Feed forward control method for wall thickness of tension reducing machine

A technology of stretching and reducing machine and pipe wall, which is applied in the fields of rolling mill control device, metal rolling, manufacturing tools, etc., can solve the problems of deterioration, untimely adjustment and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

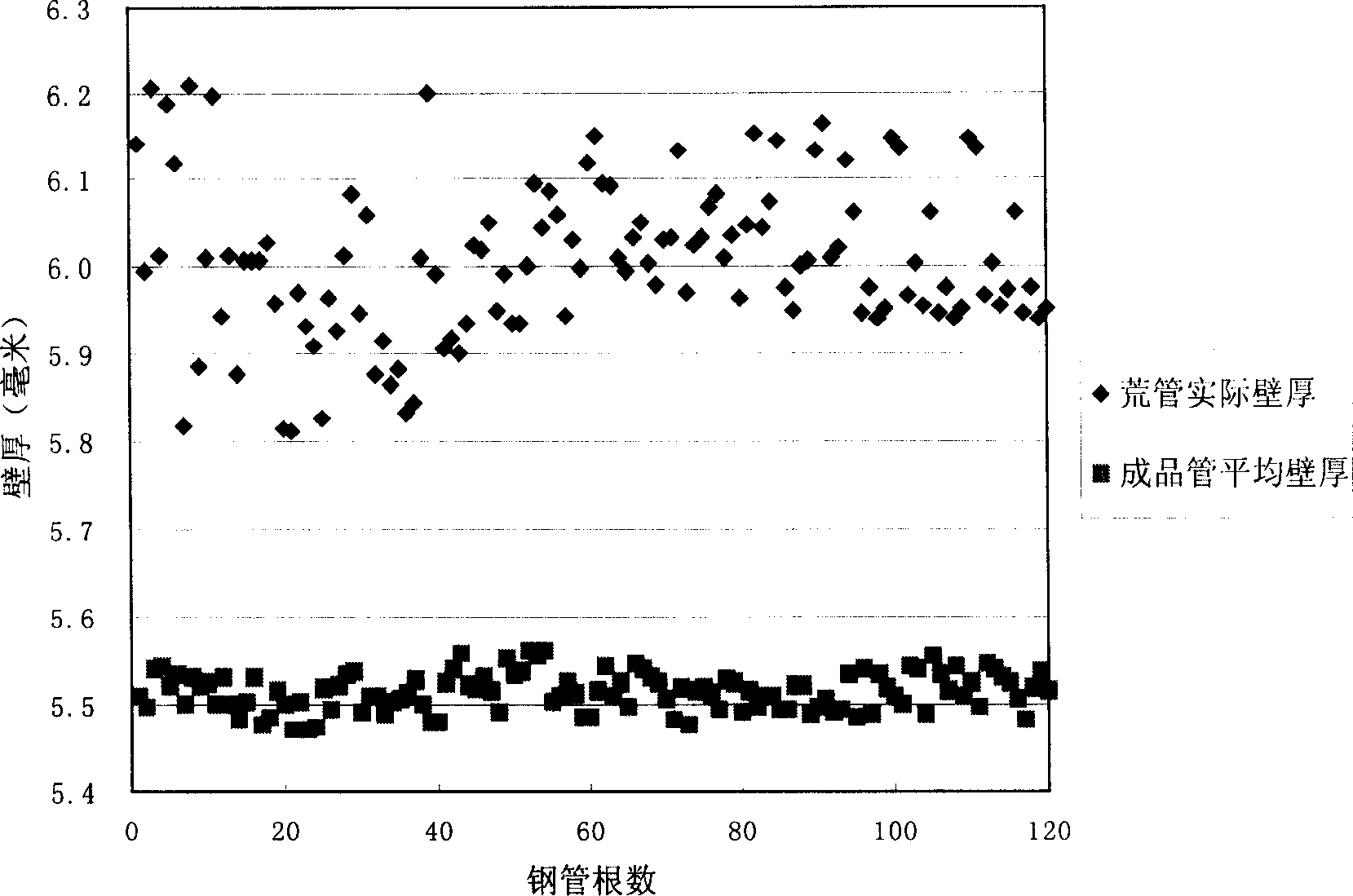

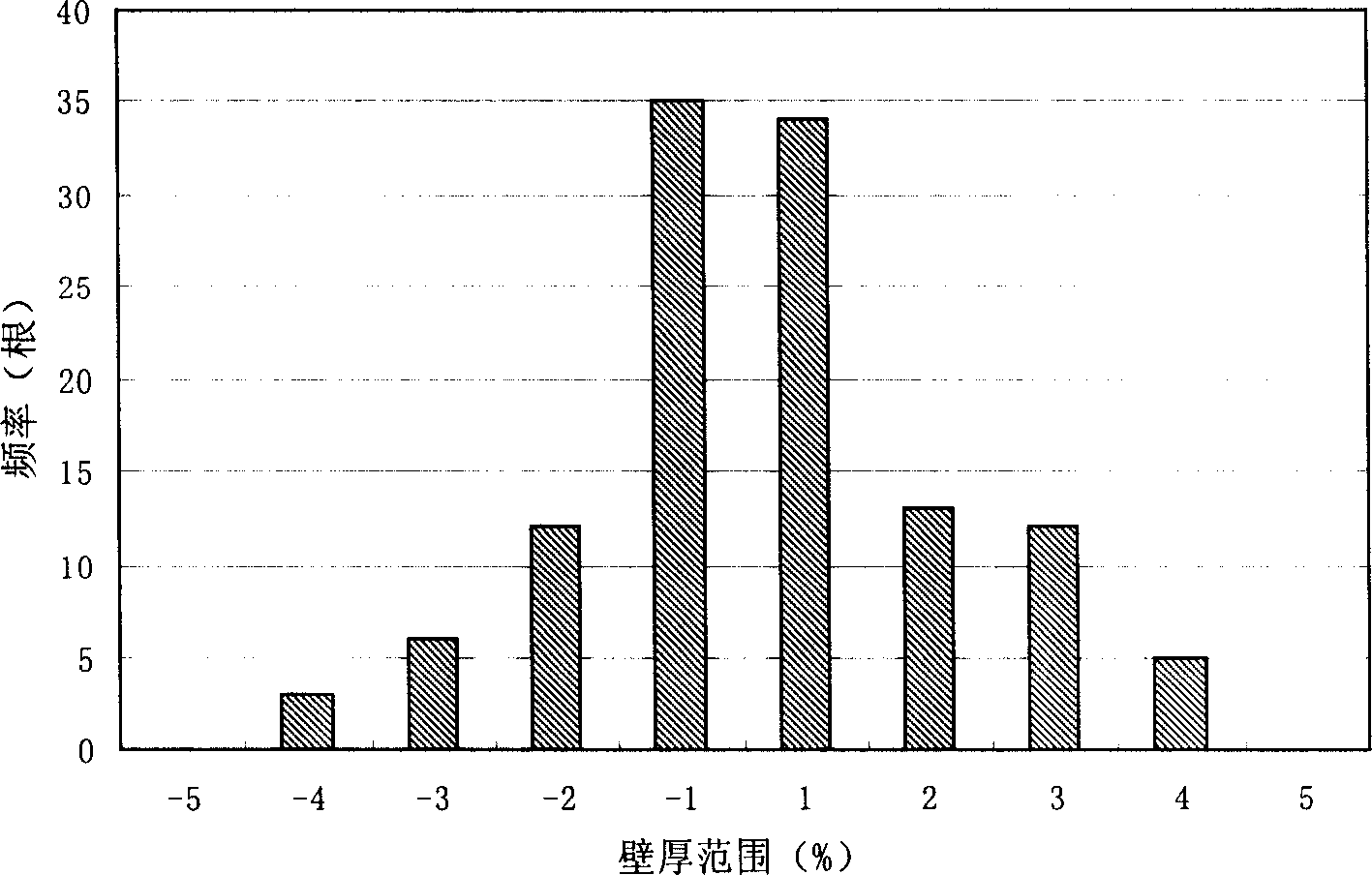

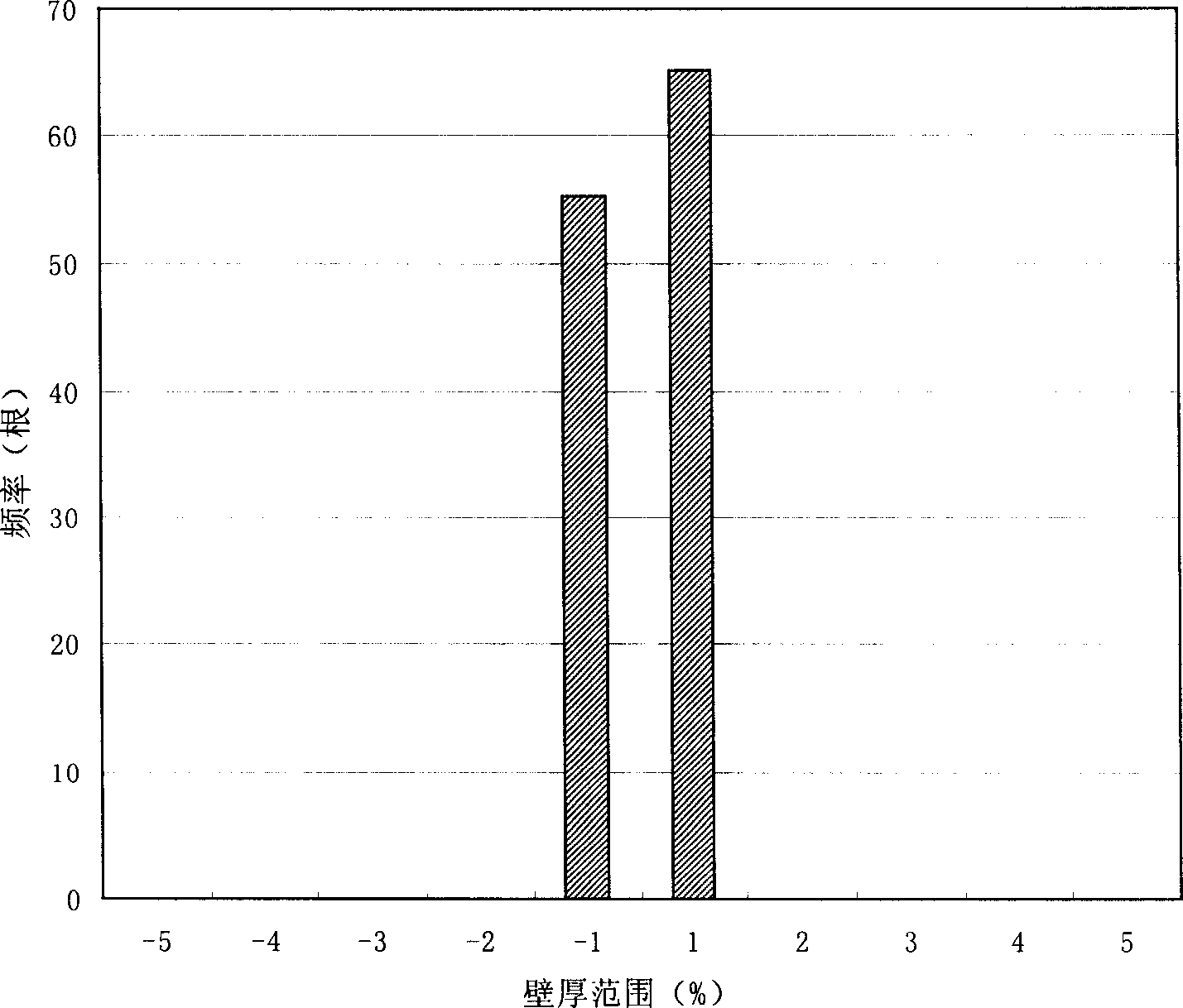

[0026] The following pass Figure 1 ~ Figure 3 , to better illustrate specific embodiments of the present invention.

[0027] Firstly, the tension-reduction process of a typical BRDBY steel pipe is selected to carry out the production test of wall thickness feed-forward adaptive control. The pipe wall thickness is 5.51mm, 18 participating rolling stands, and 12 rotating speed fixed stands;

[0028] Since the tension lowering stand is a finishing stand, its main function in rolling is to adjust the roundness of the steel pipe, therefore, for the average wall thickness control and pipe end thickening control, only the tension raising stand and the working stand are allowed Participate in steady-state speed adjustment and dynamic speed adjustment.

[0029]

Number of steel pipes

The actual wall thickness of waste pipe

(mm)

Average wall thickness of finished pipe

(mm)

1

6.142

5.510

2

5.993

5.497 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com