Synthesis method of Li-containing I-III-VI2 type mid and far infrared polycrystalline

A technology of I-III-VI2 and synthesis method, which is applied in the synthesis field of mid-far infrared polycrystal, can solve the problems of troublesome quartz tube protection method, inaccurate product stoichiometric ratio, etc., and achieves the effect of reducing the probability of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

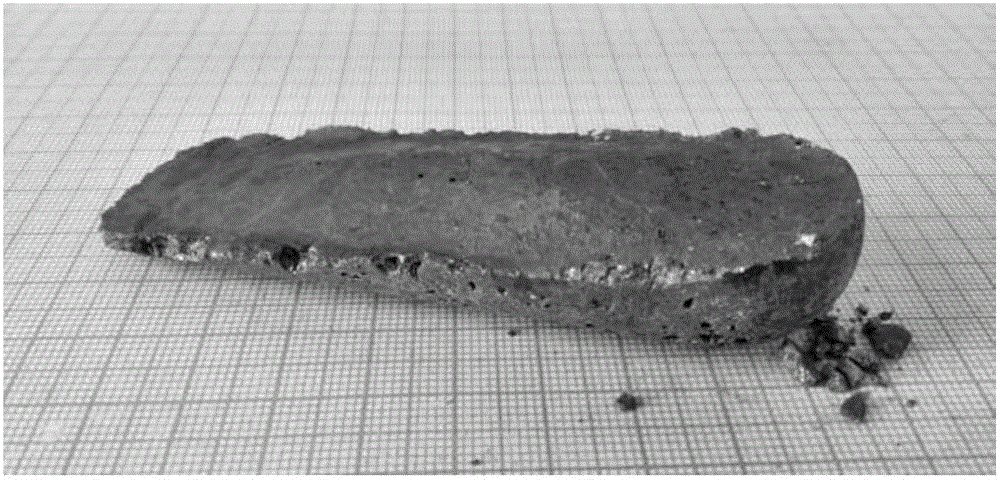

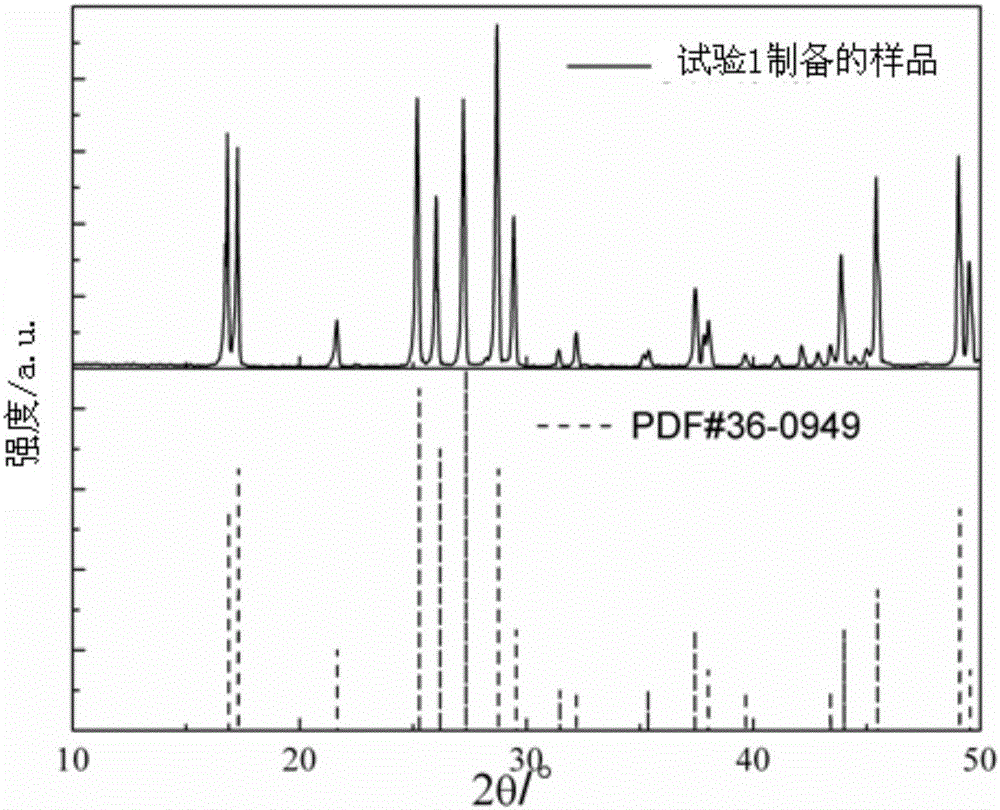

Examples

specific Embodiment approach 1

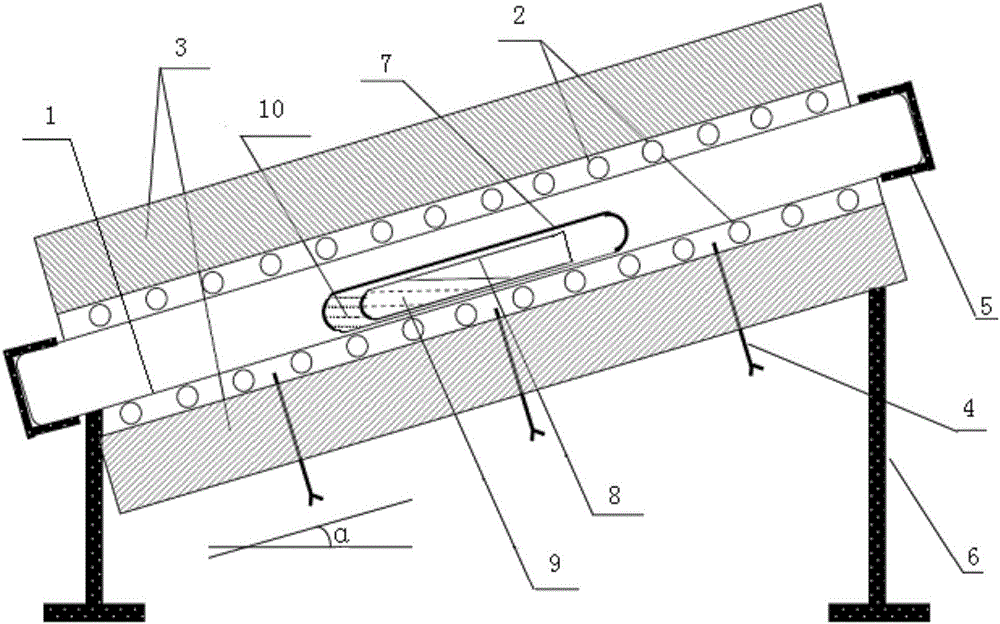

[0017] Specific embodiment one: the synthesis method of the Li-containing I-III-VI2 type mid-far infrared polycrystal of the present embodiment is carried out according to the following steps:

[0018] 1. Soak the tubular crucible and quartz tube used for filling with aqua regia, then wash with ultrapure water, and dry for later use, wherein the tubular crucible is graphite crucible or PBN crucible;

[0019] 2. Weigh the elemental raw materials of Li-containing I-III-VI2 type mid-to-far infrared crystals, wherein the molar ratio of Li to the elemental elements of the third main group is 1:1, and the molar ratio of Li to the elemental elements of the sixth main group is 1 : (2.000~2.002);

[0020] 3. Put Li and the element of the third main group into the tubular crucible, put the element of the sixth main group into the bottom of the quartz tube, then put the tubular crucible in the middle of the quartz tube; then vacuum the quartz tube to 10 -4 Pa-10 -6 Pa, the quartz tube ...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the soaking time in aqua regia in step 1 is 4 to 6 hours. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the molar ratio of Li to the element of the sixth main group in step 2 is 1:2.001. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com