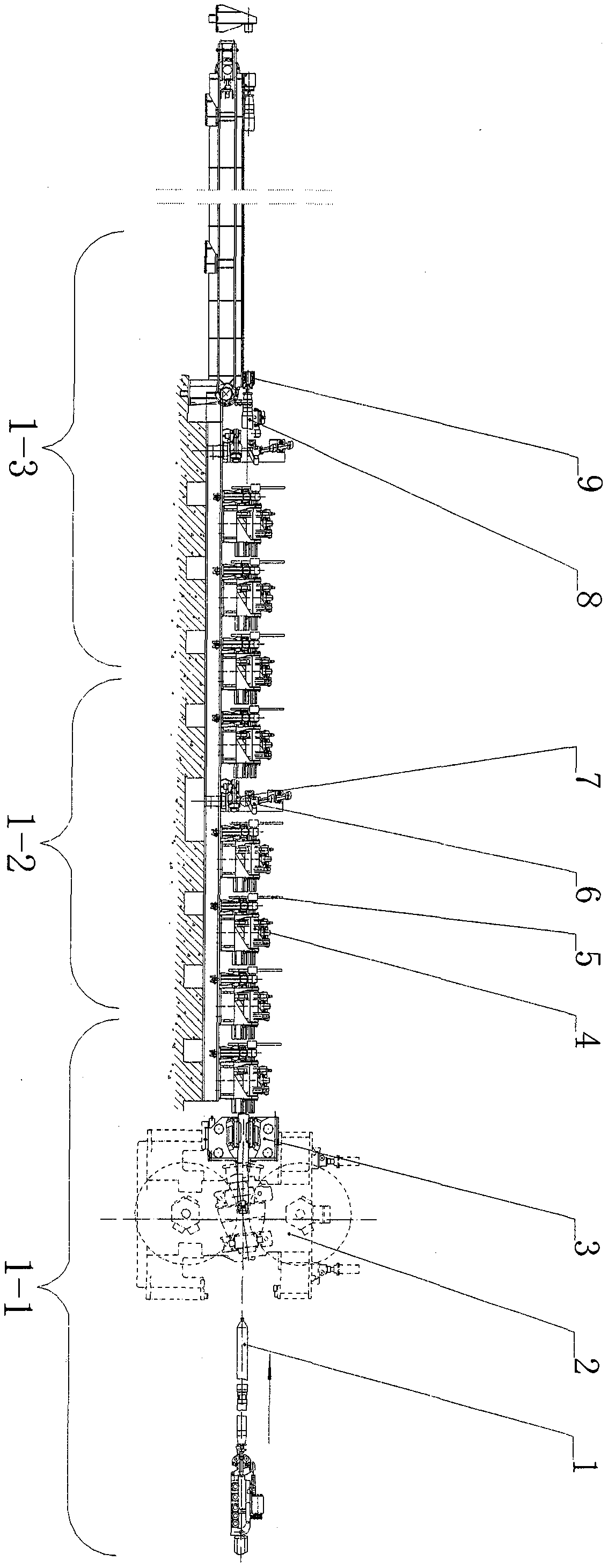

Hot-rolled seamless steel pipe cross-rolling mill front and back mandrel fully supported rolling equipment

A technology of seamless steel pipe and skew rolling mill, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of precision drop, surface quality defect, unstable swing, etc., and achieve the goal of improving rolling stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

