Zr: 0.16%, Re: 0.05%, Os: 0.02%, Hf: 0.13%, Bi: 0.14%, calcium oxide : 0.31%, talc powder: 0.15%, magnesium oxide: 0.24%, copper oxide: 0.44%, iron oxide: 0.29%, manganese dioxide: 0.33%, copper hydroxide: 0.17%, iron hydroxide: 0.08%, hydrogen Calcium oxide: 0.07%, barium hydroxide: 0.06%, sodium chloride: 0.02%, calcium carbonate: 0.11%, potassium nitrate: 0.26%, magnesium chloride: 0.18%, calcium chloride: 0.21%, potassium chlorate: 0.31%, sulfuric acid Barium: 0.37%, copper sulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com