Multilink rear axle for a motor vehicle

A rear axle, multi-link technology, applied in the direction of vehicle springs, vehicle components, interconnection systems, etc., can solve problems such as the inability to realize the driving dynamic characteristics of trailing arm axles, and achieve improved effectiveness and increased roll stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

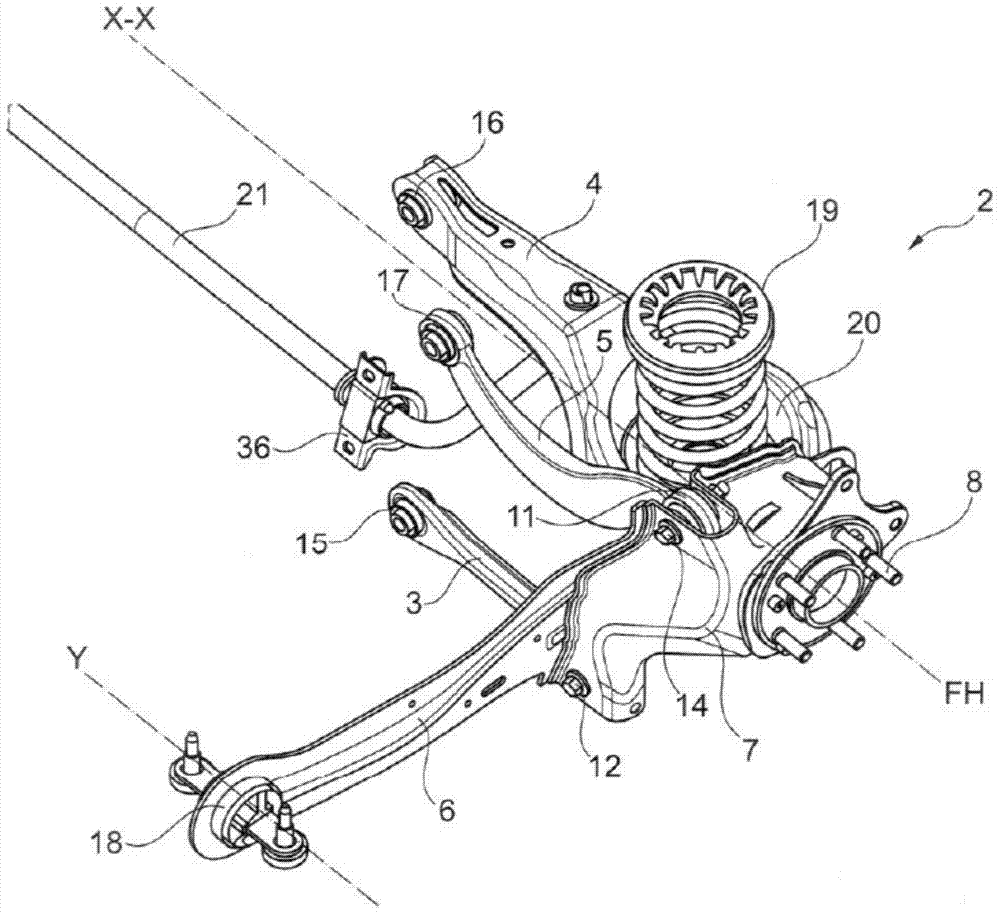

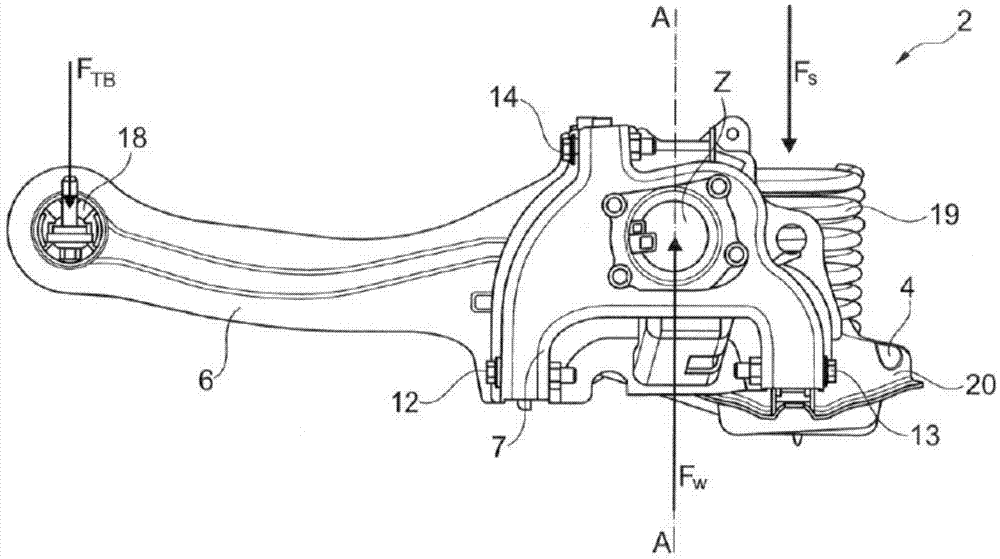

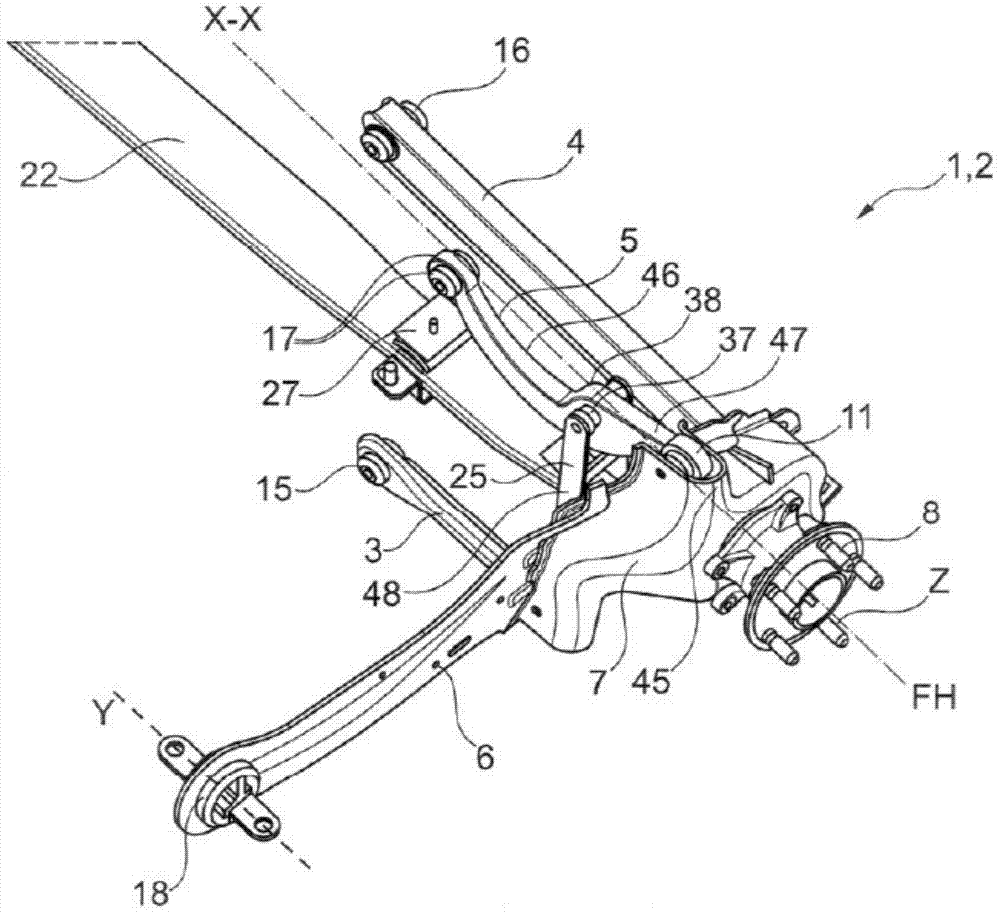

[0104] figure 1 and figure 2 The perspective views of the wheel suspension 2 ( figure 1 ) and side view ( figure 2 ). Wheel suspensions 2 according to the prior art are known as trailing arm axles.

[0105] The wheel suspension 2 is usually arranged on both sides of the vehicle, wherein the structure of the wheel suspension 2 opposite the wheel suspension 2 and not shown is exactly the same as that of the wheel suspension 2 shown, but is naturally adapted to The specific structure of the side of the wheel suspension 2.

[0106] The wheel suspension 2 has two lower control arms 3 and 4 , an upper control arm 5 and a trailing arm 6 . The control arms 3, 4 and 5 are pivotally connected to the wheel carrier 7 transversely to the longitudinal direction of the vehicle by bearing bushes 9, 10 and 11 at pivot points 12, 13 and 14, wherein only the bearing bush 11 and the Its pivot point 14 on the frame 7 can be seen. Bearing bushes 9 and 10 for lower control arms 3 and 4 (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com