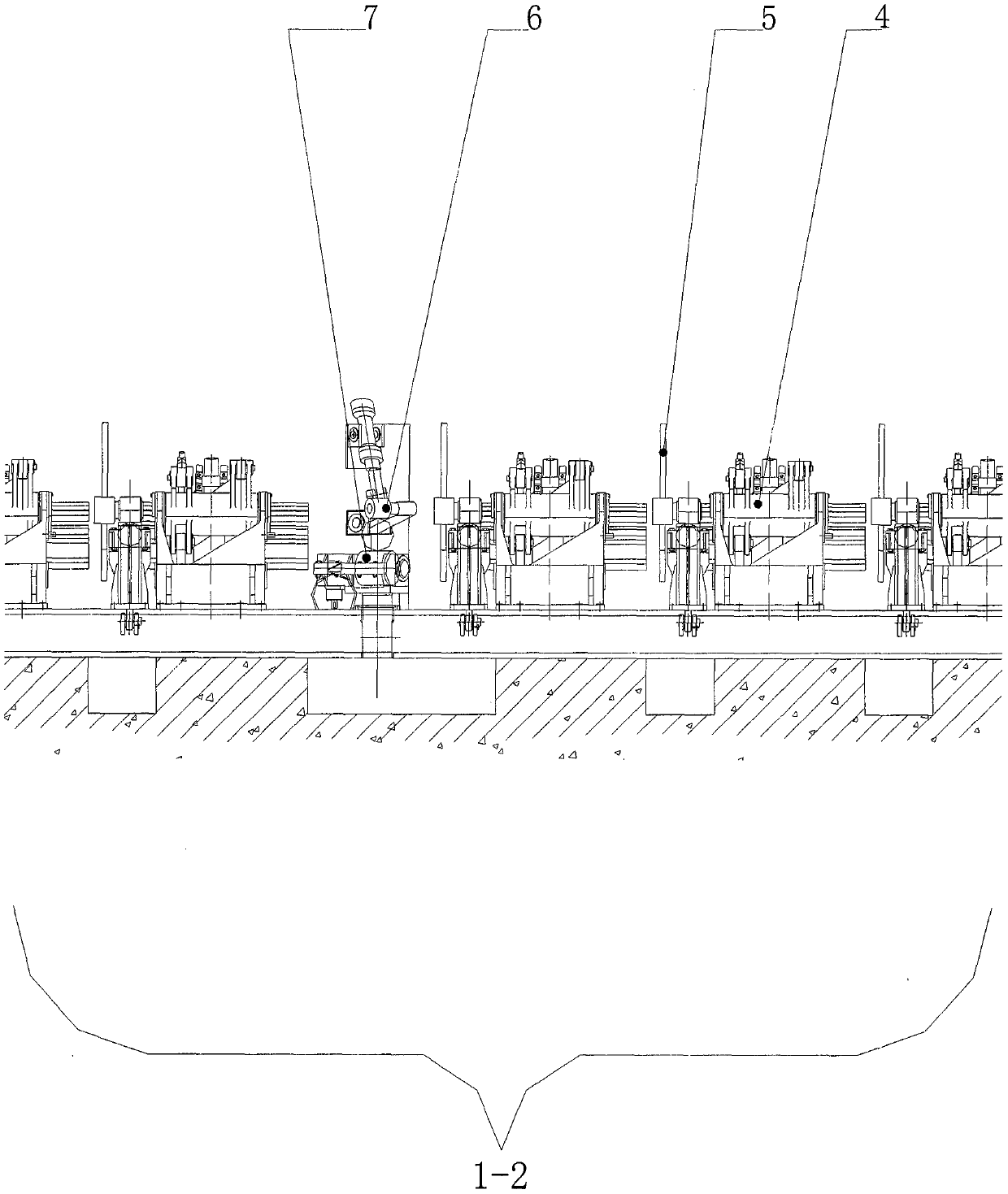

Method used

Image

Examples

Embodiment Construction

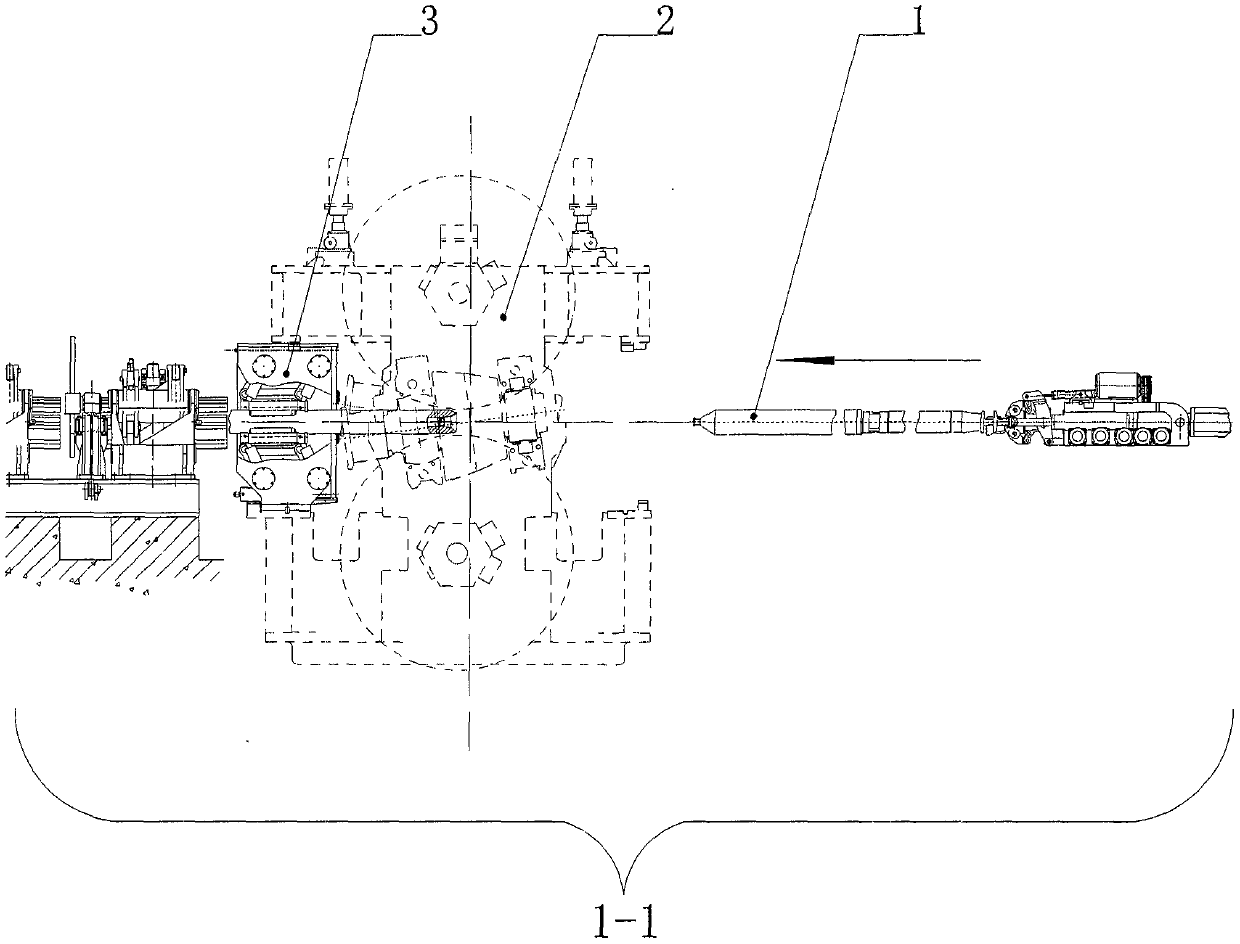

[0055] Use the front limit method. The mandrel still works in a traditional way at the foreground, that is, the mandrel (1) is limited by the front stop mechanism (14), and the mandrel is stabilized together with the throat diameter of the roll.

[0056] The mandrel (1) in the present invention adopts a three-section structure, that is, a joint section, a working section (39), and a supporting section (40). It is the working section (39) that plays a direct role in metal deformation. This section is designed into a section with a relatively short length according to the limit speed, which can greatly reduce the tool manufacturing cost. The head end of the mandrel working section (39) is designed as a conical surface with a fixed angle, which is engaged with the mandrel positioning rod It acts as a centering effect. And support section (40) is the steel pipe manufacture of common material, and price is low. The engagement section is an external gear shaft section, and the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com