A surface-enhanced inner step shaft inner hole precision forming process

A surface strengthening and precision forming technology, applied in the field of machining, can solve the problems of damaged mandrel forming, long cycle, low efficiency, poor coaxiality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

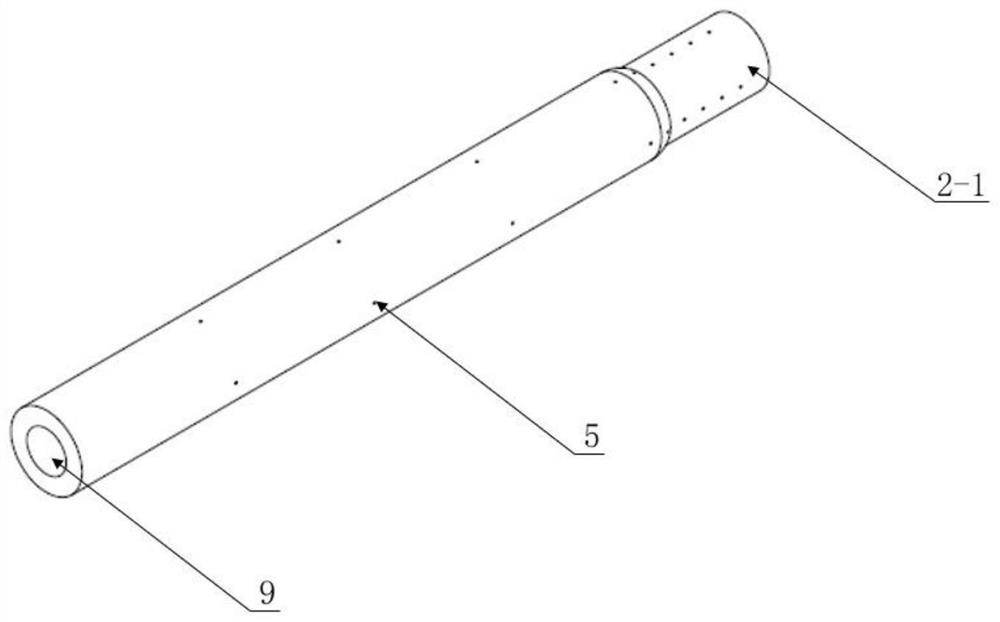

[0044] Embodiment 1, using the integral mandrel 2-1, a surface-strengthened internal step shaft inner hole precision forming process, including the following steps:

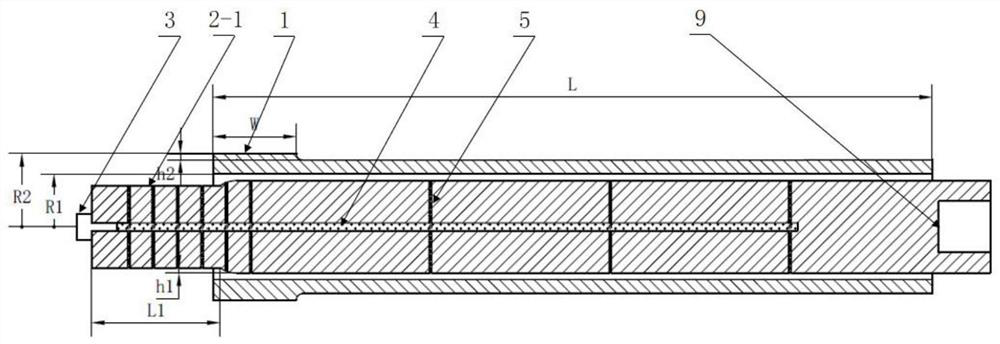

[0045] 1) Design blank: refer to image 3 , the design length of blank 1 is L, the design inner and outer diameters are R1 and R2 respectively, the length of the raised part of the blank is W, and the height of the raised part is h2; Step length L1; billet 1 design reference ratio W:L1:(h2-h1)=(6~7):(9~10):1, the more refined billet 1 size design needs to be based on finite element simulation and experimental experience results Pick;

[0046] 2) Remove the lubricant plug 3 of the integral mandrel 2-1, pump lubricant into the lubricant main channel 4 of the integral mandrel 2-1, so that the pumped lubricant fills the lubricant main channel 4, lubricant In the inner area formed by the shunt channel 5, after the pumping is completed, the lubricant plug 3 is installed to prevent the lubricant from leaking;

[0047...

