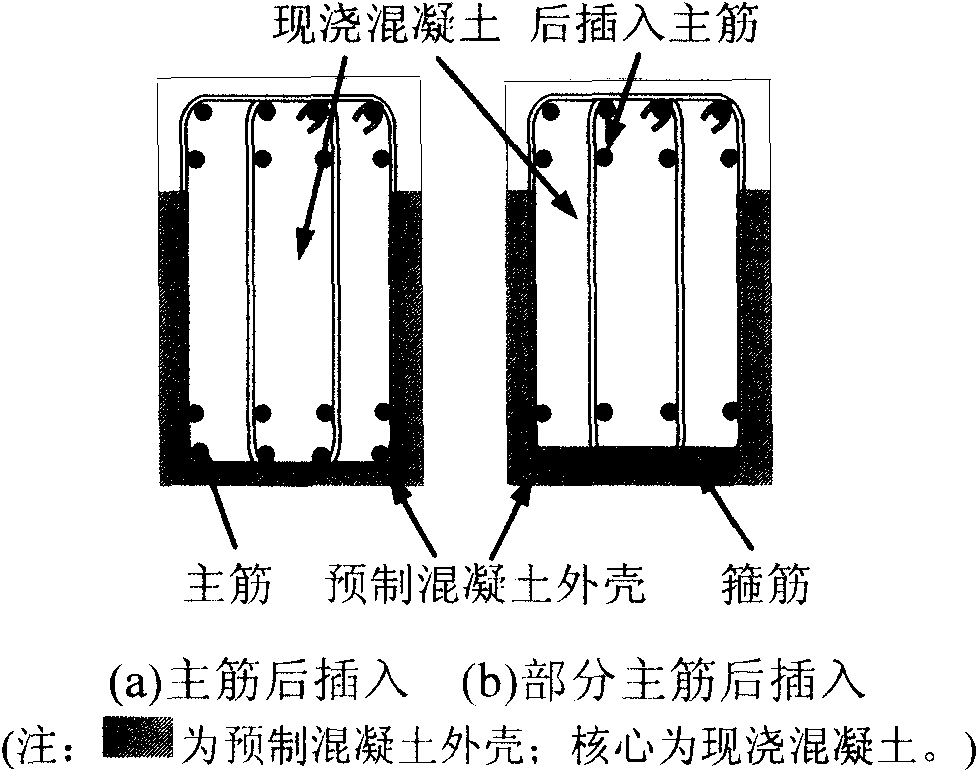

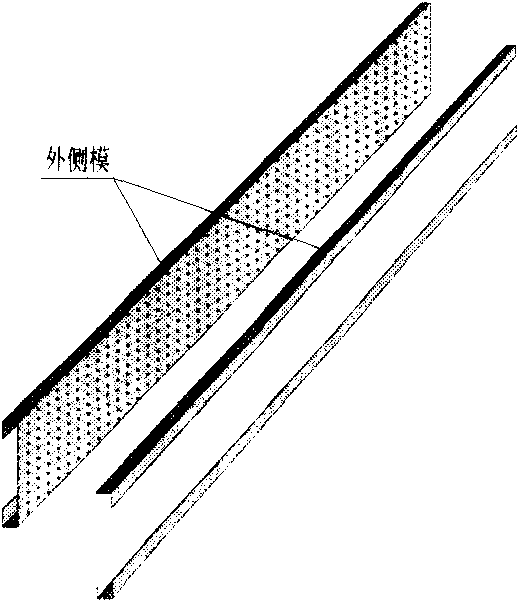

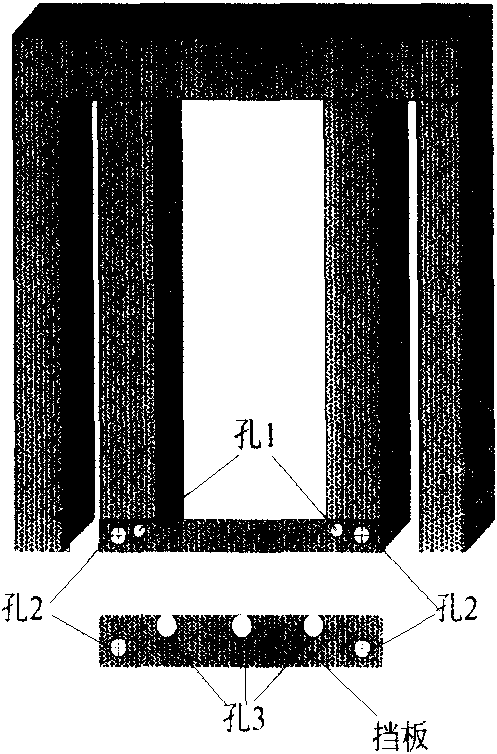

U-shaped precast concrete shell with inner ribs and manufacture method thereof

A prefabricated concrete and concrete technology, which is applied to manufacturing tools, formwork/formwork/work frame, and on-site preparation of building components, etc. The effect of reducing usage, saving workload, saving wood and other resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In summary, the U-shaped precast concrete shell with inner ribs can be used for the production of reinforced concrete beams, and the U-shaped precast concrete shell with inner ribs can be used as the construction formwork of reinforced concrete beams, which greatly reduces the use of formwork and is conducive to saving wood, etc. resources, saving a lot of work for tying steel bars and pouring on-site concrete, which is conducive to environmental protection and the development of green buildings. The manufacturing method of the U-shaped precast concrete shell ensures the rapid production and forming of the U-shaped shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com