Cold drawing accurate steel tube wall thickness adjusting mechanism

A technology of precision steel pipe and adjustment device, applied in the direction of wire drawing die, etc., can solve the problem of the change of the wall thickness of the finished steel pipe, and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

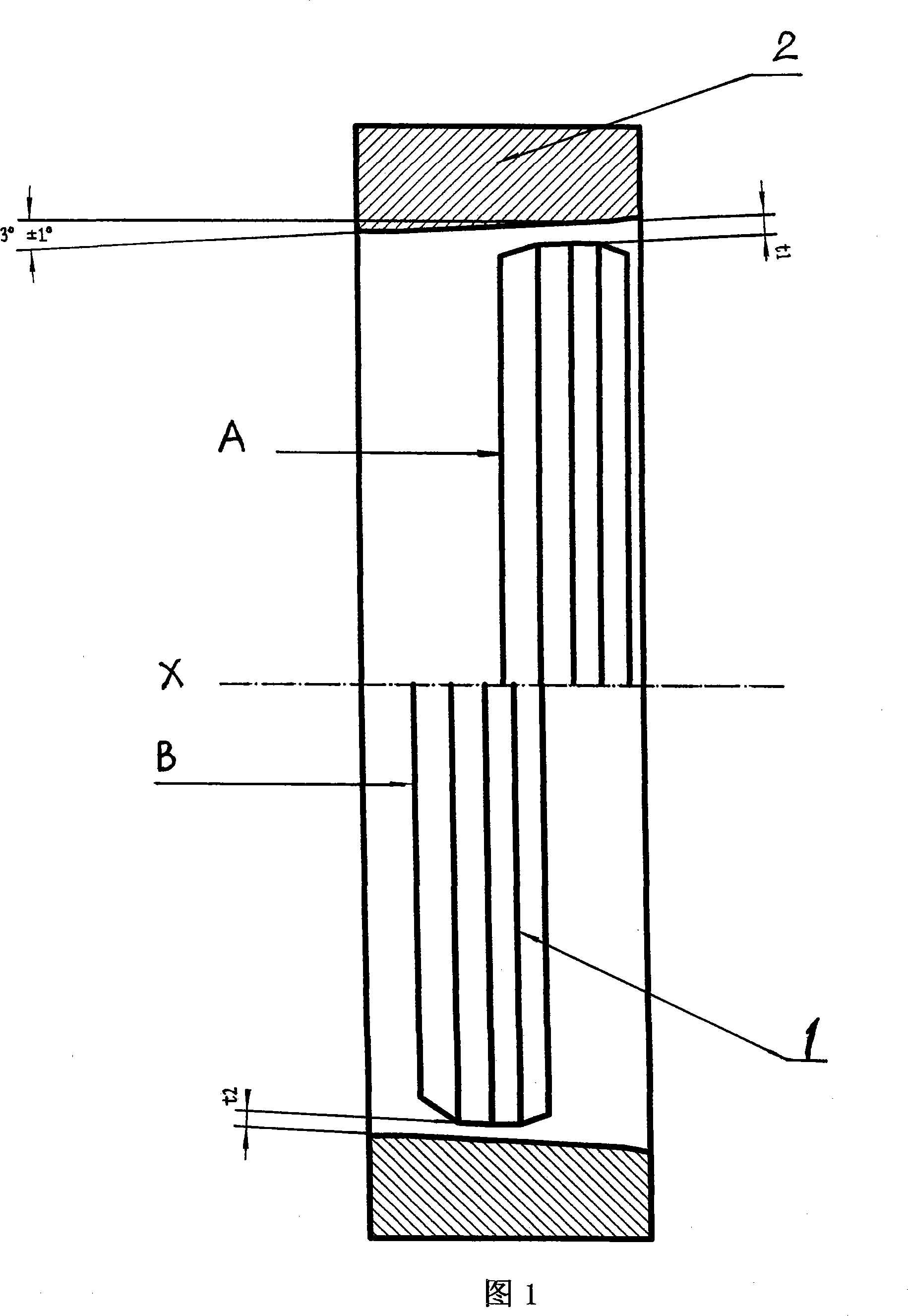

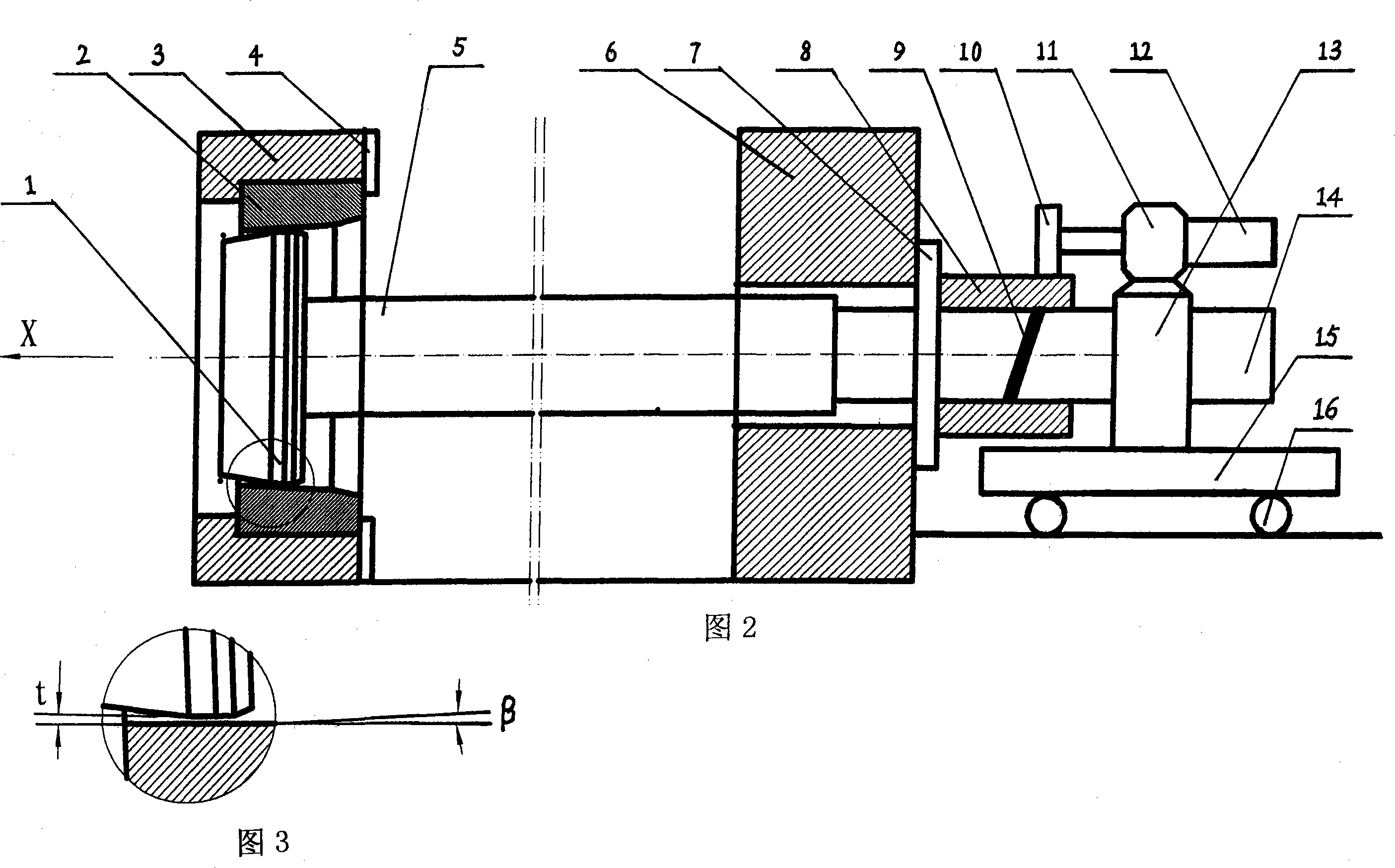

[0011] Symbols in the figure: 1. Core mold, 2. Outer mold, 3. Middle frame, 4. Outer mold baffle, 5. Pull rod, 6. Rear frame, 7. Positioning ring, 8. Spiral body, 9. Screw rod, 10. Gear, 11. Reducer, 12. AC servo motor, 13. Tie rod frame, 14. Tie rod tail, 15. Trolley car, 16. Rolling wheel.

[0012] Figure 1 shows that when the inner ring working belt of the outer mold 2 has a small cone angle of 2° to 4°, when the core mold 1 is at a different position from the central axis of the outer mold 2, the relationship between the inner ring working belt of the core mold 1 and the outer mold 2 The gap distance between them is different. When in A (position 1), there is a larger gap t1, and when in B (position 2), there is a smaller gap t2. As this relative position changes, the wall thickness of the steel pipe passing through the gap changes.

[0013] In Fig. 2 and Fig. 3, this cold-drawn precision steel pipe wall thickness adjustment device includes an outer mold 2 and a core mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com