Mould for building spherical or cylindrical cellar and method for building cellar by adoption of mould

The technology of spherical body and cylindrical body is applied in the field of cellar construction, which can solve the problems that affect cellar construction efficiency and quality, formwork production, troublesome transportation and installation, and difficult production of multi-layer airbags, and achieves light weight, convenient installation and construction operation. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples further illustrate the technical solutions of the present invention, and do not limit the content of the present invention.

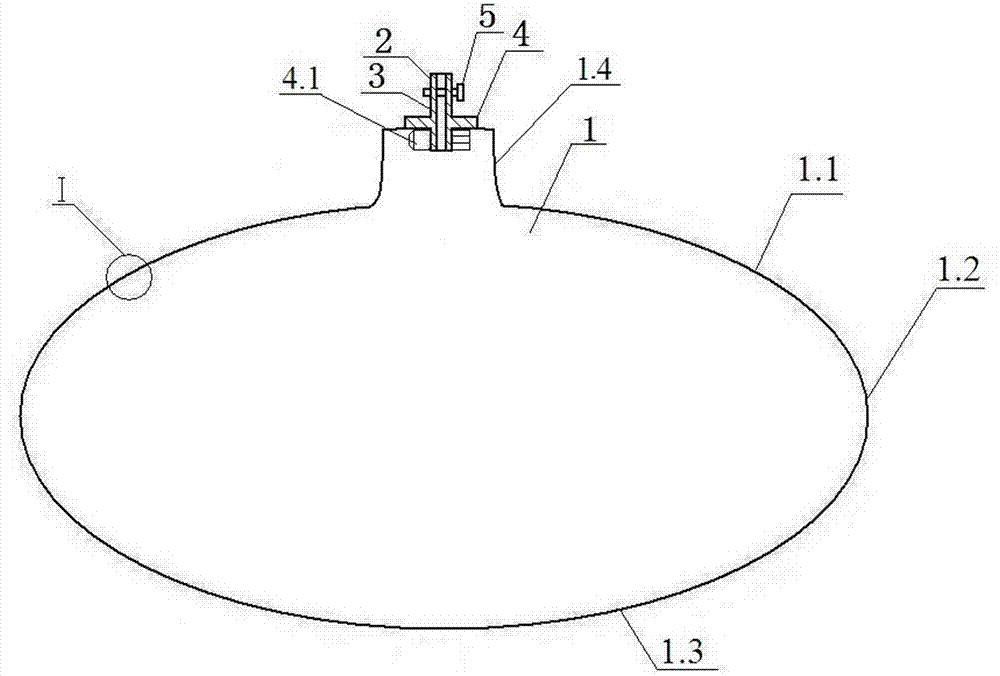

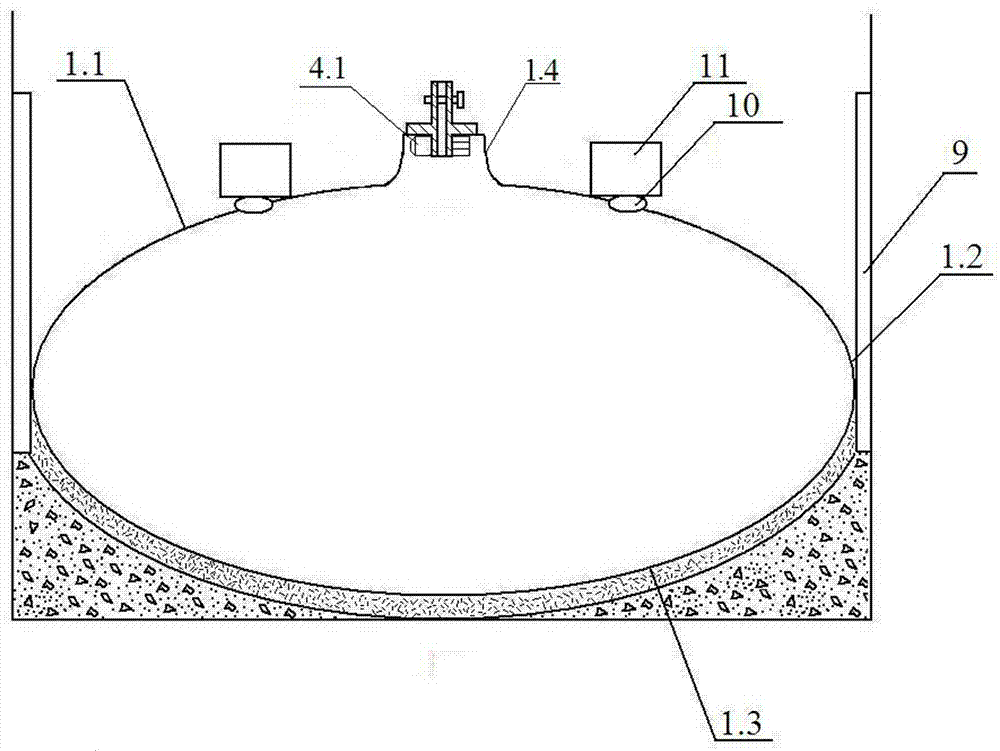

[0029] A mold for building spherical and cylindrical cellars, the present invention is characterized in that it includes an air bag and an inflation and deflation device fixed on the air bag; wherein the air bag 1 is set as a spherical body or a cylindrical body, and is formed of only one layer of soft material, There is a bag cap 1.4 connected to the top of the air bag 1; the inflation and deflation device 2 is arranged on the bag cap 1.4, and the inflation and deflation device 2 is composed of the inflation and deflation tube 3, the disc 4 fixed on the lower section of the inflation and deflation tube 3 and the disc 4 arranged on the inflation and deflation tube The valve 5 on the 3 constitutes.

[0030] The shape of the airbag 1 of the present invention is set to be circular when viewed from the top, and oval or cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com