Embodiment 2

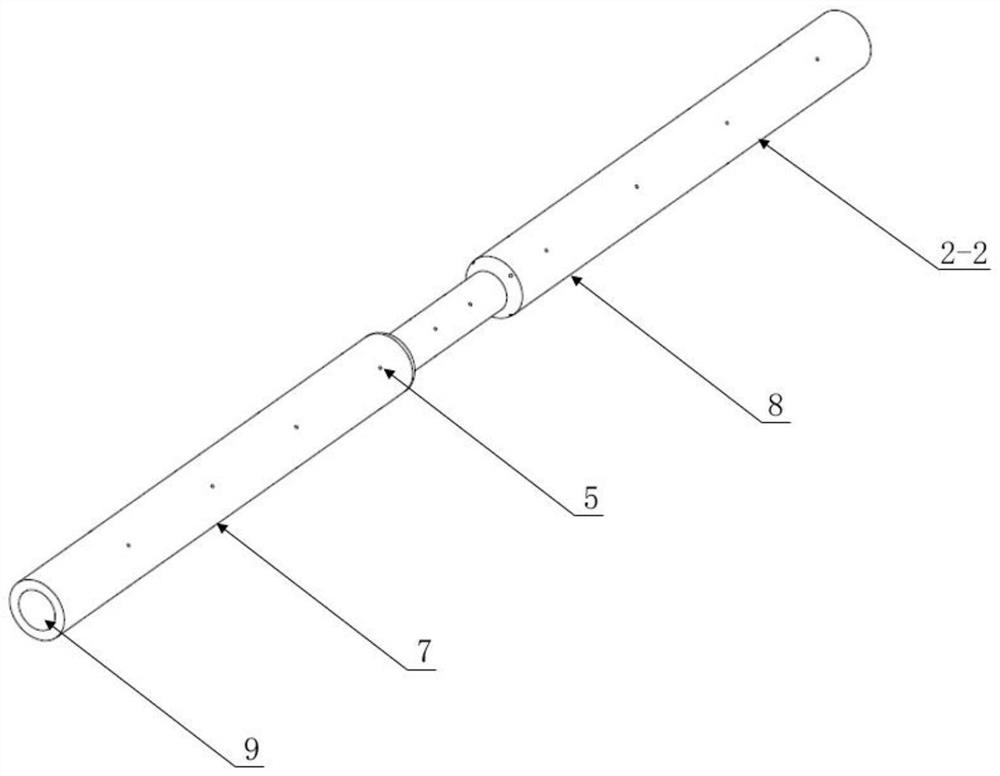

[0051] Embodiment 2, using the split mandrel 2-2, a surface-strengthened internal step shaft inner hole precision forming process, including the following steps:

[0052] 1) Design blank: refer to Image 6 , the design length of blank 1 is L, the design inner and outer diameters are R1 and R2 respectively, the length of the raised part of the blank is W, and the height of the raised part is h2; -2 step length L1; billet 1 design reference ratio W:L1:(h2-h1)=(6~7):(9~10):1, the more refined billet 1 size design needs to be based on finite element simulation and experimental experience results to fetch;

[0053] 2) Remove the lubricant plug 3 of the split mandrel 2-2, pump lubricant into the main lubricant channel 4 of the split mandrel 2-2, and make the pumped lubricant fill the main lubricant channel 4, The internal area formed by the lubricant flow channel 5, after the pumping is completed, the lubricant plug 3 is installed to prevent the lubricant from leaking;

[0054] 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com